Crude polypropylene fiber for concrete and preparation method thereof

A polypropylene and crude fiber technology, applied in the field of polypropylene fiber and its preparation, can solve the problems of affecting the toughening effect, low tensile strength and elastic modulus, and achieve no deterioration of mechanical properties, avoid thermal and oxygen aging, and improve Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

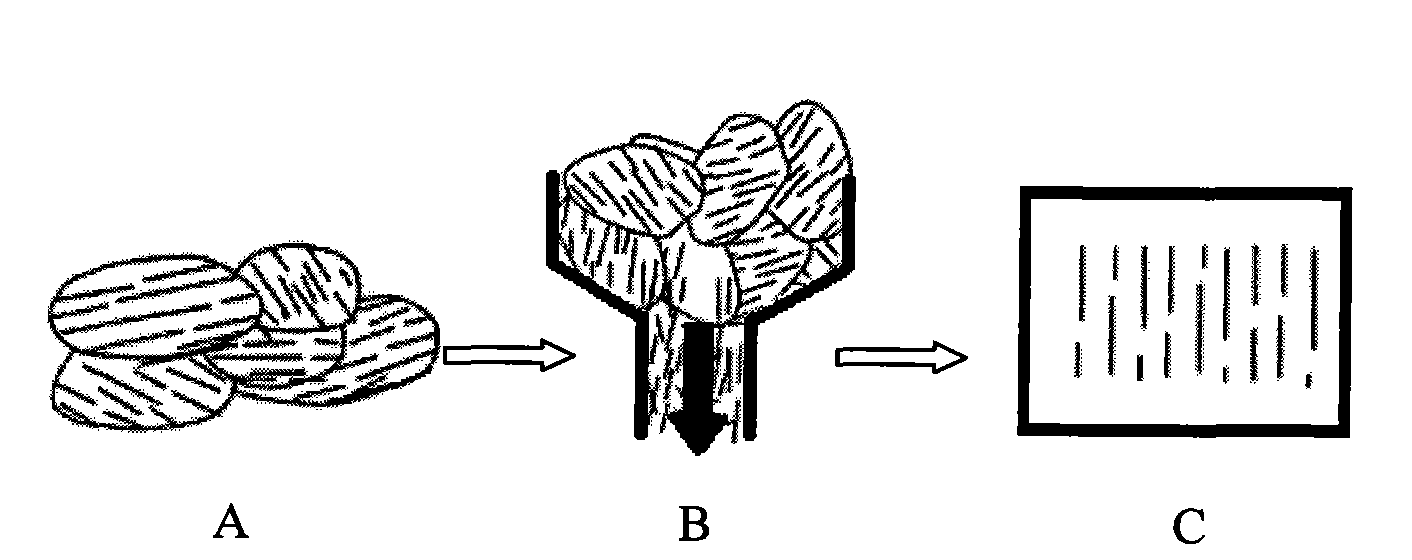

Method used

Image

Examples

Embodiment 1

[0049] VectraA950 was vacuum-dried at 140°C for 10 hours to constant weight for use. And other components were dried to constant weight for later use. Add 5kg of polypropylene slices with a melt index of 5g / 10min into the high-speed mixer, then add 5g of VectraA950, 0.1kg of maleic anhydride grafted polypropylene, 25g of antioxidant 1076, and 5g of ultraviolet absorber UV327, and mix them evenly before transferring the materials Into the hopper of the twin-screw extruder, the set temperature of each zone of the screw is as follows:

[0050] a district

[0051] After the melt is melted, mixed with a static mixer, and filtered by a filter, it is extruded from the circular spinneret hole of the spinneret and cooled in a water bath at 10 ° C. The water bath contains 3.0% conventional polypropylene spinning oil agent HAPP -66 (Jiangsu Hai'an Petrochemical Plant), the fiber after leaving the water bath is drawn 7.0 times on the hot roller at 90°C, then heated in the heat...

Embodiment 2

[0053] The Rodrun LC5000 was vacuum-dried at 130°C for 4 hours to constant weight for use. And other components were dried to constant weight for later use. Add 5kg of polypropylene slices with a melt index of 12g / 10min into the high-speed mixer, then add 0.25kg of dried Rodrun LC5000, 0.1kg of maleic anhydride grafted polypropylene, 7.5g of antioxidant DLTP, and 8g of ultraviolet absorber UV327, After mixing evenly, transfer the material to the hopper of the twin-screw extruder, and set the temperature of each zone of the screw as follows:

[0054] a district

[0055] After the melt is melted, mixed with a static mixer, and filtered by a filter, it is extruded from the regular pentagonal spinneret hole of the spinneret and cooled in a water bath at 12°C. The water bath contains 3.0% conventional polypropylene spinning oil Agent 2038 (Changzhou Lingda Chemicals Co., Ltd.), the fiber after leaving the water bath is drawn 6.0 times on a hot roll at 90°C, then heated ...

Embodiment 3

[0057] Vectra B950 was vacuum-dried at 140°C for 24 hours to constant weight for use. And other components were dried to constant weight for later use. Add 5kg of polypropylene slices with a melt index of 15g / 10min into the high-speed mixer, then add 0.75kg of VectraB950, 0.15kg of acrylic acid grafted polypropylene, 10.0g of antioxidant DLTP, and 7.5g of ultraviolet absorber UV327. After mixing evenly, put the materials Transferred to the twin-screw extruder hopper, the temperature settings for each zone of the screw are as follows:

[0058] a district

[0059] After the melt is melted, mixed with a static mixer, and filtered by a filter, it is extruded from the circular spinneret hole of the spinneret, and cooled in a water bath at 18°C. The water bath contains 3.0% conventional polypropylene spinning oil 2038 (Changzhou Lingda Chemical Co., Ltd.), the fiber after leaving the water bath is drawn 9.0 times on the hot roller at 100°C, then heated in the heating tan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com