Patents

Literature

37results about "Diaphragm materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

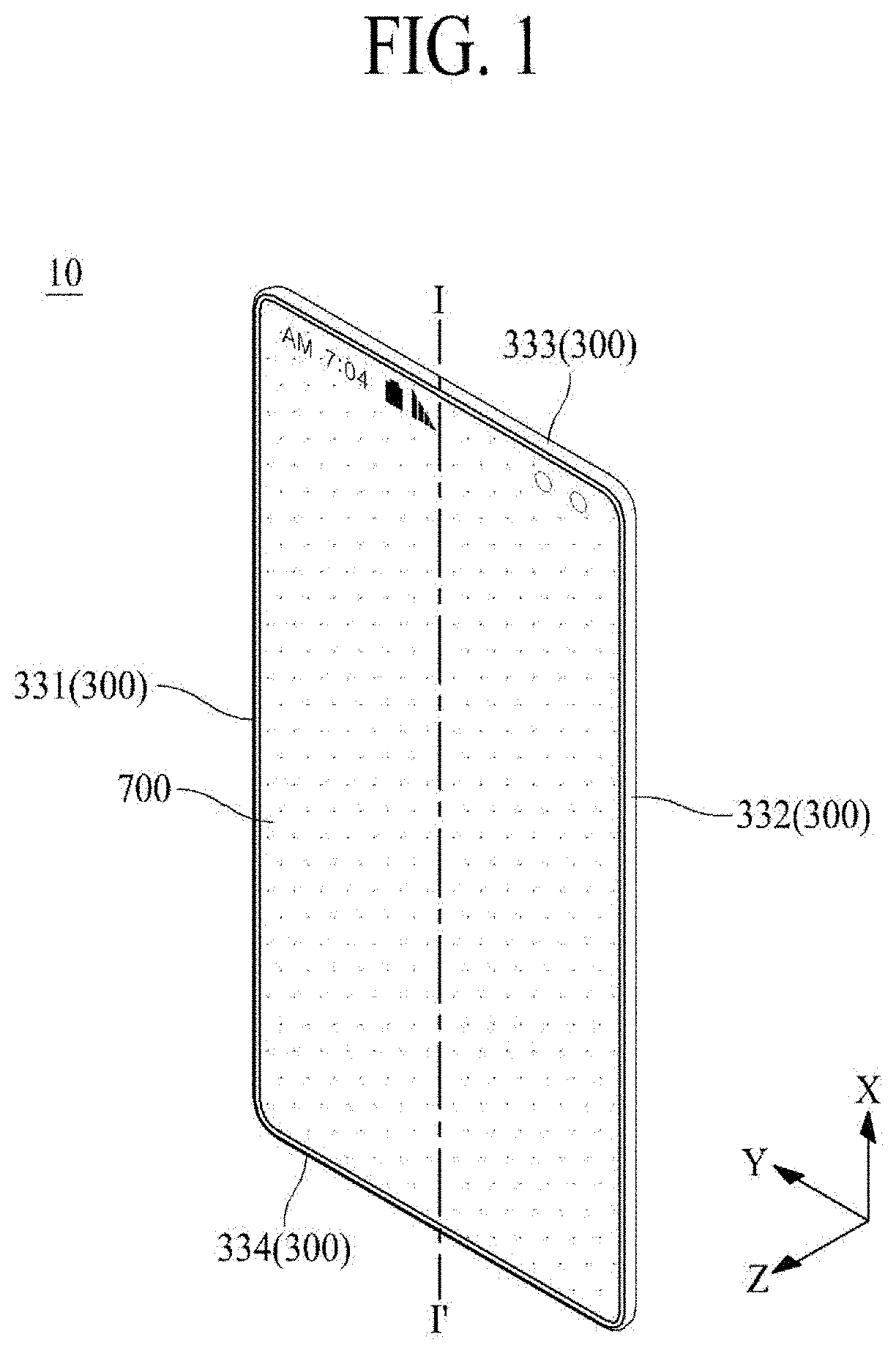

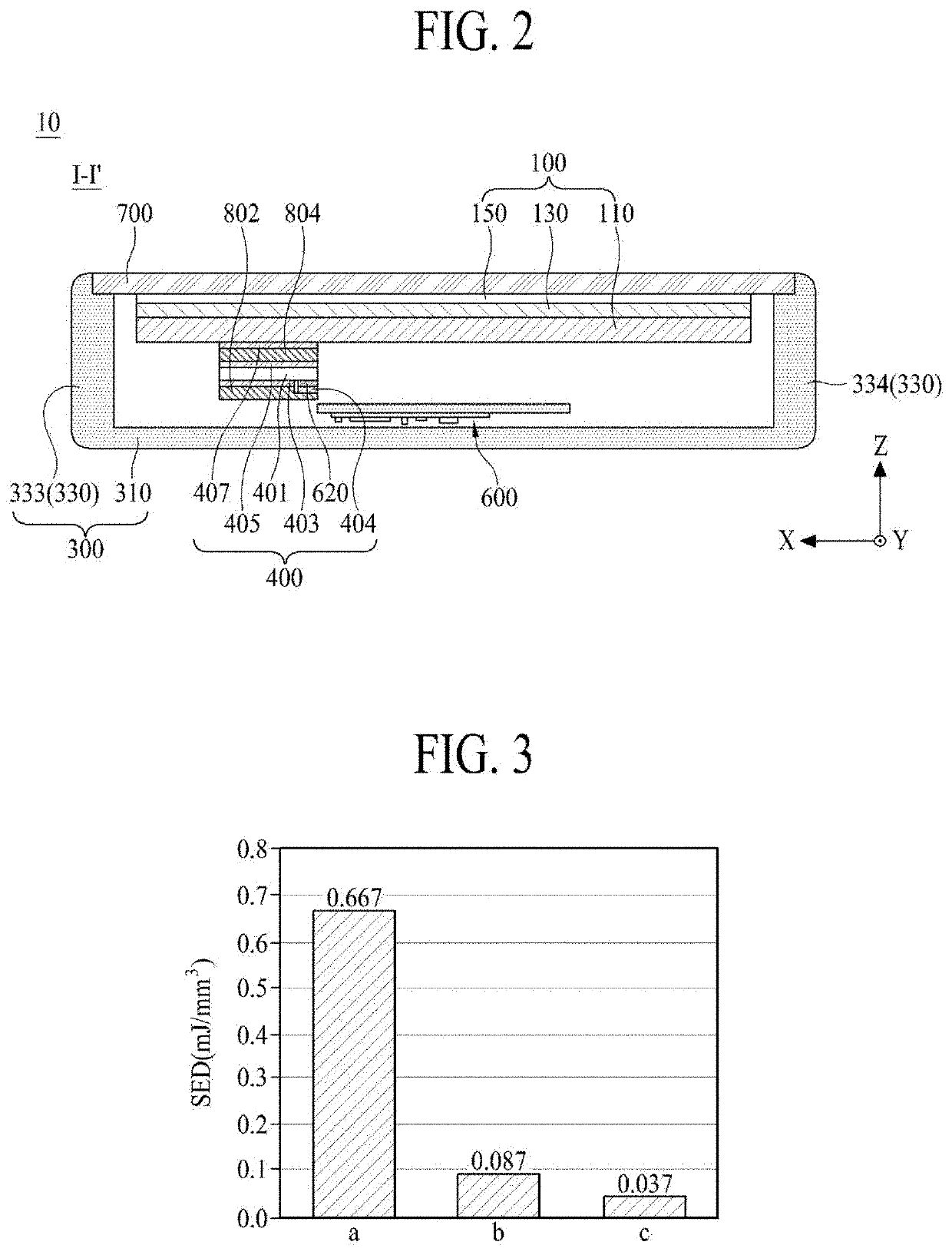

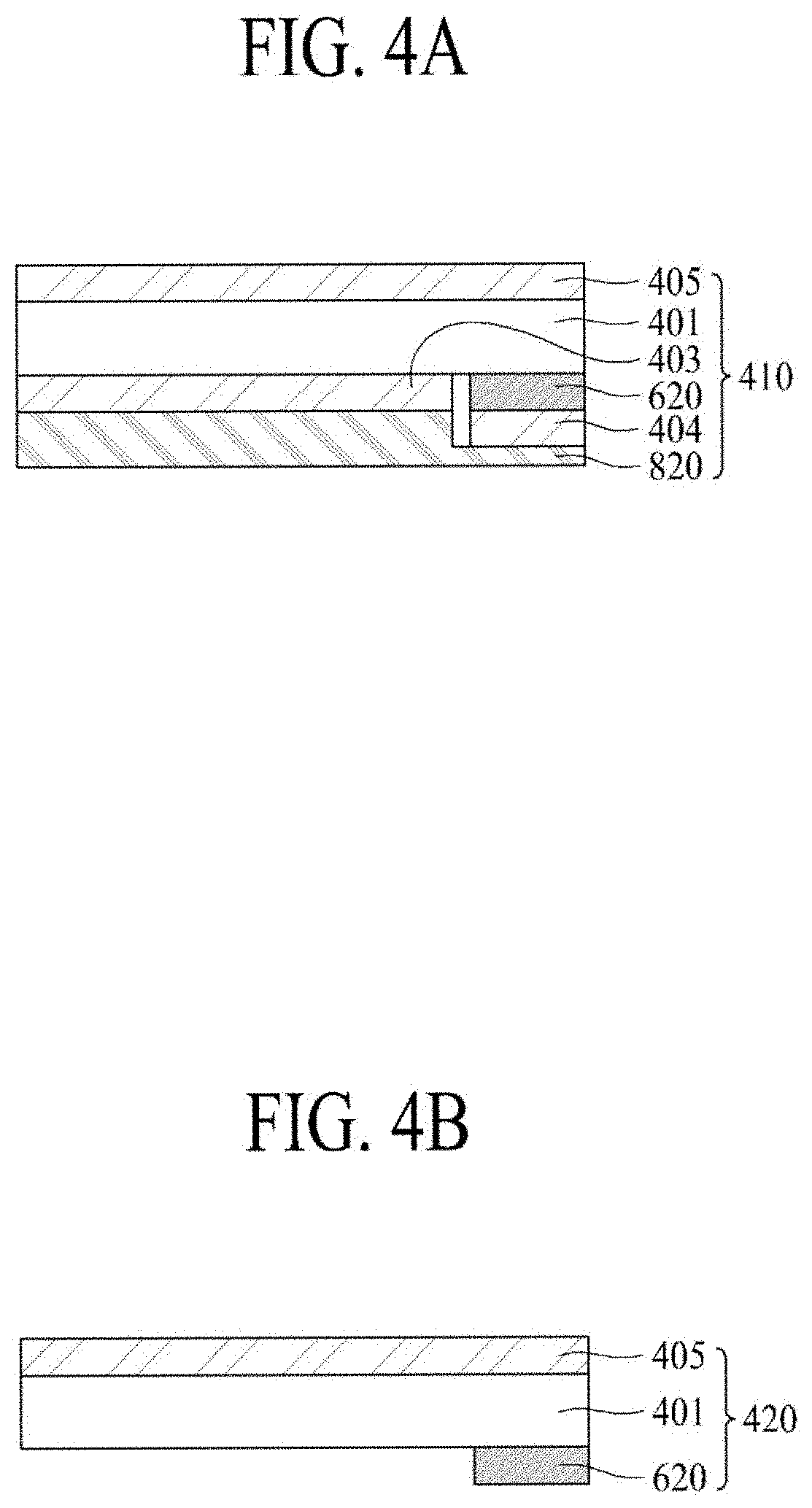

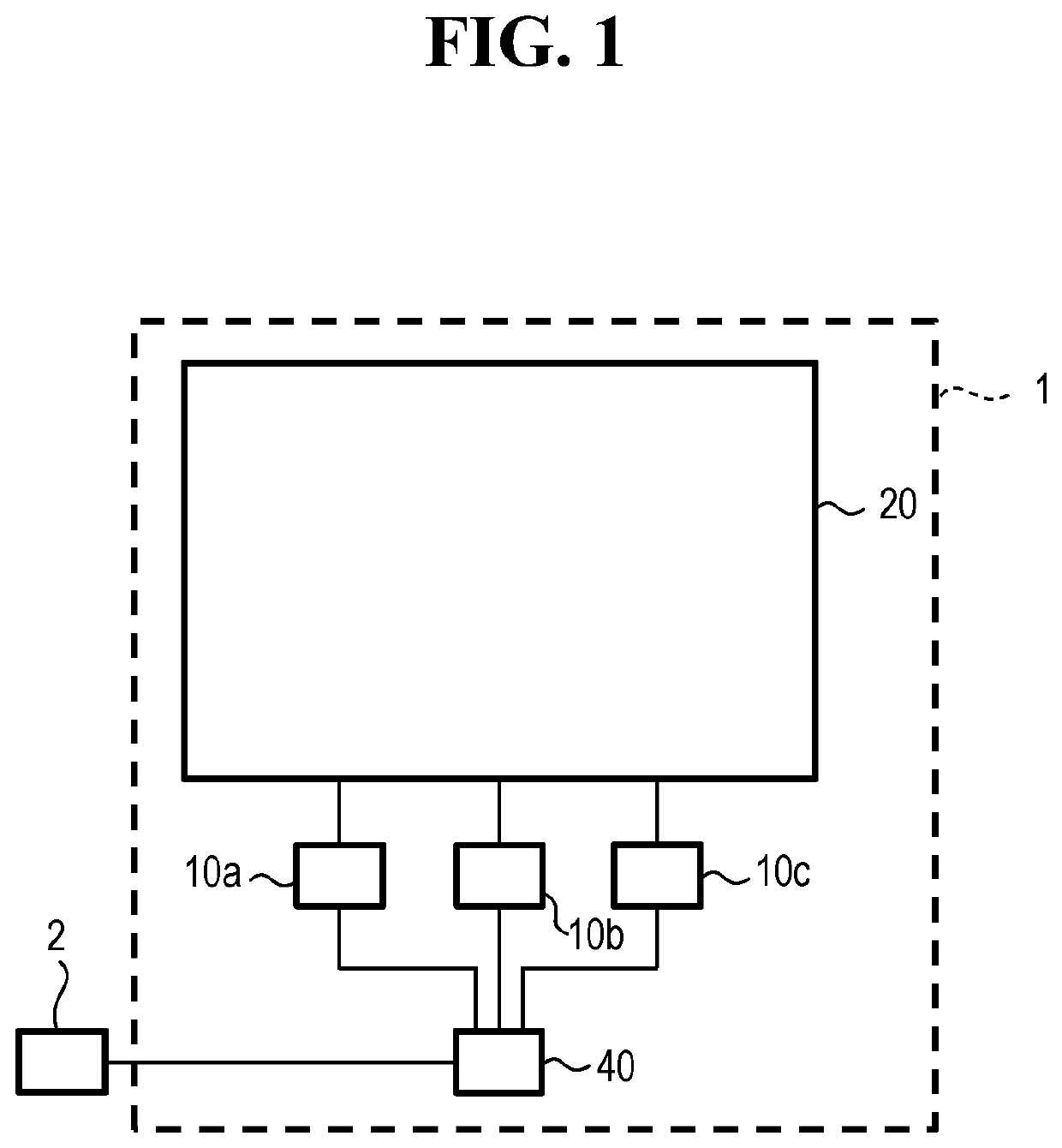

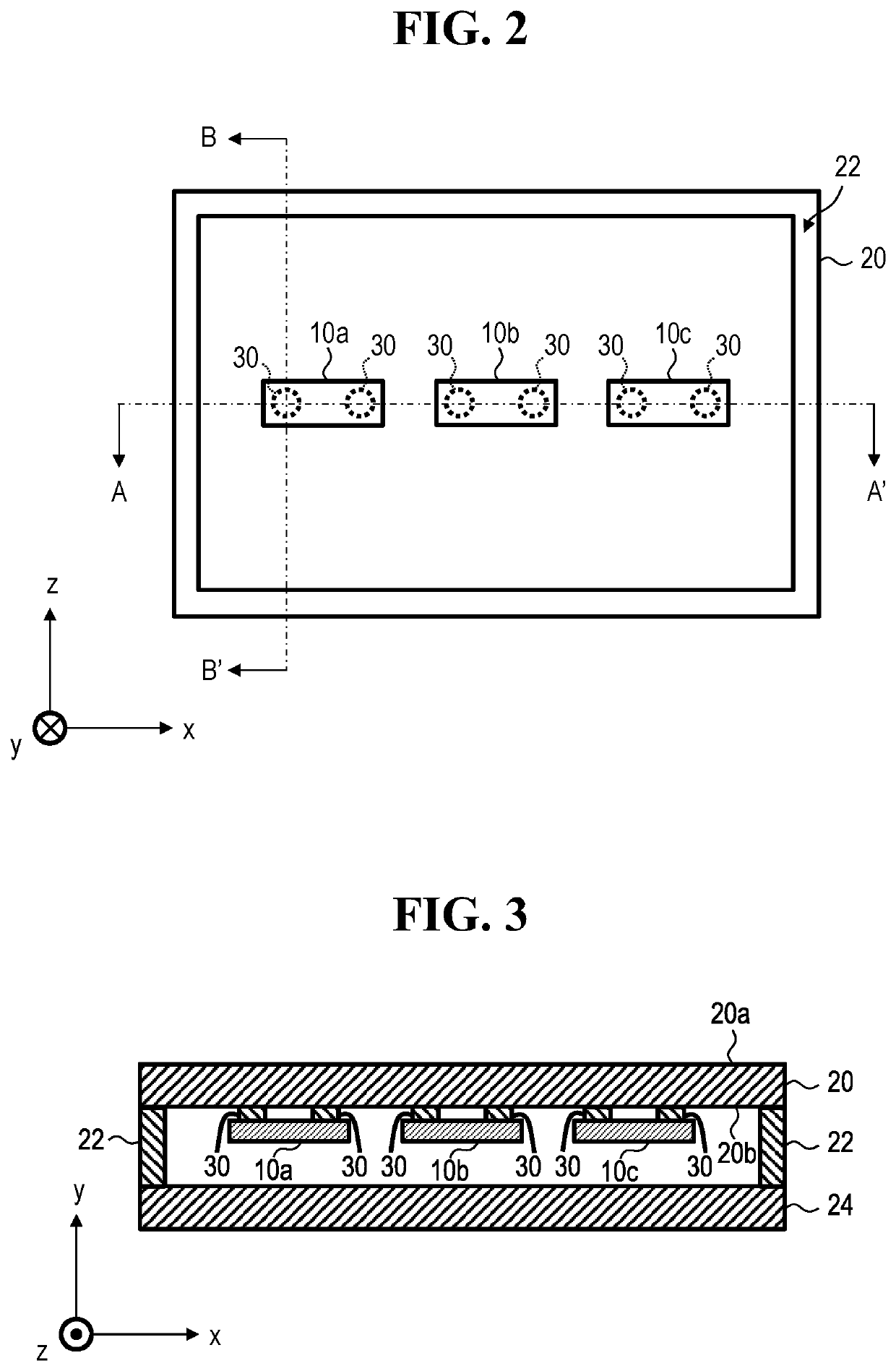

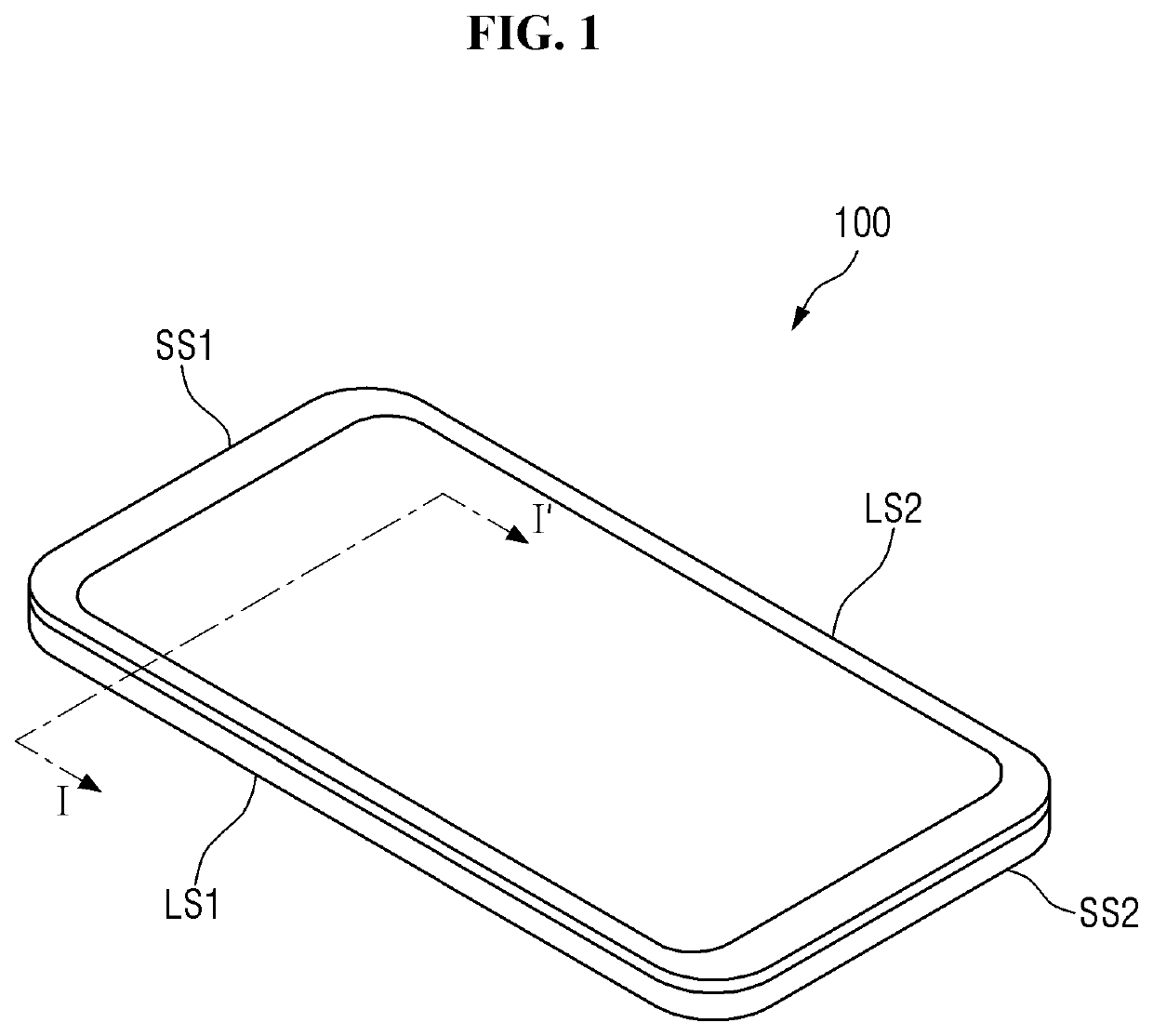

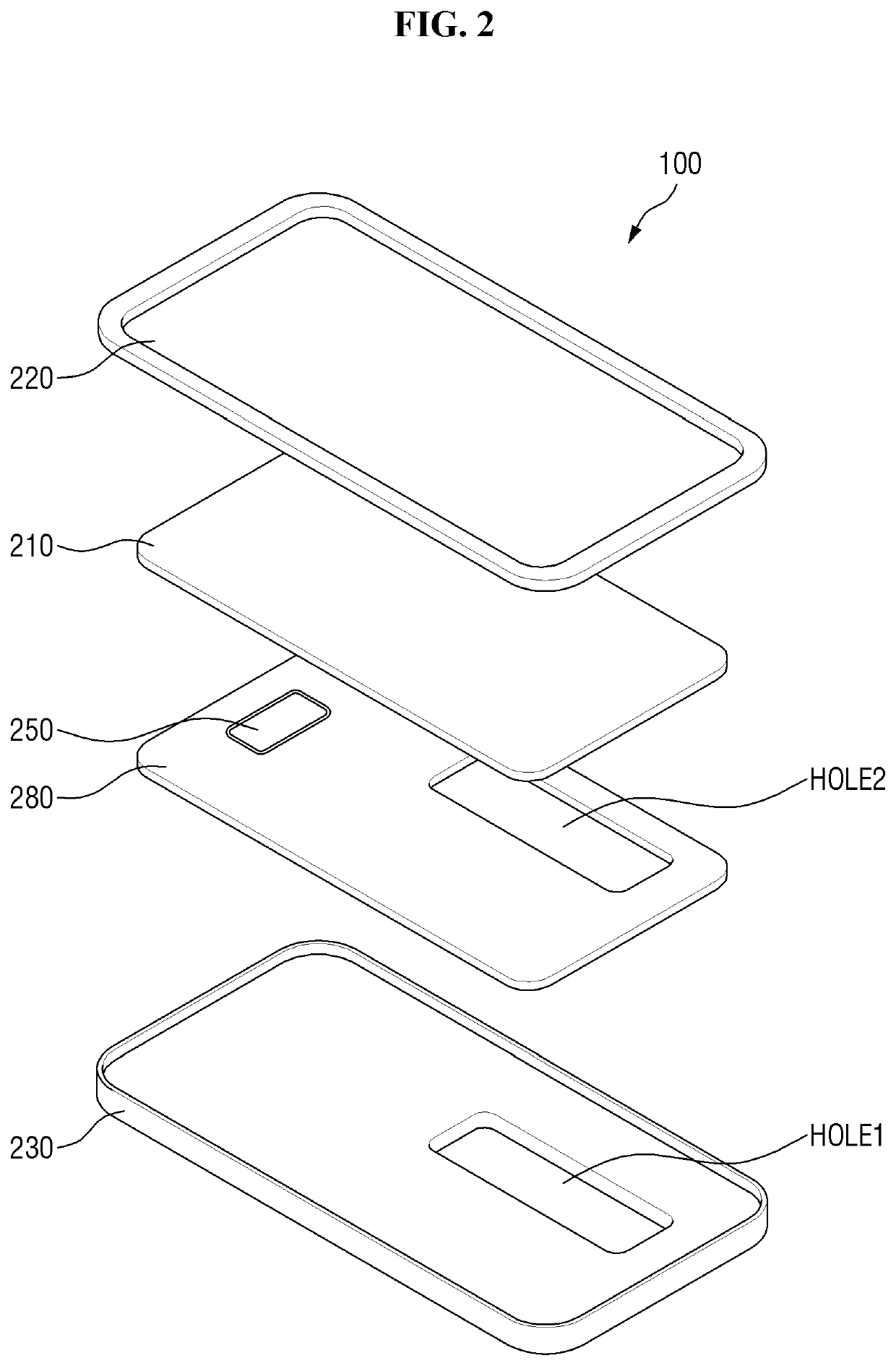

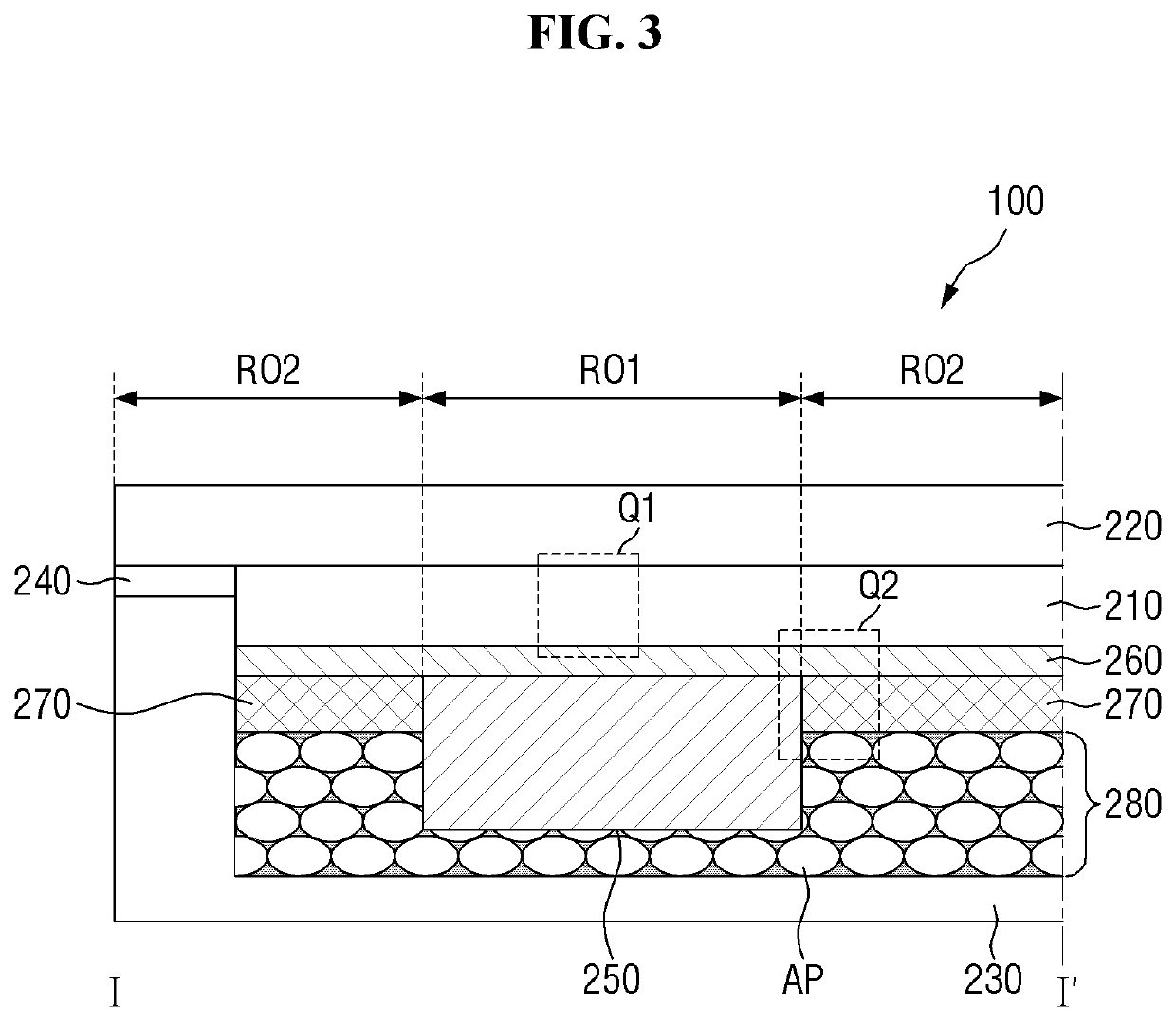

Display apparatus

ActiveUS20200204924A1Increased durabilityIncrease impactTelevision system detailsLoudspeaker transducer fixingSound generationMedicine

A display apparatus includes a display module including a display panel configured to display an image and a sound generating module on a rear surface of the display panel, the sound generating module includes a vibration generating device, a circuit board on a lower surface of the vibration generating device, a first adhesive member between the circuit board and the vibration generating device, and a second adhesive member between the vibration generating device and the display panel, an elastic modulus of the second adhesive member differing from an elastic modulus of the first adhesive member.

