Surface layer mortar, grindstone, board and preparation method of grindstone and board

A mortar and surface layer technology, applied in the field of stone, can solve the problems of large deformation in the later stage, easy cracking and warping, and easy return to alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] One embodiment, the white fast setting rapid hardening high belite sulfoaluminate cement is mixed and ground into cement according to the following weight percentages: cement clinker 26-97%, anhydrite 3-19%, slag powder 0-55% %. Cement clinker consists of minerals in the following percentages by weight: 22.67-37.24% of 37.02-46.21% C 2 S, 13.51-26.33% CaSO 4 , 0.5-4.6% f-CaO, 0.46-3.04% C 4 AF, the balance is miscellaneous mineral composition. The clinker has the following chemical composition in weight percent: 12.9-16.1% SiO 2 , 12-19% Al 2 o 3 , 0.15-1% Fe 2 o 3 , 49-53% CaO, 12-18.46% SO 3 , the balance is mixed chemical components; clinker ratio value range Cm: 1.01-1.137, P: 0.62-1.44.

[0040] In another embodiment, the mineral components contained in the cement clinker include 3-9%C 4 AF, 37-47%C 2 S, 0.5-4.6% f-CaO, 14-26.3% CaSO 4 . The clinker has a chemical composition in weight percent: 12.9-16.1% SiO 2 , 12-19% Al 2 o 3 , 1-3% Fe 2 o3 ...

