Precursor for foaming thermoplastic polyester elastomer, foaming body and its preparation method

A thermoplastic polyester and elastomer technology, which is applied in the field of thermoplastic elastic material foaming, can solve the problems of coarse cell structure size, high melt fluidity, low melt viscosity, etc., and achieve the optimization of elasticity and compression performance, cell The effect of uniform diameter and wide operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The invention also discloses a preparation method of the thermoplastic polyester foam as described above, which comprises the following steps:

[0077] Precursor preparation: In parts by weight, add 100 parts of thermoplastic polyester elastomer, 2-10 parts of melt melt viscosity modifier, 0.2-1.2 parts of cell size stabilizer and 0.1-0.5 parts of UV stabilizer into the high-mixer The mixture is uniformly mixed in the medium, melted and kneaded by a twin-screw extruder, and then cooled down by extruder stranding or underwater pelletizing and cutting into pellets to obtain a thermoplastic polyester elastomer foaming precursor.

[0078] In some embodiments of the present invention, it is preferable to use underwater pelletizing for pellet preparation. When underwater pelletizing is used, due to the pressure of water, the particles can be formed into water droplets and the edges of the particles are reduced, which is beneficial to improve Subsequent foaming effect.

[0079] In s...

Embodiment approach

[0082] As an alternative embodiment of the present invention, the "blowing agent penetration" step includes:

[0083] Add the thermoplastic polyester elastomer foaming precursor and water into the autoclave, add the volatile foaming agent, pressurize to form an aqueous suspension mixture, and heat up to the softening point of the thermoplastic polyester elastomer foaming precursor , Pressurization makes the volatile foaming agent in a supercritical state, heat preservation and pressure retention.

