Activated sintering preparation method for high-density titanium product

A technology of activated sintering and densification, which is applied in the field of powder metallurgy, can solve the problems of long sintering process, high production cost, excessive energy consumption, etc., and achieve fine grain size, high tensile strength, and adjustable powder particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

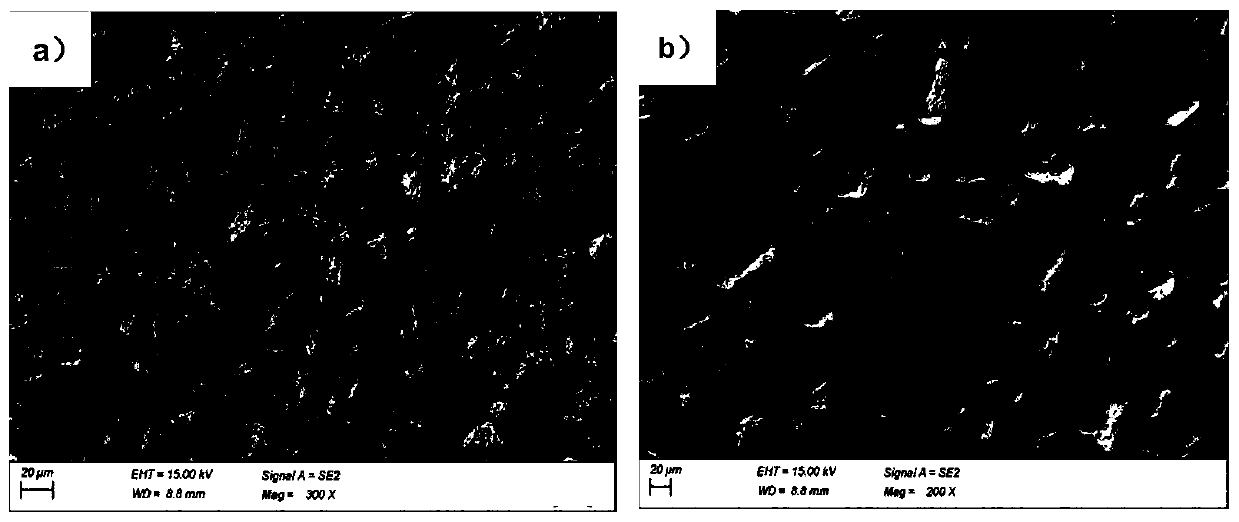

[0024] 1. The raw material powder is commercially available hydrogenated dehydrogenation titanium powder with a median diameter of 32.2 μm. Weigh 1000g, place the titanium powder in the grinding chamber of a fluidized bed jet mill, fill it with high-purity nitrogen as a protective gas and grind Gas, the air pressure is 0.7MPa, after 8 minutes of treatment, a high-activity titanium powder with a large specific surface area is obtained;

[0025] 2. Then collect the highly active titanium powder by airflow classification, adjust the frequency of the sorting wheel to 50Hz, and obtain titanium powder with a median diameter of 20 μm after treatment;

[0026] 3. The oxygen content of the titanium powder obtained above is lower than 2000ppm, and the bulk density is 2.51g / cm 3 ;

[0027] 4. Molding the titanium powder obtained above under a pressure of 10 MPa to obtain a green body;