Owner:LG DISPLAY CO LTD

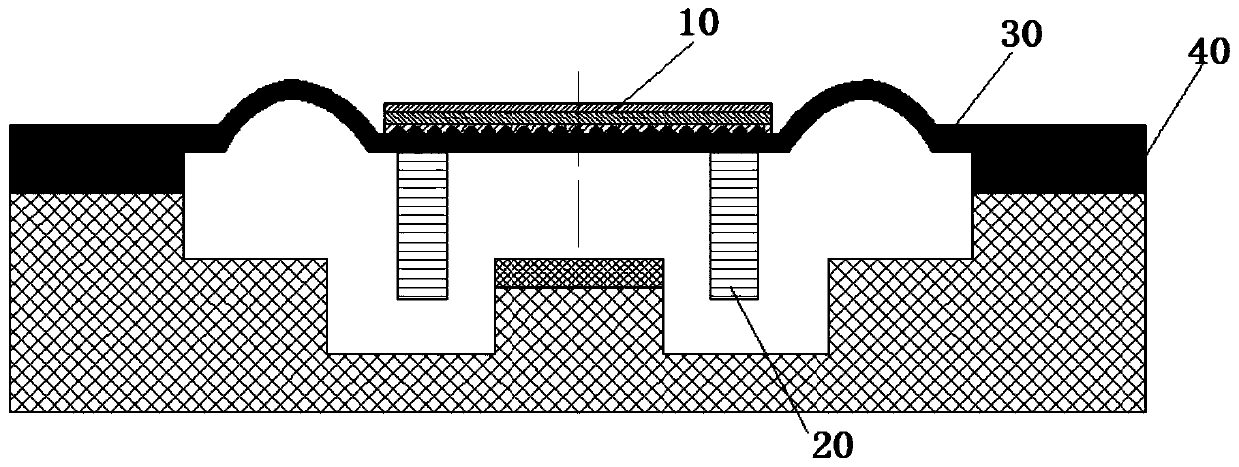

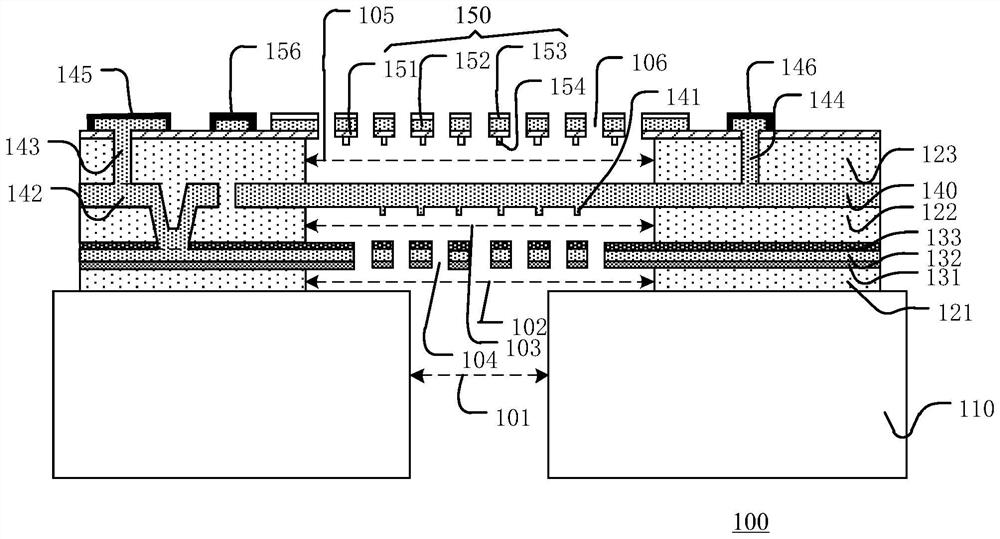

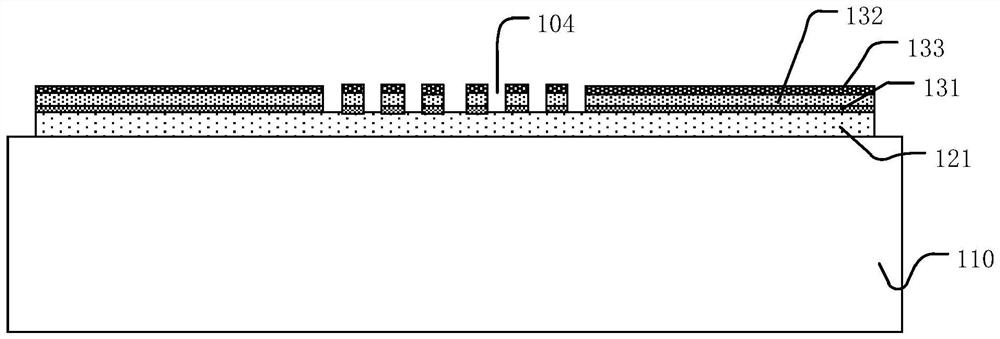

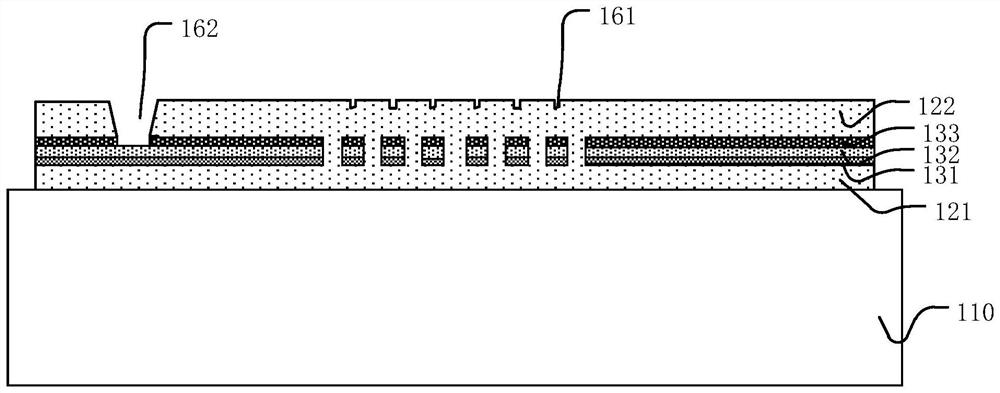

A piezoelectric mems microphone

ActiveCN111405441BSolve technical problems such as sensitivityDiaphragm materialsSemiconductor electrostatic transducersVibrating membranePiezoelectric mems

The present invention relates to the technical field of acoustic-electric conversion, and provides a piezoelectric MEMS microphone, including: a base with a cavity back and a piezoelectric diaphragm, the piezoelectric diaphragm includes a suspension part and a base fixing part connected to the base, The piezoelectric diaphragm also includes a support part connecting the fixed part of the base and the suspension part, and the suspension part is suspended above the back cavity through the support part. The piezoelectric MEMS microphone also includes a limit structure, and the suspension part includes a position-limiting structure. The middle film overlaps with the projection range along the vibration direction, and the limiting structure and the middle film form a fixed structure of the piezoelectric diaphragm. After the piezoelectric diaphragm is released from the oxide layer, under the action of the residual stress in the piezoelectric diaphragm, the middle film deforms upwards or downwards and connects with the corresponding limiting structure to completely release the stress and gradient stress. The application of the technical solution solves the technical problem in the prior art that the diaphragm is deformed due to uneven stress distribution in the process of processing, which further affects the consistency of performance such as the sensitivity of the microphone.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

