Precursor for thermoplastic polyeher ester elastomer foaming, foaming body and preparation method thereof

A thermoplastic polyester and elastomer technology, which is applied in the foaming field of thermoplastic polymer elastic materials, can solve the problems of difficult foaming uniformity, coarse cell structure size, low product yield, etc., and shorten the aging time. , optimize elasticity and compression properties, the effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

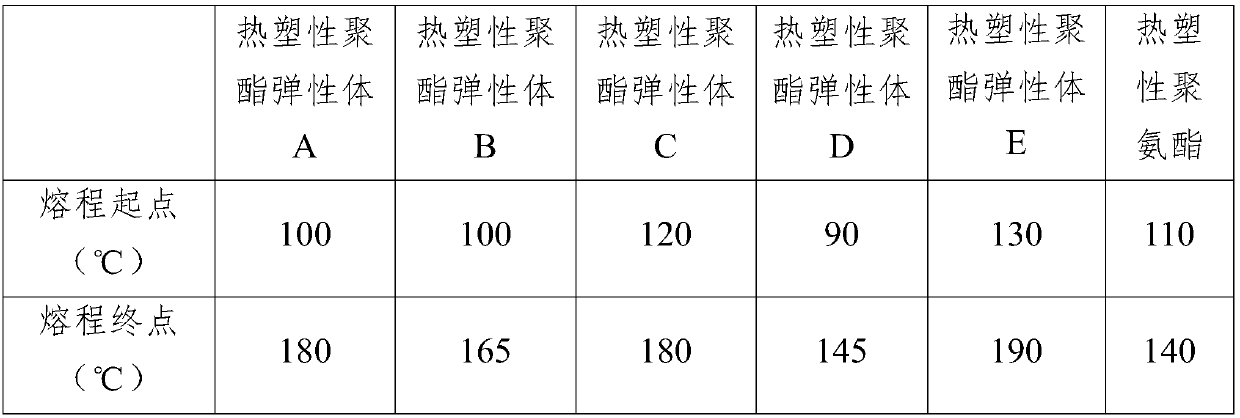

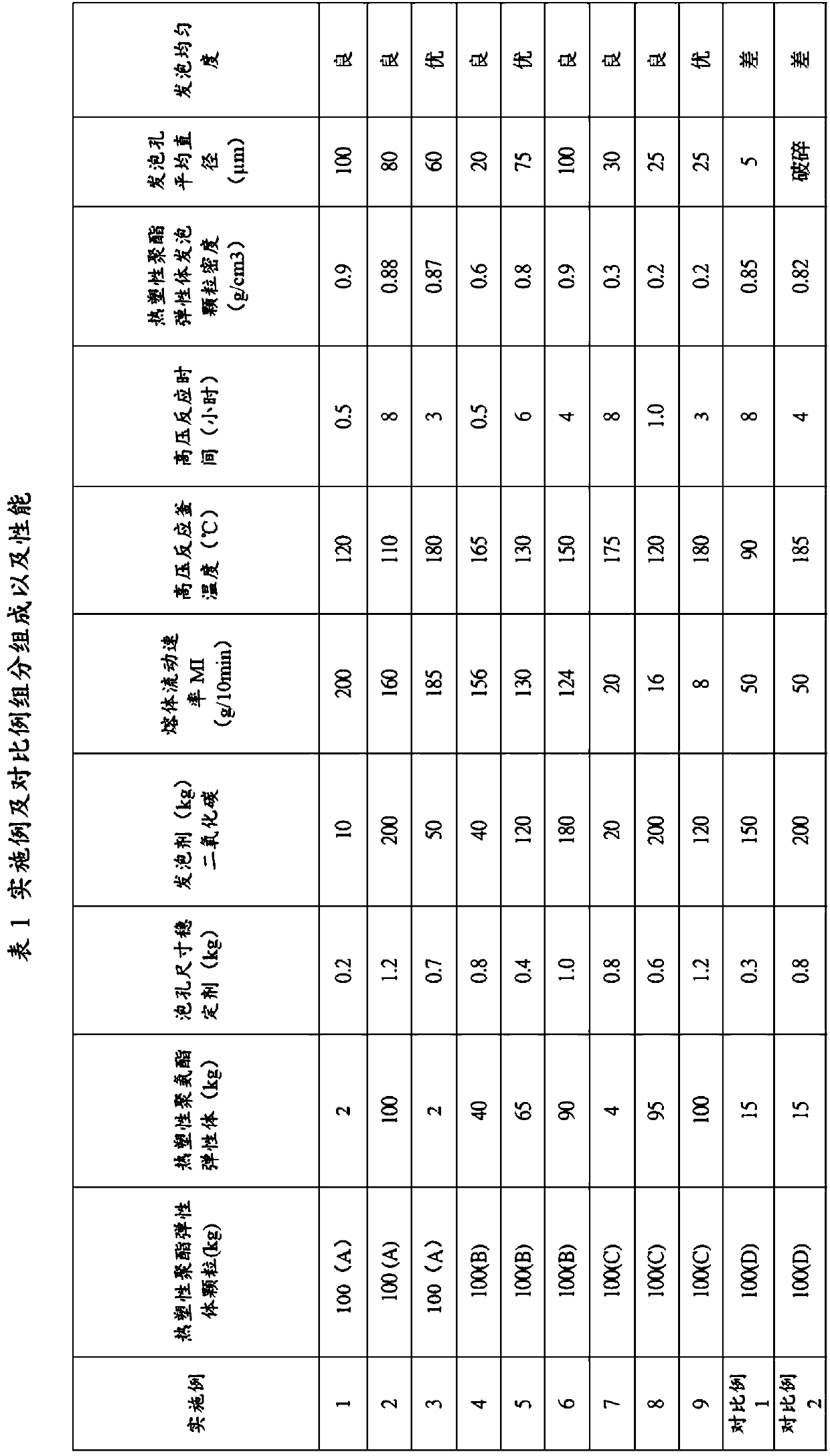

[0088] a) Add 100kg of thermoplastic polyester elastomer particle A, 2kg of thermoplastic polyurethane, and 0.2kg of cell size stabilizer into the mixer. After mixing, it was introduced into a twin-screw extruder through a hopper for melt mixing, and the melt flow rate was tested at a constant temperature of 230°C and a load of 2.16kg. The melted and kneaded