Light aggregate for composite thermal-insulation and fire-prevention wall material, and production method thereof

A technology of bulk materials and lightweight aggregates, applied in the field of lightweight aggregates, can solve the problems of resource exhaustion, high long-distance transportation costs, and heavy wall materials, and achieve the effects of convenient construction, saving transportation costs, and small specific gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

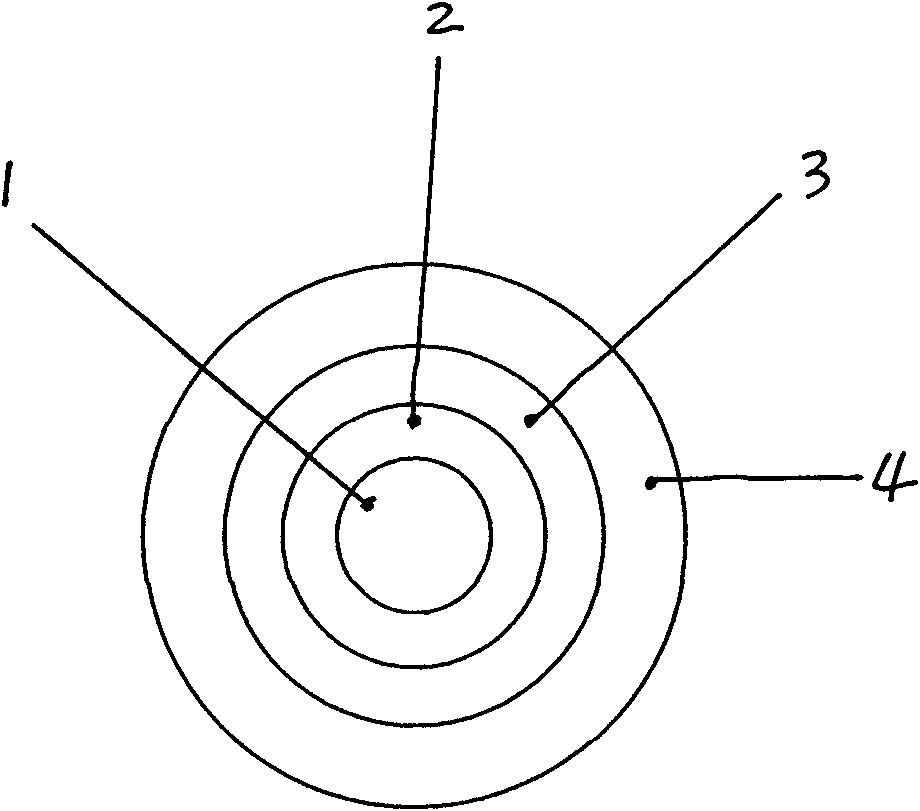

[0012] It includes a bone core 1 made of cement and fly ash. The bone core 1 is covered with a middle layer 2 made of cement and urea-formaldehyde foam or polystyrene foam powder. The outside of the middle layer 2 is covered with cement and plant ash or carbon powder. Or the shell layer 3 that polystyrene foam powder makes.

[0013] It is also possible to cover the shell layer 4 made of cement and fly ash on the outside of the shell layer 3 .

[0014] The specific production method: mix the cement and fly ash according to the volume ratio of 1:2, put it into the shaker, drip water into the shaker, and shake it into a bone core with a diameter of 2mm, 3mm or 5mm;

[0015] Then spray into the shaking plate machine, add cement, urea-formaldehyde foam or polystyrene foam powder into the shaking plate machine while spraying according to the volume ratio of 1:2-3 The mixture made, make the middle layer, shake it to a diameter of 5mm or 7mm or 10mm;

[0016] Then spray into the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com