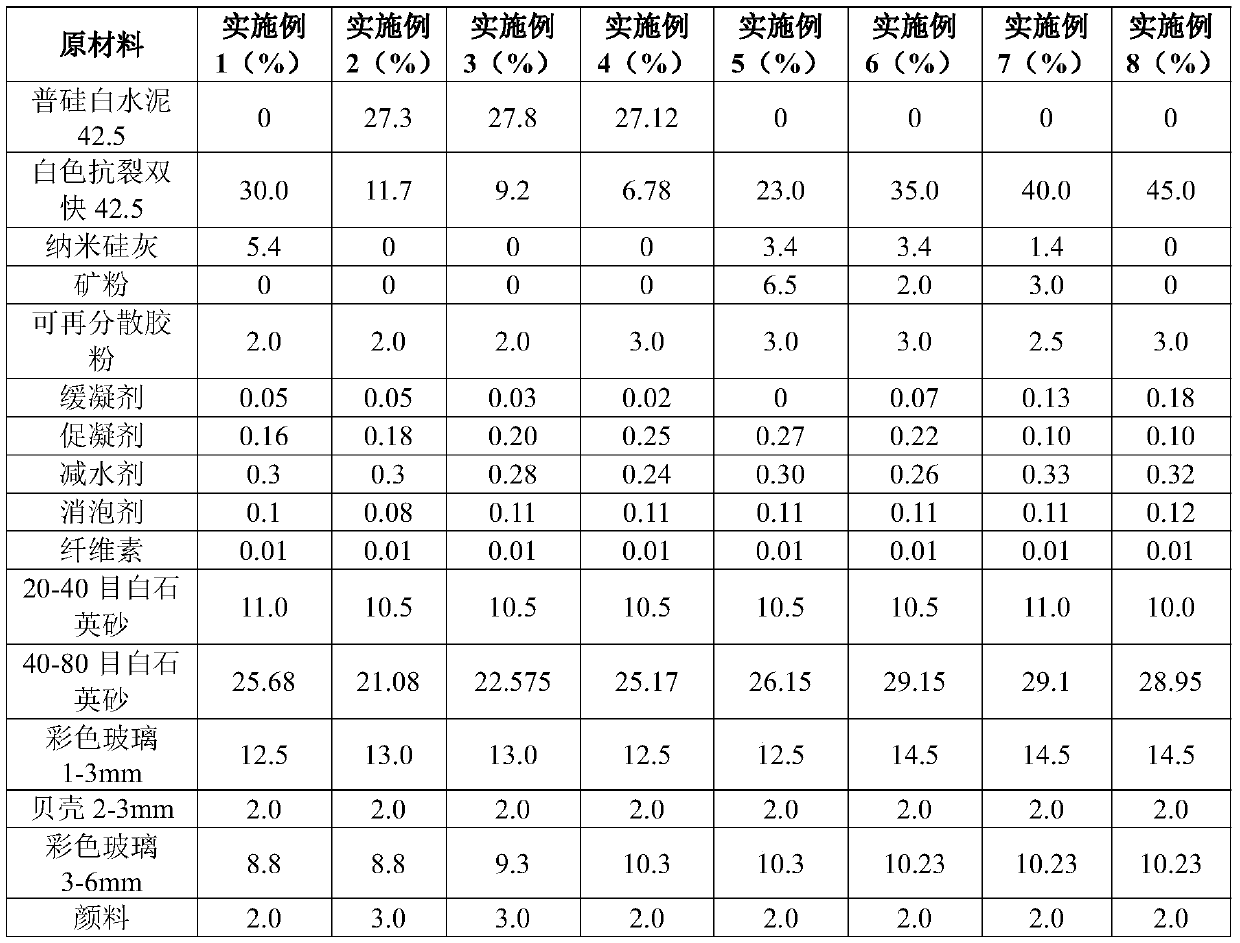

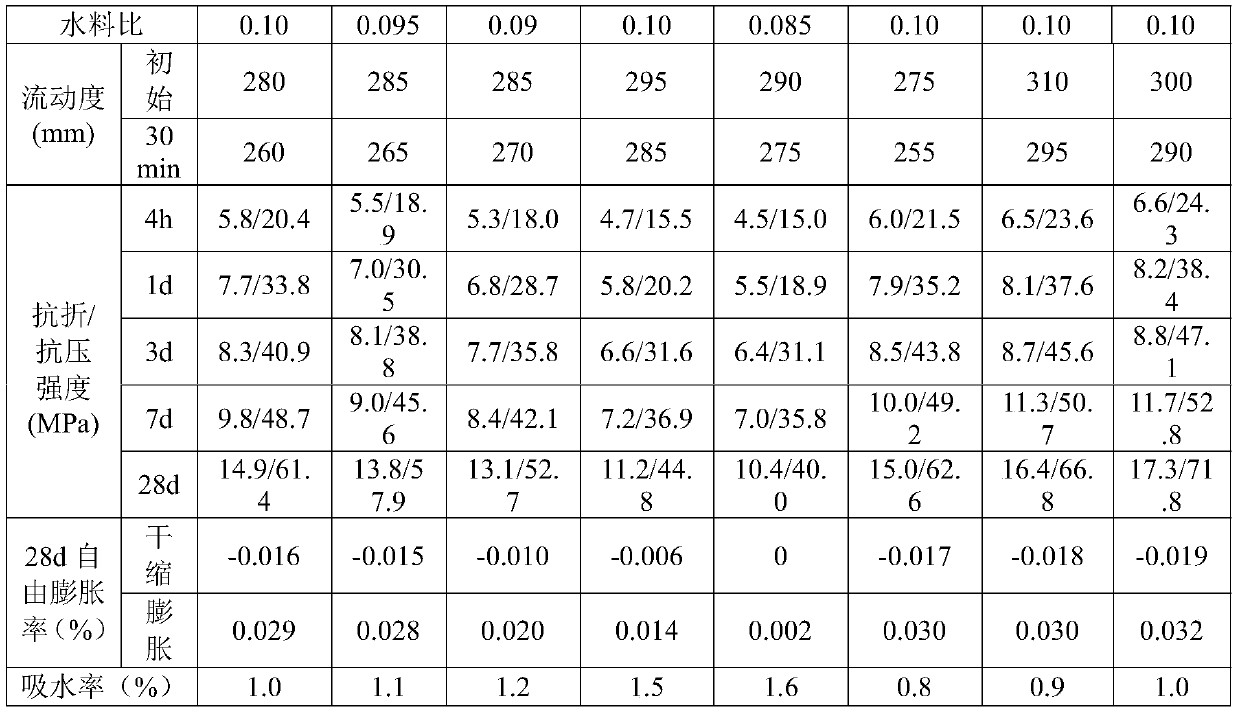

Embodiment 1-8

[0108] See Table 1 for the raw material proportions of the surface mortars provided in Examples 1-8 by mass percentage.