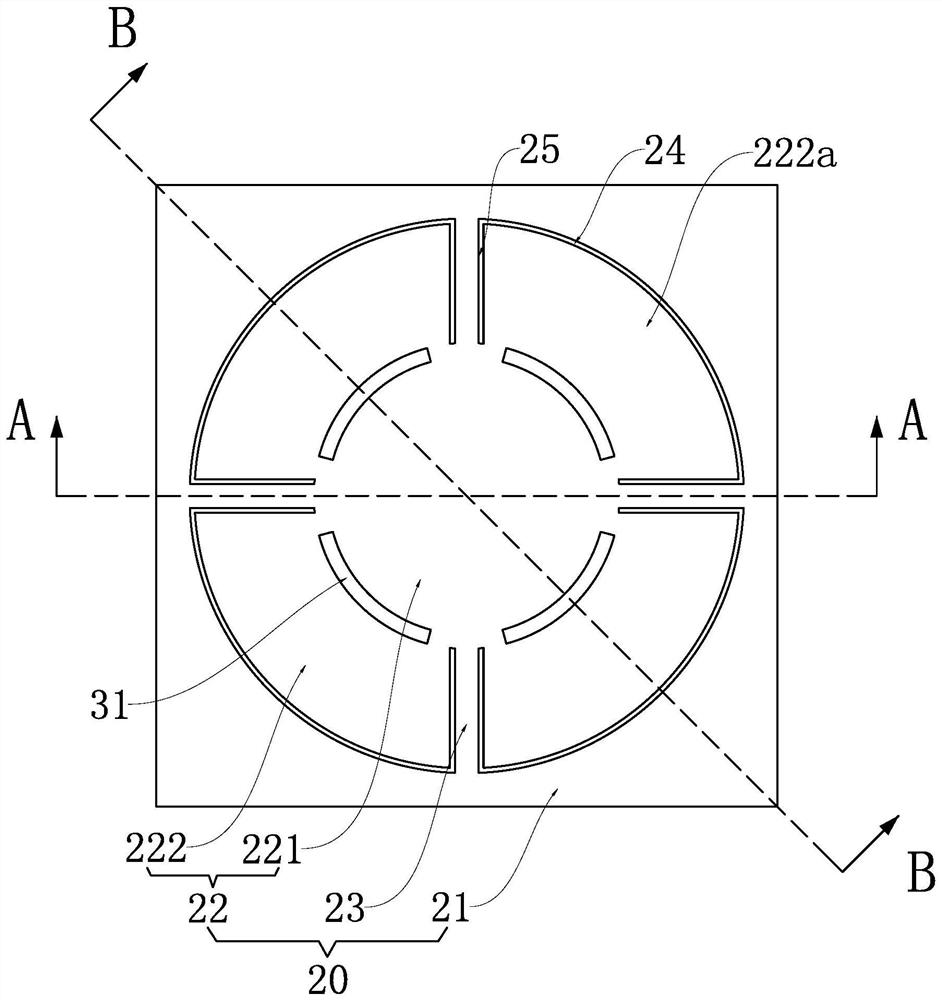

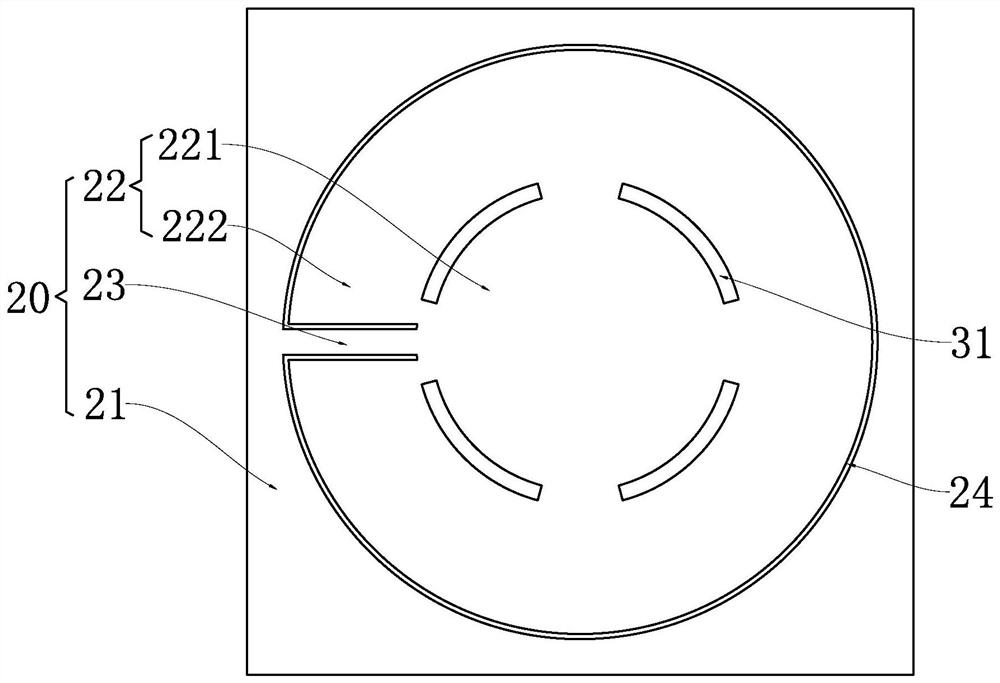

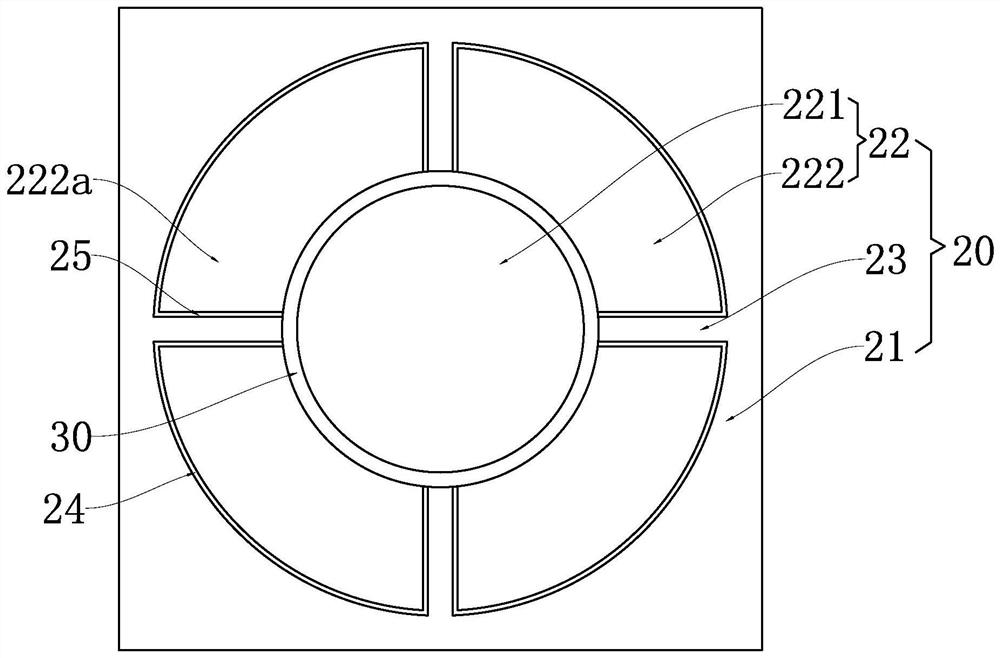

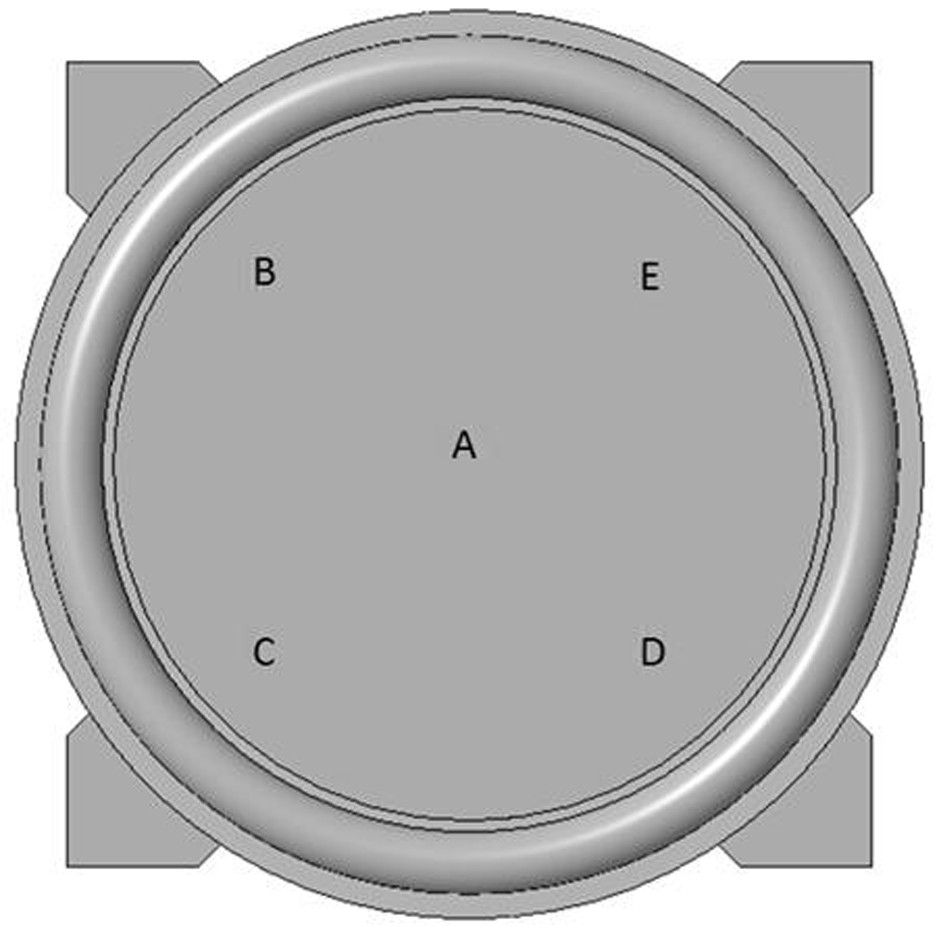

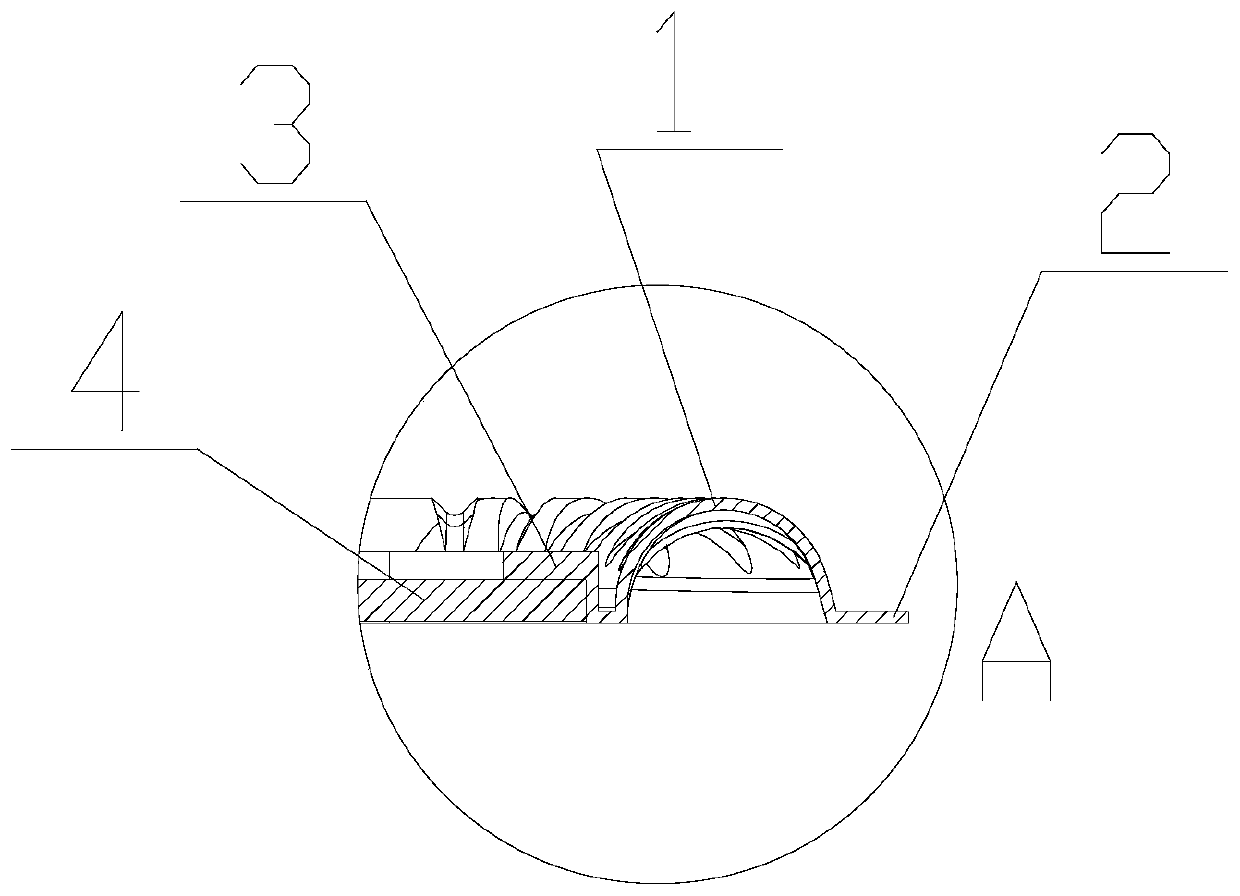

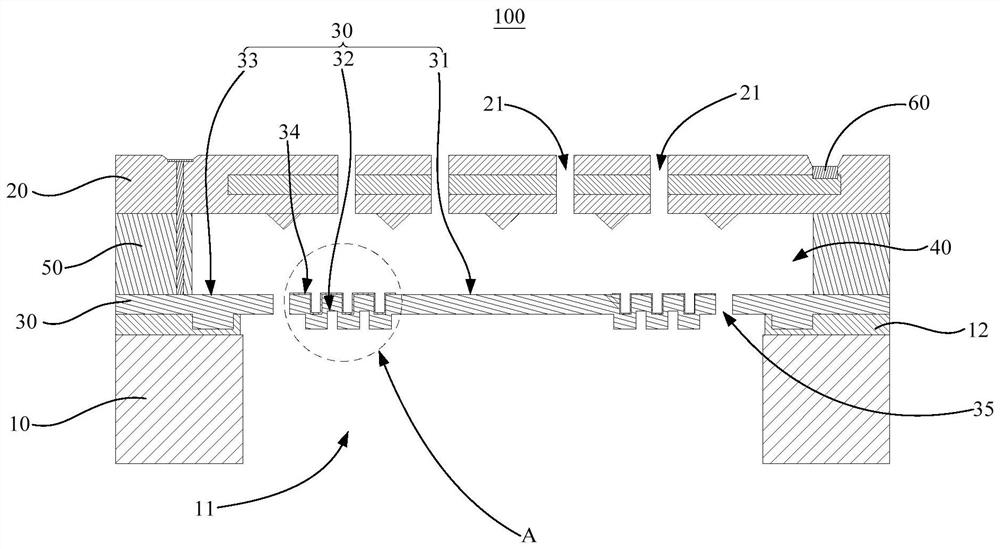

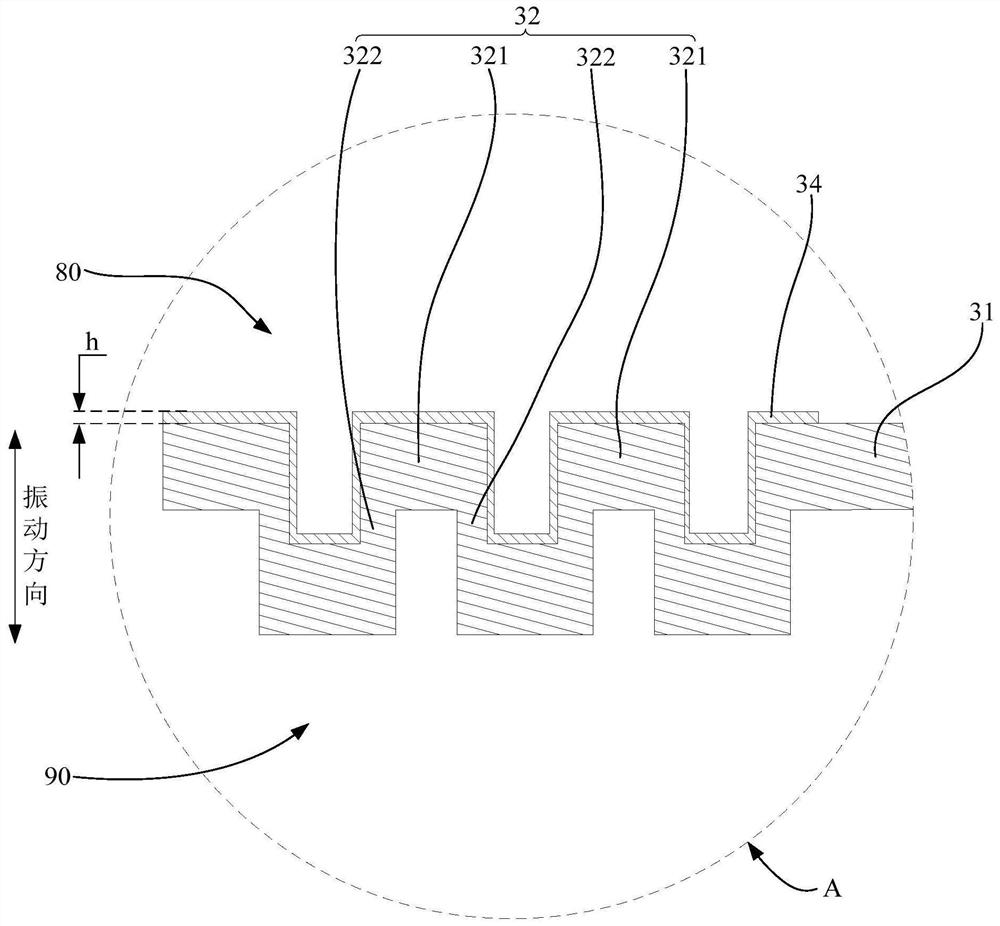

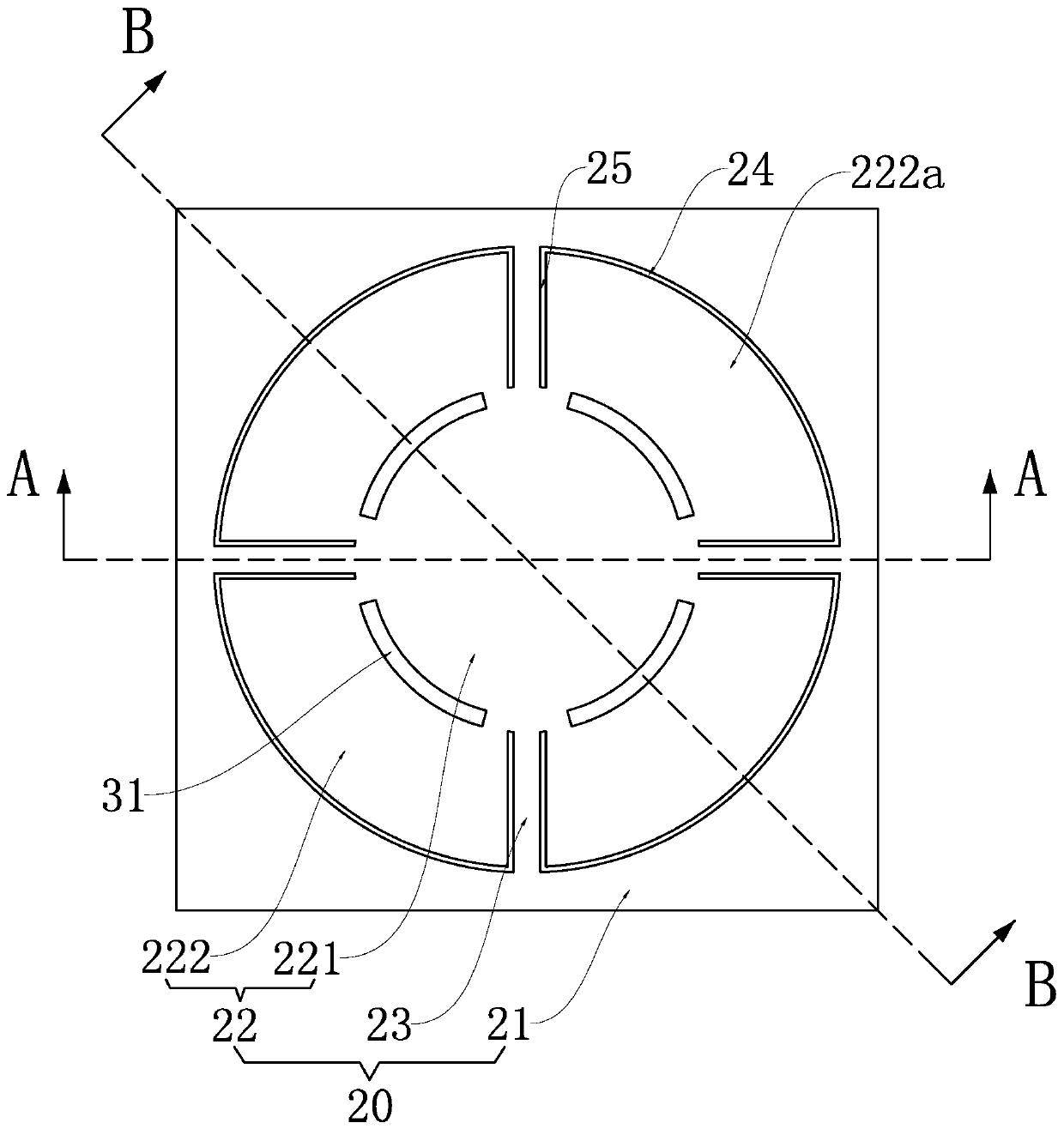

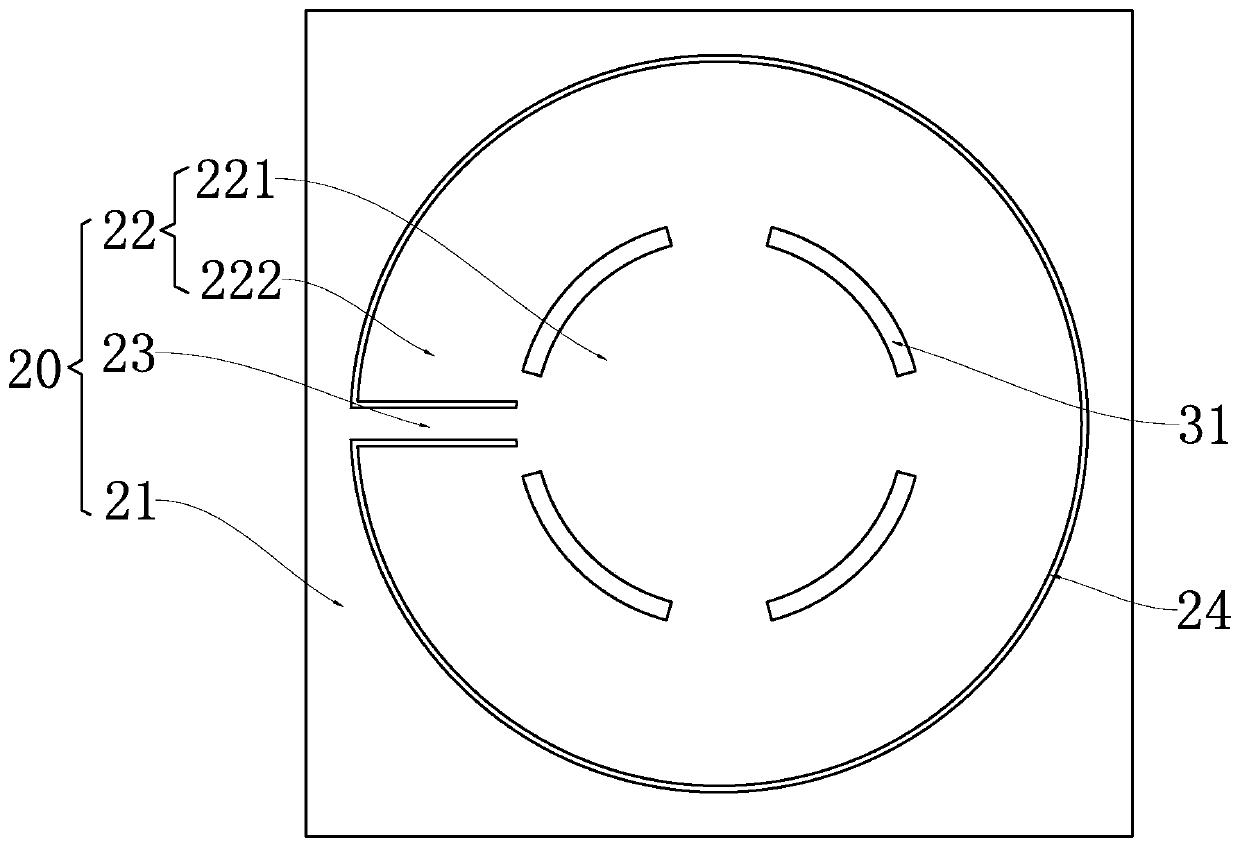

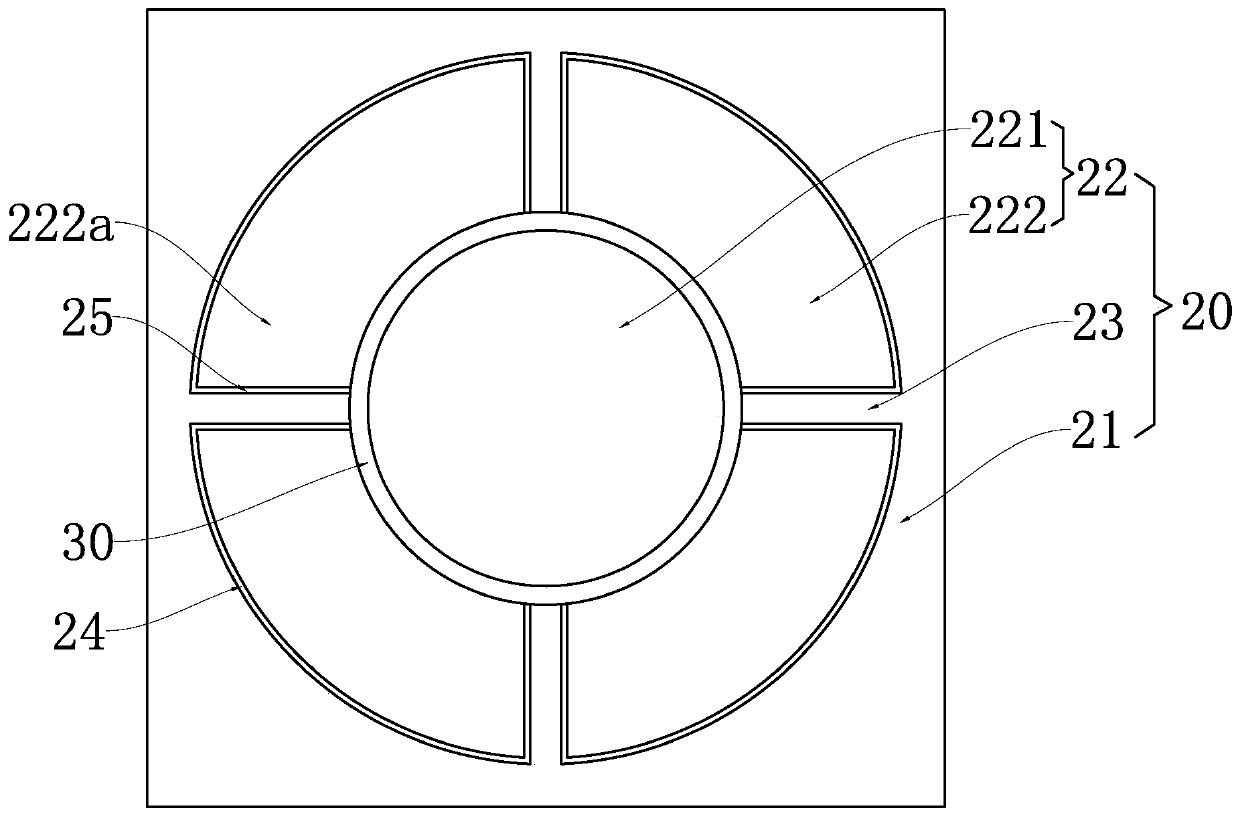

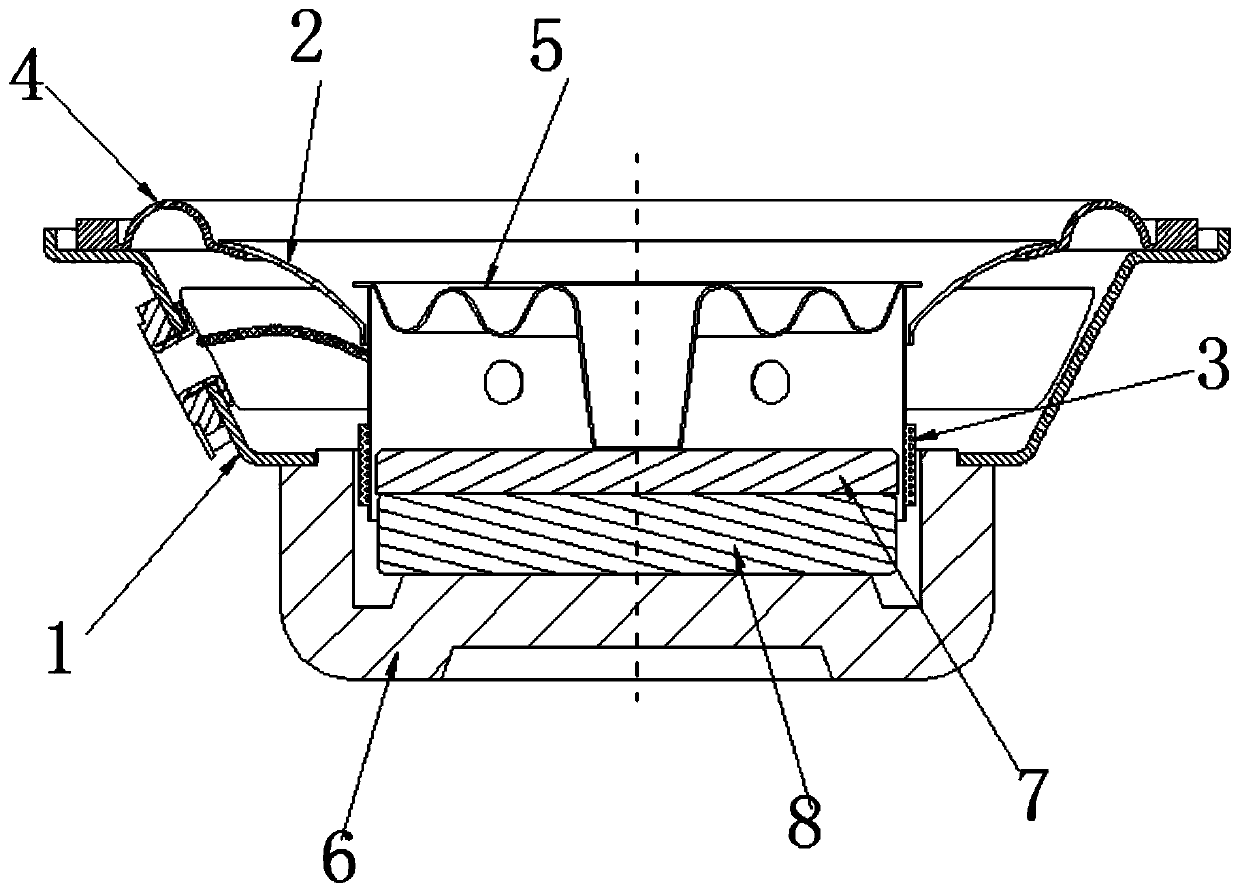

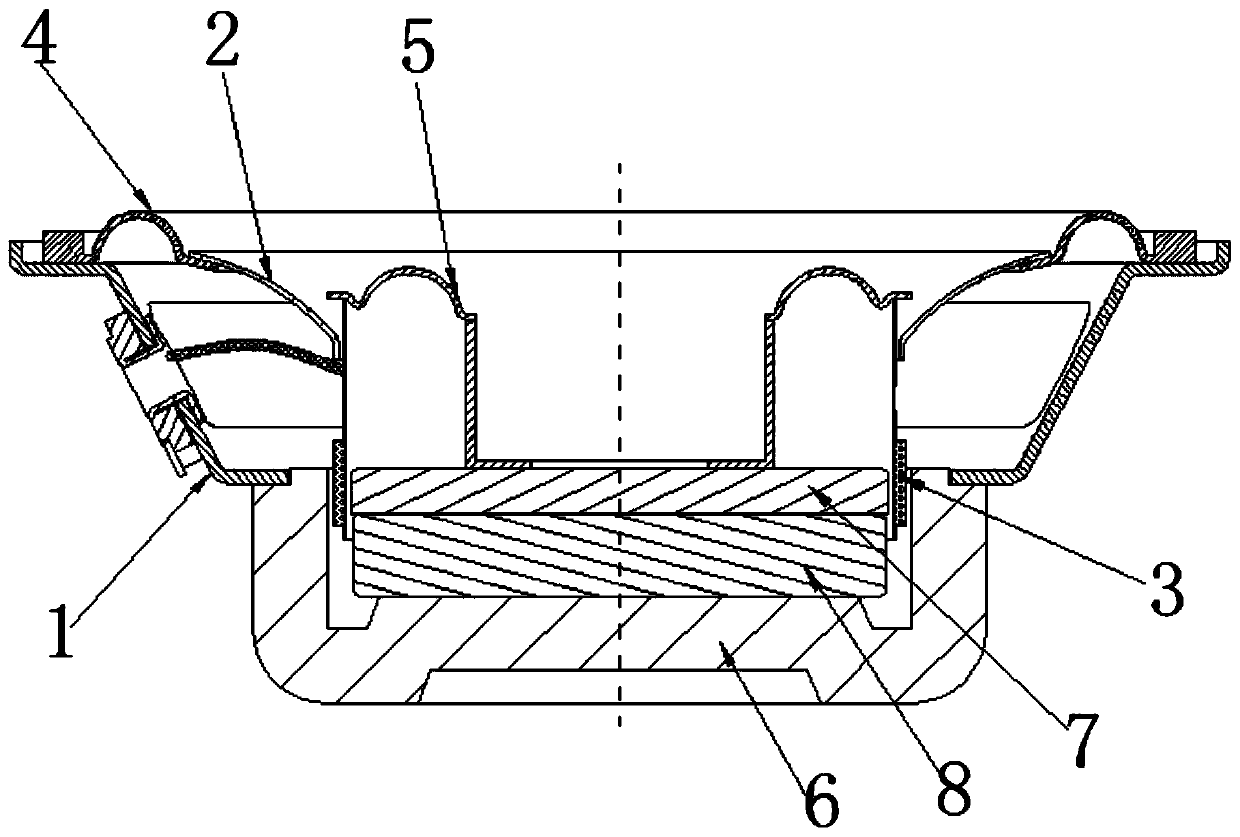

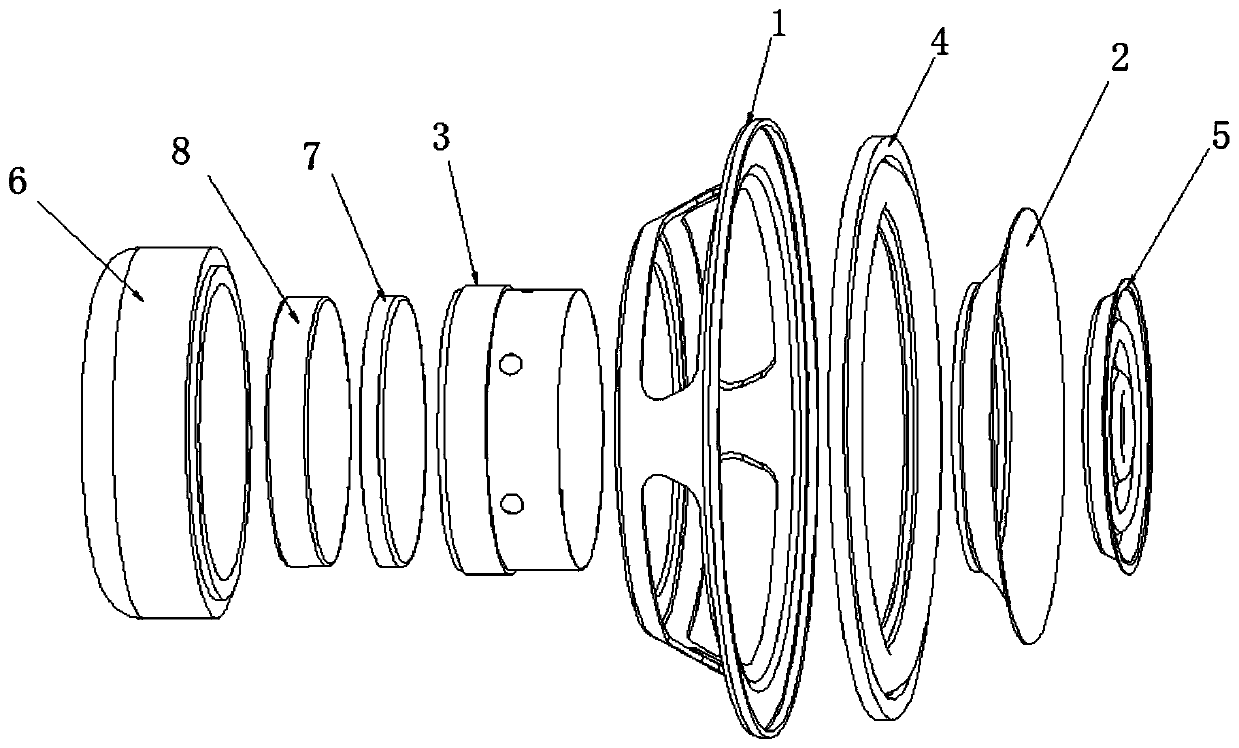

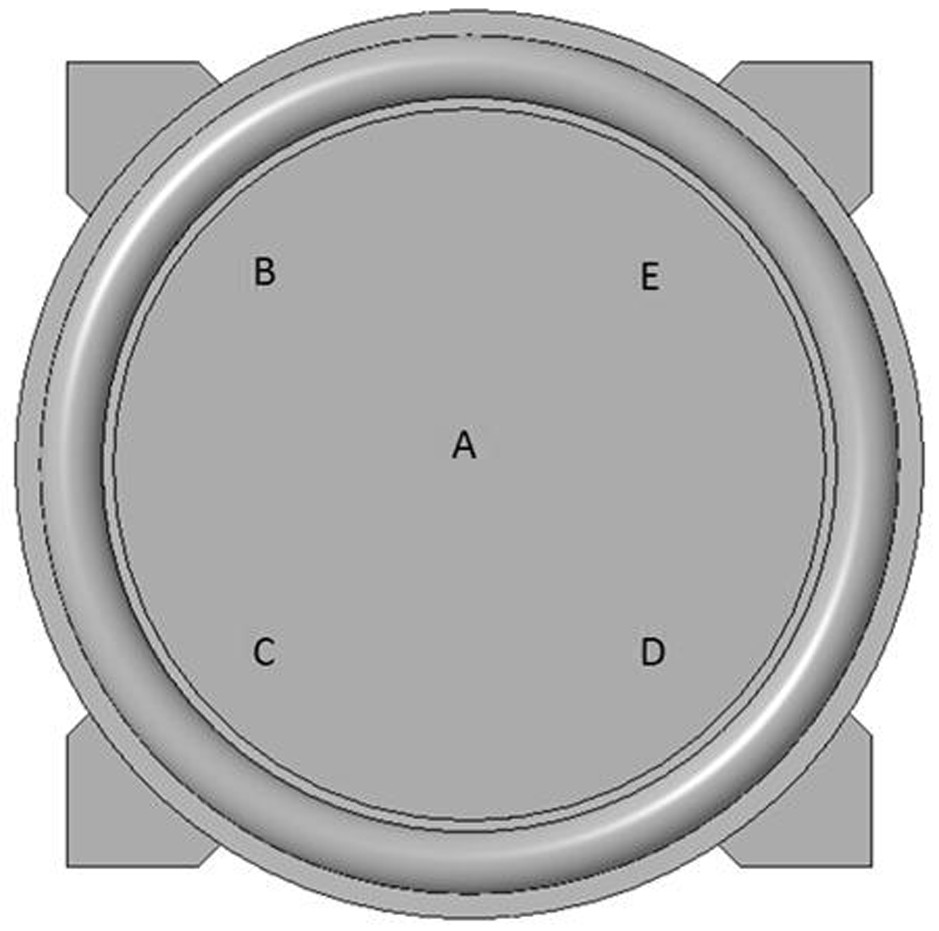

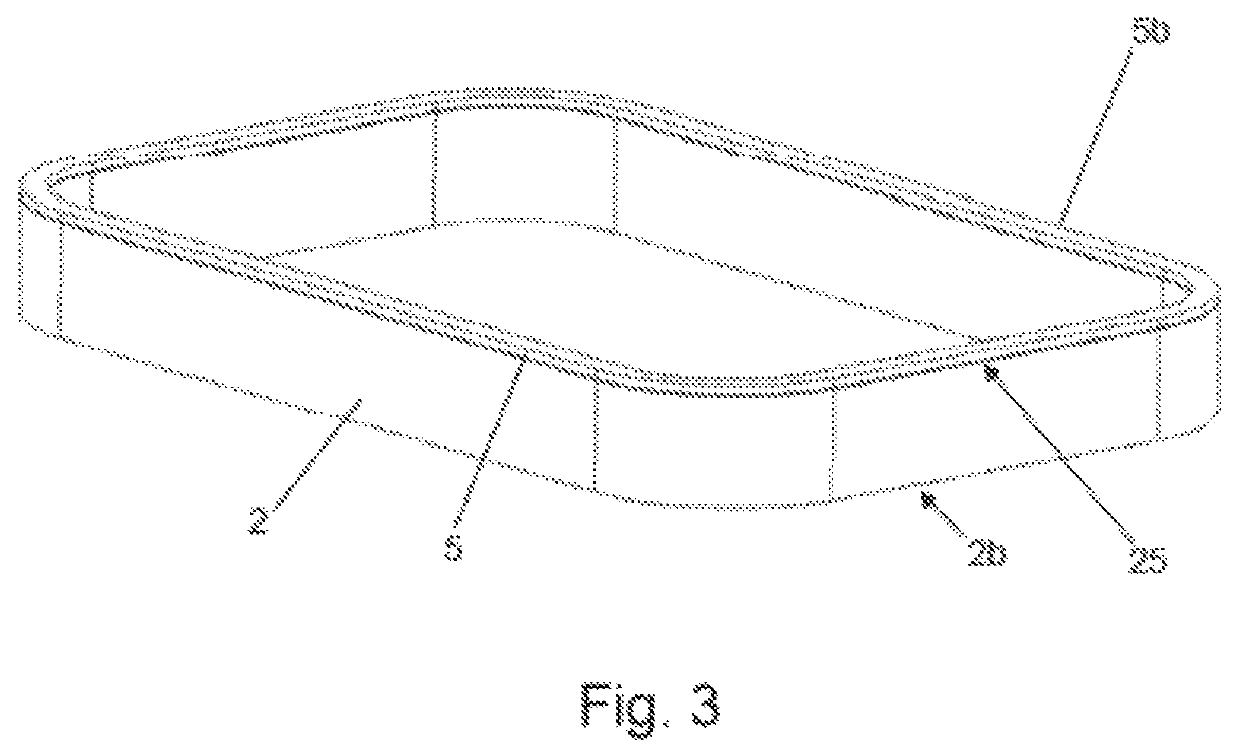

Sounder and electronic product comprising sounder

ActiveCN111901734AImprove polarizationSolve the problem of asymmetric elastic distributionDiaphragm materialsStructural engineeringVoice coil

The invention discloses a sounder and an electronic product comprising the sounder. The sounder comprises a shell; a magnetic circuit system positioned in the shell; wherein the magnetic circuit system comprises a side magnetic part and a central magnetic part; the central magnetic part comprises a support plate located in the middle. The sounder also comprises two central magnets positioned on two sides of the supporting plate. Central magnetic parts are of central hollow structures. The sounder also comprises two groups of vibration assemblies positioned on two sides of the support plate; each group of vibration assembly comprises a vibrating diaphragm and a voice coil; the sounder further comprises a centering structure located on the inner side of the central hollowed-out edge of thecentral magnetic part, the centering structure comprises two annular frameworks which are fixedly connected to the central parts of the two vibrating diaphragms, the adjacent ends of the two annular frameworks are fixedly connected with elastic supporting pieces, and the outer side edges of the elastic supporting pieces are fixedly connected to the central magnetic part of the hollowed-out edge. Polarization generated when double vibrating diaphragms in the bidirectional sounder structure vibrate can be reduced, product distortion is reduced, and product performance and stability are improved.

