Tea uniform blending machine

A technology of leveling machine and tea leaves, which is applied in the direction of tea processing before extraction, etc., can solve the problems that the operator cannot reasonably use the leveling machine, the leveling machine cannot guarantee the production continuity, and the labor cost of the leveling machine is high, so as to save manpower. , Low production cost, the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

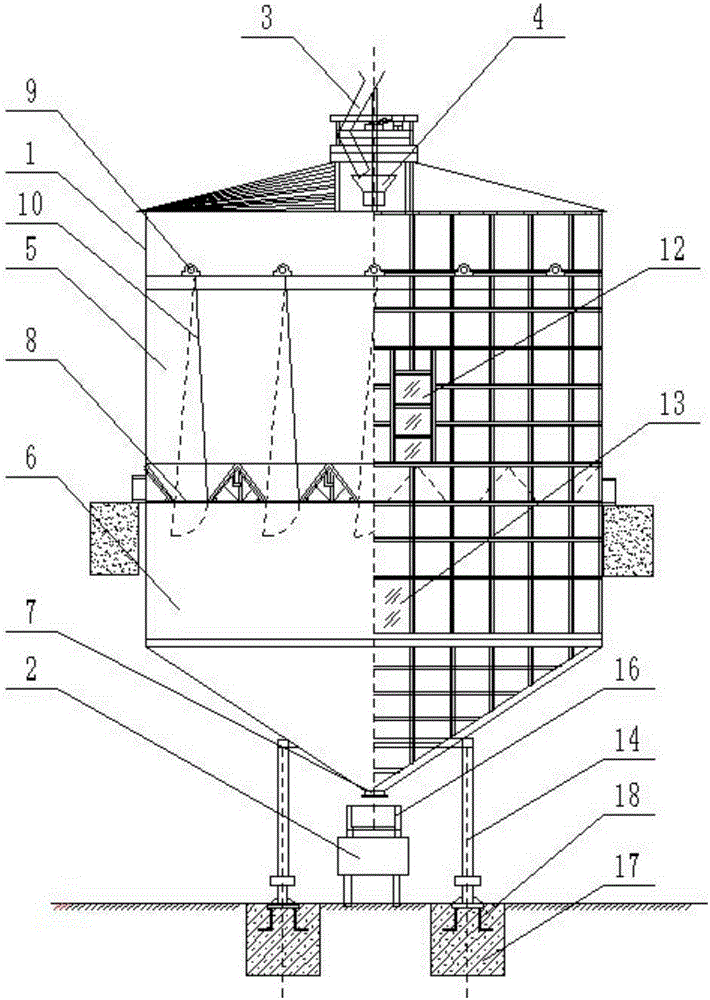

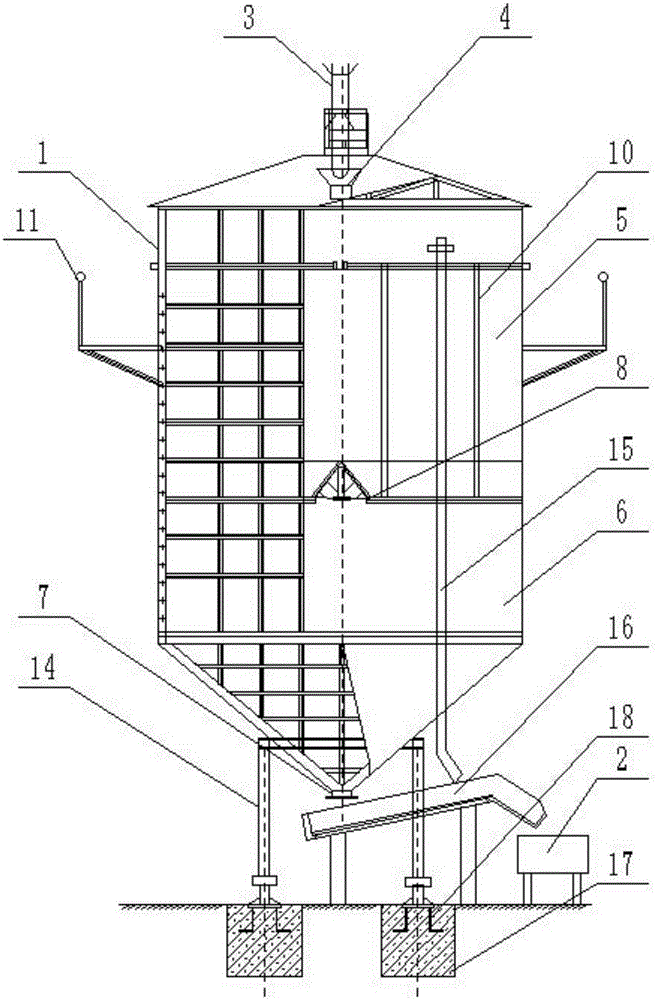

[0021] refer to figure 1 , figure 2 As shown, a tea even stacking machine includes a stacking port for the initial stacking of tea leaves, a conveyor belt, a control box 1 and a stacking box 2, the feeding port of the conveyor belt is connected to the stacking port, and the conveyor belt gradually The stage lifting lifts the tea leaves that have been homogenized to the feed inlet at the top of the control box 1, and the end of the conveyor belt is provided with a lower tea pipe 3; the inside of the control box 1 is sequentially provided with a tea spreader assembly 4, The upper control chamber 5, the lower control chamber 6 and the discharge pipe 7, the feed port of the tea spreader assembly 4 is connected to the discharge port of the lower tea pipe 3, and the discharge port of the tea spreader assembly 4 is located in the upper control chamber 5. Above, the tea leaves evenly fall into the upper control chamber 5 after being sprinkled from the tea spreader assembly 4; there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com