Polyvinyl acetal foam material, preparation method thereof and cervical dilatation device

A technology of polyvinyl acetal and polyvinyl alcohol, which is applied in the field of medical devices, can solve the problems of difficult to meet the needs of clinical use, low water swelling rate, etc., and achieve the effects of decreased porosity, slow hydrolysis speed, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

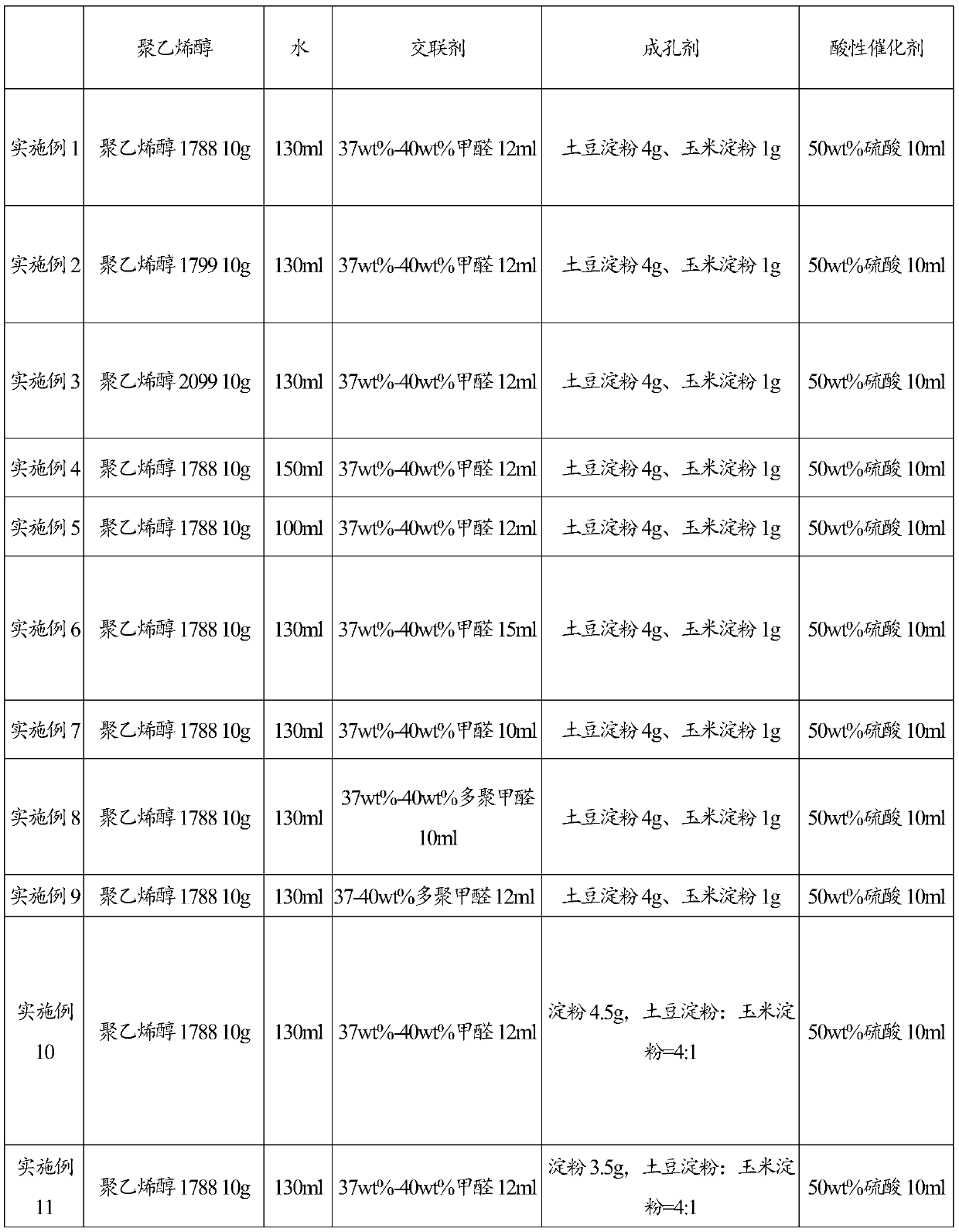

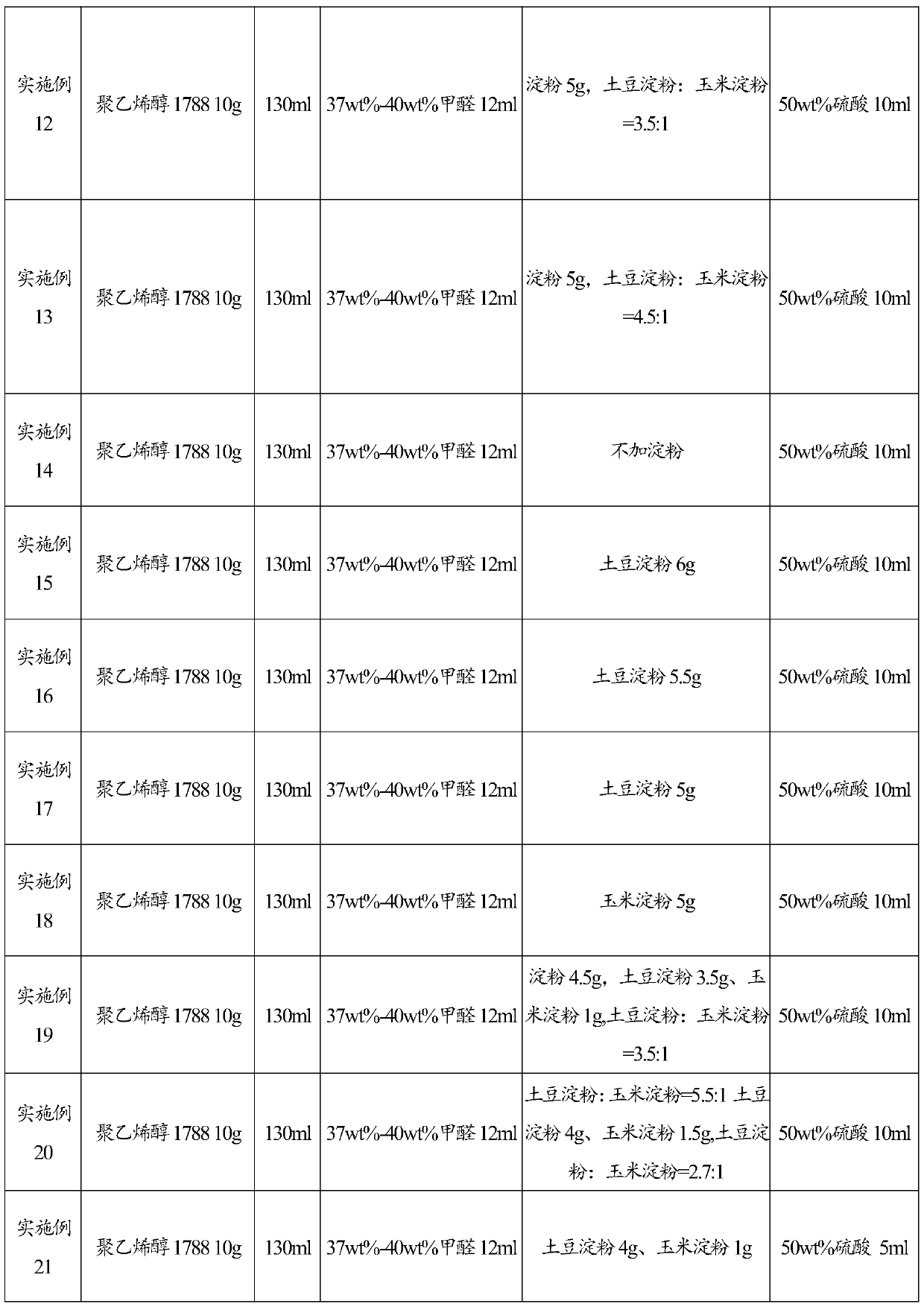

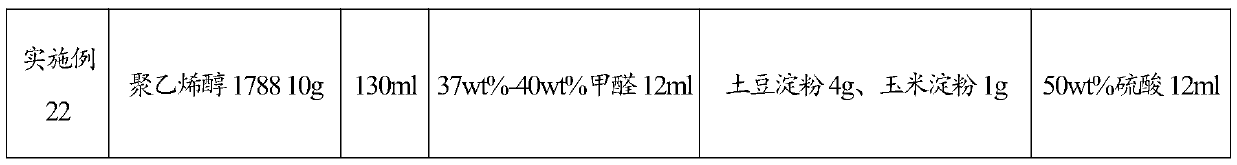

Embodiment 1~22

[0065] Effect of raw materials on product performance

[0066] A method of preparing a polyvinyl acetal porous foam, comprising:

[0067] (1) Mix polyvinyl alcohol and water, stir at 200r / min, and heat at 97°C until the polyvinyl alcohol is completely dissolved;

[0068] (2) Control the temperature at 67°C, add the pore-forming agent, stir at 200r / min, and react for 5-20min;

[0069] (3) Control the temperature at 53° C., add the crosslinking agent, stir at 200 r / min, and react for 5 to 20 minutes; the crosslinking agent is formaldehyde or paraformaldehyde;

[0070] (4) Control the temperature at 50°C, add the acidic catalyst, stir at 200r / min, and react for 10-25min;

[0071] (5) Keep warm at 50°C for 6-12 hours;

[0072] (6) Treat the polyvinyl acetal porous foam with aqueous sodium hydroxide solution to pH=6-7, and remove residual formaldehyde with hydrogen peroxide.

[0073] The selection and amount of polyvinyl alcohol, the amount of water, the selection and amount of...

Embodiment 1、23~29