Owner:GOERTEK INC

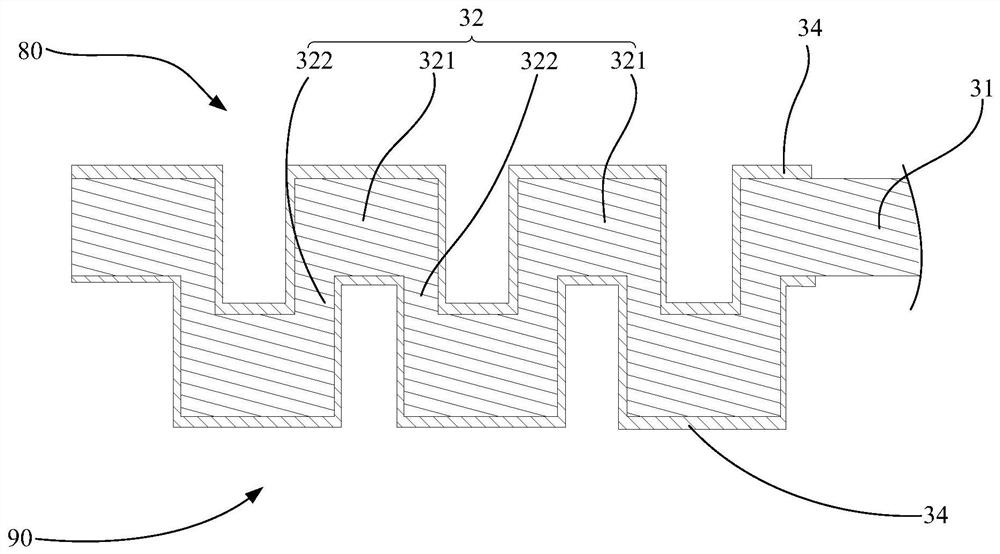

Vibrating diaphragm assembly forming method of sound production device, vibrating diaphragm assembly and sound production single body

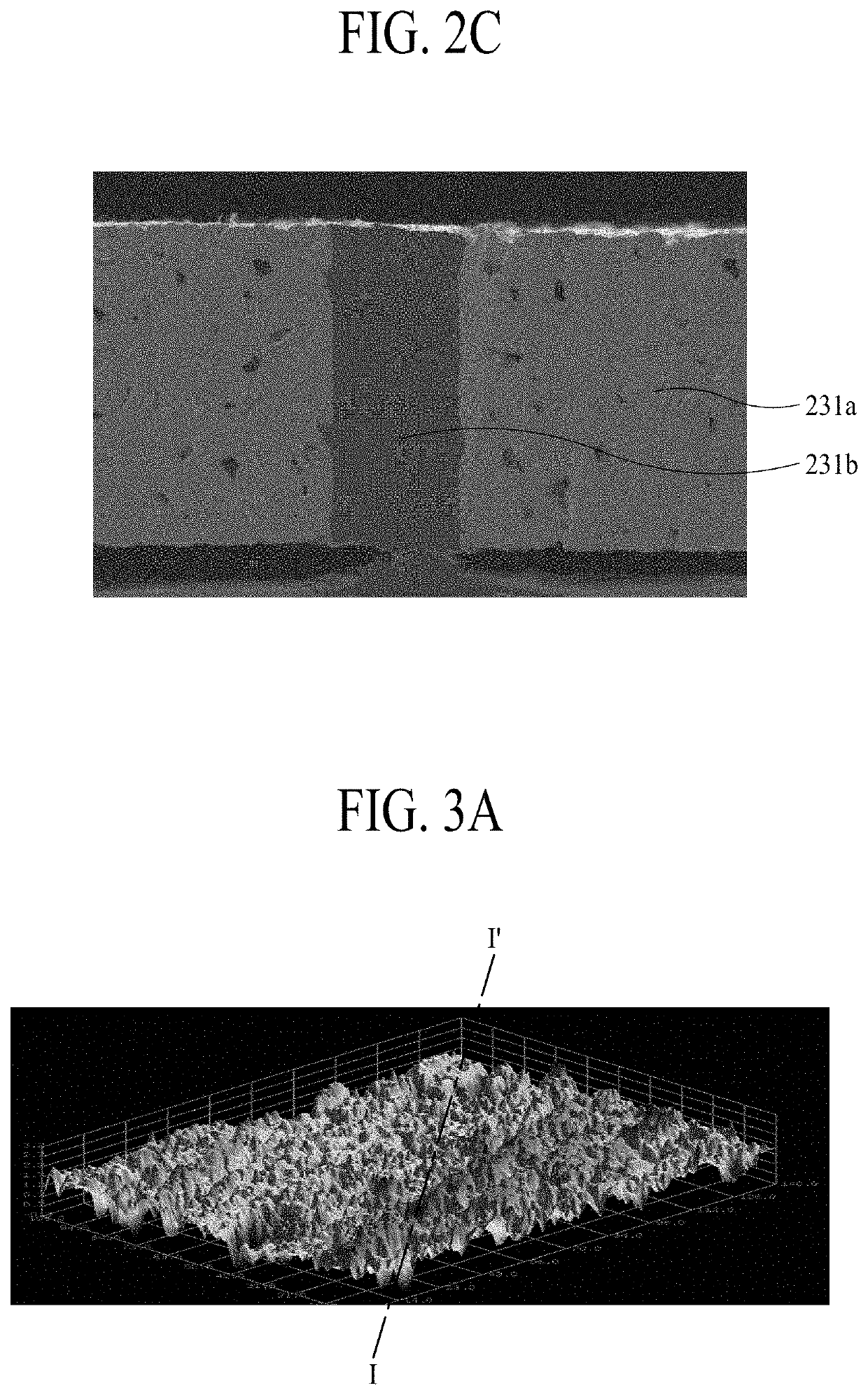

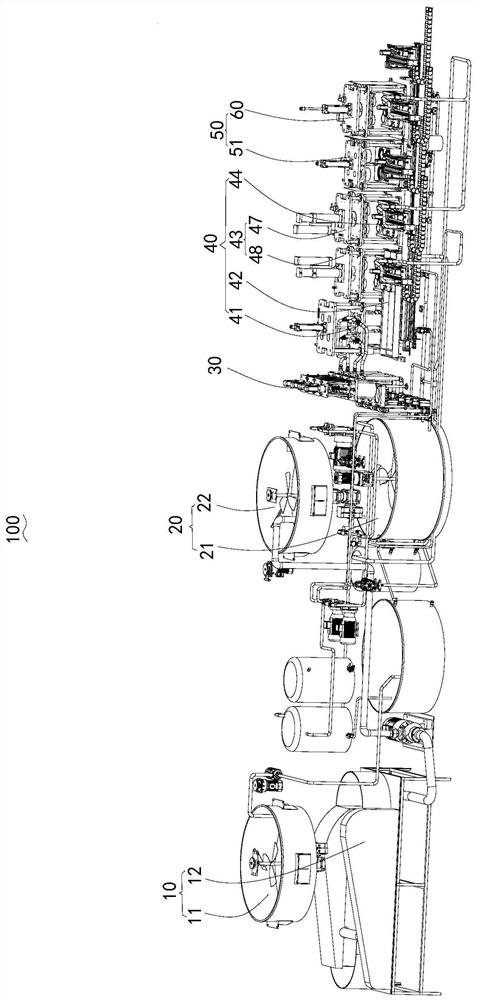

ActiveCN110913320AHigh strengthSmall amount of deformation and shrinkageDiaphragm materialsNon-planar diaphragms/conesMicro nanoNano structuring

The invention provides a vibrating diaphragm assembly forming method of a sound production device, and the vibrating diaphragm assembly comprises a vibrating diaphragm body and an auxiliary assembly.The method comprises the steps: providing a forming die, and an inner cavity of the forming die being provided with an inner cavity surface; providing an auxiliary assembly, wherein the surface of theauxiliary assembly is provided with a micro-nano structure; the auxiliary assembly being arranged in a forming mold, and the surface, provided with the micro-nano structure, of the auxiliary assemblyand the inner cavity surface forming a forming surface used for forming the vibrating diaphragm body; filling an inner cavity of the forming mold with a vibrating diaphragm body material, manufacturing a vibrating diaphragm body, and the surface, provided with the micro-nano structure, of the auxiliary assembly being connected with the vibrating diaphragm body; and demolding the vibrating diaphragm body and the auxiliary assembly. The invention further provides a vibrating diaphragm assembly formed by using the forming method and a sound production single body with the vibrating diaphragm assembly. The vibrating diaphragm assembly obtained through the forming method of the vibrating diaphragm assembly has high strength and small deformation shrinkage amount, and the assembled sound production single body has good waterproof sealing performance and excellent acoustic performance.

Owner:GOERTEK INC

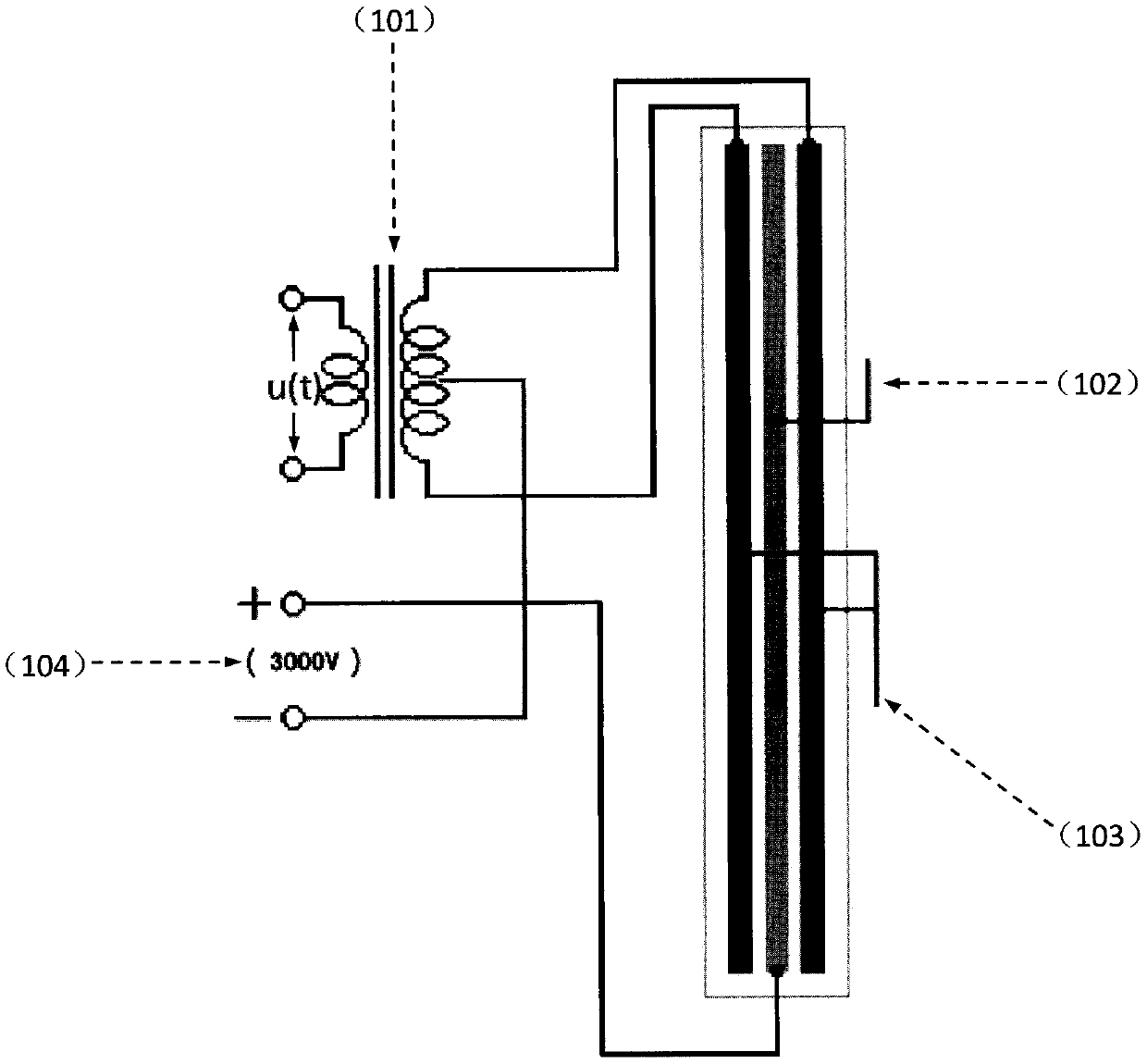

Electron generator, net charge generating device and electrostatic loudspeaker

PendingCN110996237AIncrease electrostatic voltageMicrophonesDiaphragm materialsEngineeringElectrostatic loudspeaker

The invention provides a net charge generating device and an electron generator used for the net charge generating device, and also provides a vibrating diaphragm used in an electrostatic loudspeaker.In the prior art, electrostatic charges required by a vibrating diaphragm of an electrostatic loudspeaker are injected through a high-voltage direct-current power supply, and the high-voltage direct-current power supply is large in size, so that the electrostatic loudspeaker is not suitable for being used on portable electronic equipment, which is a defect of the electrostatic loudspeaker. The invention provides a net charge generation device to replace a high-voltage direct-current power supply in an electrostatic loudspeaker in the prior art. The net charge generating device is simple in structure and convenient to miniaturize, so that the size of the electrostatic loudspeaker designed by the net charge generating device is greatly reduced, and the using requirements of miniaturization,lightness and thinness of the electrostatic loudspeaker in mobile portable equipment can be met.

