A high-efficiency enhanced halogen-free flame-retardant heat-conducting and light-shielding multifunctional masterbatch for PBT direct injection molding and its preparation method

An injection molding and reinforced technology, which is applied in the field of high-efficiency reinforced halogen-free flame-retardant, thermally conductive, light-shielding multifunctional masterbatch and its preparation, can solve problems such as mutual loss of modification efficiency, improve modification efficiency and solve modification efficiency. Mutual loss, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

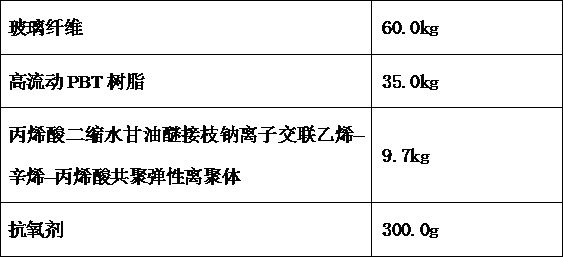

[0037] A high-efficiency enhanced halogen-free flame-retardant, heat-conducting, and light-shielding multifunctional masterbatch for direct injection molding of PBT resin. It is composed of two masterbatches, A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0038]

[0039] The antioxidants are 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name Antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

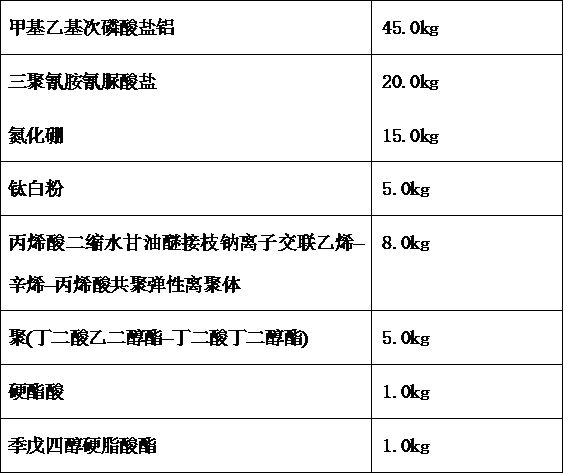

[0040] The mass ratio of the raw materials of the B masterbatch is as follows:

[0041]

[0042] The preparation method of A masterbatch is as follows: Weigh all the raw materials according to the above mass ratio requirements, then put all the raw materials except glass fiber into the high-speed mixer and mix them evenly, and then feed the obtained mixture from the main feeder into the twin-screw extruder, the chopped g...

Embodiment 2

[0045] A high-efficiency enhanced halogen-free flame-retardant, heat-conducting, and light-shielding multifunctional masterbatch for direct injection molding of PBT resin. It is composed of two masterbatches, A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0046]

[0047] The antioxidants are 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name Antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

[0048] The mass ratio of the raw materials of the B masterbatch is as follows:

[0049]

[0050] The preparation method of A masterbatch is as follows: Weigh all the raw materials according to the above mass ratio requirements, then put all the raw materials except glass fiber into the high-speed mixer and mix them evenly, and then feed the obtained mixture from the main feeder into the twin-screw extruder, the chopped g...

Embodiment 3

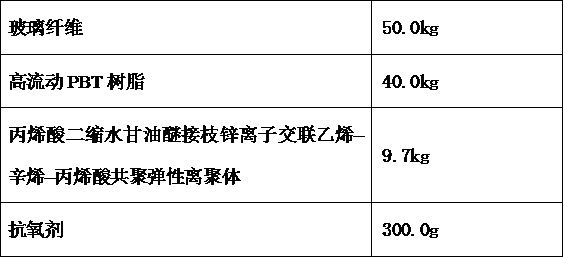

[0053] A high-efficiency enhanced halogen-free flame-retardant, heat-conducting, and light-shielding multifunctional masterbatch for direct injection molding of PBT resin. It is composed of two masterbatches, A and B. The quality ratio of the raw materials for the A masterbatch is as follows:

[0054]

[0055] The antioxidants are 1,3,5-trimethyl-2,4,6-(3,5-di-tert-butyl-4-hydroxybenzyl)benzene (trade name Antioxidant 1330) and bis( 2,4-dicumylphenyl) pentaerythritol diphosphite (trade name: Antioxidant S9228) is a compound composed of 1:1 mass ratio.

[0056] The mass ratio of the raw materials of the B masterbatch is as follows:

[0057]

[0058] The preparation method of A masterbatch is as follows: Weigh all the raw materials according to the above mass ratio requirements, then put all the raw materials except glass fiber into the high-speed mixer and mix them evenly, and then feed the obtained mixture from the main feeder into the twin-screw extruder, the chopped g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com