Polyimide microsphere slurry, composite separator and lithium ion battery

A technology of polyimide microspheres and polyimide, which is applied to battery components, circuits, electrical components, etc., can solve the problems of poor air permeability and pore blockage of composite lithium battery separators, and achieve excellent mechanical properties and surface Effect of low density and improved high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] According to some embodiments of the present invention, the dianhydride is 4,4'-oxydiphthalic anhydride (ODPA), pyromellitic dianhydride (PMDA), 4,4'-terephthalic dioxyphthalic anhydride Phthalic anhydride (triphenylene ether dianhydride, HQDPA), bisphenol A dianhydride (BPADA), 3,3',4,4'-biphenyltetracarboxylic dianhydride (BPDA), 3,3', 4,4'-benzophenonetetracarboxylic dianhydride (BTDA), hexafluorodianhydride (6FDA), 2,3,3',4'-biphenyltetracarboxylic dianhydride, 1,2,3,4-cyclo Pentylenetetracarboxylic dianhydride, 1,2,4,5-cyclohexanetetracarboxylic dianhydride, cyclobutanetetracarboxylic dianhydride, 3,4'-oxydiphthalic anhydride, hydrogenated biphenyltetracarboxylic dianhydride anhydride, 3,3',4,4'-diphenylsulfone tetracarboxylic dianhydride, 5-[2-(1,3-dioxoisobenzofuran-5-yl)propan-2-yl] One or more combinations of isobenzofuran-1,3-dione.

[0044]According to some embodiments of the present invention, the diamine is 4,4'-diaminodiphenyl ether (ODA), m-phenylenedia...

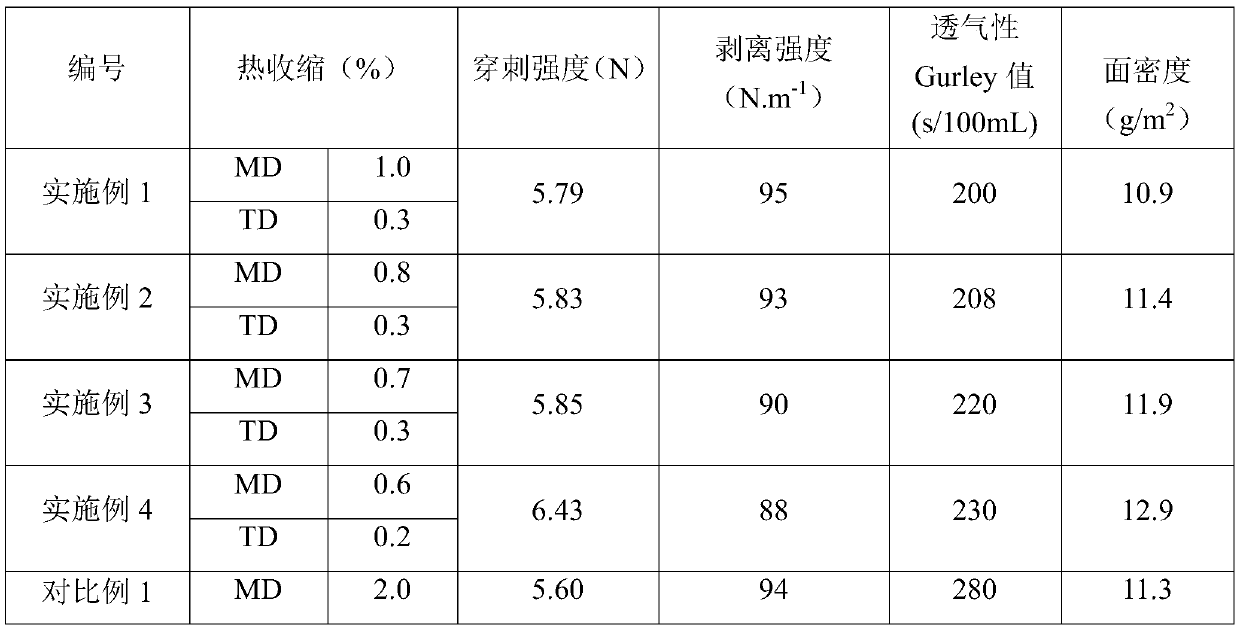

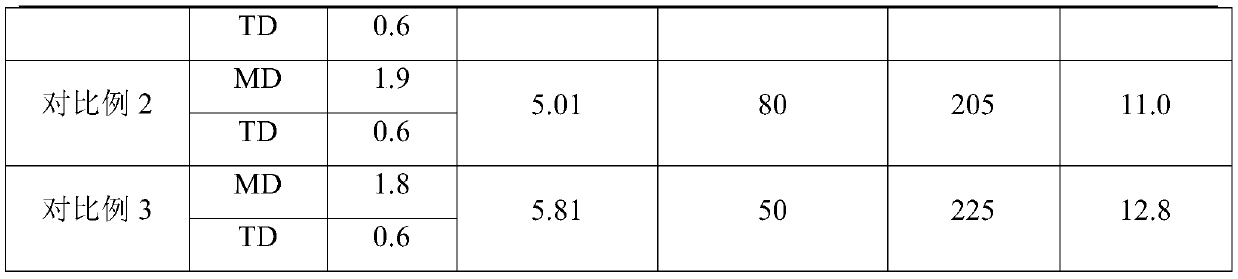

Embodiment 1

[0079] 30 parts of PI microspheres, 2 parts of surfactant polyoxyethylene alkylamide and 60 parts of deionized water were fully stirred and ground at 3000rpm for 2h, and then 5 parts of water-based adhesive styrene-butadiene latex and 3 parts of wetting agent twelve were added The sodium alkylbenzene sulfonate was uniformly dispersed and continued to stir at 1000rpm for 2h to obtain PI microsphere slurry.

[0080] The above slurry was coated on one side of the 12μm PE base film layer, the coating speed was 30m / min, the coating thickness was 50μm, and dried at 80°C for 10min to obtain a lithium battery separator with a coating thickness of 2μm on one side.

[0081] Then apply the above slurry on the other side of the PE base film, the coating speed is 30m / min, the coating thickness is 50μm, and it is dried at 80°C for 10min to obtain a double-sided polyimide with a coating thickness of 2μm on one side Composite lithium battery diaphragm.

Embodiment 2

[0083] According to the operation method in Example 1, PI microspheres and PI microsphere aqueous mixed slurry were prepared.

[0084] 25 parts of PI microspheres, 2 parts of surfactant polyoxyethylene alkylamide and 65 parts of deionized water were fully stirred and ground at 3000rpm for 2h, and then 5 parts of water-based adhesive styrene-butadiene latex and 3 parts of wetting agent twelve were added The sodium alkylbenzene sulfonate was uniformly dispersed and continued to stir at 1000rpm for 2h to obtain PI microsphere slurry.

[0085] The above slurry was coated on one side of the 12 μm PE base film layer, the coating speed was 30 m / min, the coating thickness was 75 μm, and dried at 90°C for 10 minutes to obtain a lithium battery separator with a coating thickness of 2.5 μm on one side.

[0086]Then apply the above slurry to the other side of the PE base film, the coating speed is 30m / min, the coating thickness is 75μm, and dried at 90°C for 10min to obtain a double-sided...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com