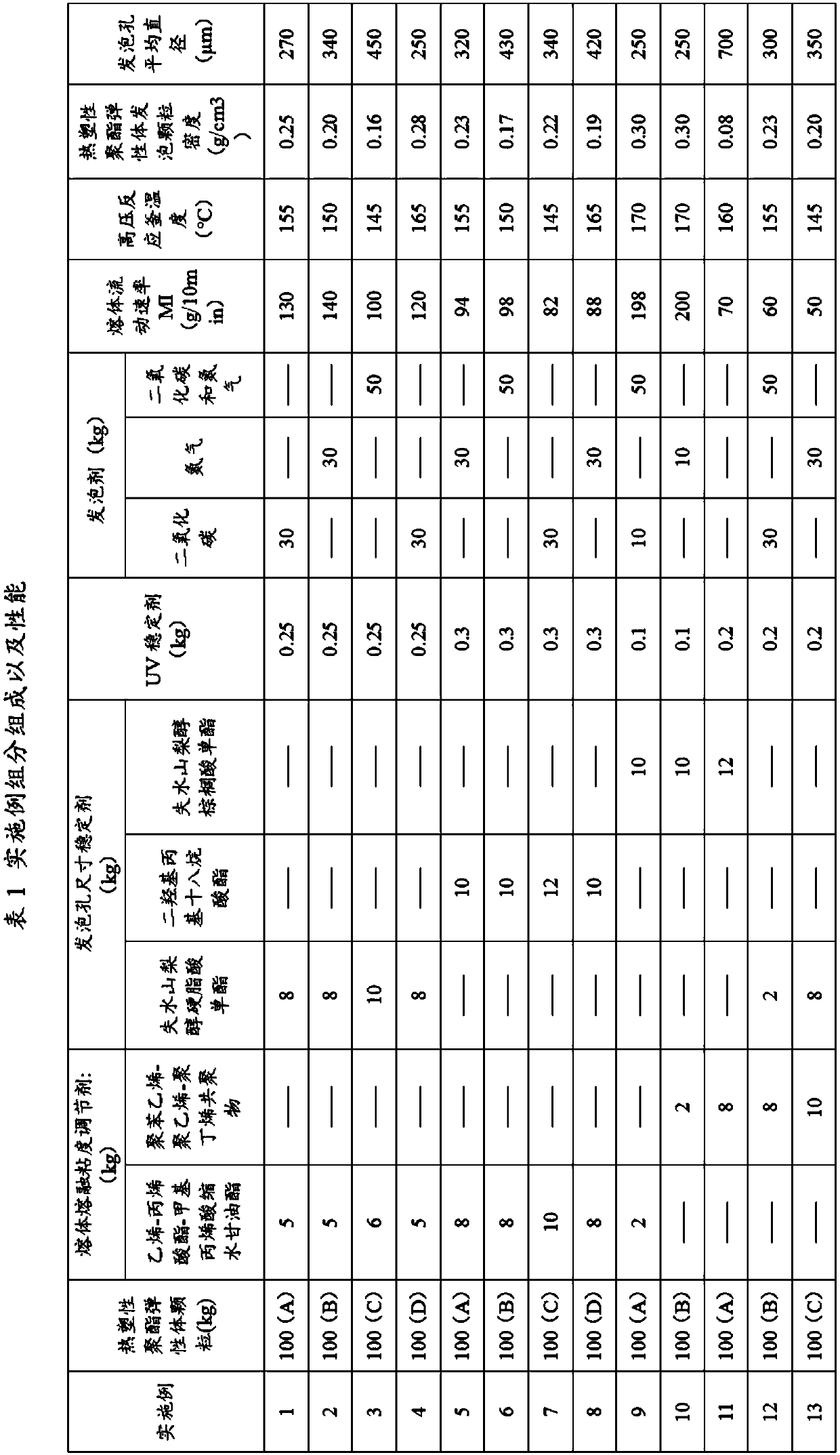

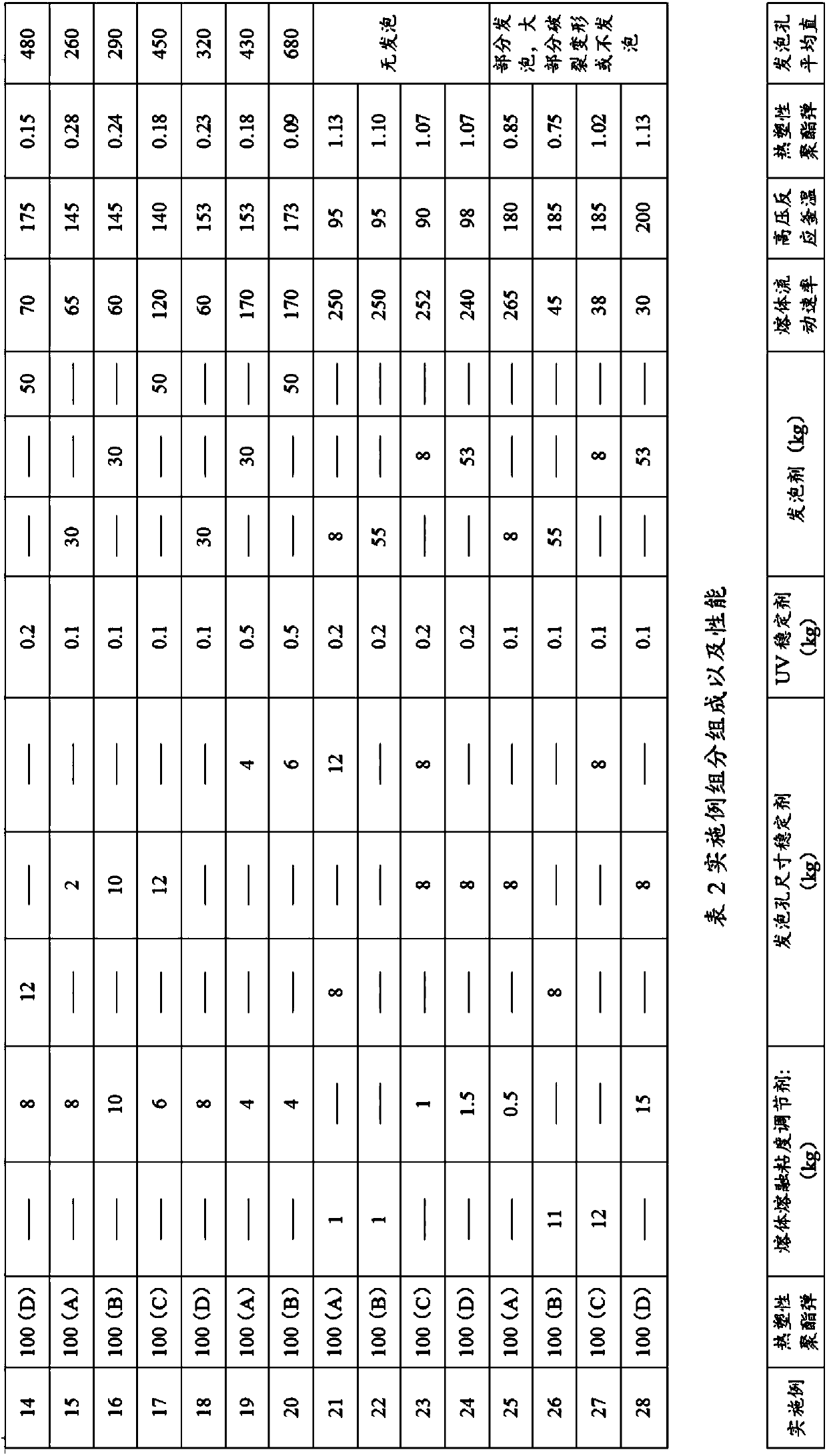

[0084] The following examples further illustrate the present invention.

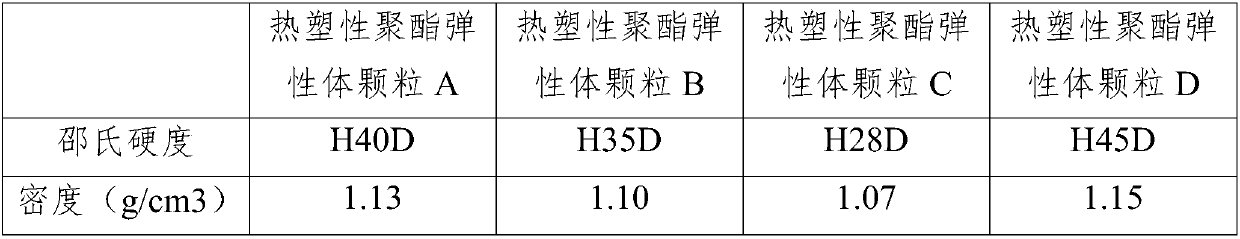

[0085] The physical indicators of the thermoplastic polyester elastomer particle material used in the following embodiments are:

[0086]

[0087] The above thermoplastic polyester elastomer granular materials can be purchased from China Jiangyin Hechuang Elastomer New Material Technology Co., Ltd., China Taiwan Changchun Chemical Co., Ltd., South Korea's SK company, and the United States DuPont company.

[0088] Plast...

Embodiment 1

[0091] a) Add 100 kg of thermoplastic polyester elastomer particles A, 5 kg of ethylene-acrylate-glycidyl methacrylate, 8 kg of sorbitan monostearate, and 0.25 kg of UV stabilizer into the mixer. After mixing, it was introduced into a twin-screw extruder through a hopper for melting and kneading, and the melt flow rate was tested at a constant temperature of 230°C and a load of 8.7kg. Extrude the molten kneaded product that meets the melt flow rate index from the die hole of the extruder with a diameter of 1.5mm into a strip shape, and cool it into a shape by cooling in a cooling water tank of about 5 meters in length, and cut it into 2.5mm with a pelletizer. Long particles to obtain a precursor for thermoplastic polyester elastomer foaming.

[0092] b) Mixing 100 kg of the obtained thermoplastic polyester elastomer foaming precursor and 500 kg of purified water into the autoclave to form an aqueous suspension mixture. While stirring, 30kg of carbon dioxide volatile blowing agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com