Owner:董耀斌

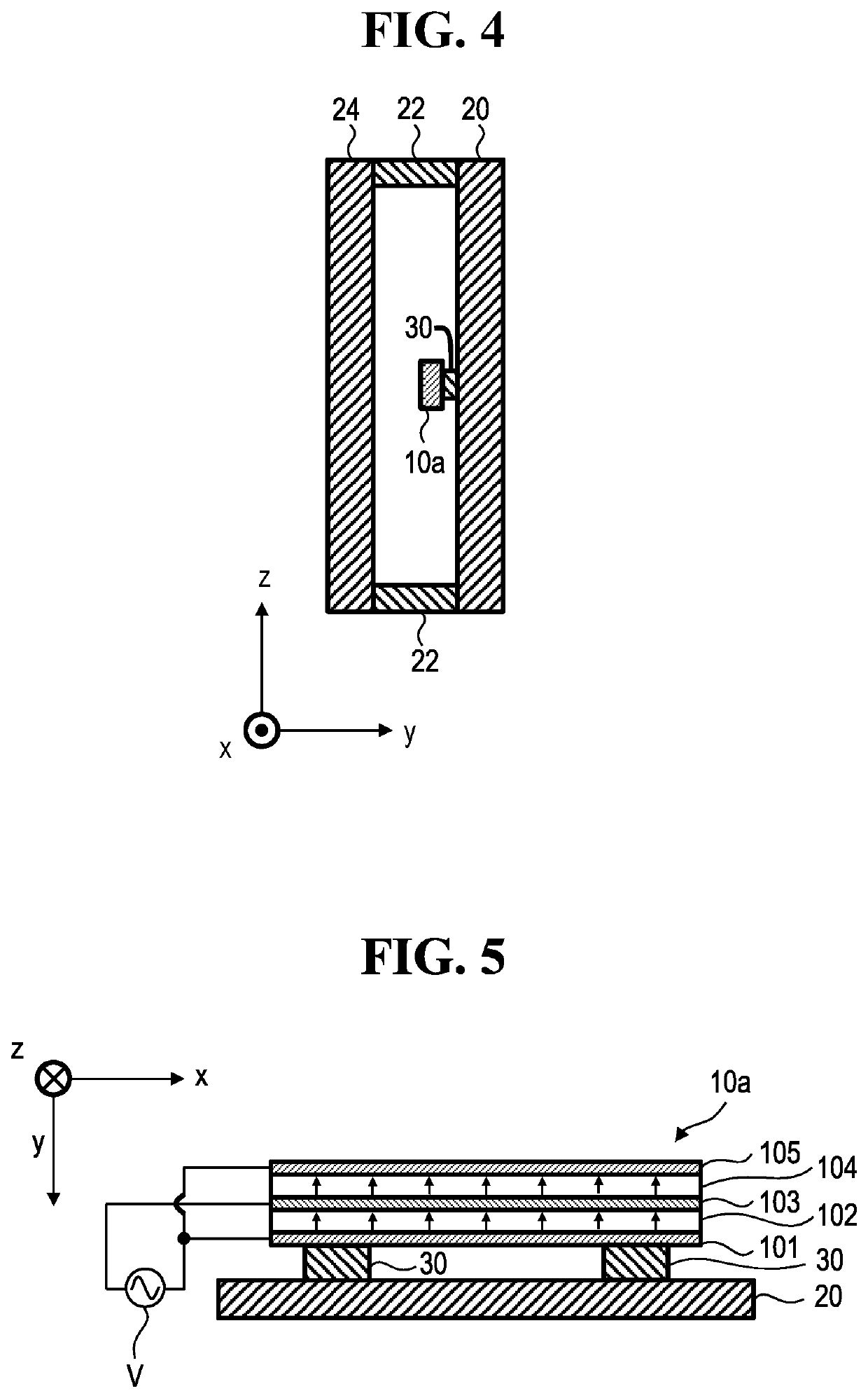

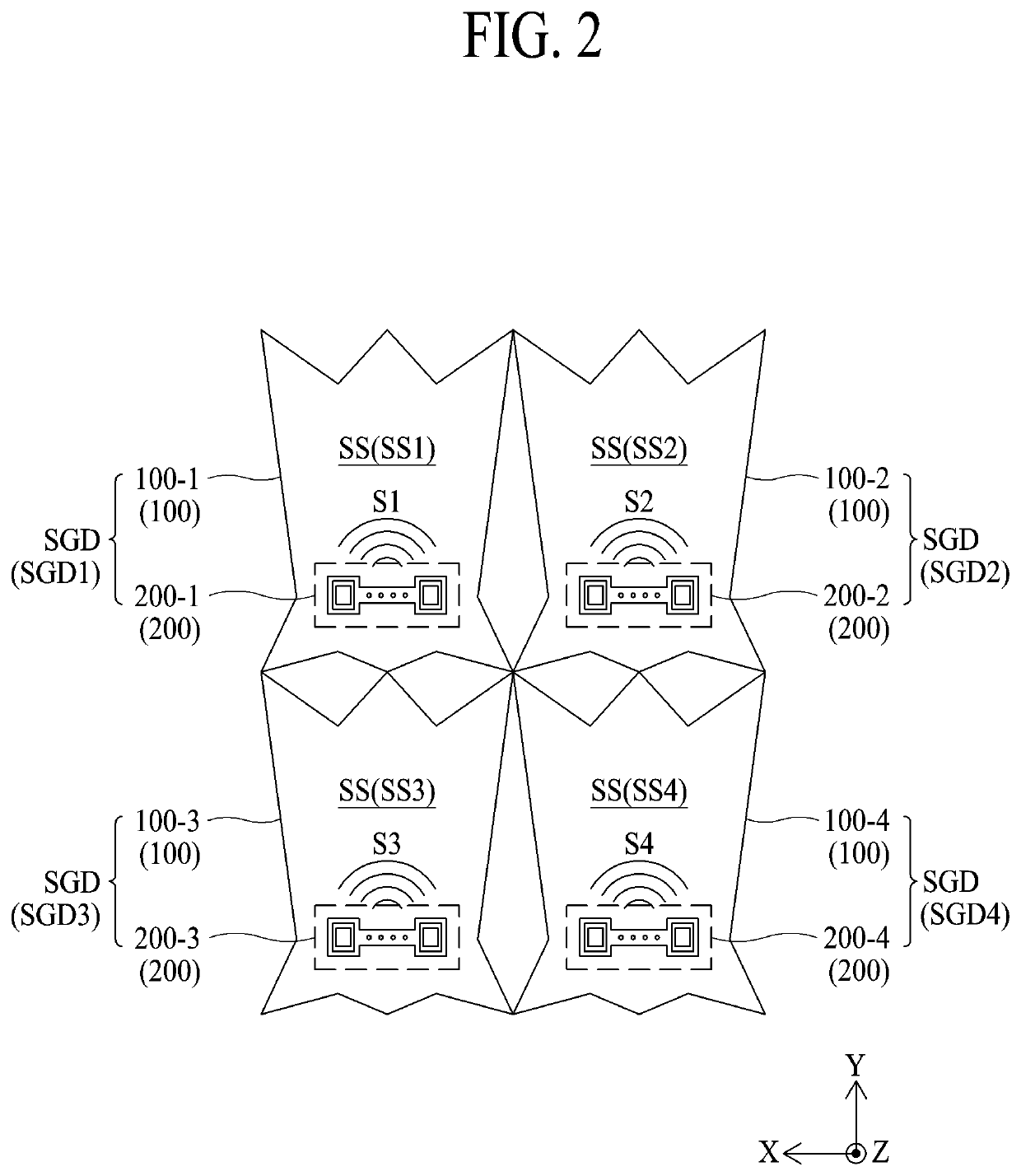

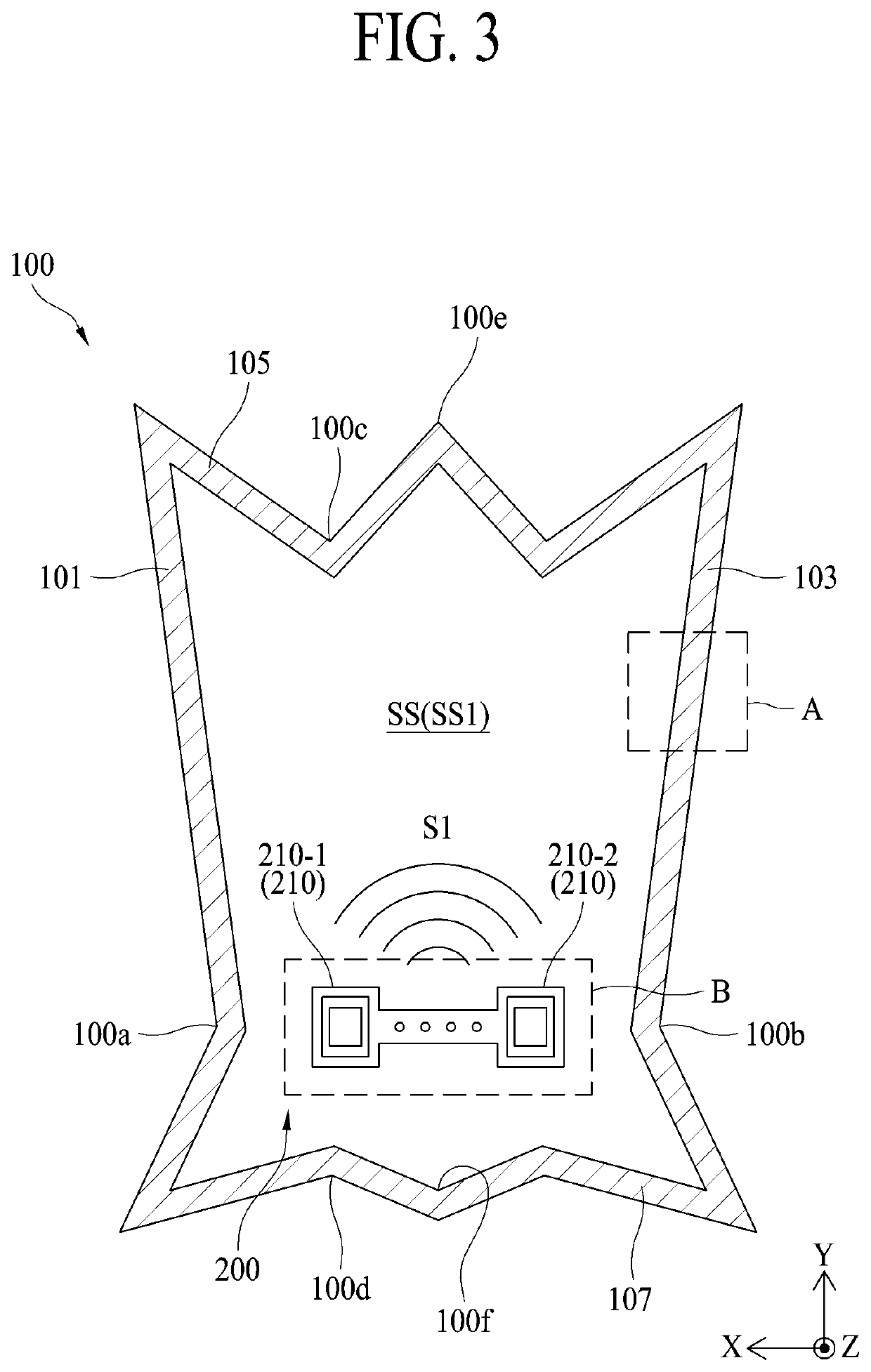

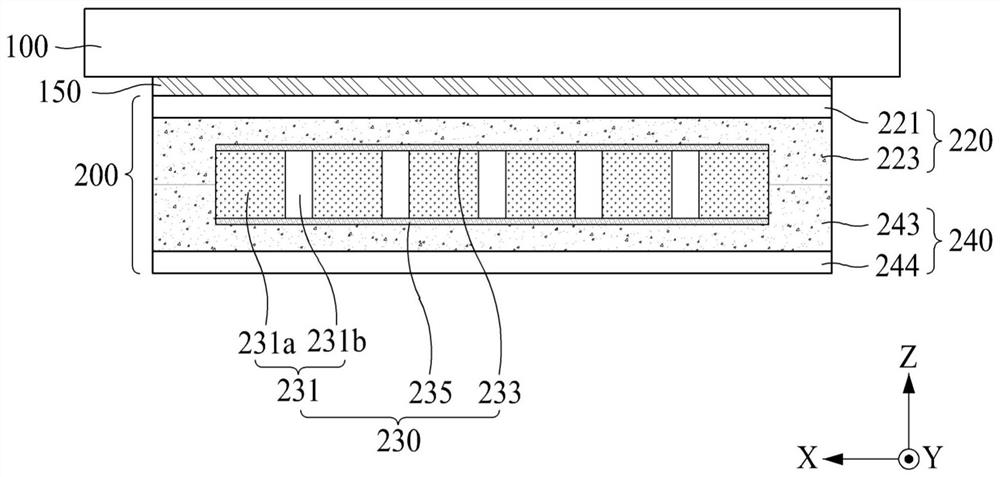

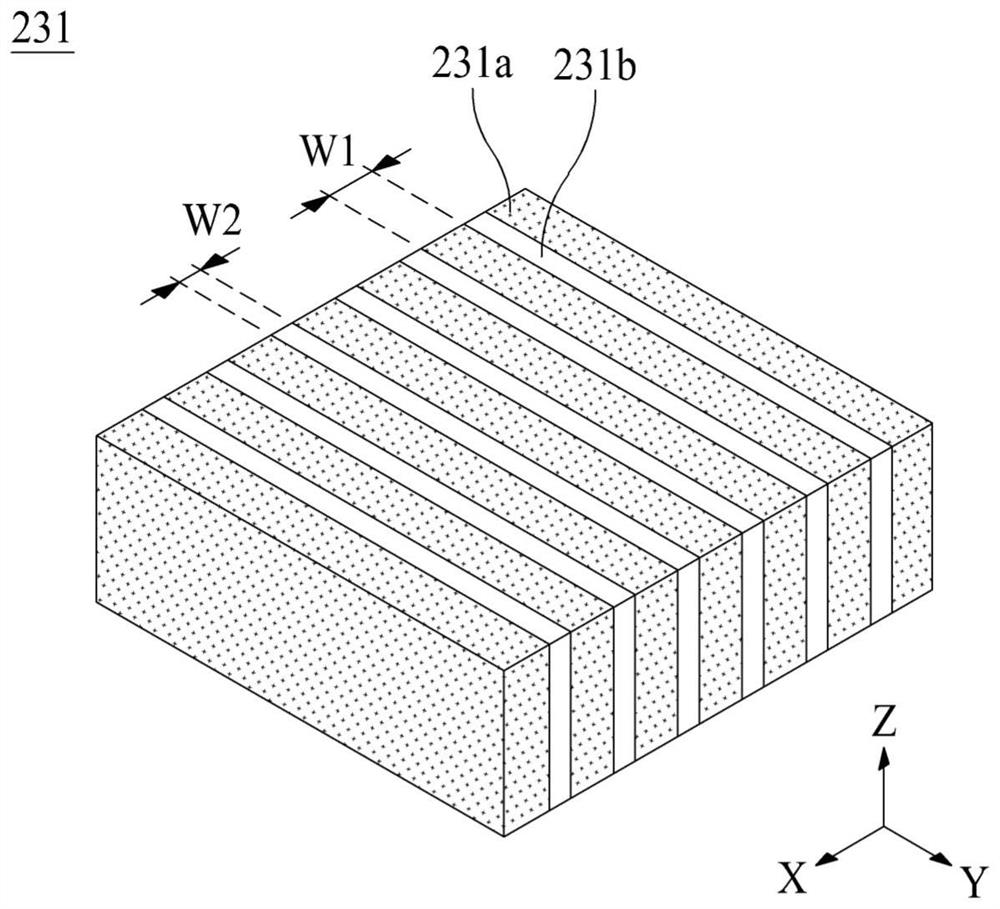

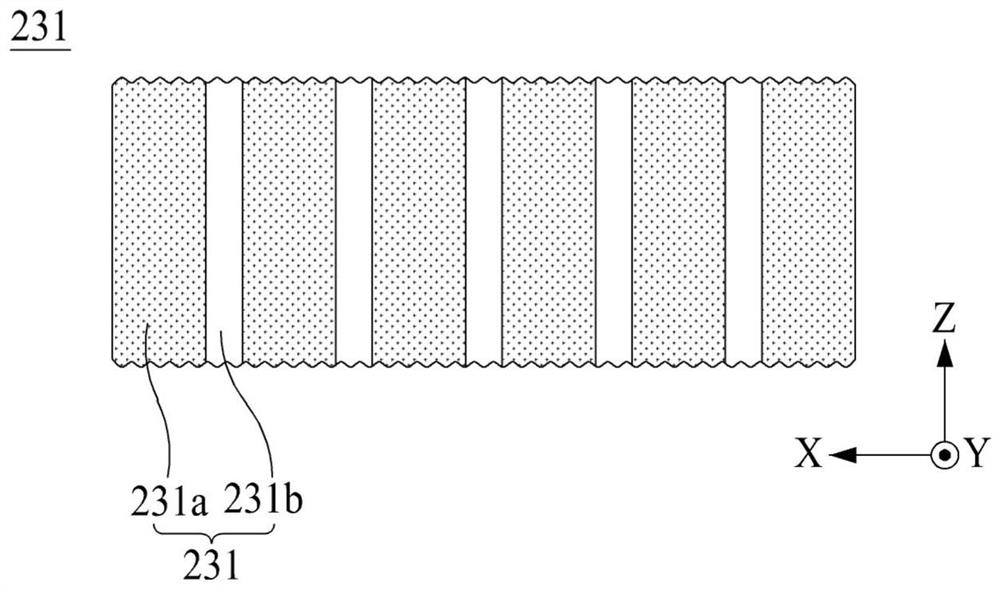

Sound apparatus and display apparatus including the same

PendingUS20220132236A1Improve sound qualityPiezoelectric/electrostrictive microphonesBending wave transducersEngineeringAcoustics

Owner:LG DISPLAY CO LTD

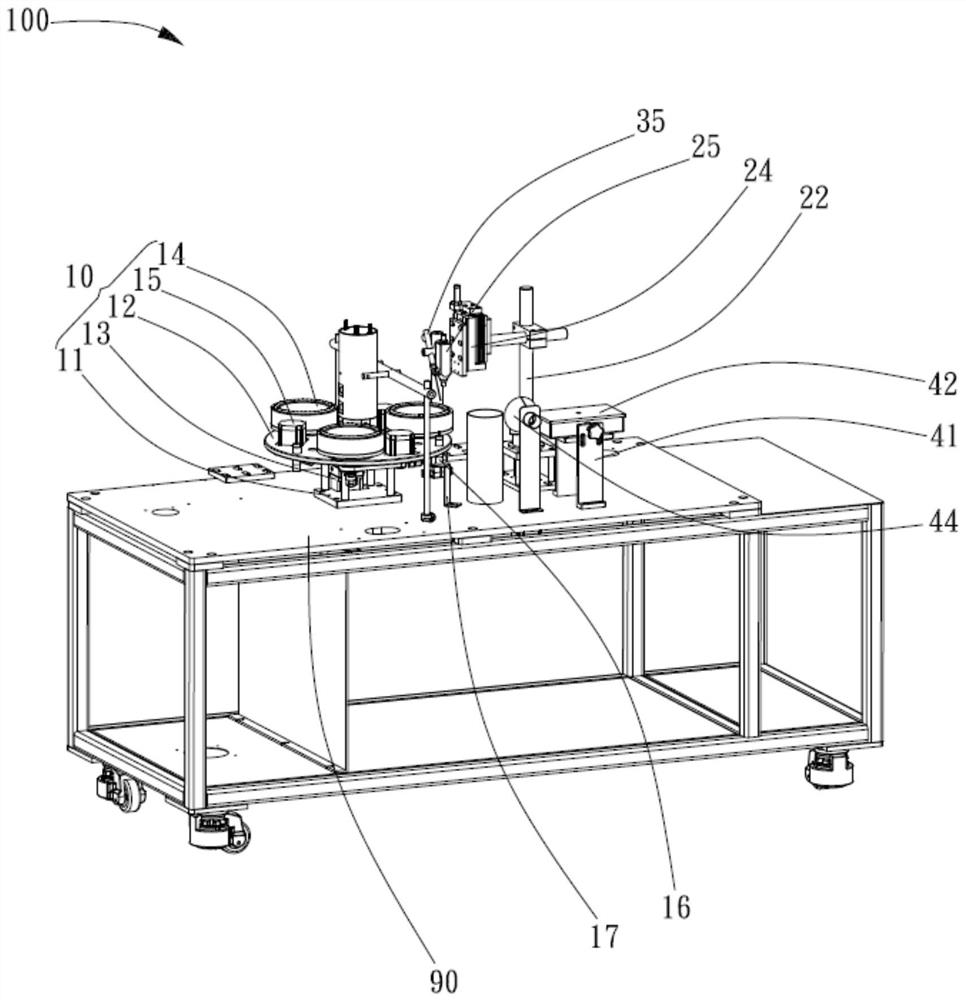

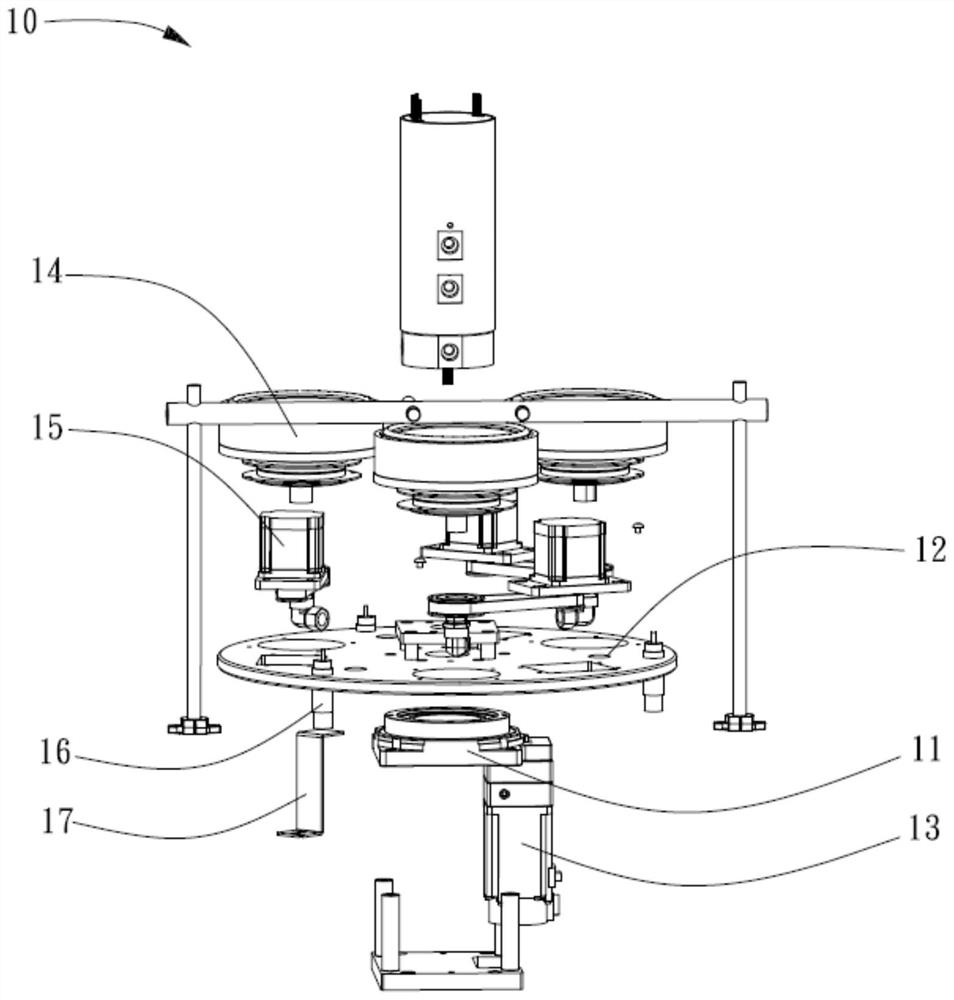

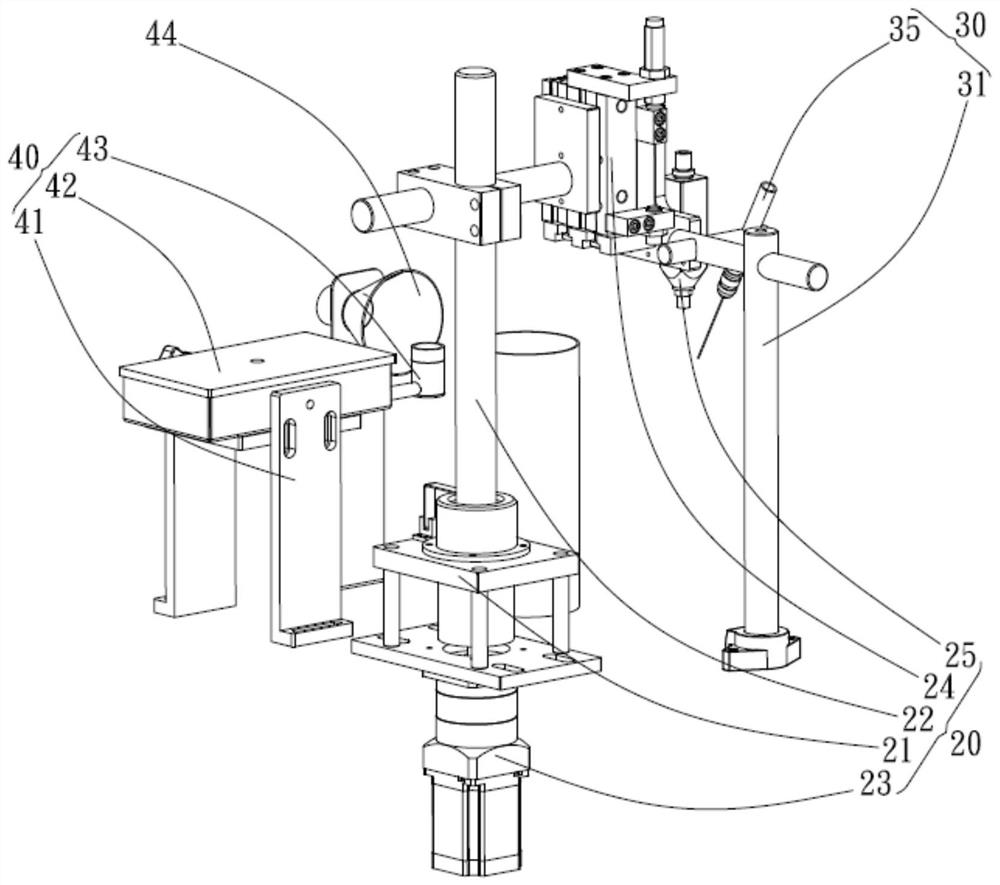

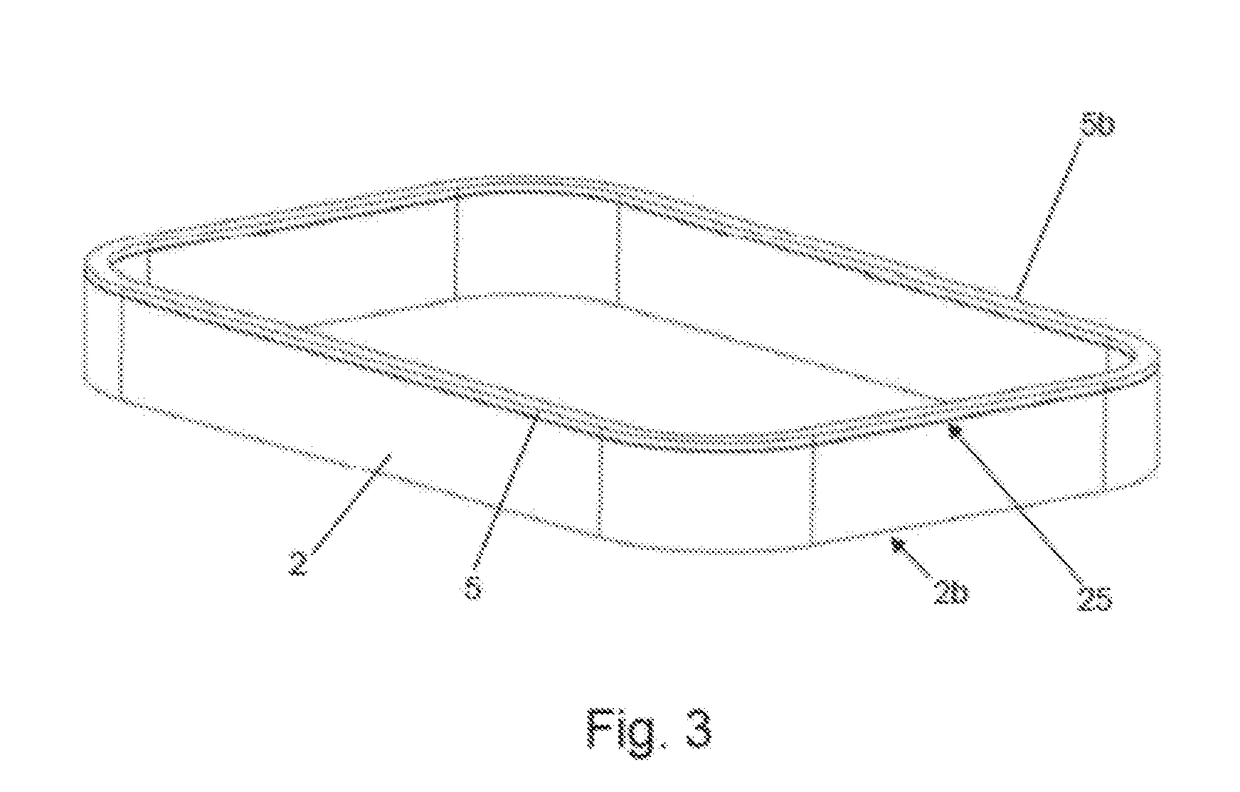

Drum paper assembling method

ActiveCN114257944AAvoid damageGuarantee the production progressDiaphragm materialsDiaphragm constructionMechanical engineeringIndustrial engineering

The invention discloses a drum paper assembling method. The drum paper assembling method comprises the following steps that S1, a vibration ring material is cut into an annular body, and an annular material is obtained; s2, pasting the annular material to the outer edge of a drum paper carcass to obtain a combined body; s3, positioning the assembly by using the center of the drum paper carcass, and forming the annular material of the assembly to obtain a semi-finished product; and S4, the edge of the semi-finished product is punched, and a finished product is obtained. According to the drum paper assembling method, the carcass can be grabbed for forming, damage to the vibrating ring is avoided, the production progress and the machining precision are guaranteed, and the product yield is increased.

