Wafer processing laminate, temporary adhesive material for wafer processing, and method for manufacturing thin wafer

一种晶片加工、晶片的技术,应用在晶片加工体领域,能够解决剥离长的时间、难以应用制造工艺等问题,达到耐热性高、耐性优异、膜厚均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0172] Hereinafter, although an Example and a comparative example are shown and this invention is demonstrated more concretely, this invention is not limited to these Examples.

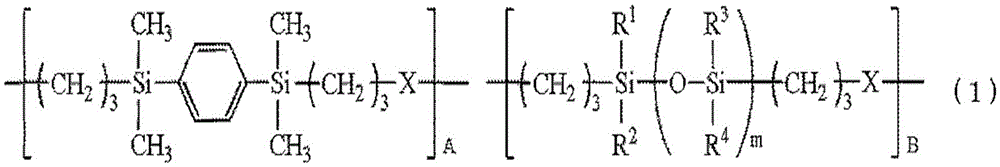

Synthetic example 1

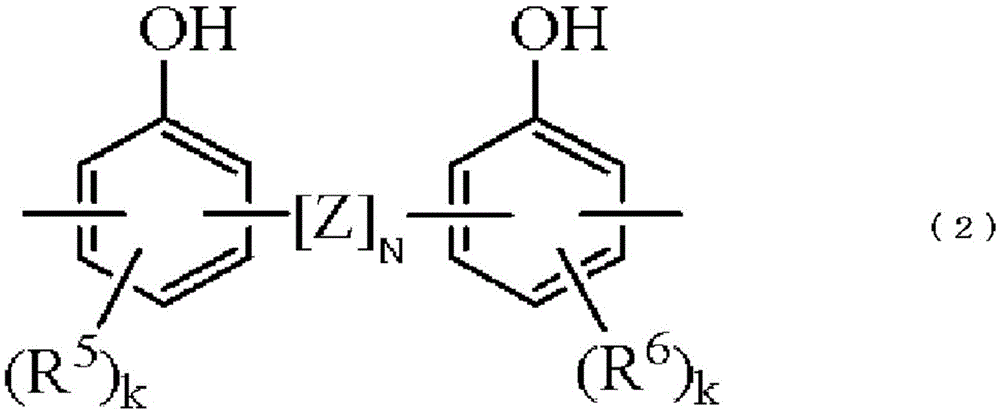

[0174] In a flask equipped with a stirrer, a thermometer, a nitrogen substitution device and a reflux cooler, 43.1 g of 9,9'-bis(3-allyl-4-carboxyphenyl)fluorene (M-1) was charged, and the average structural formula ( 29.5 g of organohydrogensiloxane represented by M-3), 135 g of toluene, and 0.04 g of chloroplatinic acid were heated up to 80°C. Then, 17.5 g of 1,4-bis(dimethylsilyl)benzene (M-5) was dripped in the flask over 1 hour. At this time, the temperature in the flask rose to 85°C. After completion of the dropping, aging was carried out at 80° C. for 2 hours, toluene was distilled off, and 80 g of cyclohexanone was added to obtain a resin solution in which the resin solid content concentration was 50% by mass of cyclohexanone as a solvent. The molecular weight of the resin fraction of the solution was measured by gel permeation chromatography (GPC), and the weight average molecular weight in terms of polystyrene was 45,000. Further in the described resin solution of ...

Embodiment 1

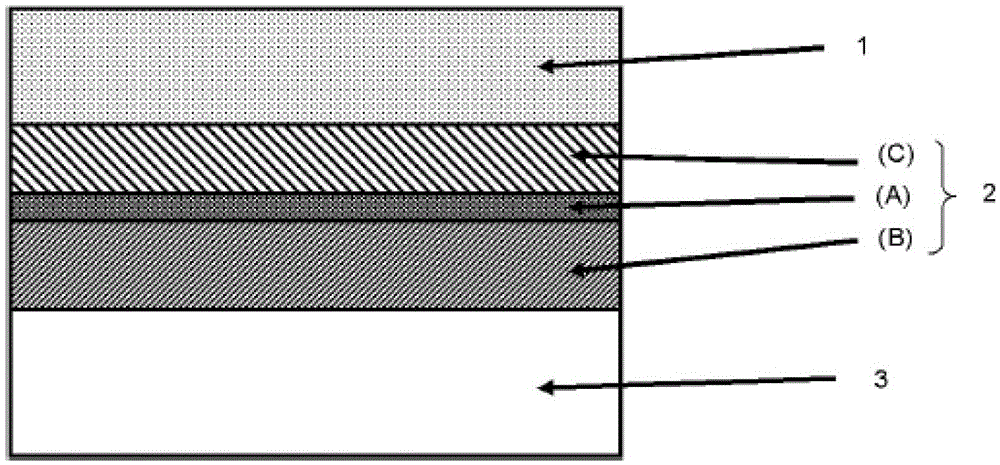

[0202]A silicon wafer (thickness: 725 μm) with a diameter of 200 mm and a copper post with a height of 10 μm and a diameter of 40 μm formed on the entire surface was spin-coated with the above (C-1) solution, and heated at 150° C. for 3 minutes on a hot plate to make The material corresponding to the (C) layer was formed into a film with the film thickness shown in Table 1 on the bump formation surface of the wafer. Then, a solution (A-1) of a thermosetting siloxane polymer corresponding to the (A) layer was formed on the (C) layer on the silicon wafer by spin coating, and the film thicknesses in Table 1 were formed. Then, it was further heated on a hot plate at 150° C. for 3 minutes. On the other hand, using a glass plate with a diameter of 200 mm (thickness: 500 μm) as a support, the polymer solution (B-1) corresponding to the (B) layer was first spin-coated on the support, and using a heating plate By heating at 150° C. for 5 minutes, the film thickness described in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com