[0109] The preparation method of the surface layer mortar is as follows: white fast setting rapid hardening high belite sulfoaluminate cement 42.5, ordinary white cement, nano silica fume, mineral powder, redispersible rubber powder, retarder, accelerator, Water reducer, defoamer, cellulose, 20-40 mesh white quartz sand, 40-80 mesh white quartz sand, colored glass 1-3mm, colored glass 3-6mm, shell 2-3mm and pigments are mixed together to obtain the surface layer dry mortar. The surface layer dry mortar of Examples 1-8 is uniformly stirred with an appropriate amount of water, and its main properties are tested according to the test methods specified in the following standards:

[0110] Fluidity implements JC / T986-2015 "cement-based grouting materials";

[0111] The free expansion rate implements JC / T-2009 "Testing method for expansion rate of expansive cem...

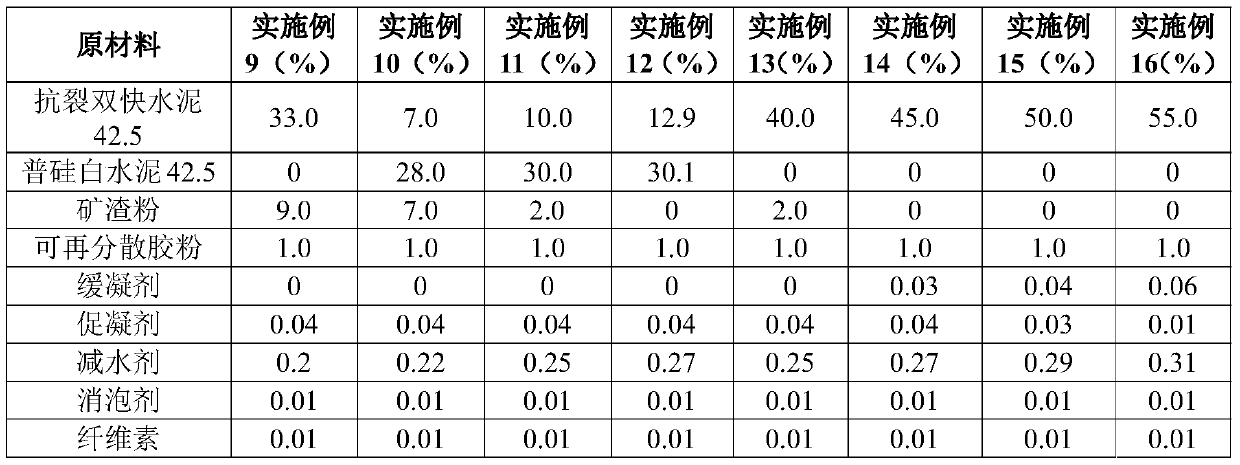

Embodiment 9-16

[0117] See Table 2 for the raw material proportions of the bottom mortars provided by Examples 9-16 by mass percentage.

[0118] The preparation method of the bottom mortar is as follows: white fast-setting rapid-hardening high-belite sulfoaluminate cement 42.5, ordinary white cement, slag powder, redispersible rubber powder, retarder, accelerator, water reducer, Foaming agent, cellulose, 20-40 mesh white quartz sand, 40-80 mesh white quartz sand and high alkali-resistant fiber (12mm) are mixed together to obtain the bottom dry mortar. The bottom dry mortar of Examples 9-16 was uniformly stirred with an appropriate amount of water, and its main properties were tested according to the same method as in Example 1. The results are shown in Table 2.

[0119] The bottom mortar of table 2 embodiment 9-16

[0120]

[0121]

[0122] It can be seen from Table 1-Table 2 that the fluidity, flexural and compressive strength, free expansion rate and water absorption rate of the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com