Light steel frame-foamed concrete-steel wire mesh composite wall and connecting method thereof

A technology of foam concrete and connection method, which is applied in the direction of walls, anti-seismic, thermal insulation, etc., can solve the problems of unsatisfactory anti-seismic performance of the connection part, unsatisfactory anti-seismic performance and strength, poor thermal insulation performance, etc., to reduce project costs and manufacture The effect of low transportation cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

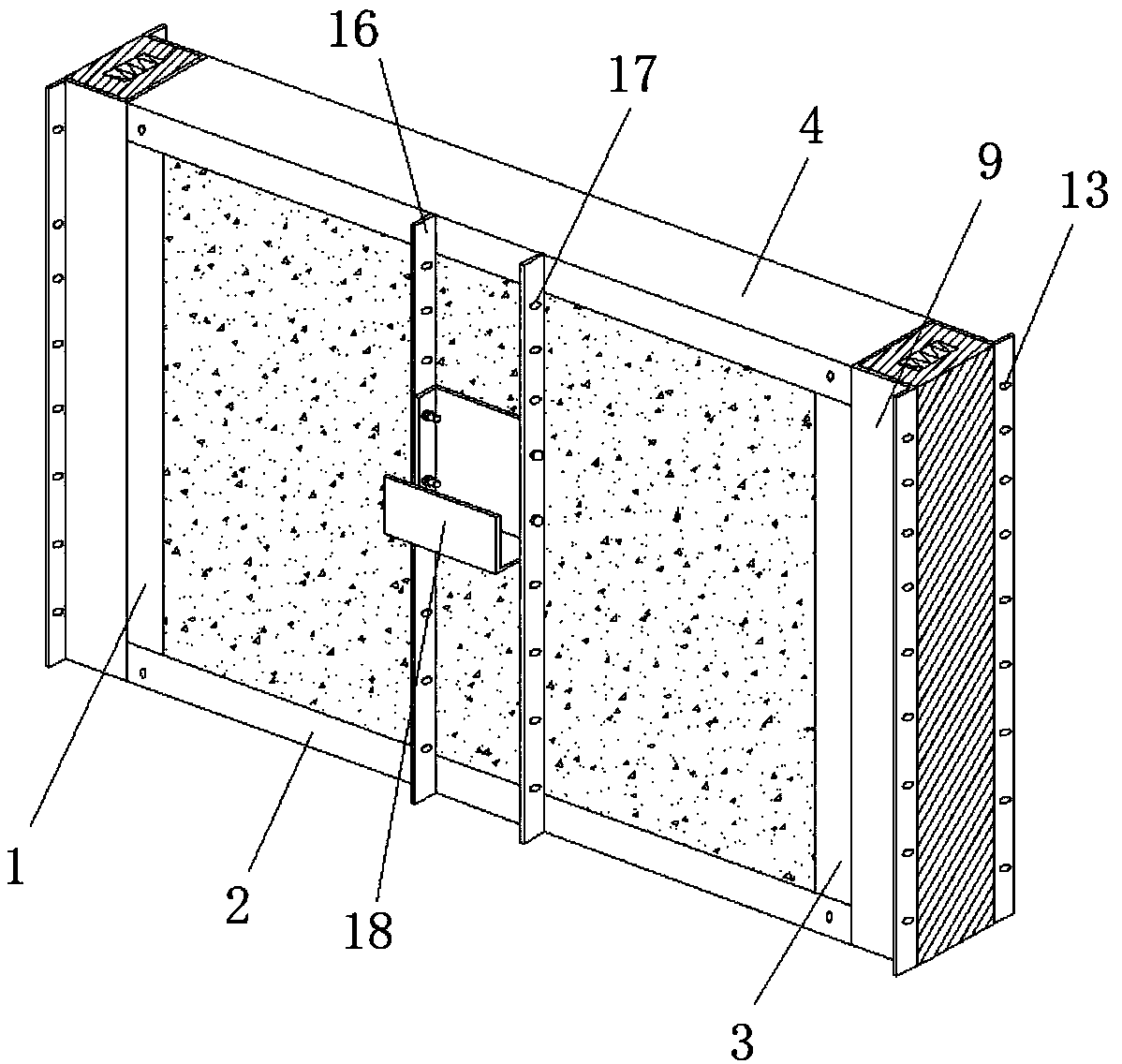

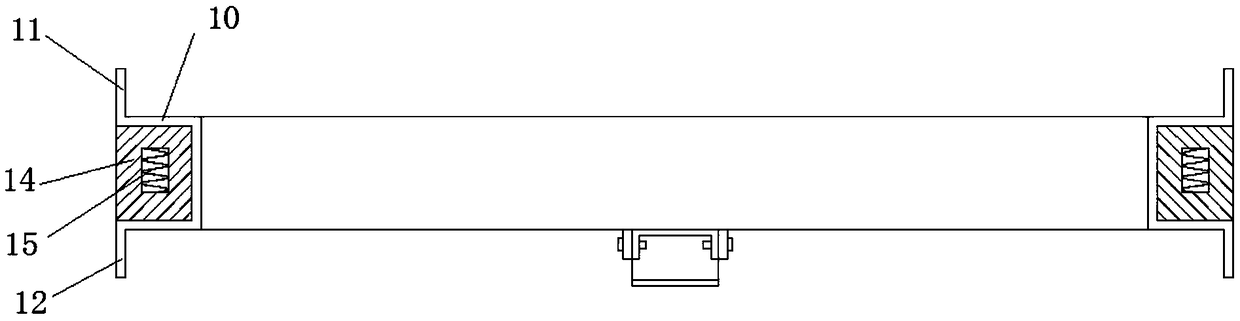

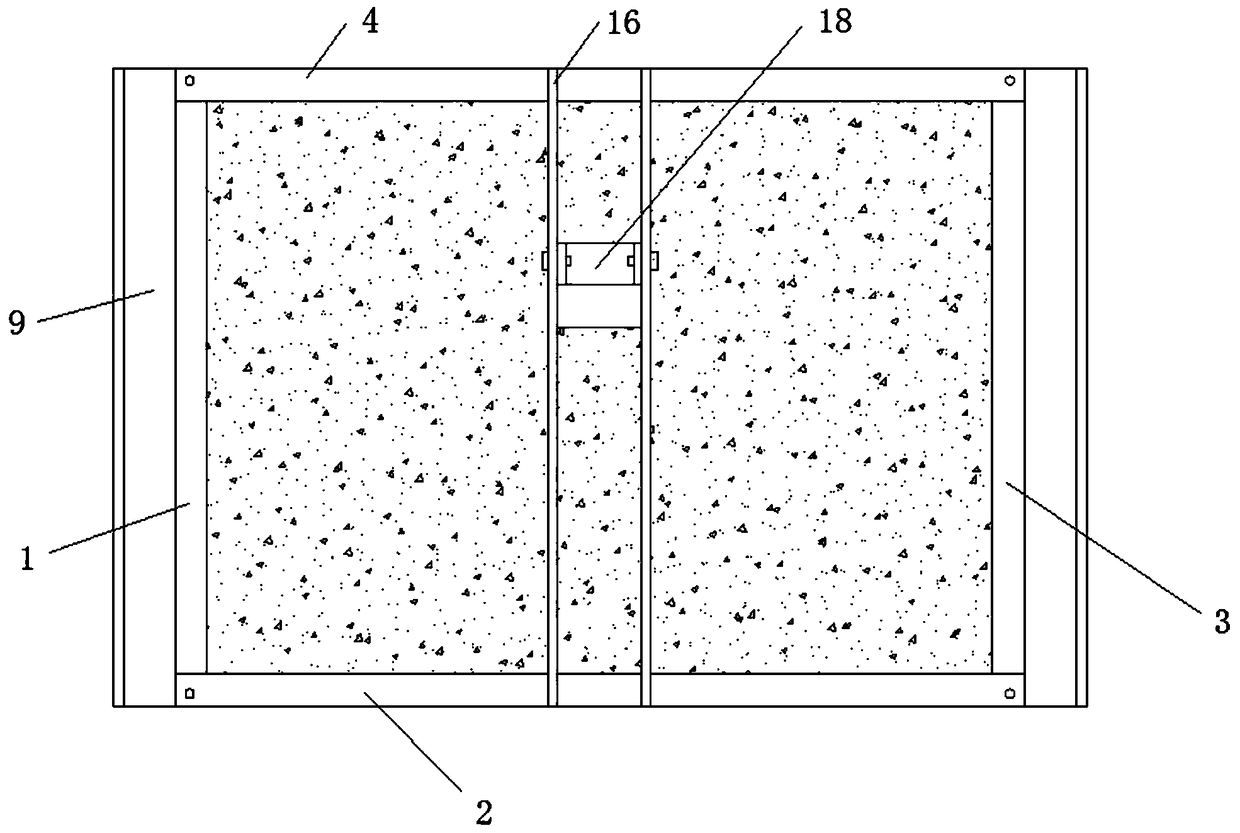

[0029] Such as Figure 1-Figure 4 As shown, a light steel frame-foam concrete-steel mesh composite wall includes four cold-formed thin-walled C-shaped channel steels, which are respectively the first channel steel 1, the second channel steel 2, the third channel steel 3 and The fourth channel steel 4, the first channel steel 1, the second channel steel 2, the third channel steel 3 and the fourth channel steel 4 are sequentially terminated and vertically intersected to form a light steel frame. The first channel steel 1, The second channel steel 2, the third channel steel 3 and the fourth channel steel 4 are welded with steel wire mesh 5 on the inner surface of the same side of the flange, and the foam concrete block 6 is symmetrically arranged in the cavity of the light steel frame, and two foam concrete Braces 7 are arranged between the bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com