Automatic sorting machine for bearing retainer workpiece concave and convex surfaces

A bearing retainer and automatic sorting technology, which is applied in sorting and other directions, can solve the problems of unmatched production line equipment, difficult production efficiency, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

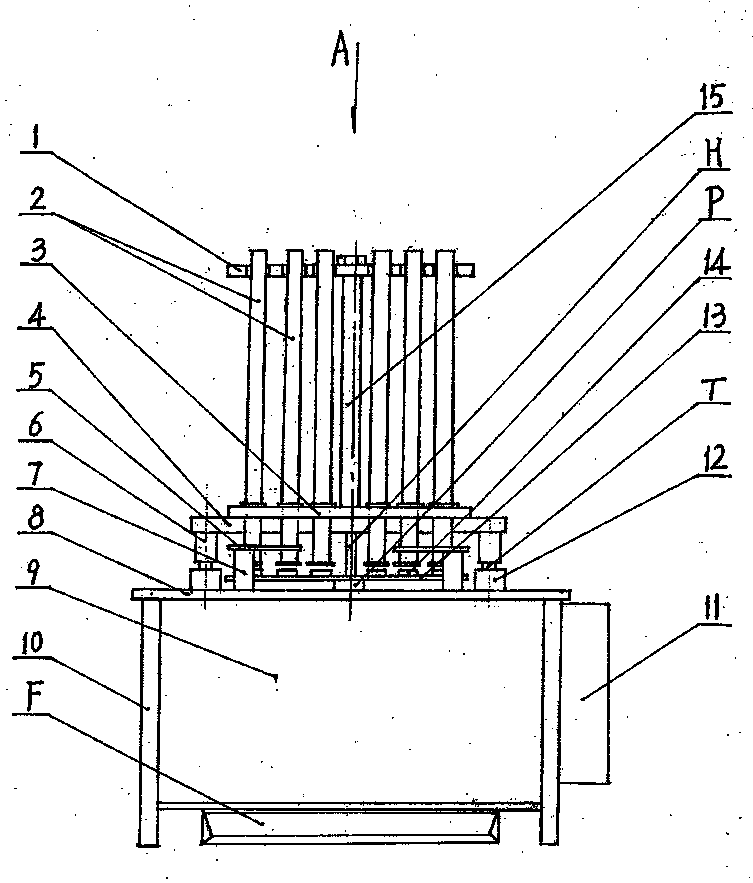

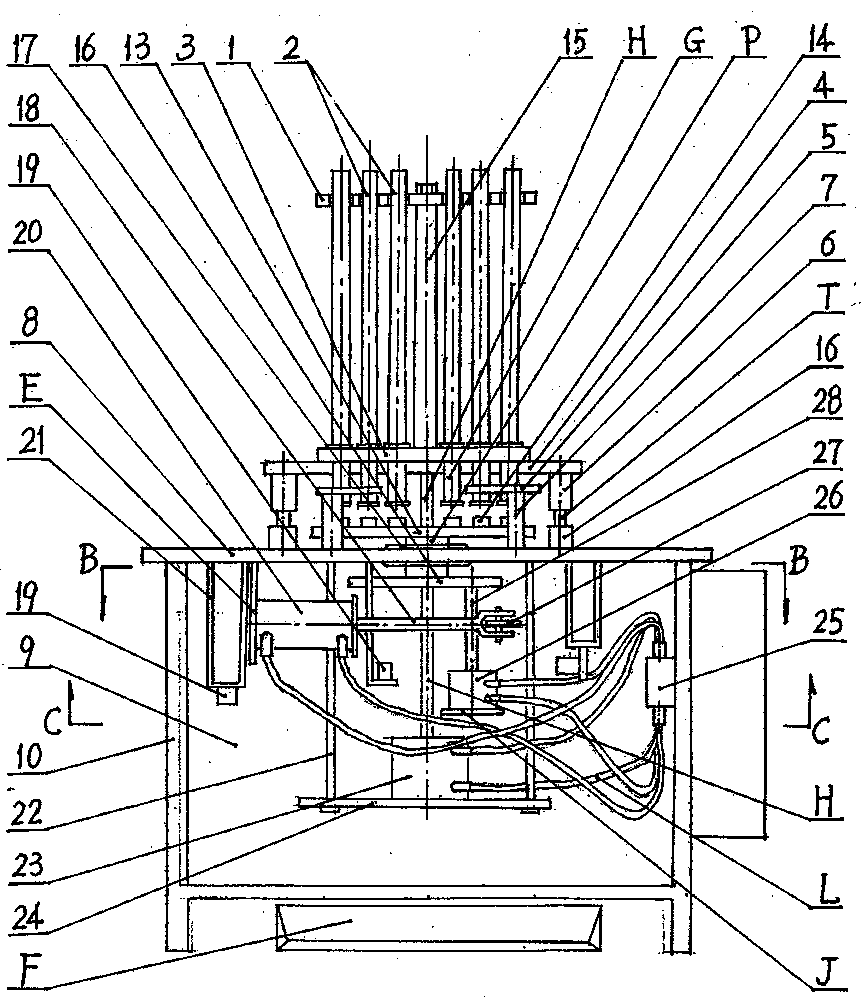

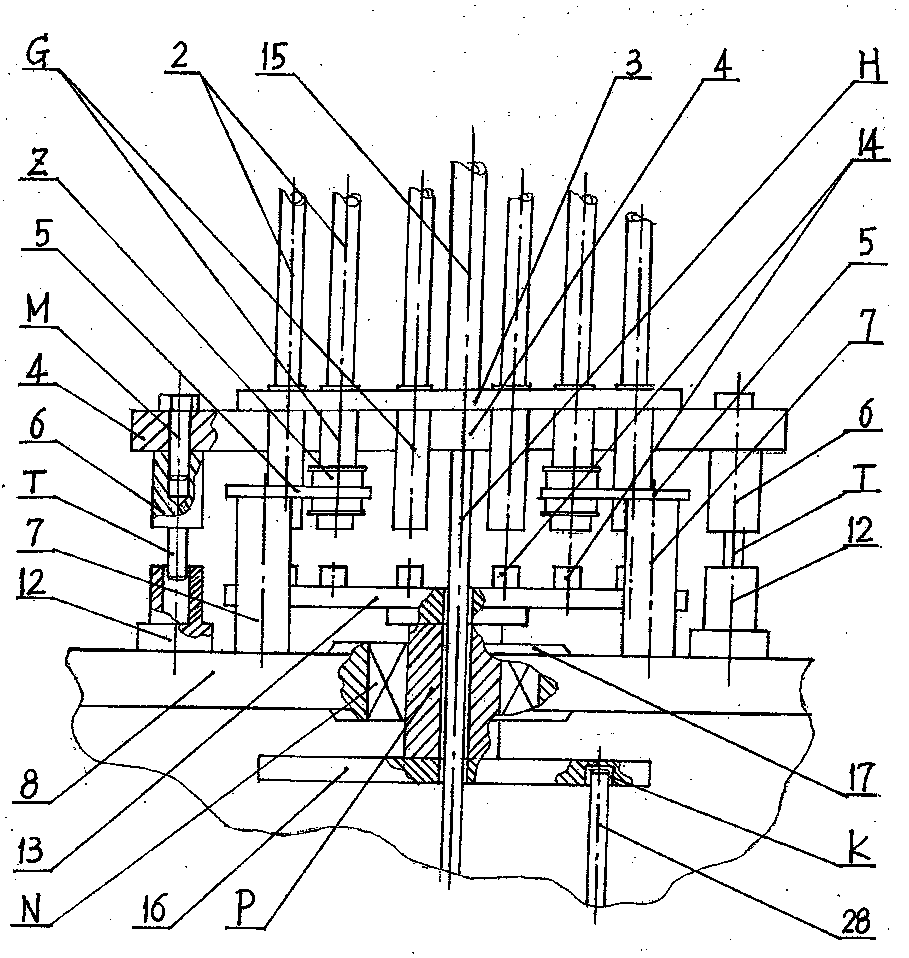

[0016] refer to figure 1 , figure 2 , image 3 A number of sorting rods 2 are correspondingly inserted into the positioning and sorting sleeve G on the positioning plate 3. The positioning plate 3 is erected on the horizontal positioning beam 4. The positioning beam 4 is a long straight metal plate with The center column 15 that vertically erects is installed, and the two ends are erected on the positioning beam pillar 6, and are movably assembled with the positioning bearing 12 fixed on the base plate 8. Several through holes are evenly opened on the circumferential plane of the positioning plate 3, and the positioning sorting sleeve G is embedded to cooperate with the sorting rod 2. The top of the sorting rod 2 is embedded in the clamping rod groove U provided on the peripheral surface of the top plate 1, and the top of the center post 15 in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com