Efficient metal powder raw material mixing device of 3D printer

A 3D printer and metal powder technology, applied in mixers, metal processing equipment, additive processing, etc., can solve problems such as uneven mixing, poor effect, and single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

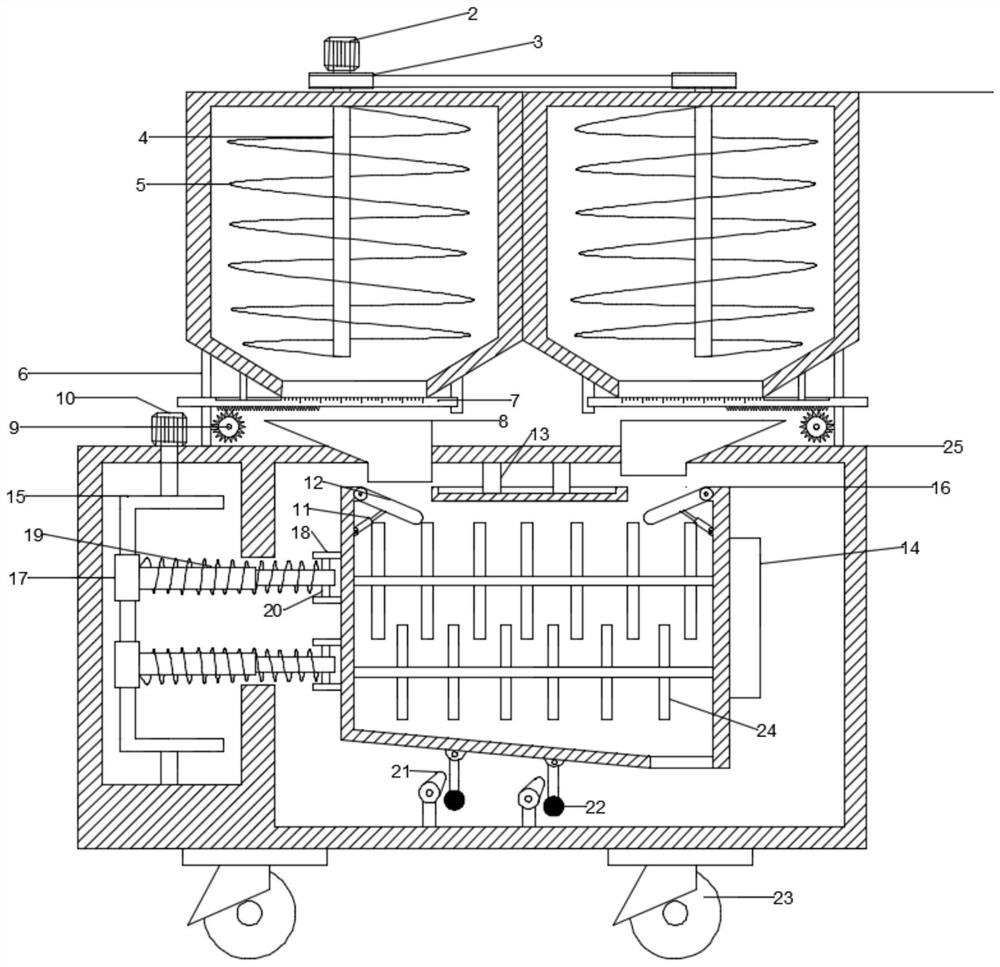

[0023] see Figure 1~3, in an embodiment of the present invention, a high-efficiency mixing device for metal powder raw materials of a 3D printer includes a first raw material box and a second raw material box 1, a first motor 2 is installed on the top of the first raw material box, and the first The output end of the motor 2 is fixedly connected with the first rotating shaft 4, and the first pulley 3 is installed on the first rotating shaft 4, and the first pulley 3 is connected with a second pulley through a belt, and the second pulley is installed on the second pulley. On the rotating shaft, the first rotating shaft 4 and the second rotating shaft extend to the first raw material box and the second raw material box 1 respectively, and the first rotating shaft 4 and the second rotating shaft are equipped with stirring blades 5. A motor 2 drives the first rotating shaft 4 to rotate, and the first pulley 3 drives the second rotating shaft to rotate through the belt. Through th...

Embodiment 2

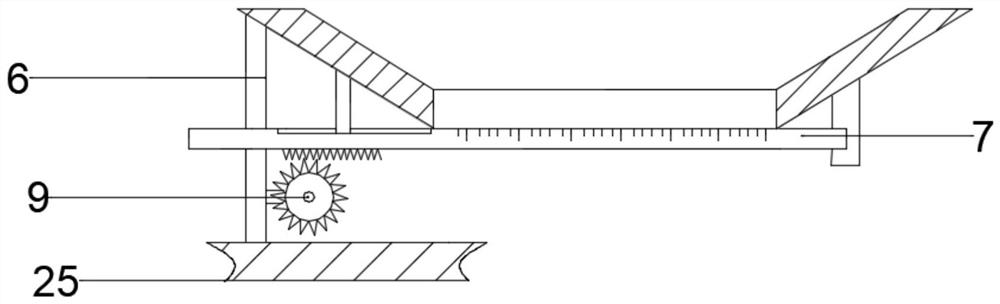

[0025] see Figure 1~3 , on the basis of Embodiment 1, the material control device includes a riser 6, the riser 6 is fixedly connected to the top of the fixed frame 25, and a through hole is opened on the riser 6, and a through hole is set in the through hole There is a scale plate 7, the corresponding scale is marked on the scale plate 7, the top of the scale plate 7 is slidably connected with the connection plate, the slide rail for the connection plate to slide is provided on the scale plate 7, and the bottom of the scale plate 7 There is a tooth groove, and a fourth gear 9 is arranged under the tooth groove, and the fourth gear 9 is fixedly connected with the output end of the fourth motor. The end of the scale plate 7 away from the vertical plate 6 runs through the discharge of the first raw material box. mouth, and through the card slot opened on the fixed plate and the fixed plate clamped, through the fourth motor to drive the fourth gear 9 to rotate, the fourth gear 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com