Owner:JIANGSU FENGDI TECH CO LTD

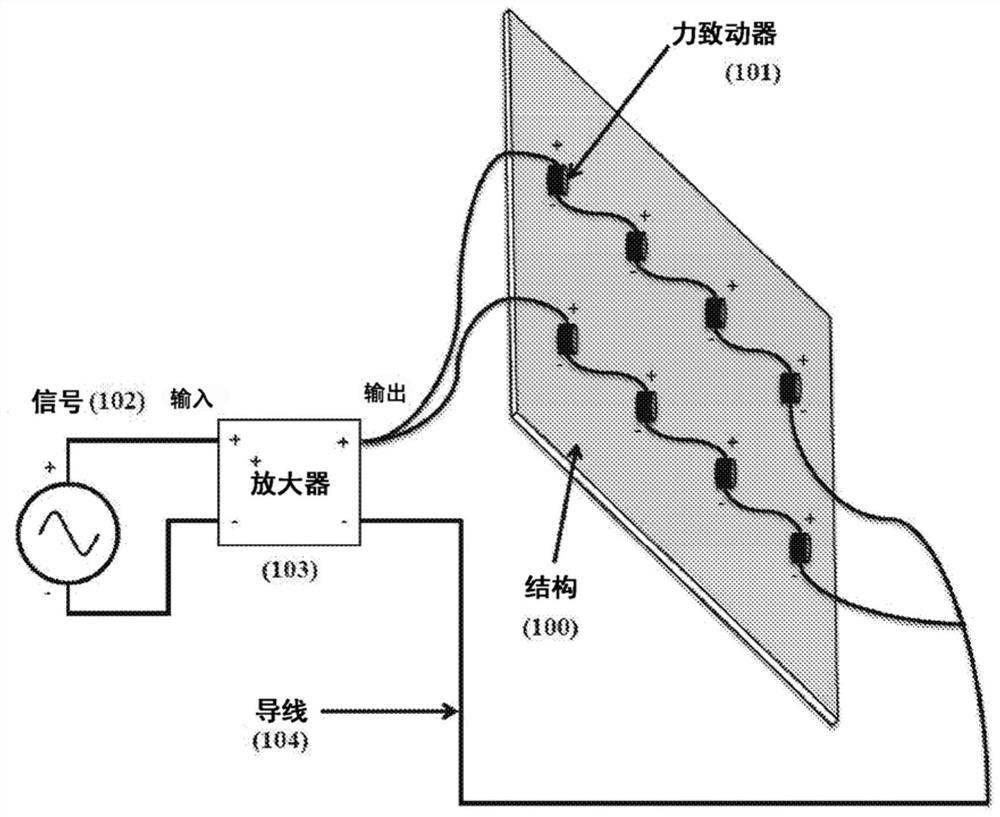

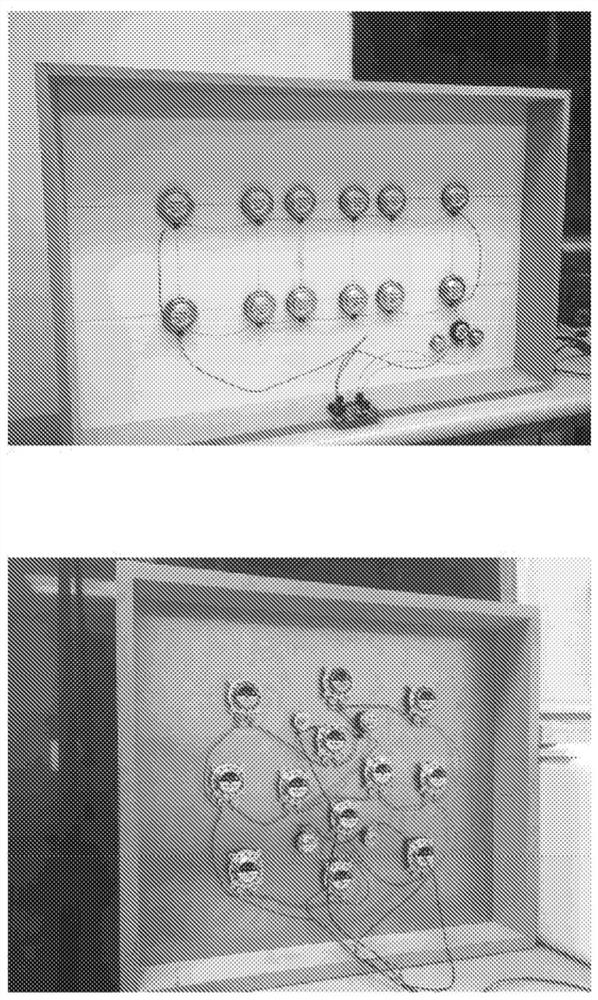

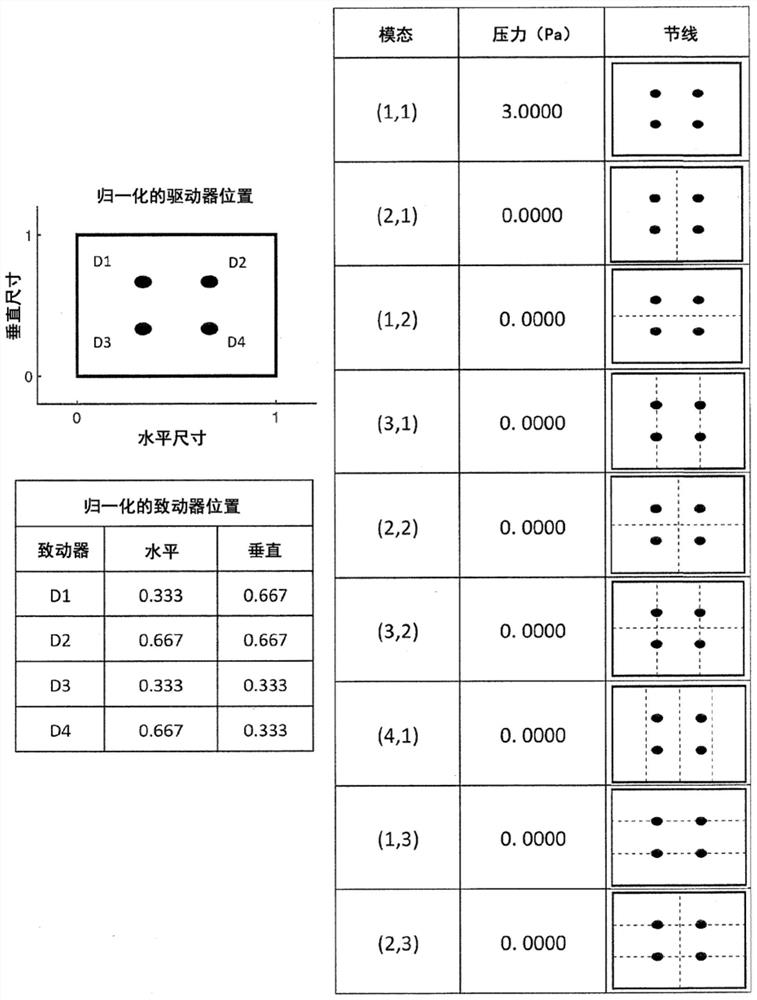

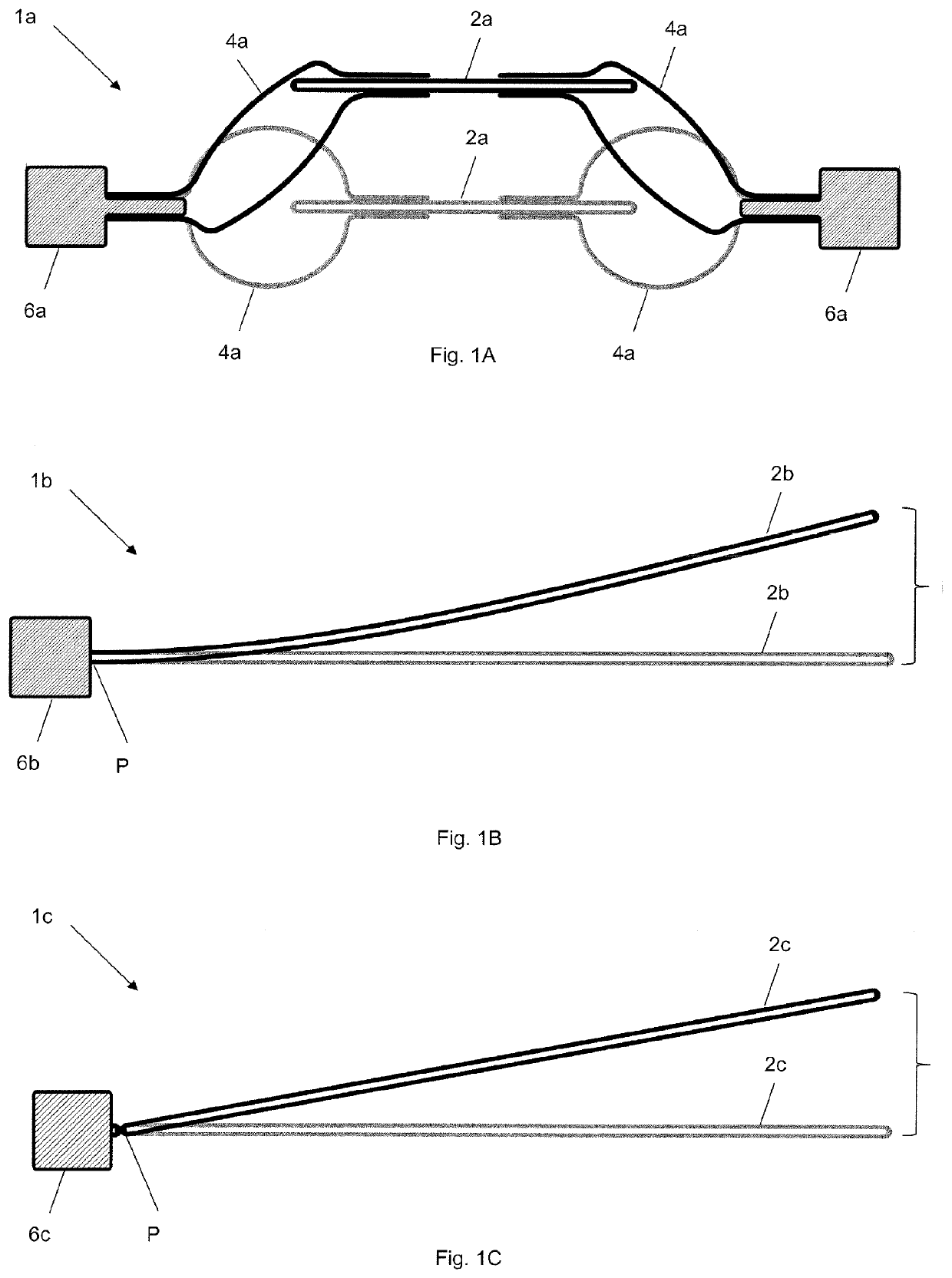

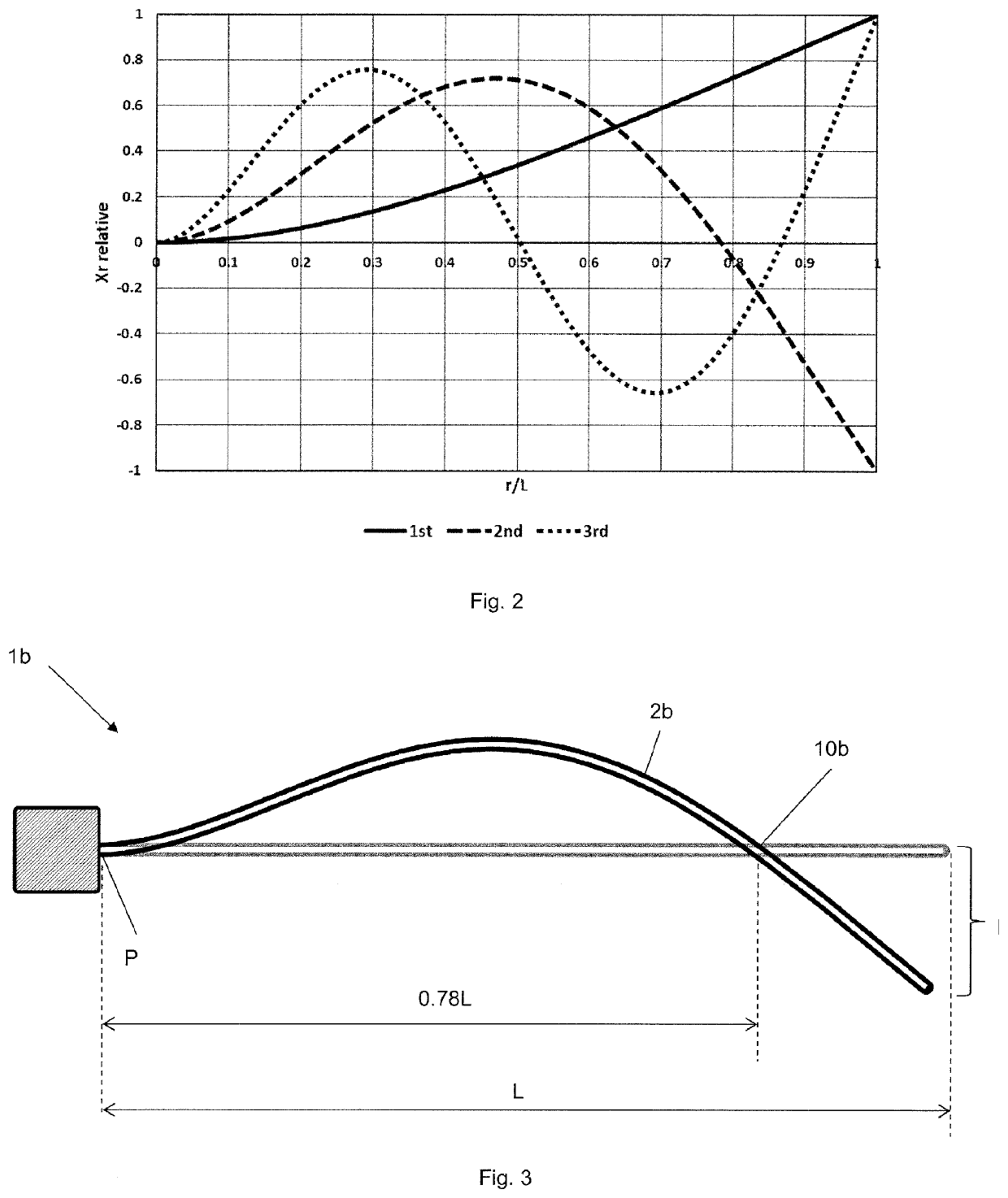

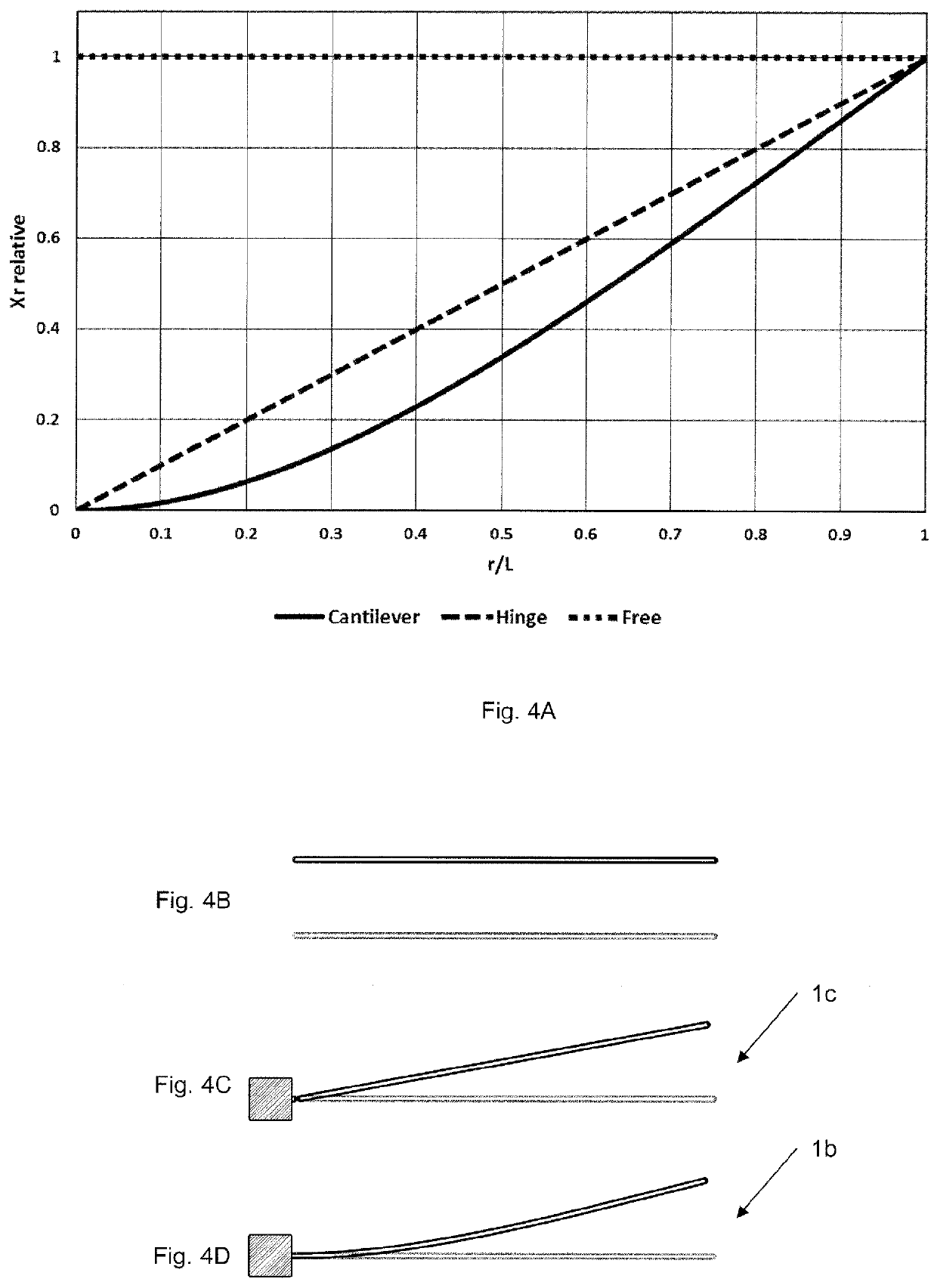

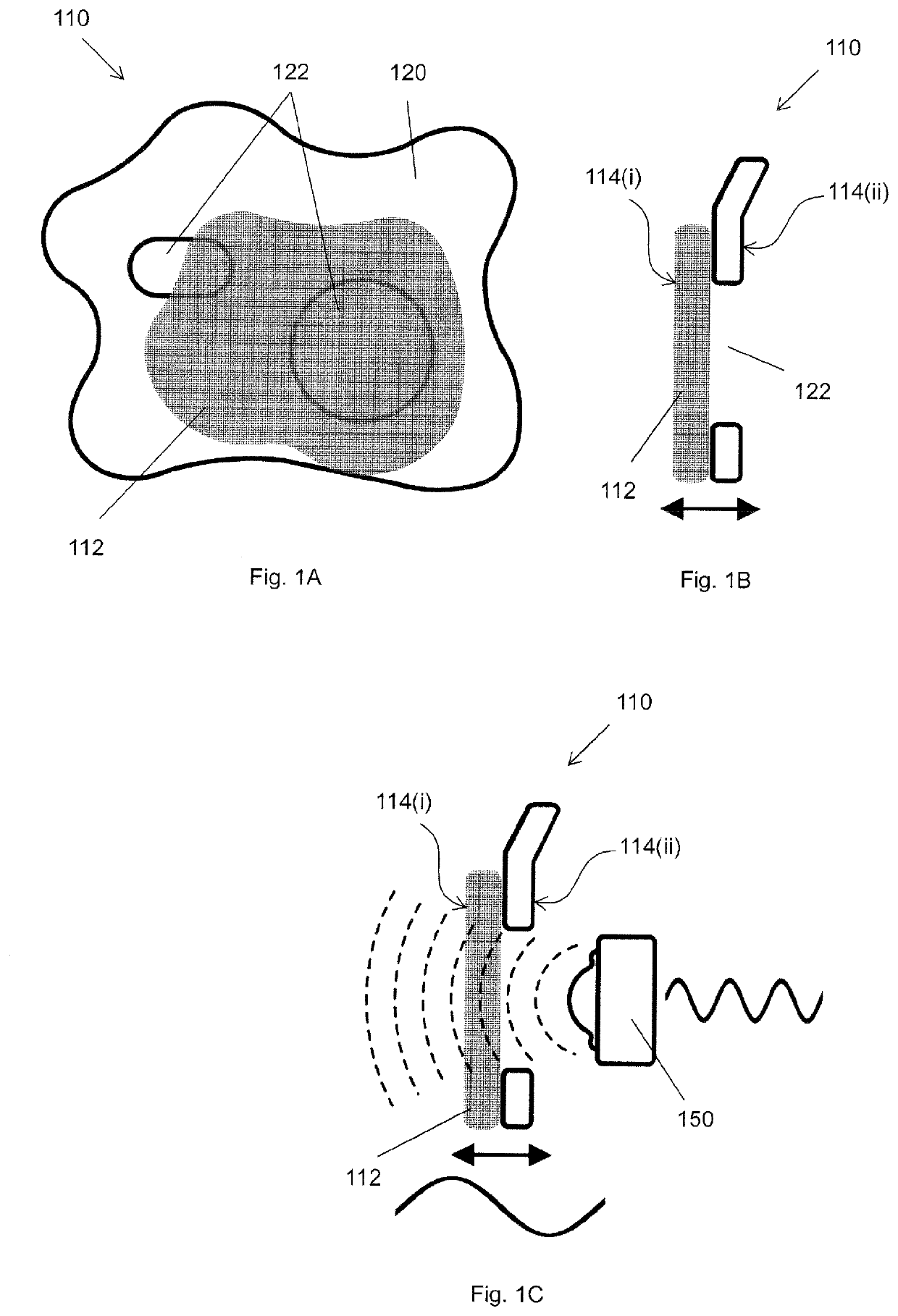

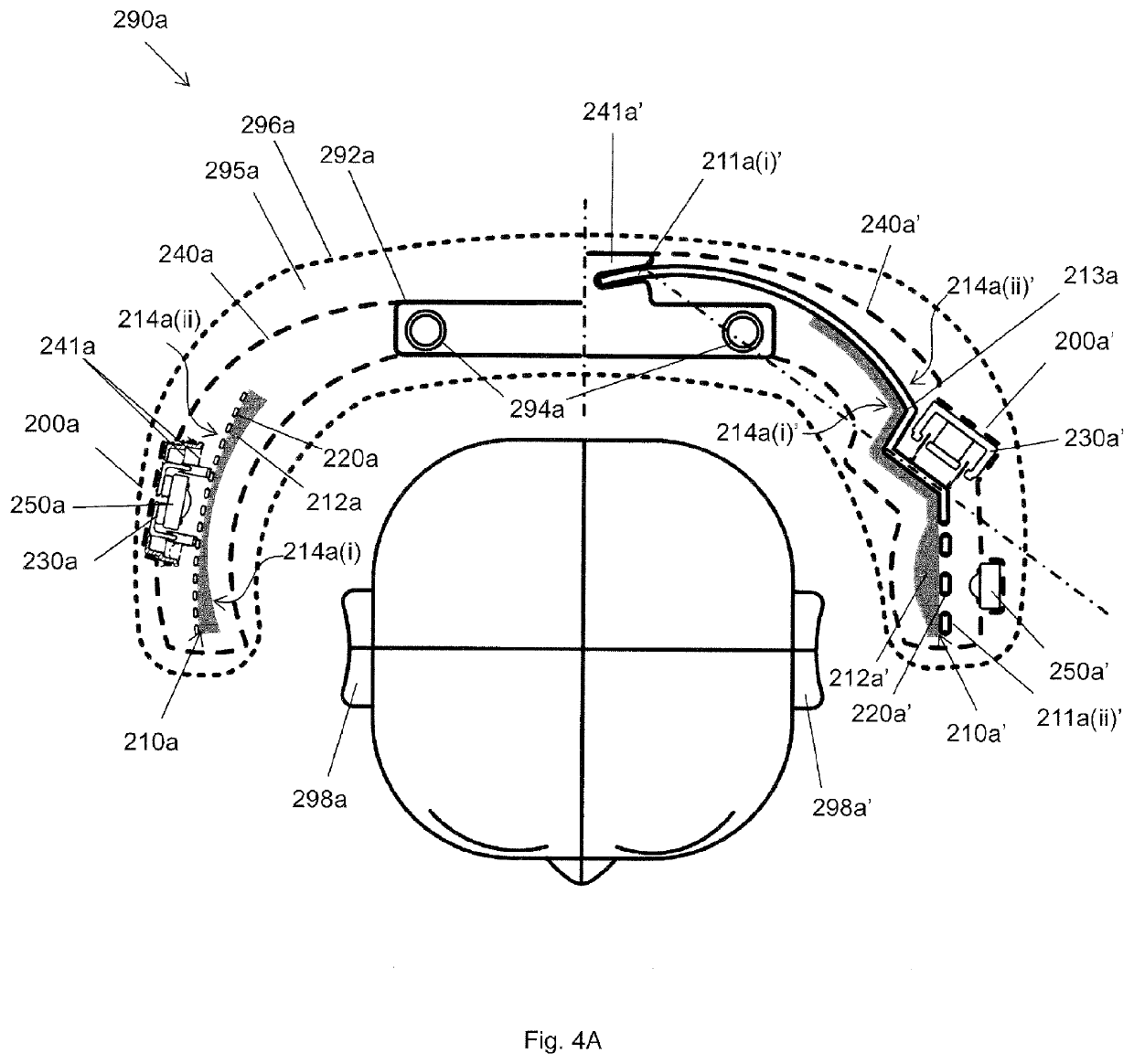

Method, system and devices for selective modal control for vibrating structures

A method, system and devices to selectively control modal vibrations in an elastic panel with a number of force actuators distributed throughout the surface of the elastic panel to excite / depress the response of one or more vibrational resonant modes included in a prescribed subset. The force actuators are disposed such that prescribed modal excitation / depression may be realized when the actuators are driven by a common source signal.

Owner:UNIVERSITY OF ROCHESTER

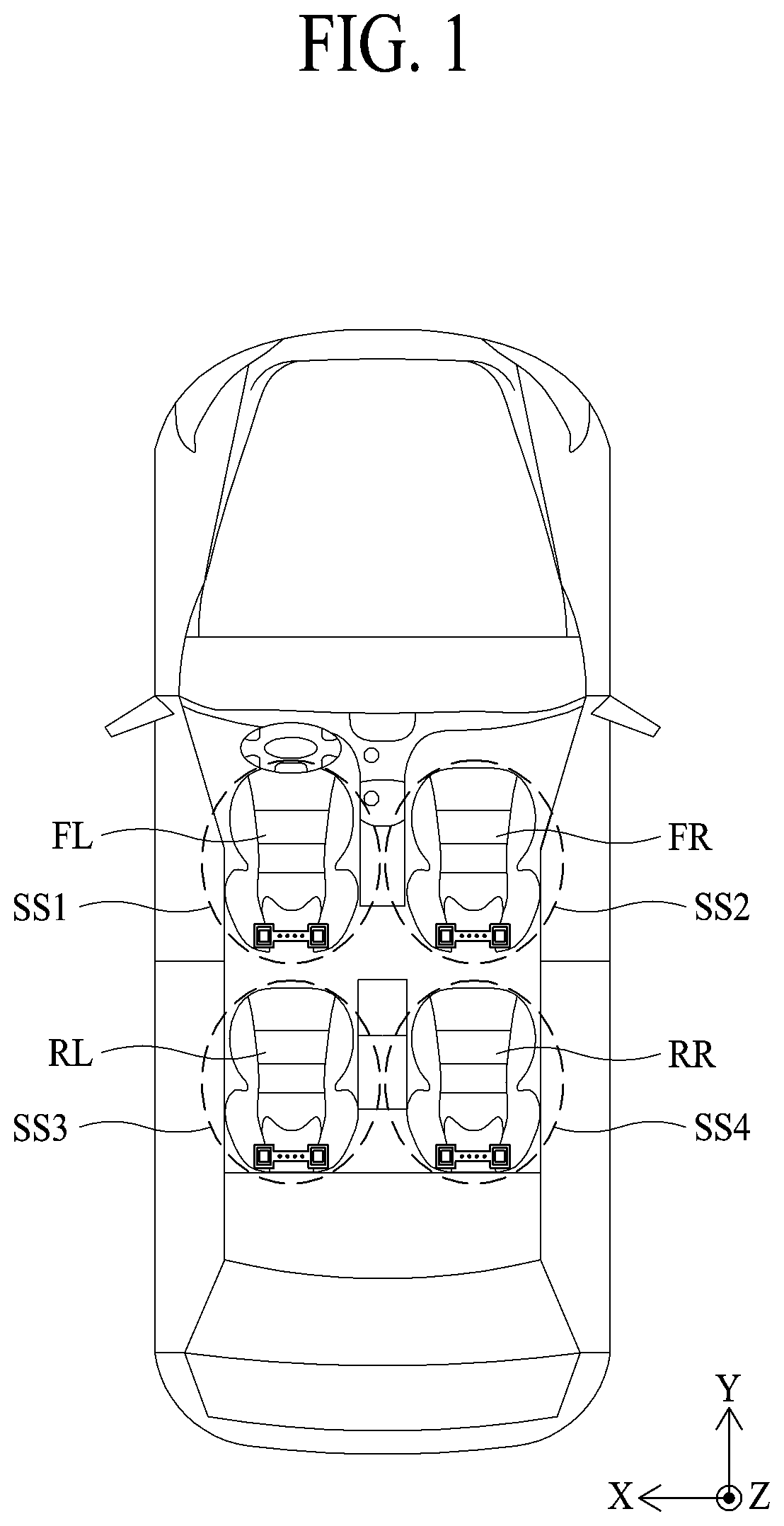

Sound control system, vehicle including the same, and sound control method

PendingUS20220210558A1Improve sound qualityMinimize adverse effectsMicrophones signal combinationPseudo-stereo systemsSound generationControl system

A sound control system comprises a sound generating device disposed at a vehicle ceiling corresponding to a seat region of the vehicle and disposed at a sound space formed within the vehicle to correspond to the seat region, and a sound processing circuit for providing a vibration driving signal to the sound generating device, the sound generating device vibrates based on the vibration driving signal to vibrate a vibration region of the vehicle ceiling corresponding to the sound space to provide a sound to the sound space.

Owner:LG DISPLAY CO LTD

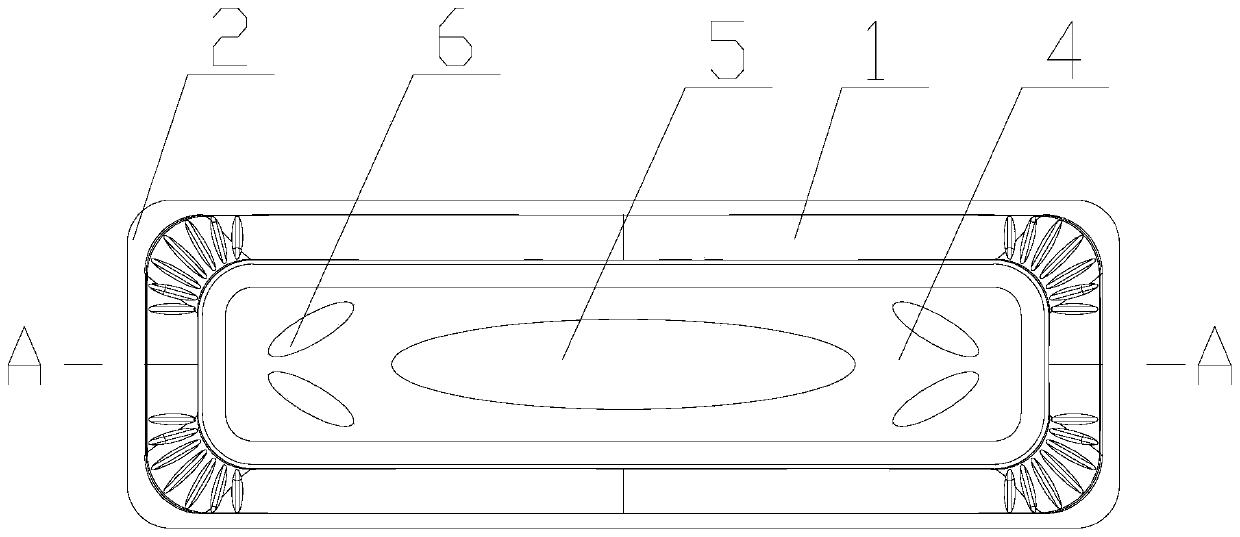

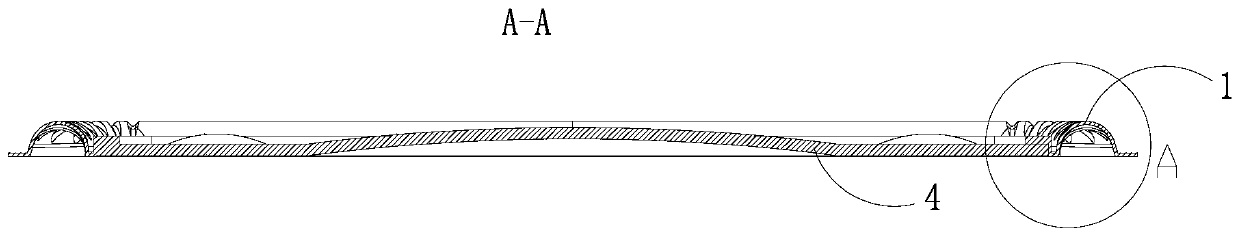

High-foam embedded voice diaphragm and loudspeaker

InactiveCN110913314ASimple structural designReduce volumeDiaphragm materialsNon-planar diaphragms/conesLoudspeakerMechanical engineering

The invention relates to the technical field of electroacoustic conversion, in particular to a high-foam embedded voice diaphragm and a loudspeaker. The invention comprises a frame body which comprises a high-foam folding ring part with a cavity in the middle, an attaching part connected to the outer ring of the high-foam folding ring part and a pressing and folding part connected to the inner ring of the high-foam folding ring part. A spherical top is arranged in a cavity in the middle of the high-foam folding ring part and embedded in the pressing and folding part, a spherical surface part protruding upwards or downwards to form an arc surface is arranged on the spherical top, auxiliary spherical surface parts protruding upwards or downwards to form arc surfaces are further arranged on the spherical top on the two sides of the spherical surface part, and the total height of the voice diaphragm is larger than the adjusting space of an original scheme. The strength of the globe roof isimproved by about 30-40% compared with that of the original scheme; the up-and-down amplitude of the loudspeaker is increased by 0.1-0.15 mm compared with the original scheme; and the high-frequencycurve of the loudspeaker is smoother than that of the original scheme without attenuation.

