Automatic feeding device of construction waste crusher

A construction waste, automatic feeding technology, applied in grain processing and other directions, can solve the problems of adding construction waste, large volume of construction waste crusher, and high height of the feeding port, saving manpower, reducing occupied space, and improving Using the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

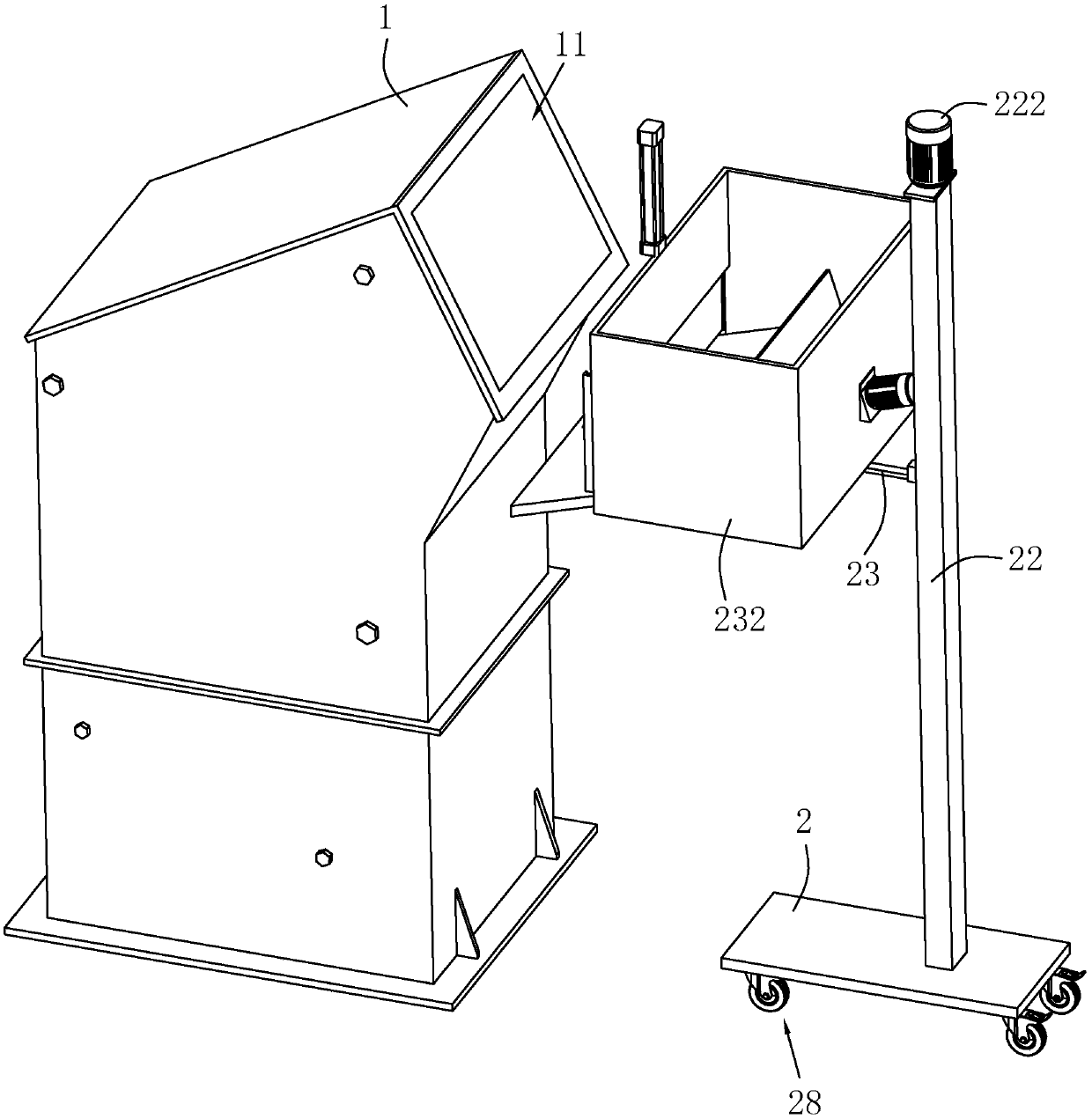

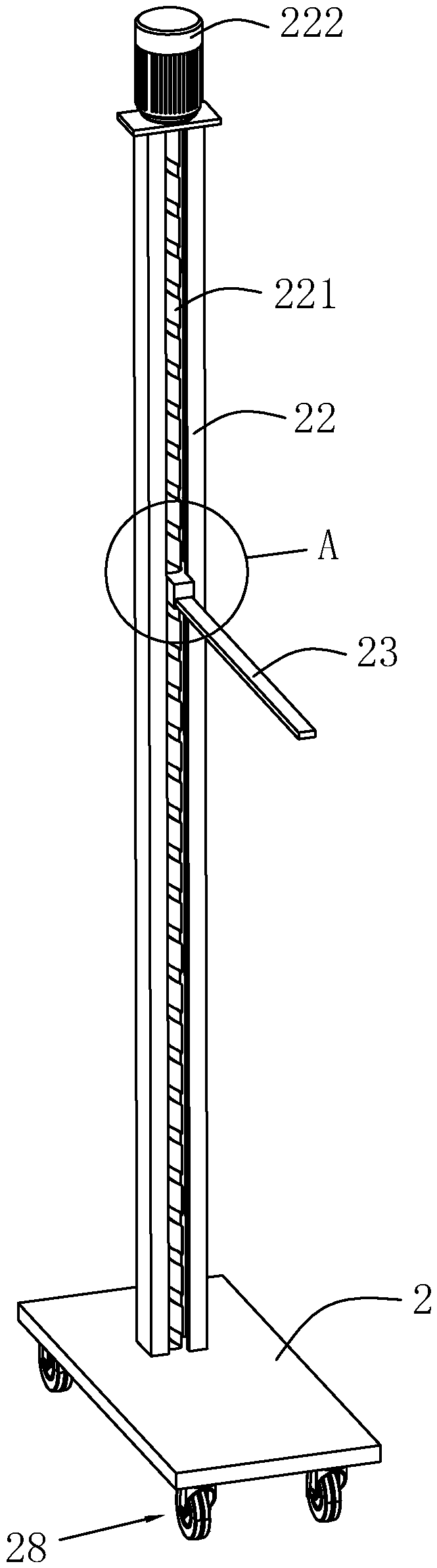

[0040] refer to figure 1 , is an automatic feeding device for a construction waste pulverizer disclosed in the present invention, comprising a body 1, which is provided with a feed port 11, and one side of the body 1 is provided with