Composition for enhancing dimensional stability of HDPE water supply pipe

A dimensional stability and composition technology, which is applied in the field of compositions that enhance the dimensional stability of HDPE water supply pipes, can solve the problems of poor dimensional stability of HDPE water supply pipes, and achieve easy control of processing technology, simple processing technology, and other excellent properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

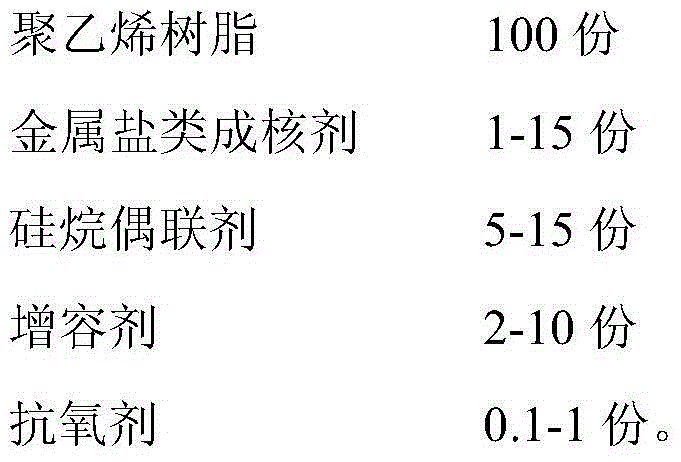

[0036] Composition described in the present embodiment comprises the raw material component of following weight portion:

[0037]

[0038] Wherein, the polyethylene resin is a high-density polyethylene resin with a melt index of 0.7g / 10min at 190°C and 2.16kg;

[0039] The metal salt nucleating agent is sodium benzoate; the silane coupling agent is 3-aminopropyltriethoxysilane; the compatibilizer is polyethylene octene co-elastomer; the antioxidant is Antioxidant 1076.

[0040] The method for preparing the composition as described above in the present embodiment comprises the following steps:

[0041] 1) According to the parts by weight of each raw material component, polyethylene resin, metal salt nucleating agent, silane coupling agent, compatibilizer and antioxidant are mixed;

[0042] 2) adding to a twin-screw extruder to extrude and granulate. The extrusion temperature of the twin-screw extruder is 190° C., and the screw speed is 200 rpm.

Embodiment 2

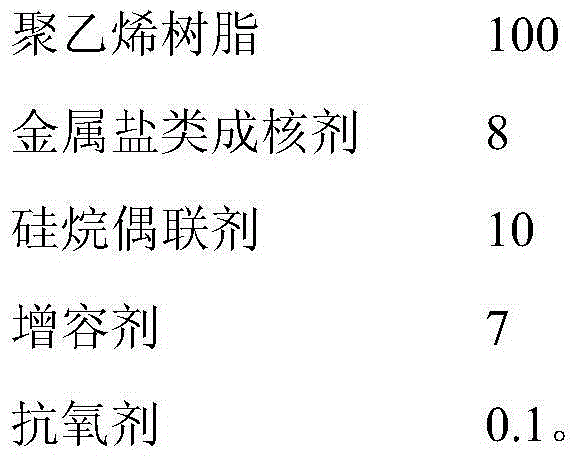

[0044] Composition described in the present embodiment comprises the raw material component of following weight portion:

[0045]

[0046] Wherein, the polyethylene resin is a linear low-density polyethylene resin with a melt index of 5.1g / 10min at 190°C and 2.16kg;

[0047] The metal salt nucleating agent is calcium stearate; the silane coupling agent is 3-aminopropyltriethoxysilane; the compatibilizer is EPDM rubber; the antioxidant is Antioxidant 1010.

[0048] The method for preparing the composition as described above in the present embodiment comprises the following steps:

[0049] 1) the parts by weight of each raw material component, mixing polyethylene resin, metal salt nucleating agent, silane coupling agent, compatibilizer and antioxidant;

[0050] 2) adding to a twin-screw extruder to extrude and granulate. The extrusion temperature of the twin-screw extruder is 190° C., and the screw speed is 200 rpm.

Embodiment 3

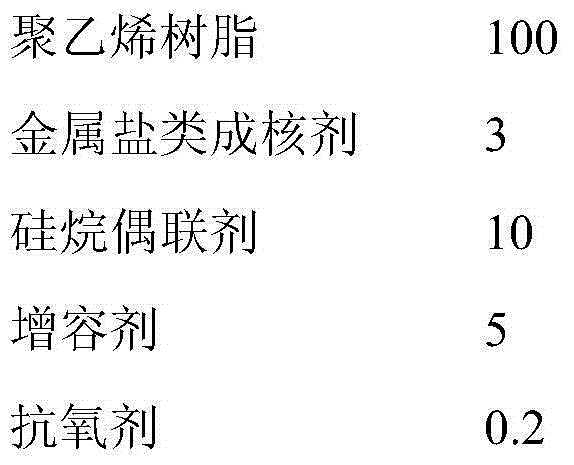

[0052] Composition described in the present embodiment comprises the raw material component of following weight portion:

[0053]

[0054] Wherein, the polyethylene resin is a high-density polyethylene resin with a melt index of 1.1g / 10min at 190°C and 2.16kg;

[0055] The metal salt nucleating agent is zinc stearate; the silane coupling agent is 3-aminopropyltriethoxysilane; the compatibilizer is polyethylene wax; the antioxidant is antioxidant Agent 1010.

[0056] The method for preparing the composition as described above in the present embodiment comprises the following steps:

[0057] 1) According to the parts by weight of each raw material component, polyethylene resin, metal salt nucleating agent, silane coupling agent, compatibilizer and antioxidant are mixed;

[0058] 2) adding to a twin-screw extruder to extrude and granulate. The extrusion temperature of the twin-screw extruder is 190° C., and the screw speed is 200 rpm.

[0059]Add 2 wt% of the composition de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com