Surface mortar, grinding stone, board and preparation method thereof

A mortar and surface layer technology, applied in the field of stone, can solve the problems of large shrinkage, poor weather resistance, poor environmental protection, etc., and achieve the effect of small size shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] One embodiment, white fast-faster hard high Pectulose aluminate cement is mixed in the following weight percent, grinding into cement: cement clinker 26-97%, hard gypsum 3-19%, mine floss 0-55 %. Cement clinker consists of a percentage of minerals: 22.67-37.24% 37.02-46.21% C 2 S, 13.51-26.33% of CASO 4 , 0.5-4.6% F-CAO, 0.46-3.04% C 4 AF, the margin is a hybrid mineral component. Clinker has a chemical component of the following weight percentage: 12.9-16.1% SiO 2 12-19% Al 2 O 3 0.15-1% Fe 2 O 3 , 49-53% CAO, 12-18.46% SO 3 The margin is a hybrid chemical component; the clinker value range cm: 1.01-1.137, P: 0.62-1.44.

[0040] Another embodiment, including mineral components contained in cement clinker 3-9% C 4 AF, 37-47% C 2 S, 0.5-4.6% F-CAO, 14-26.3% CASO 4 . Chemical component group with weight percentage is: 12.9-16.1% SiO 2 12-19% Al 2 O 3 1-3% Fe 2 O3 , 49-54% CAO, 12-18.43% SO 3 Specifically, a weight percentage of 33-62% of limestone, 10.5-28% fly ash and 19-4...

Embodiment 1-8

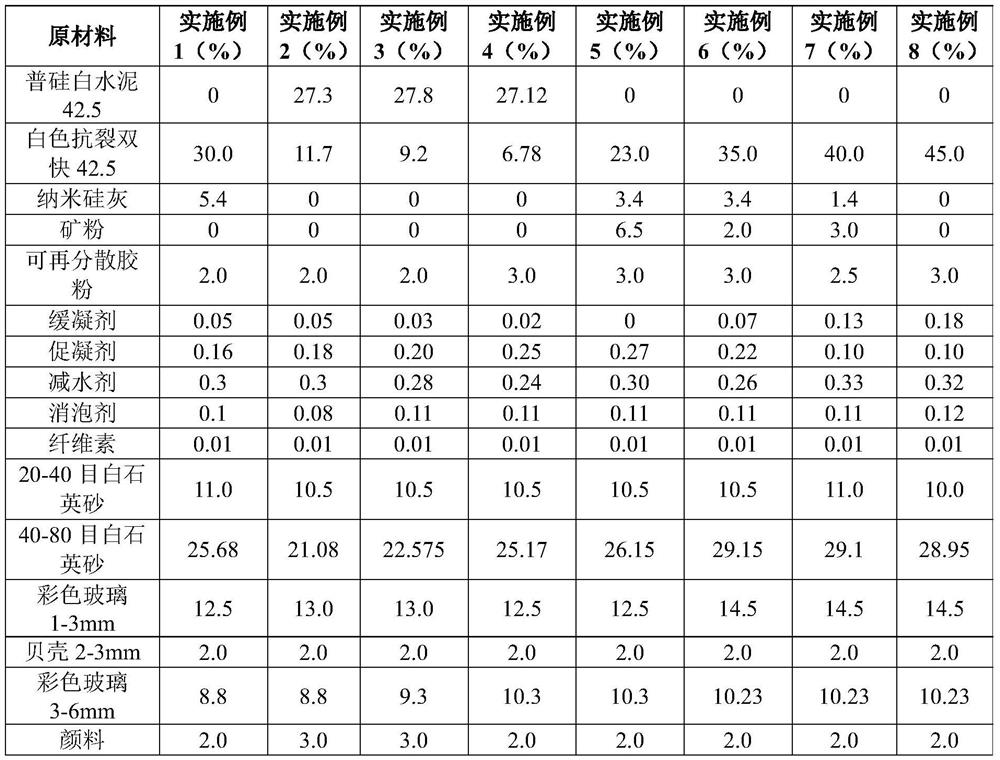

[0108] Examples 1-8 The surface layer mortar supplied is compared with a mass percentage of raw materials, shown in Table 1.