a feeder for feeding to the position where the feed port 11 is located. The feeding device for feeding material at the feed port 11. The feeding device includes a bottom plate 2. In order to facilitate the bottom plate 2 to drive the feeding device to move to any pulverizer for feeding, universal wheels 28 are provided under the bottom plate 2 and at the four corners of the bottom plate 2. , in this embodiment, the universal wheel 28 is set as a universal wheel 28 with brake pads, when the bottom plate 2 moves to any position, the bottom plate 2 can be locked to any position by the brake pads.

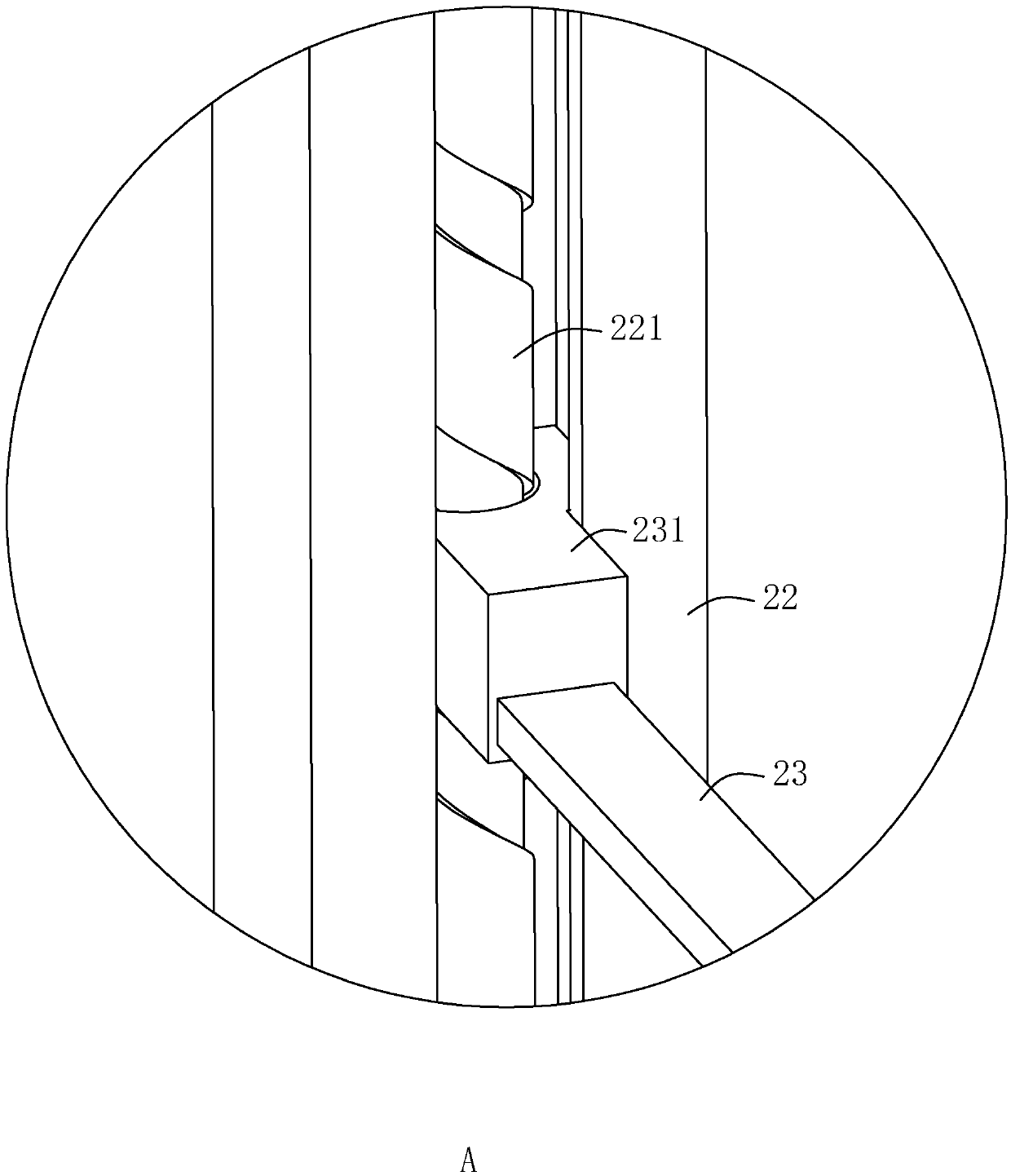

[0041] combine figure 1 and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com