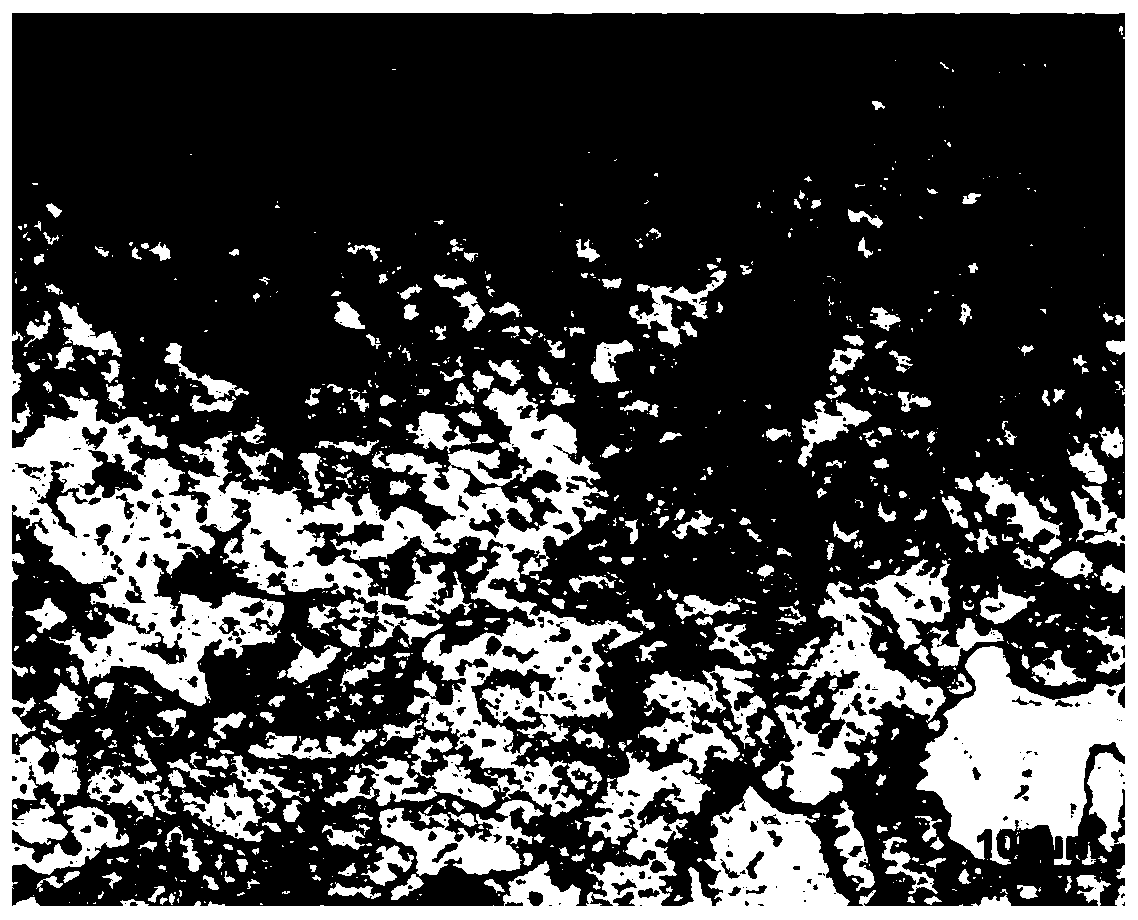

[0028] 5. Place the above-mentioned green body in a high-vacuum molybdenum wire furnace for sinterin...

Embodiment 2

[0031] 1. The raw material powder is commercially available hydrogenated dehydrogenation titanium powder, with a median diameter of 32.2 μm, weighed 800g, placed the titanium powder in the grinding chamber of a fluidized bed jet mill, filled with high-purity argon as a protective gas and Grinding gas, the air pressure is 0.8MPa, after processing for 10min, the highly active titanium powder is collected by airflow classification, and the frequency of the sorting wheel is adjusted to 40Hz to obtain titanium powder with a median diameter of 22.5μm;

[0032] 2. The oxygen content of the titanium powder obtained above is lower than 2000ppm, and the bulk density is 2.43g / cm 3 ;

[0033] 3. The titanium powder obtained above is molded under a pressure of 11.3MPa to obtain a green body;

[0034] 4. Place the above green body in a high vacuum molybdenum wire furnace for sintering. The final sintering temperature is 1150°C, the heating rate is 10°C / min, the holding time is 2h, and the ...

Embodiment 3

[0037] 1. The raw material powder is commercially available titanium powder with a median diameter of 42 μm. Weigh 600g, place the titanium powder in the grinding chamber of a fluidized bed jet mill, and fill it with high-purity nitrogen as protective gas and grinding gas. The air pressure is 0.7MPa, collect highly active titanium powder through airflow classification, adjust the frequency of the sorting wheel to 35Hz, and obtain titanium powder with a median diameter of 30.4μm;

[0038] 2. The oxygen content of the titanium powder obtained above is lower than 1900ppm, and the bulk density is 2.45g / cm 3 ;

[0039] 3. The titanium powder obtained above is molded under a pressure of 11.5MPa to obtain a green body;

[0040] 4. Place the above green body in a high vacuum tungsten wire furnace for sintering. The final sintering temperature is 1150°C, the heating rate is 20°C / min, the holding time is 1h, and the relative density is 98.1%. The tensile strength is 685MPa, and the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com