Owner:JIANGSU YUCHENG ELECTRONICS

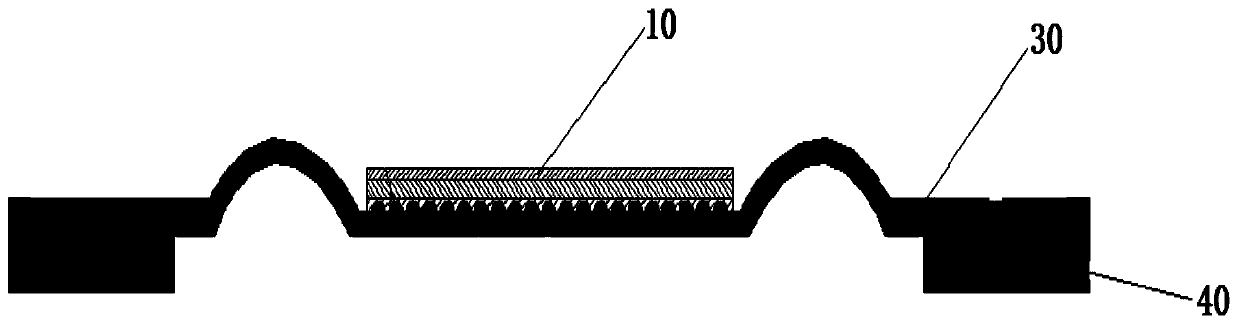

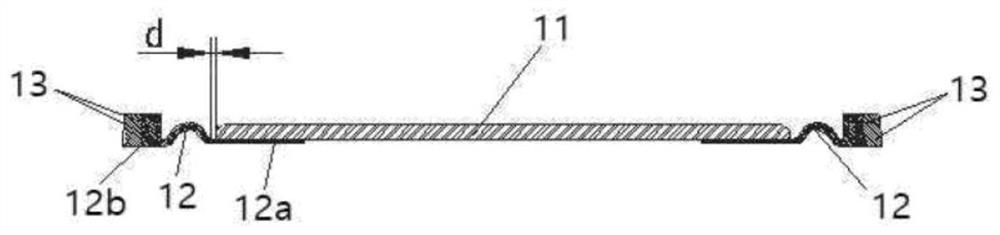

High water pressure waterproof micro speaker

ActiveCN111556414BEliminate the possibility of waterproof failureEasy to prevent intrusionDiaphragm materialsLoudspeaker screensClassical mechanicsEngineering

An object of the present invention is to provide a waterproof speaker with a waterproof rating of 8 or above, which can provide a waterproof function under high water pressure. The present invention provides a high water pressure waterproof loudspeaker, which has a frame and a vibrating part inside the frame. a diaphragm inside the frame; and a waterproof ring placed on a side wall of the frame and configured to protrude outwardly from the flange portion of the frame.

Owner:EM TECHNOLOGY CO LTD

Production method of drum paper carcass

PendingCN114257948ALow costConsistent concentrationDiaphragm materialsDiaphragm constructionFiberChemical agent

The invention discloses a drum paper carcass production method. The drum paper carcass production method comprises the following steps: S1, mixing a fiber material with water, and crushing the fiber material to form fiber slurry; s2, the fiber slurry is quantitatively taken out and formed, and an initial pressing piece is formed; s3, the initial pressing piece is soaked in pigment liquid for second preset time, and the initial pressing piece with pigment is formed; s4, water of the initial pressing piece with the pigment is pumped out, and a semi-finished product is formed; and S5, the semi-finished product is subjected to hot press molding, and a primary finished product is formed. According to the drum paper carcass production method, materials can be continuously supplied, pigments and chemical agents do not need to be added, the drum paper carcass production method is environmentally friendly, the water treatment cost and the cost of water resources and fiber material resources are greatly saved, the concentration of fiber pulp in each batch is consistent, and the consistency and the yield of products are guaranteed.

Owner:JIANGSU FENGDI TECH CO LTD

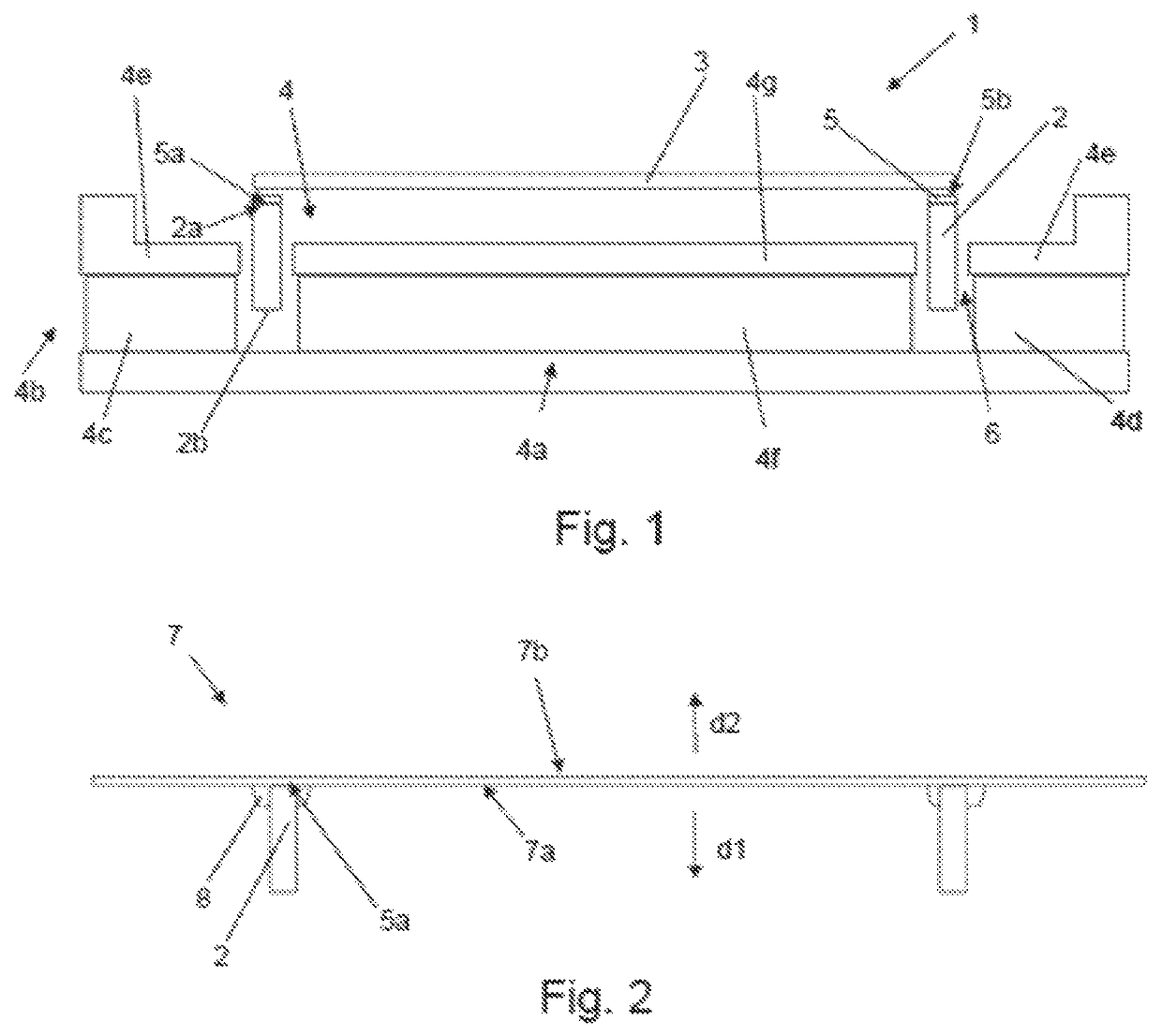

Loudspeaker

PendingUS20220201385A1Maximize surface areaReduce Harmonic DistortionDiaphragm materialsLoudspeakersEngineeringBass (sound)

A loudspeaker for producing sound at bass frequencies including: a diaphragm; a frame, wherein a proximal end of the diaphragm is suspended from the frame by at least one proximal suspension element, wherein the at least one proximal suspension element is configured to substantially prevent translational movement of the proximal end of the diaphragm relative to the frame, whilst permitting translational movement of a distal end of the diaphragm which is opposite to the proximal end of the diaphragm; a drive unit configured to move the distal end of the diaphragm based on an electrical signal.

