Double-sided adhesive tape convenient for automatic cut-off and processing process thereof

An automatic cutting and double-sided adhesive technology, applied in the field of double-sided adhesive tape, can solve the inconvenience of tearing plastic film and other problems, and achieve the effect of simple structure, convenient use, and easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

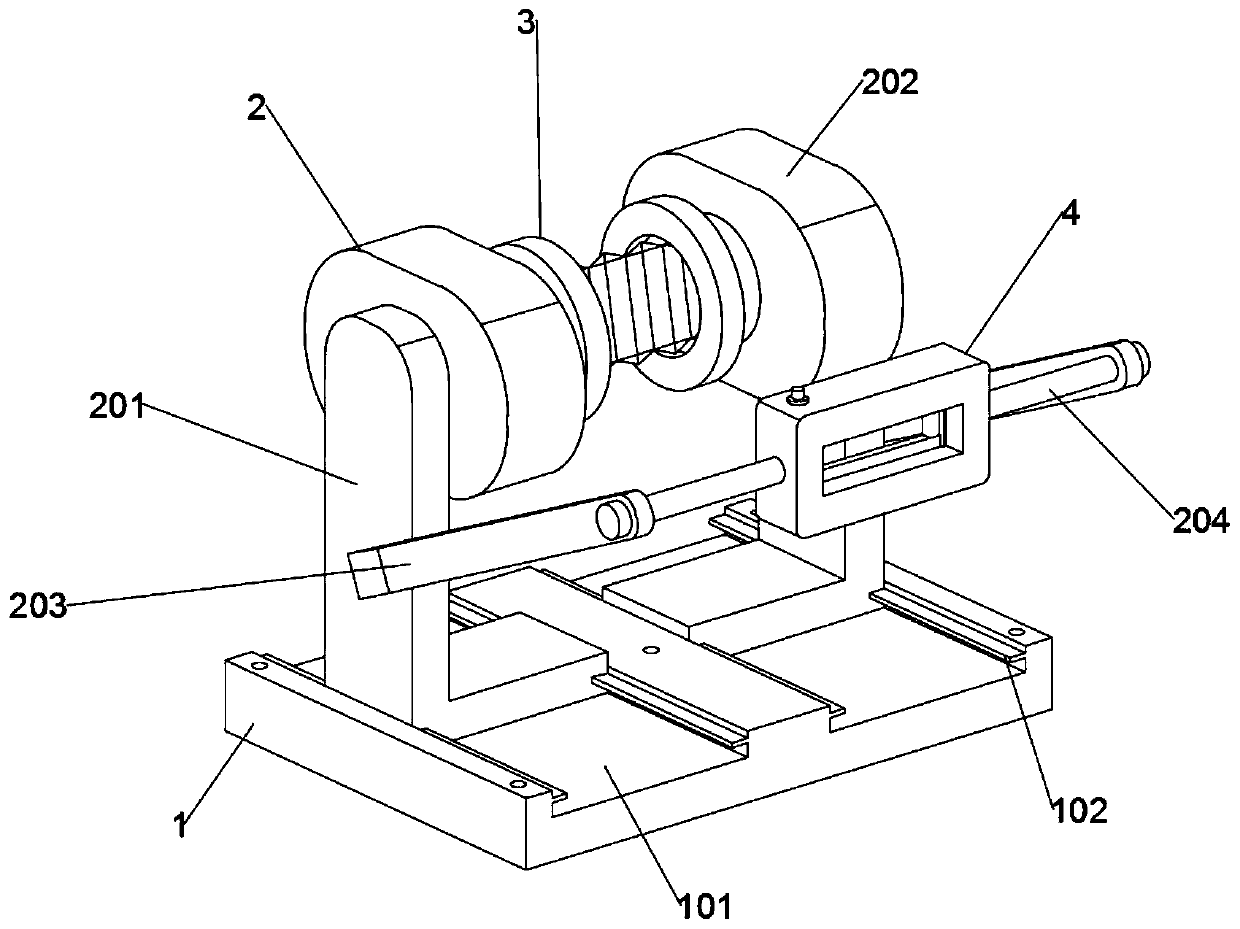

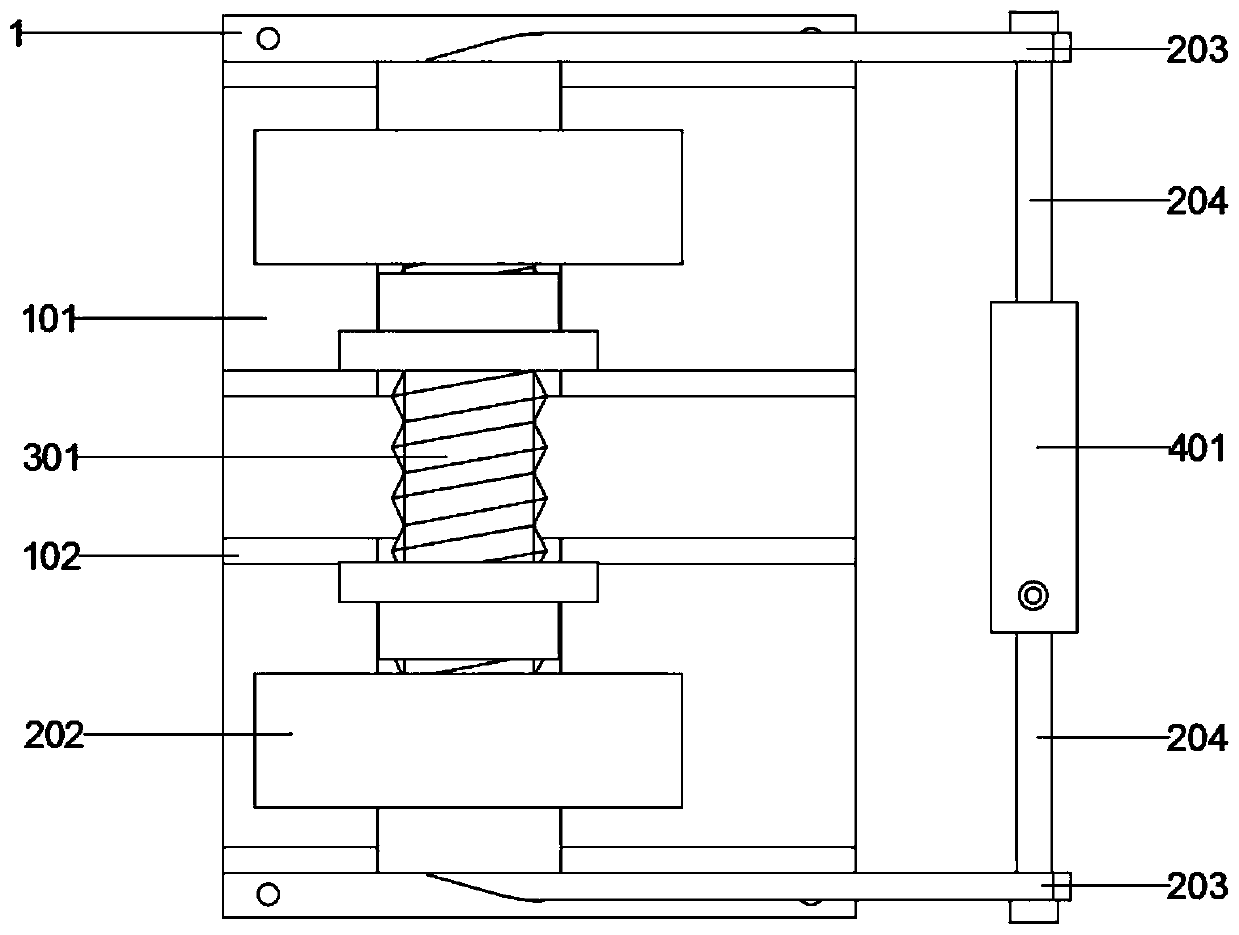

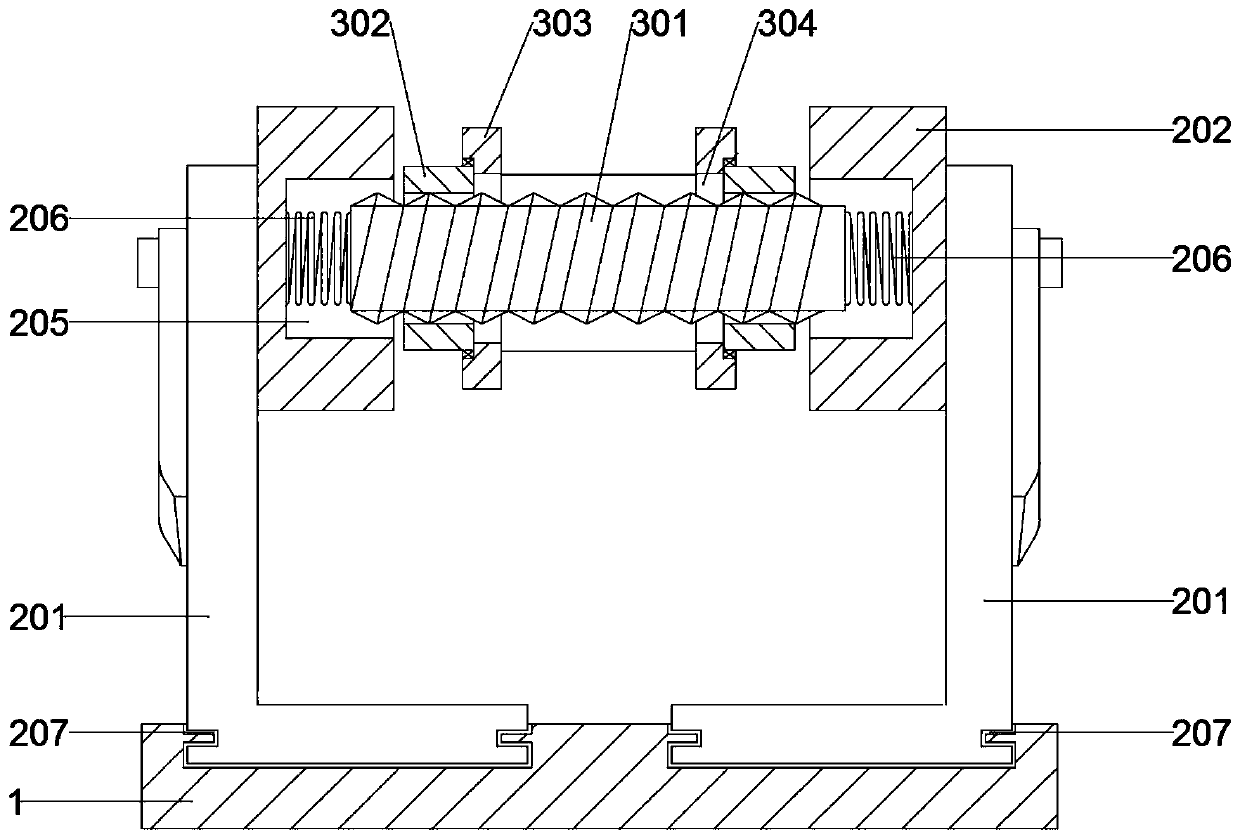

[0038] refer to Figure 1 to Figure 5 , a double-sided tape that is convenient for automatic cutting in this embodiment includes a mounting base 1; a support mechanism 2 is provided at the upper end of the mounting base 1, and specifically, sliding grooves 101 are provided on the left and right sides of the upper end of the mounting base 1, and the sliding groove 101 side Limiting bar 102 is arranged on the side, L-shaped support plate 201 cooperates with sliding groove 101 , and L-shaped support plate 201 is provided with limiting groove 207 matched with limiting bar 102 . Mounting holes 5 are provided at the four corners and the middle of the mounting seat 1 . A clamping mechanism 3 is arranged inside the supporting mechanism 2 , and a cutting mechanism 4 is arranged on the front side of the supporting mechanism 2 , and the cutting mechanism 4 is located directly in front of the clamping mechanism 3 .

[0039] Specifically, refer to Figure 1 to Figure 3 The support mechan...

Embodiment 2

[0044] Such as Figure 1 to Figure 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as Image 6 As shown, adhesive strips 6 are adhered to the left and right sides of the lower end of the mounting base 1 . Its function is to use the adhesive tape 6 to fix the mounting base 1 in a proper position, which is convenient for fixing the support frame and convenient for users to use.

[0045] The present invention also discloses a processing technology for double-sided adhesive tape that is convenient for automatic cutting, using the above-mentioned double-sided adhesive tape that is convenient for automatic cutting, and is characterized in that the specific steps are as follows:

[0046] S1. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com