[0078] The influence of embodiment 1, 23~29 temperature conditions (polyvinyl acetal porous foam) on product performance

[0079] The difference between Examples 23-29 and Example 1 is only that the temperature conditions are different in the method for preparing polyvinyl acetal porous foam, the temperature for dissolving polyvinyl alcohol, the temperature for adding a pore-forming agent, the temperature for adding a crosslinking agent, and the temperature for adding an acidic catalyst , See Table 2 for the holding temperature.

[0080] Table 2

[0081]

Embodiment 30~56

[0083] Effect of cutting, drying and compression processes on product properties

[0084] The preparation method of polyvinyl acetal foam material comprises:

[0085] (1) Preparation of polyvinyl acetal porous foam.

[0086] (2) cutting;

[0087] (3) drying;

[0088] (4) compressed into a rod;

[0089] (5) Irradiation sterilization.

[0090] The polyvinyl acetal foam material is prepared by the above preparation method.

[0091] The cervical dilation device includes: the cervical dilation rod body; the cervical dilation rod body is the polyvinyl acetal foam material prepared by the above preparation method; the cervical dilation device is a cervical dilator or a cervical dilation rod.

[0092] Examples 30 to 39 respectively adopt wet cutting, dry cutting and freezing cutting to cut the polyvinyl acetal porous foam obtained in Example 1; freezing cutting is specifically: centrifuging the polyvinyl acetal porous foam in Example 1 and adding water to the polyethylene For th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com