Efficient halogen-free intumescent flame-retardant glass fiber reinforced polypropylene material and preparation method thereof

A polypropylene material and an intumescent technology, applied in the field of polypropylene materials, can solve the problems of easy moisture absorption of red phosphorus, reduced mechanical properties, and reduced comprehensive polymer properties, and achieve outstanding water resistance and mechanical properties, and the performance can be used for a long time. , the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

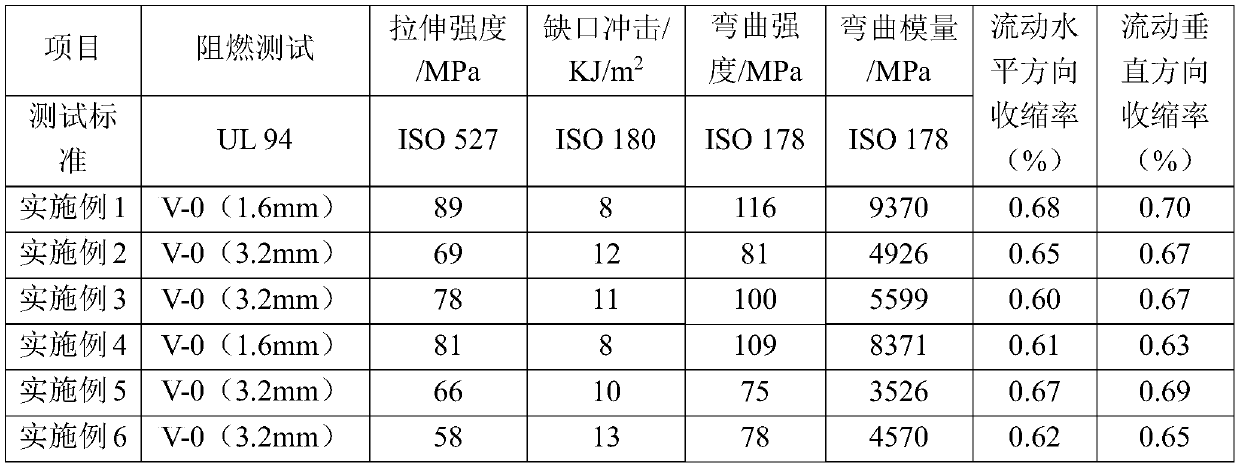

Examples

preparation example Construction

[0027] The preparation method of the high-efficiency halogen-free intumescent flame-retardant glass fiber reinforced polypropylene material of the present invention comprises the following steps:

[0028] a. Mix the coated ammonium polyphosphate, melamine and its derivatives, and the halogen-free flame-retardant char-forming agent at a temperature of 90-130°C in a low-speed (40-60 rpm) mixer 10-30 minutes, then spray 0.05-0.5% silane coupling agent for heat treatment to obtain a halogen-free intumescent flame-retardant mixture; the halogen-free intumescent flame-retardant mixture is surface-treated, and the addition amount is small, which has little effect on mechanical properties . The flame retardant accelerates the esterification reaction between the carbon source itself and the acid source through the carbon-forming synergist to improve the flame retardant efficiency, and catalyzes the main flame retardant to form a denser carbon layer, thereby reducing the intumescent fla...

Embodiment 1

[0033] The high-efficiency halogen-free intumescent flame-retardant glass fiber-reinforced polypropylene material provided in this example includes the following components by weight: 42.2 parts of polypropylene (PP K7926), 5 parts of melamine pyrophosphate, piperazine polyphosphate 15 parts, 1 part of zinc borate, 30 parts of surface-treated glass fiber, 0.1 part of coupling agent, 2 parts of maleic anhydride grafted polypropylene KT-1, 4 parts of POE 8200, 0.2 part of PE wax, 0.5 part of antioxidant ;

[0034] In this embodiment, the surface-treated glass fiber is an alkali-free long glass fiber after spraying a silane coupling agent heat-treated at a weight percentage of 0.2% at 110°C; the antioxidant is antioxidant 168 and Antioxidant 1010 is an antioxidant compounded at a weight ratio of 2:3.

[0035] The preparation method comprises the following steps:

[0036] a. After mixing melamine pyrophosphate and piperazine polyphosphate, mix the materials for 20 minutes at a t...

Embodiment 2

[0040] The high-efficiency halogen-free intumescent flame-retardant glass fiber-reinforced polypropylene material provided in this embodiment includes the following components by weight: 42.2 parts of polypropylene (PP K7926), 5 parts of coated ammonium polyphosphate, melamine coke 5 parts of phosphate, 10 parts of piperazine polyphosphate, 1 part of zinc borate, 30 parts of surface treated glass fiber, 0.1 part of coupling agent, 2 parts of maleic anhydride grafted polypropylene KT-1, 4 parts of POE 8200, PE 0.2 part of wax, 0.5 part of antioxidant; the rest are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com