Preparation method cellulose / polyimide composite aerogels

A technology of composite airgel and polyimide, applied in the field of materials, can solve the problems of affecting the quality of polyimide airgel products, large shrinkage, and low strength of airgel skeleton, and achieves the scope of application. Environmentally friendly, Improve quality and avoid hard-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

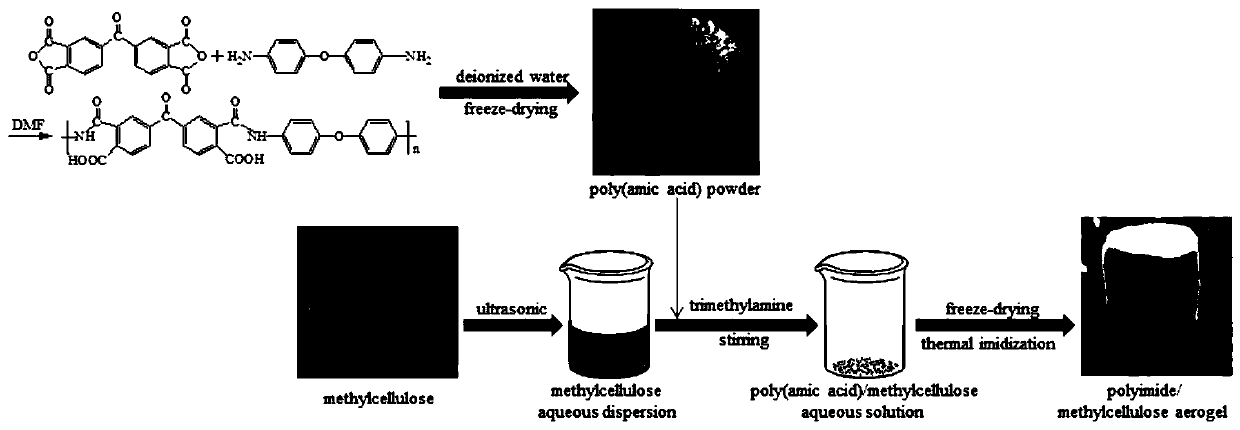

[0024] A kind of preparation method of cellulose / polyimide composite airgel of the present invention specifically comprises the following steps:

[0025] First, reacting diamine monomers and dianhydride monomers in a (strong) polar aprotic solvent to prepare a polyamic acid solution;

[0026] The specific means are as follows: ultrasonically treat single-necked flasks, beakers, molds, magnets, etc. with absolute ethanol to remove surface impurities, and dry them for later use. Put the weighed diamine in a single-necked flask with a magnet, add a strong polar aprotic solvent, and stir until the diamine is completely dissolved; slowly add the weighed dianhydride into the diamine solution, and stir at room temperature for 24 ~48h to obtain polyamic acid solution;

[0027] Secondly, the polyamic acid solution is poured into the precipitant to precipitate and dry;

[0028] The specific means are as follows: pour the polyamic acid solution into excess precipitant to precipitate, c...

Embodiment 1

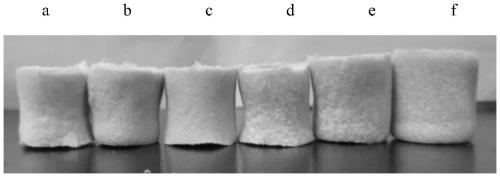

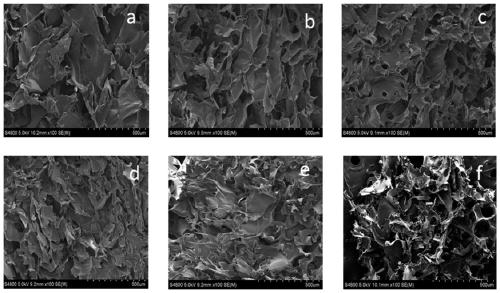

[0039] Preparation of cellulose / polyimide composite airgel: First, 2.00g 4,4'-diaminodiphenyl ether (ODA), 2.18g pyromellitic anhydride (PMDA), 25mL N,N-diphenyl Polyamic acid solution was prepared from methyl formamide, and polyamic acid powder was obtained after precipitation, washing, and freeze-drying; secondly, 0.01g methylcellulose was dispersed in 10mL 70°C deionized water, and 0.2g polyamic acid was added after cooling powder, 0.1mL triethylamine, stirred to obtain a polyamic acid / methylcellulose aqueous solution, poured into a mold, degassed, frozen, and freeze-dried to obtain a polyamic acid / methylcellulose composite aerogel; finally, after Polyimide / methylcellulose composite airgel was obtained by thermal imidization treatment, and the thermal imidization process was: 120°C (0.5h) + 150°C (0.5h) + 200°C (1h) + 250°C ( 4h). The size shrinkage of the polyimide / methylcellulose composite airgel prepared in this example is significantly reduced, thereby improving the qu...

Embodiment 2

[0041] Preparation of cellulose / polyimide composite airgel: First, 2.00g 4,4'-diaminodiphenyl ether (ODA), 2.18g pyromellitic anhydride (PMDA), 25mL N,N-diphenyl Prepare polyamic acid solution with methyl formamide, and obtain polyamic acid powder after precipitation, washing, and freeze-drying; secondly, disperse 0.06g nanocellulose in 10mL 70°C deionized water, add 0.2g polyamic acid powder after cooling , 0.1mL triethylamine, stirred to obtain a polyamic acid / nanocellulose aqueous solution, poured into a mold, degassed, frozen, and freeze-dried to obtain a polyamic acid / nanocellulose composite aerogel; The polyimide / nanocellulose composite airgel was obtained by chemical treatment, and the thermal imidization process was: 120°C (0.5h) + 150°C (0.5h) + 200°C (1h) + 250°C (4h). The size shrinkage of the polyimide / methylcellulose composite airgel prepared in this example is significantly reduced, thereby improving the quality of the polyimide airgel product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com