product meeting the melt flow rate index was introduced from the extruder into an underwater pelletizer, and cut into ellipsoidal particles with a diameter of 2.5 mm to obtain a thermoplastic polyester elastomer foaming precursor.

[0089] b) Add 100 kg of the obtained thermoplastic polyester elastomer foaming precursor to 10 kg of a carbon dioxide volatile foaming agent, add it into the autoclave while stirring, and raise the temperature of the autoclave to 120°C.

[0090] c) In the state of sufficient mixing and uniform heating, keep the temperature at this temperature for 0.5 hours, and finally open the discharge valve ...

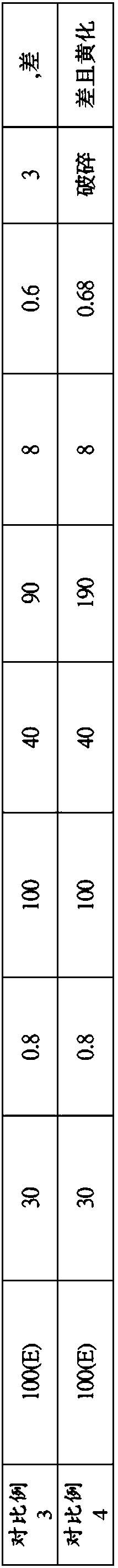

Embodiment 2~9

[0093] Embodiment 2~9 comprises most of the operation steps in embodiment 1, and its difference is:

[0094] The materials, proportions and process conditions as shown in Table 1 were adopted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com