High-efficiency reinforced halogen-free flame retardant functional masterbatch for polyoxymethylene direct injection molding and preparation method thereof

A technology of injection molding and functional masterbatch, which is applied in the field of high-efficiency reinforced halogen-free flame retardant functional masterbatch and its preparation, can solve the problems of mutual loss of modification efficiency, and achieves improved flow performance, improved modification efficiency, and strong heat sensitivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

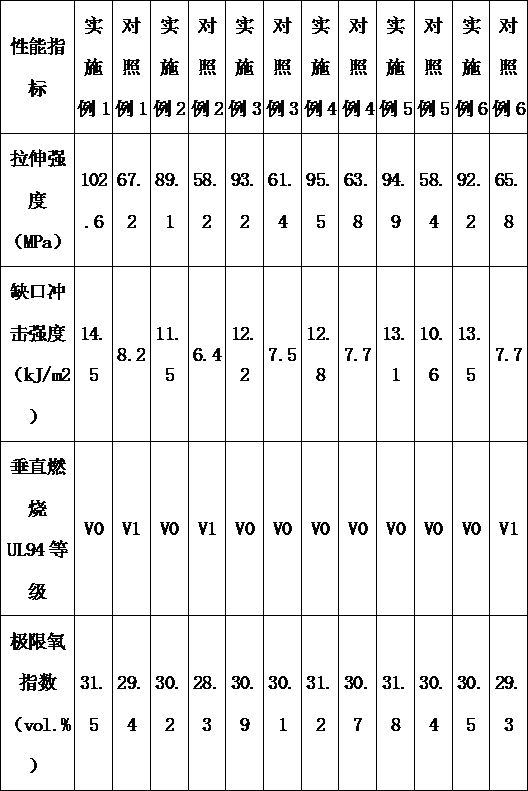

Examples

Embodiment 1

[0034] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for polyoxymethylene direct injection molding, which is composed of two masterbatches A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0035] glass fiber 70.0 kg High flow polyoxymethylene 22.0 kg polyoxyethylene 6.0 kg PTFE powder 1.7kg antioxidant 300.0 g

[0036] The antioxidants are 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanuric acid (trade name: Antioxidant 3114), bis(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite (trade name Antioxidant 626) and 5,7-bis-(2,2-dimethylethyl)-3-(3,4-dimethylphenyl)- 2–3 Hydrogen–Benzofuranone (trade name Antioxidant 168) is a compound composed of 1:1:1 by mass ratio.

[0037] The mass ratio of the raw materials of the B masterbatch is as follows:

[0038] Ammonium polyphosphate 60.0kg Melamine cyanurate 30.0kg polylactic acid 7.0kg ...

Embodiment 2

[0042] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for polyoxymethylene direct injection molding, which is composed of two masterbatches A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0043] glass fiber 50.0kg High flow polyoxymethylene 40.0 kg polyoxyethylene 6.7kg PTFE powder 3.0kg antioxidant 300.0 g

[0044] The antioxidants are 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanuric acid (trade name: Antioxidant 3114), bis(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite (trade name Antioxidant 626) and 5,7-bis-(2,2-dimethylethyl)-3-(3,4-dimethylphenyl)- 2–3 Hydrogen–Benzofuranone (trade name Antioxidant 168) is a compound composed of 1:1:1 by mass ratio.

[0045] The mass ratio of the raw materials of the B masterbatch is as follows:

[0046] Ammonium polyphosphate 50.0kg Melamine cyanurate 40.0 kg polylactic acid 8.0 kg ...

Embodiment 3

[0050] A high-efficiency enhanced halogen-free flame-retardant functional masterbatch for polyoxymethylene direct injection molding, which is composed of two masterbatches A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0051] glass fiber 61.0kg High flow polyoxymethylene 30.0kg polyoxyethylene 6.7kg PTFE powder 2.0 kg antioxidant 300.0 g

[0052] The antioxidants are 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanuric acid (trade name: Antioxidant 3114), bis(2,4-di-tert-butyl phenyl) pentaerythritol diphosphite (trade name Antioxidant 626) and 5,7-bis-(2,2-dimethylethyl)-3-(3,4-dimethylphenyl)- 2–3 Hydrogen–Benzofuranone (trade name Antioxidant 168) is a compound composed of 1:1:1 by mass ratio.

[0053] The mass ratio of the raw materials of the B masterbatch is as follows:

[0054] Ammonium polyphosphate 30.0kg Melamine polyphosphate 25.0 kg Melamine cyanurate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com