[0109] The preparation method of the surface mortar is as follows: White fast-faster high-Relite sully aluminate 42.5, ordinary white cement, nanola ash, mine powder, renewable rubber powder, laminant, laminulant, Water reducer, defoamer, cellulose, 20-40 mesh stone sand, 40-80 mesh stone sand, color glass 1-3mm, color glass 3-6mm, shell 2-3mm and pigment mixed after mixing Dry mortar. The surface layer dry mortar of Examples 1-8 was uniformly stirred with an appropriate amount of water, and the main performance was tested in accordance with the test method specified in the following criteria:

[0110] Performing JC / T986-2015 "Cement Base Grouting Material";

[0111] Free expansion ratio Perform JC / T-2009 "Expansion Cement Expansion Rate Test Method";

[0112] Plate resistance, water absorption rate: JC / T507-2012 "Water milling of architectural decor...

Embodiment 9-16

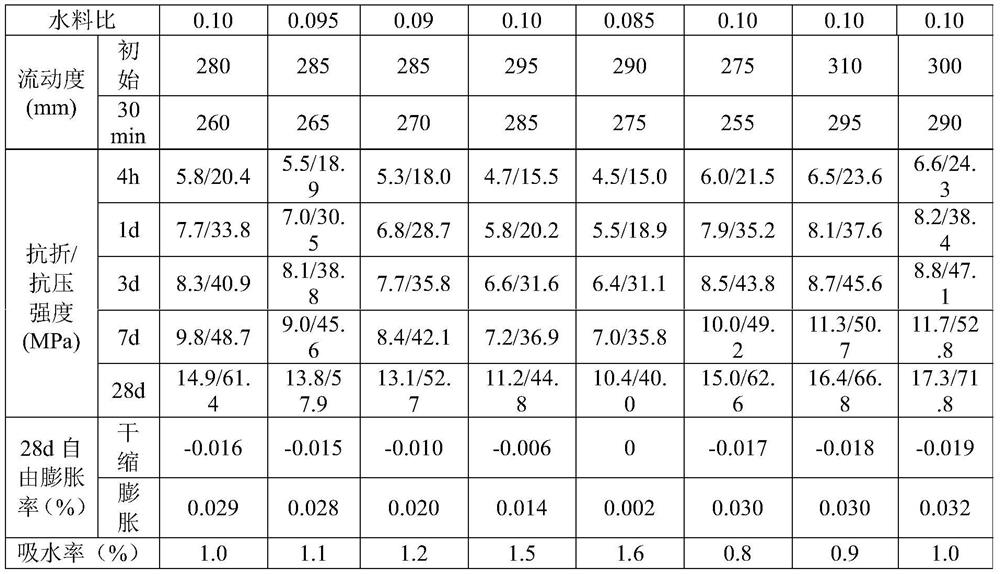

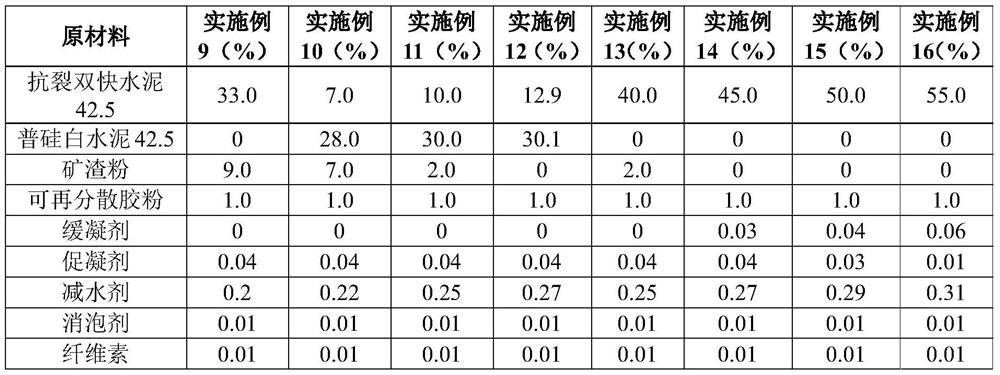

[0117] Example 9-16 The underlying mortar provided by the mass percentage is shown in Table 2.

[0118] The preparation method of the underlying mortar is as follows: White fast-faster high-Relite sully aluminate 42.5, ordinary white cement, slag powder, renewable rubber powder, laminator, laminate, water reducer, elimination Bubble, cellulose, 20-40 mesh stone sand, 40-80 mesh stone sand and high alkali fibers (12 mm) together to obtain a bottom dry mortar. The underlying dry mortar of Examples 9-16 was uniformly stirred with an appropriate amount of water, and the main properties were tested in accordance with Example 1, as shown in Table 2.

[0119] Table 2 Example 9-16 underlayer mortar

[0120]

[0121]

[0122] As can be seen from Table 1- Table 2, the flow rate, flavor, compressive strength, free expansion ratio and water absorption rate of the surface layer mortar and the underlying mortar provided by the present invention meet the relevant indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com