Owner:PSS BELGIUM

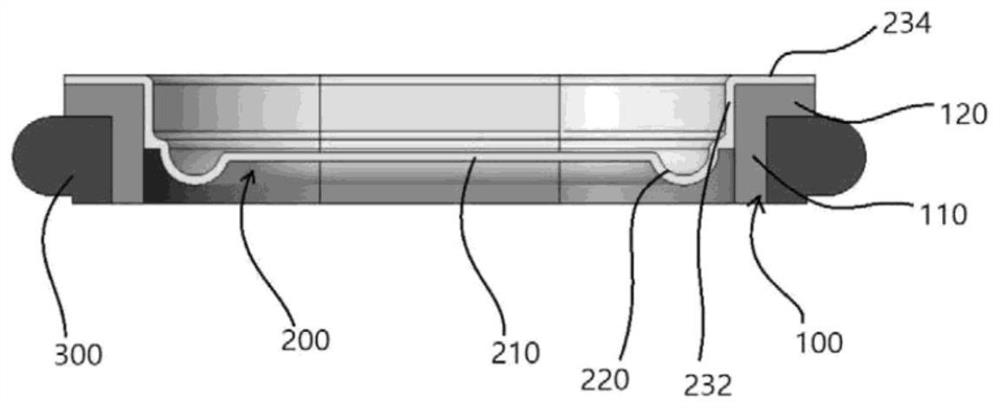

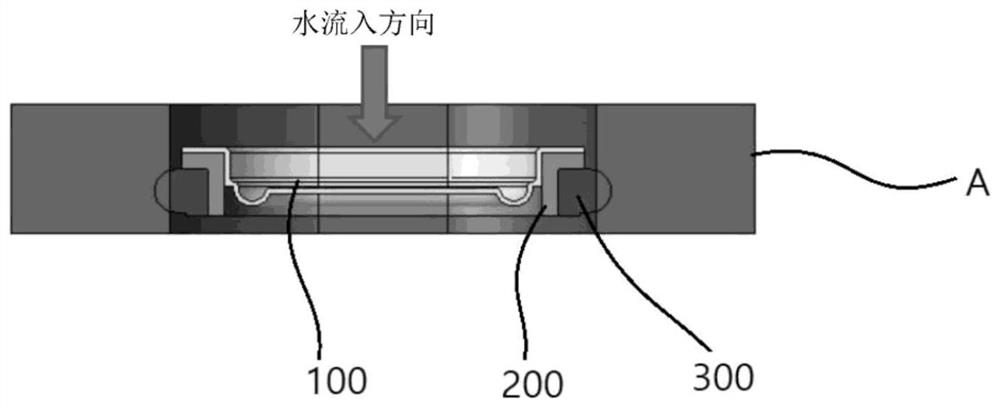

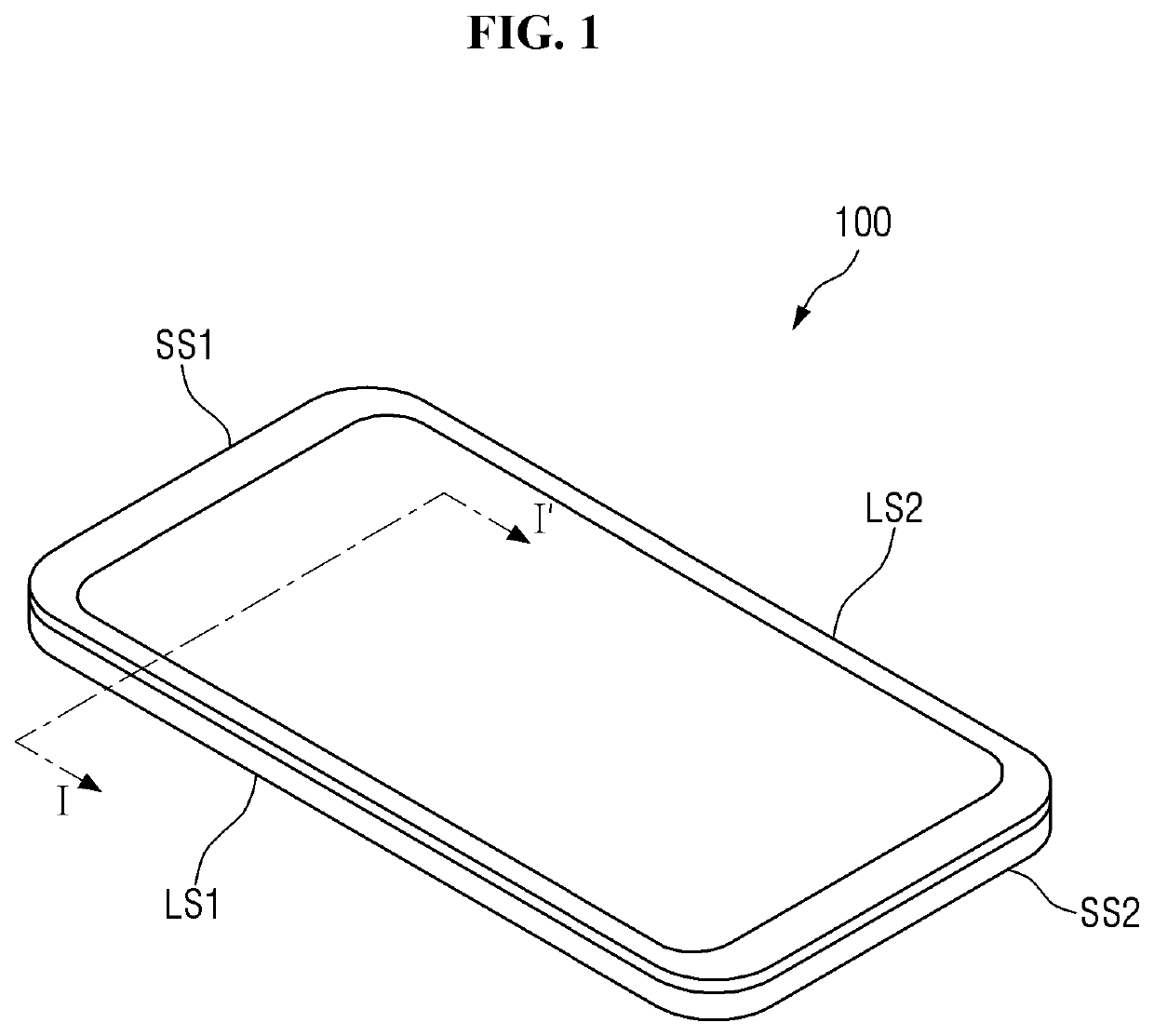

Display device

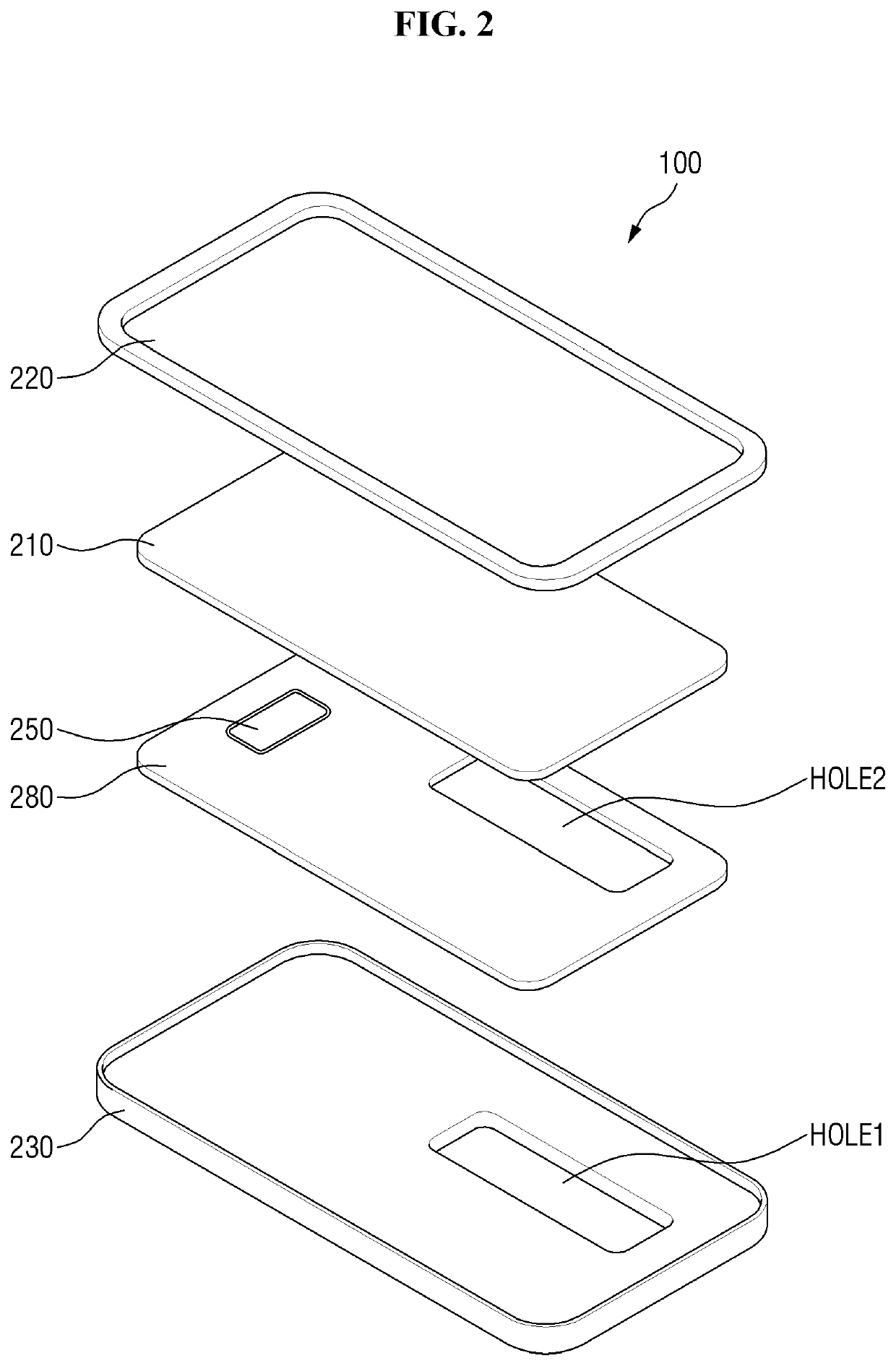

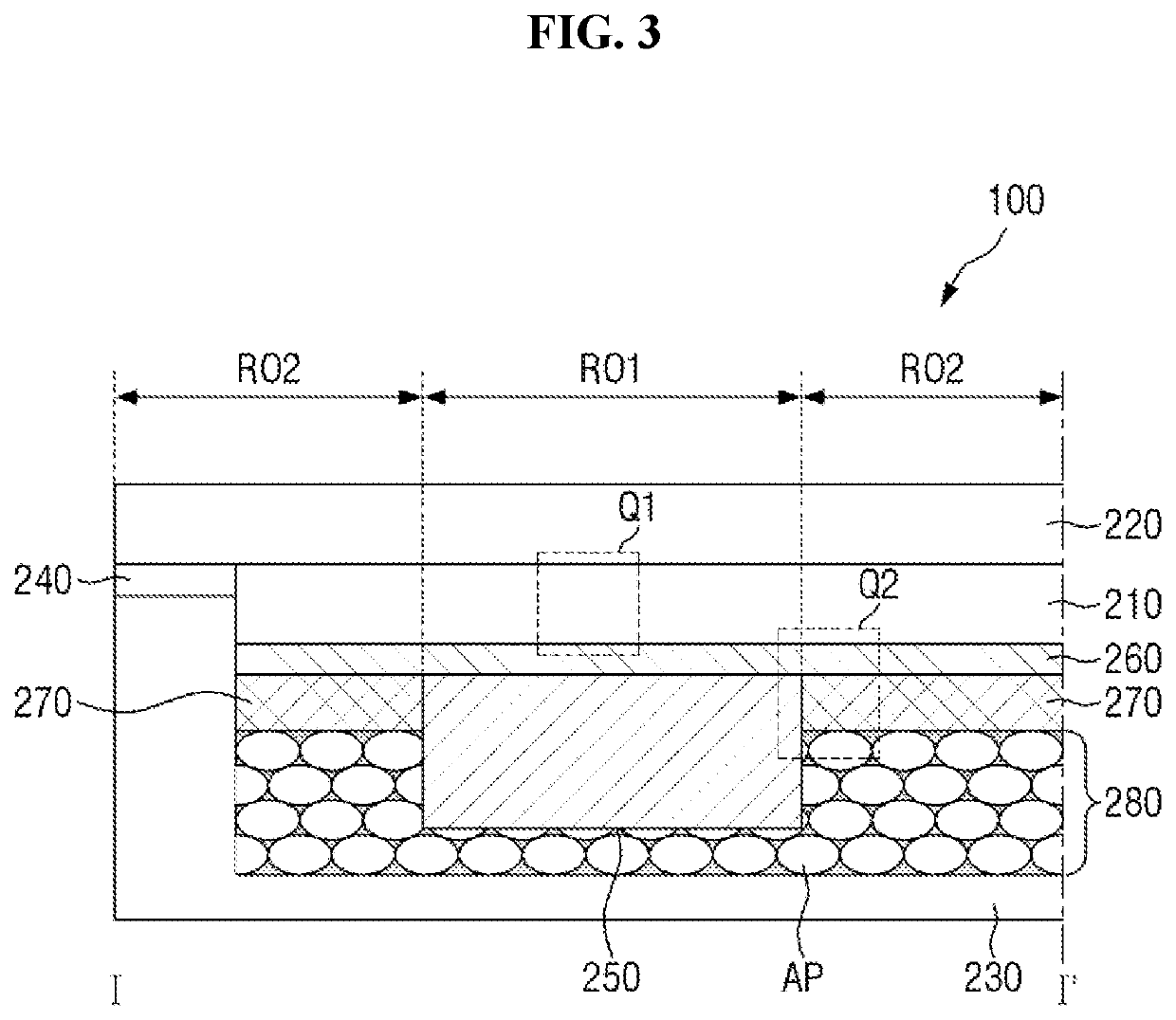

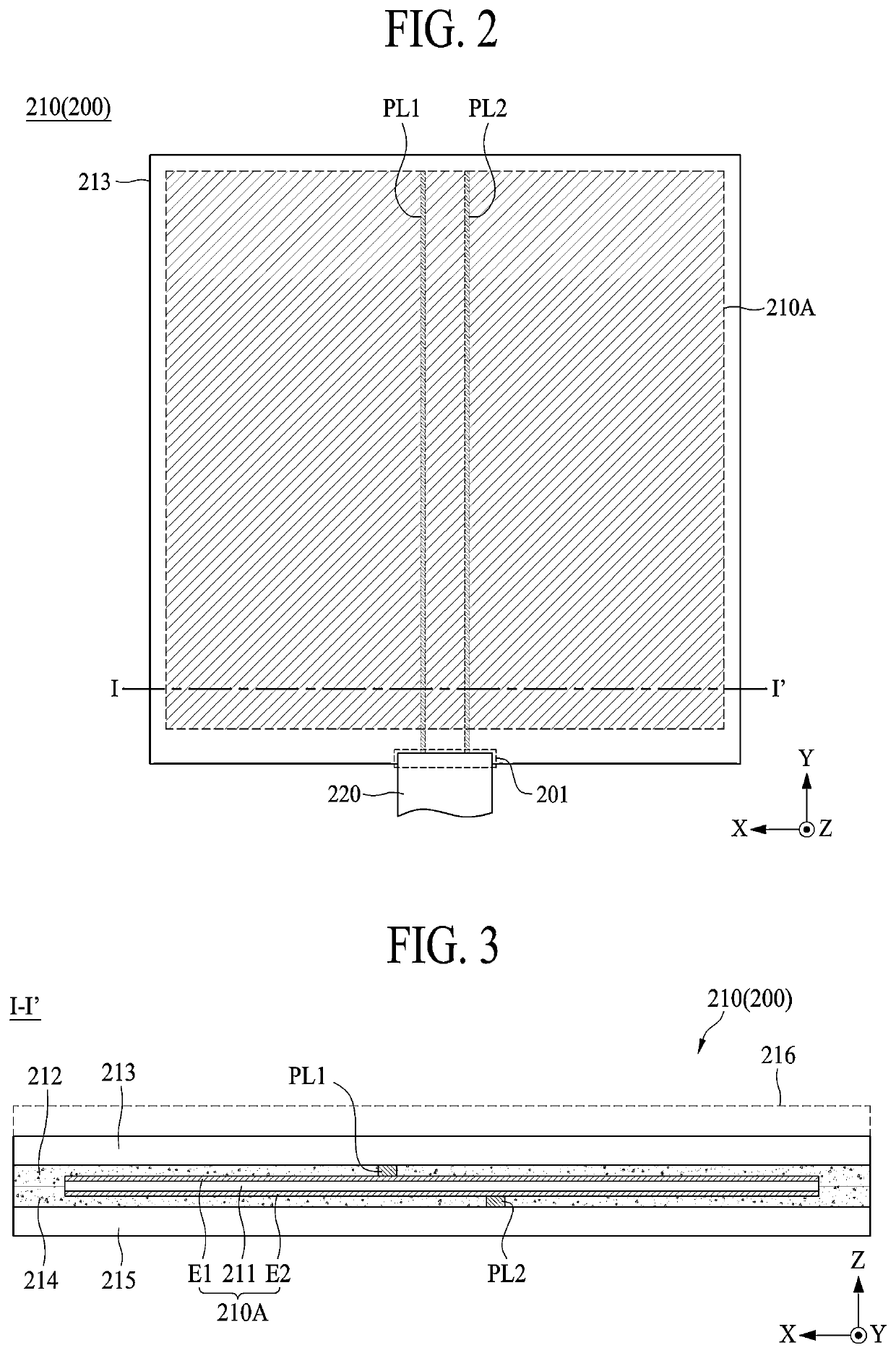

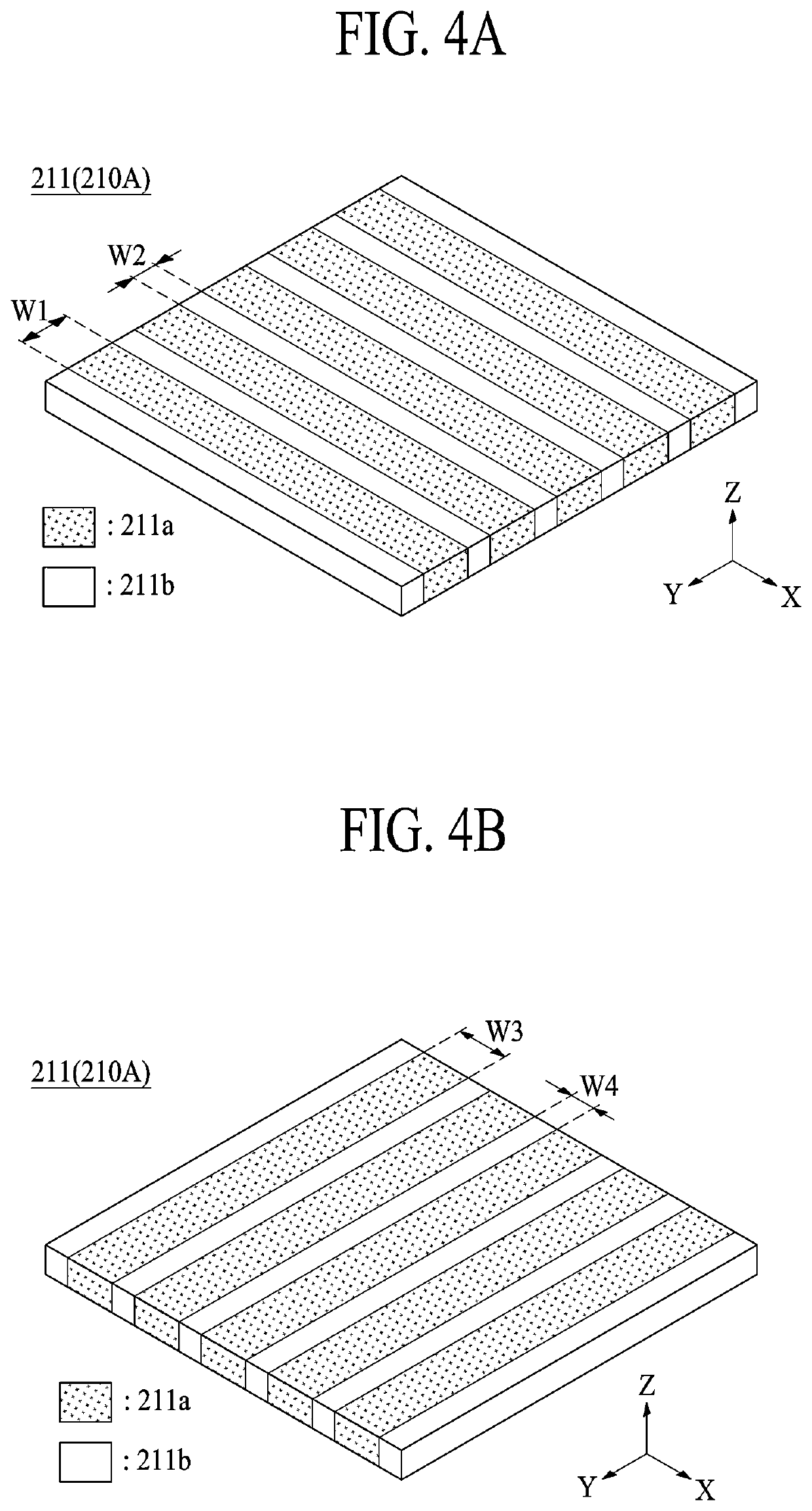

PendingUS20220102443A1Improve featuresExhibit better acoustic and low-frequency output characteristicsDiaphragm materialsStatic indicating devicesDisplay deviceMechanical engineering

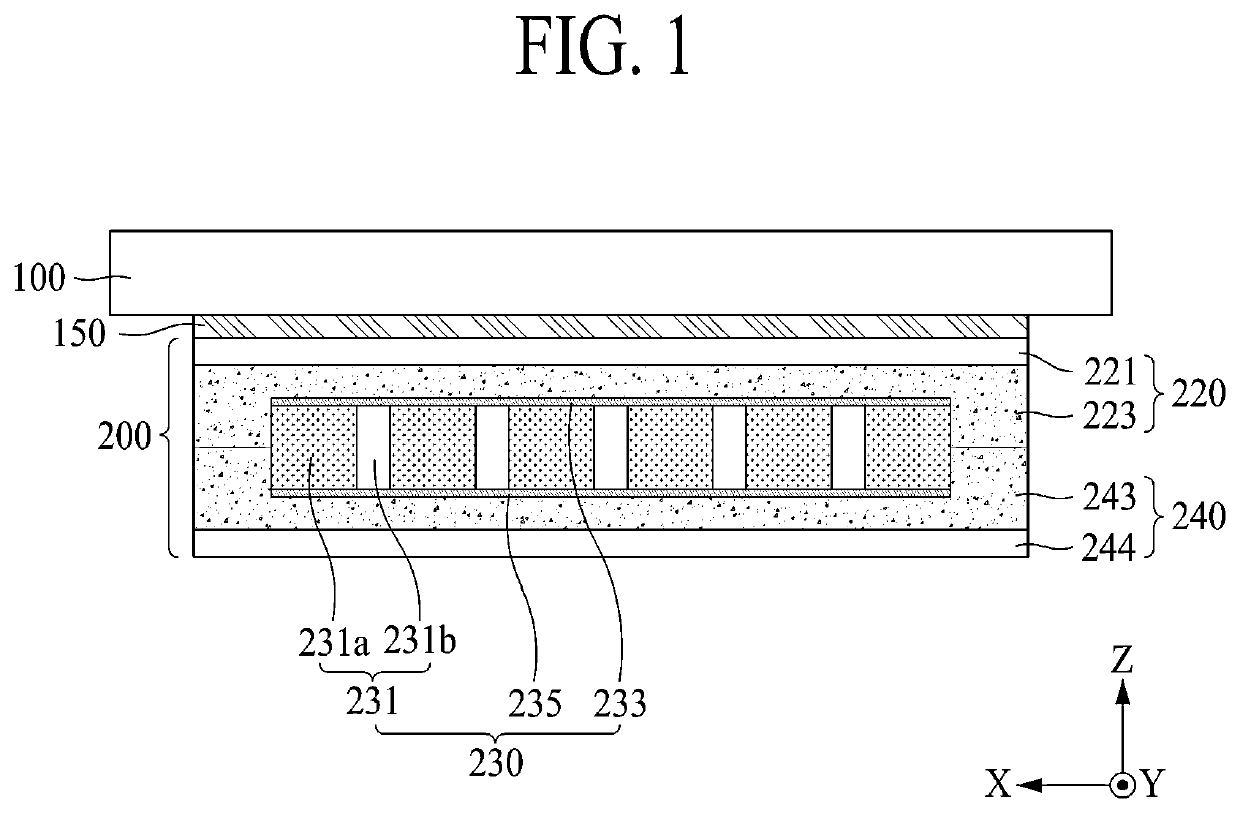

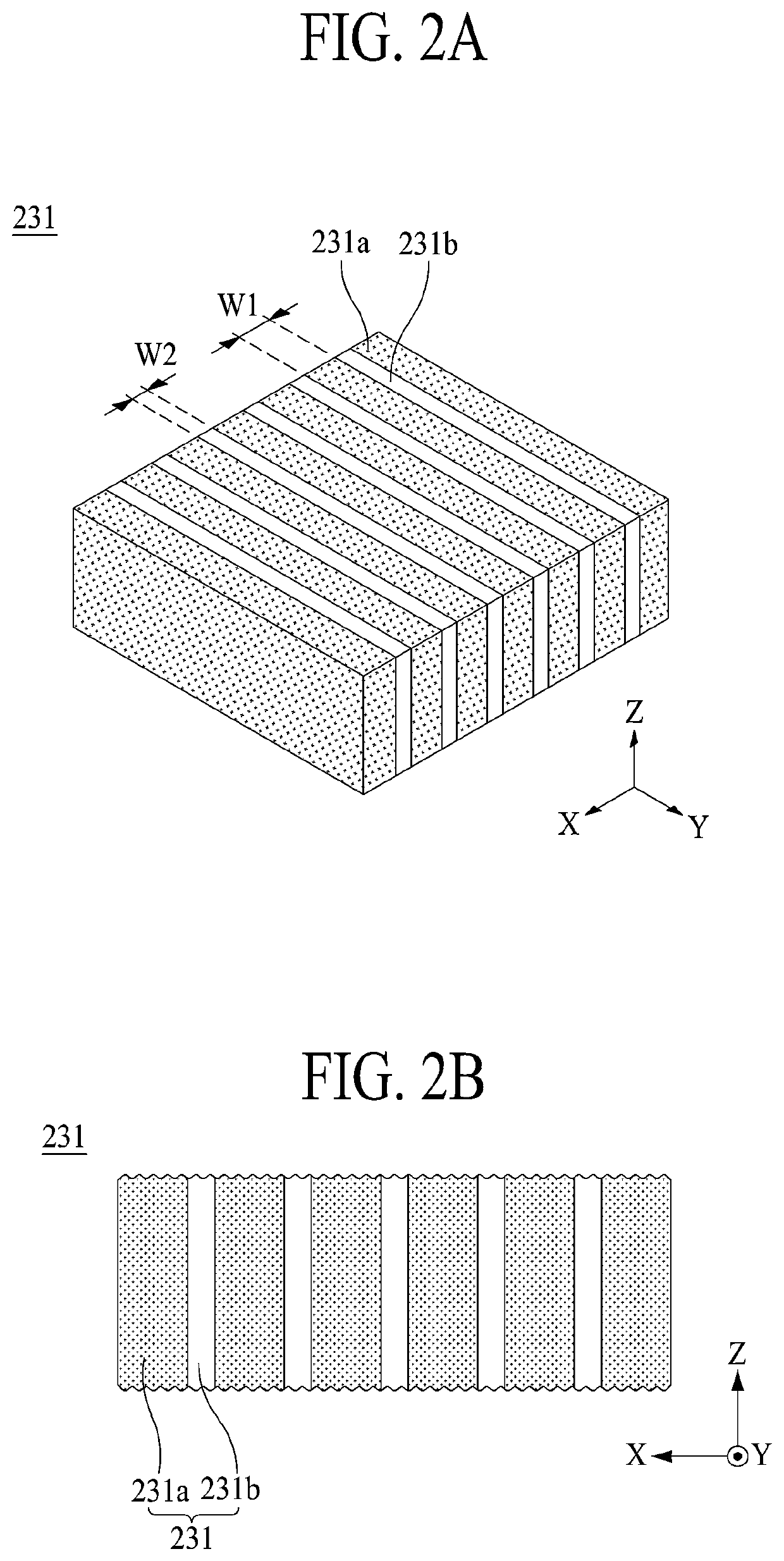

A display device including a display panel, a sound generator disposed on one surface of the display panel, and a porous layer disposed adjacent to the sound generator, in which the porous layer includes a first coupling layer, a second coupling layer, and an intermediate layer interposed between the first and second coupling layers and including a plurality of air pockets, and the first coupling layer and the intermediate layer do not overlap the sound generator in a thickness direction of the display panel.

Owner:SAMSUNG DISPLAY CO LTD

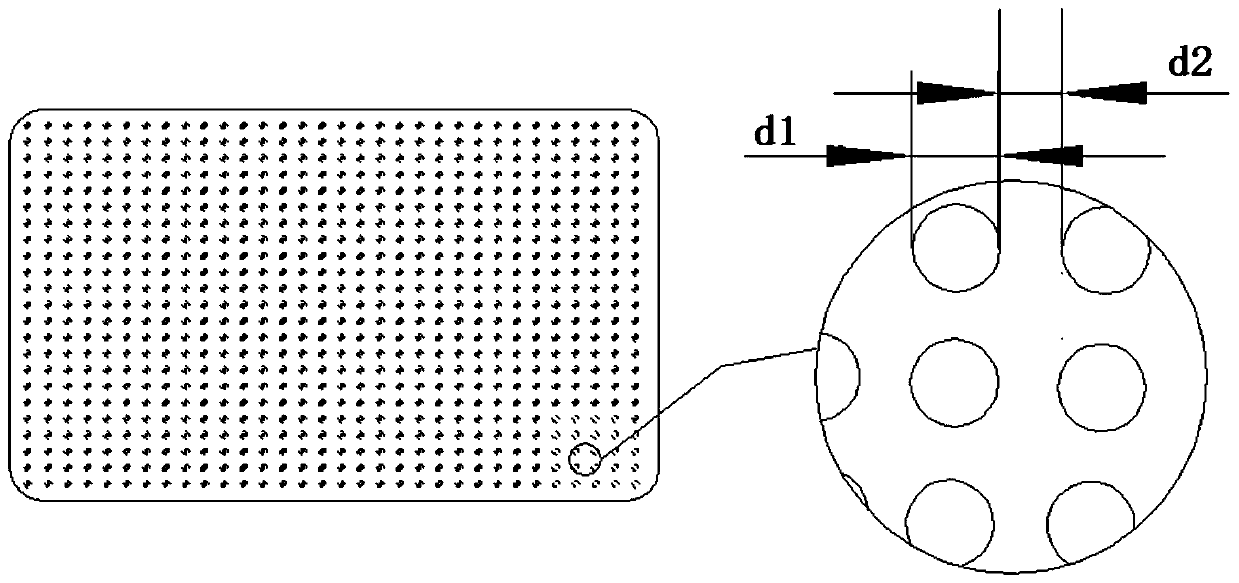

Sensitive film, MEMS microphone and manufacturing method thereof

ActiveCN112235697AIncrease amplitudeImprove structural strengthMicrophonesDiaphragm materialsEngineeringMems microphone

The invention discloses a sensitive film, an MEMS microphone and a manufacturing method thereof, and the sensitive film comprises: a sensing part which is used for sensing a vibration signal; a connecting part which is arranged around the sensing part and is used for fixing the sensing part; an action part which is connected with the sensing part and the connecting part, wherein the rigidity of the action part is smaller than that of the sensing part and / or that of the connecting part; and a reinforcing part, wherein the reinforcing part is arranged on the action part. According to the technical scheme, the structural strength of the sensitive film is improved, and the probability that the sensitive film is broken and fails is reduced.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

Piezoelectric MEMS microphone

ActiveCN111405441ASolve technical problems such as sensitivityDiaphragm materialsSemiconductor electrostatic transducersPiezoelectric memsEngineering

The invention relates to the technical field of acoustoelectric conversion and provides a piezoelectric MEMS microphone. The piezoelectric MEMS microphone comprises a substrate with a back cavity anda piezoelectric vibrating diaphragm, the piezoelectric vibrating diaphragm comprises a suspension part and a substrate fixing part connected with the substrate; the piezoelectric vibrating diaphragm further comprises a supporting part connected with the substrate fixing part and the suspension part, the suspension part is suspended above the back cavity through the supporting part; the piezoelectric MEMS microphone further comprises a limiting structure, the suspension part comprises a middle film overlapped with the projection range of the limiting structure in the vibration direction, and the limiting structure and the middle film form a fixing structure of the piezoelectric vibrating diaphragm. After the oxide layer of the piezoelectric vibrating diaphragm is released, the middle diaphragm deforms upwards or downwards under the action of residual stress in the piezoelectric vibrating diaphragm and is connected with the corresponding limiting structure so as to completely release stress and gradient stress. By applying the technical scheme, the technical problem that in the prior art, due to uneven stress distribution in the machining process, deformation of the diaphragm is notuniform, and then consistency of performance such as sensitivity of the microphone is affected is solved.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

Display device

ActiveUS11201194B2Improve featuresExhibit better acoustic and low-frequency output characteristicsDiaphragm materialsStatic indicating devicesPorous layerDisplay device

The display device comprises: a display panel; a sound generator under the display panel; a frame disposed under the display panel and the sound generator; and a porous layer disposed adjacent to the sound generator between the display panel and the frame and having a plurality of air pockets, wherein the porous layer has a porosity of about 90% or more.

Owner:SAMSUNG DISPLAY CO LTD

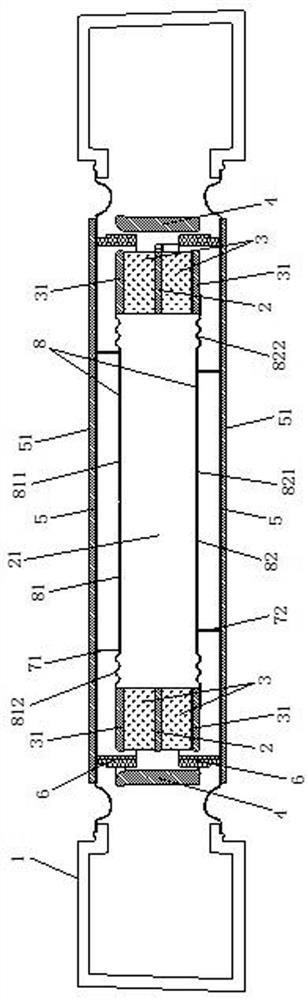

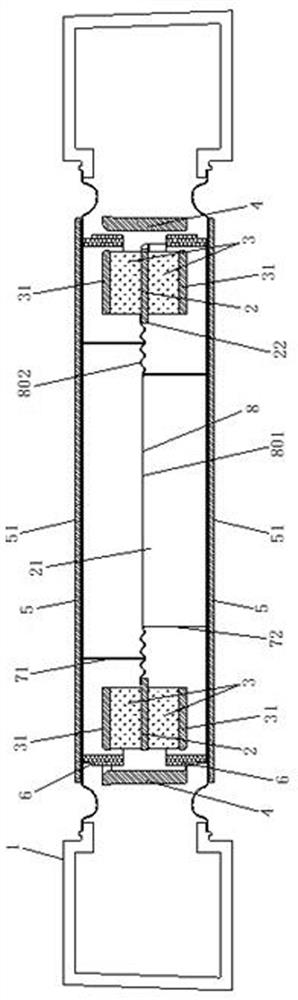

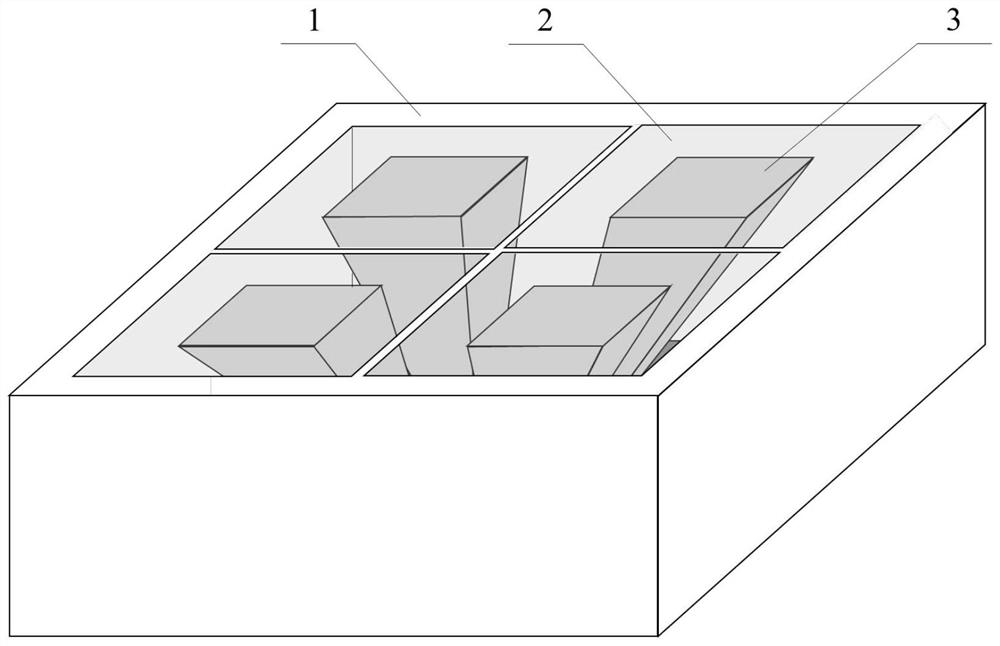

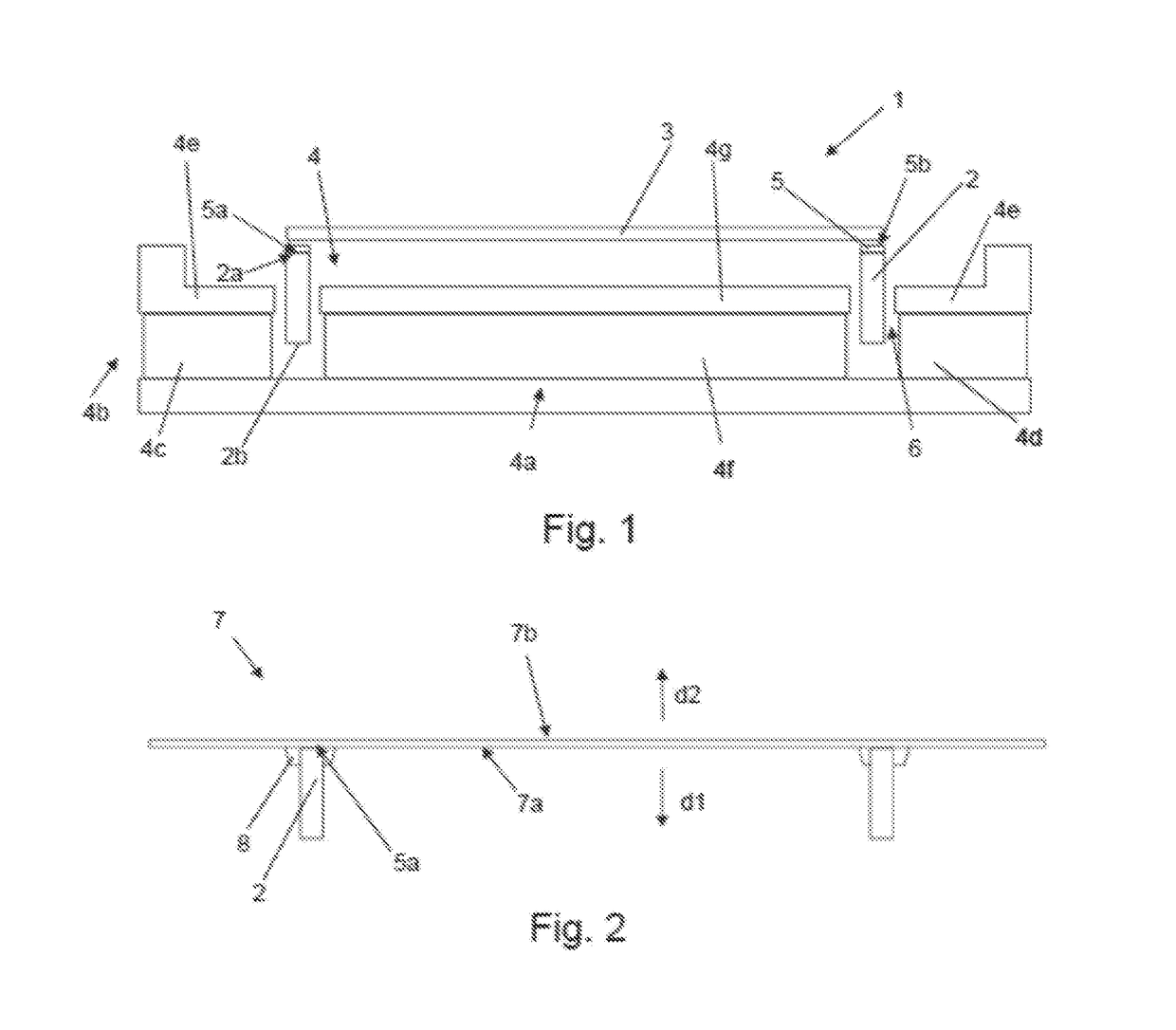

Frequency response adjustable miniature sound pressure amplification structure

PendingCN113810823ASignificant technological advancementSignificant practicalityDiaphragm materialsBone conduction transducer hearing devicesMechanical engineeringSound pressure

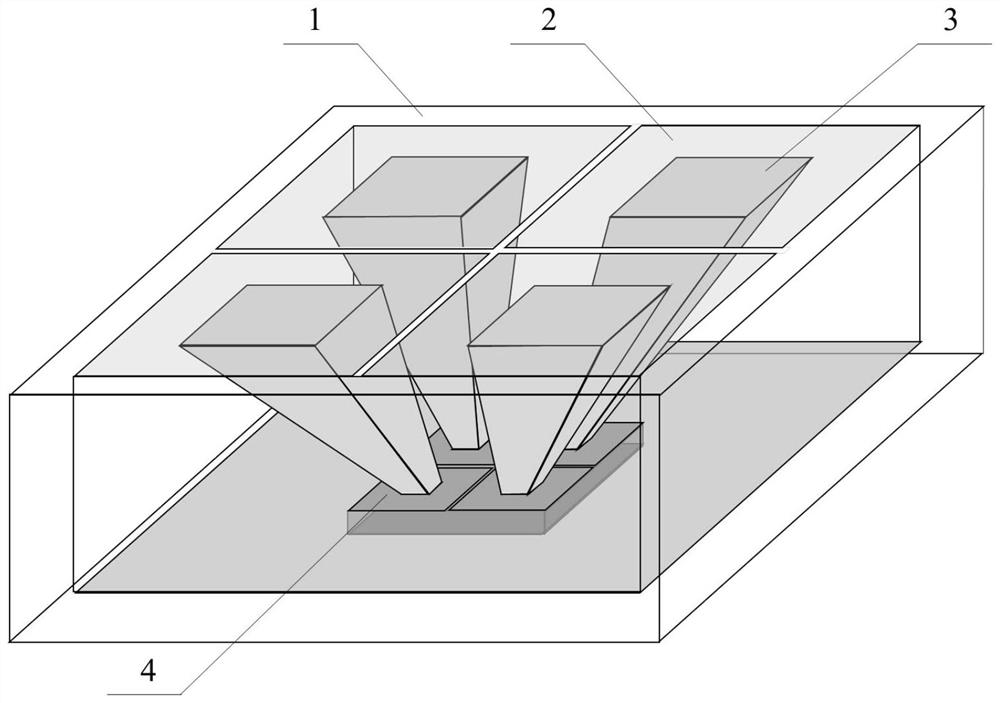

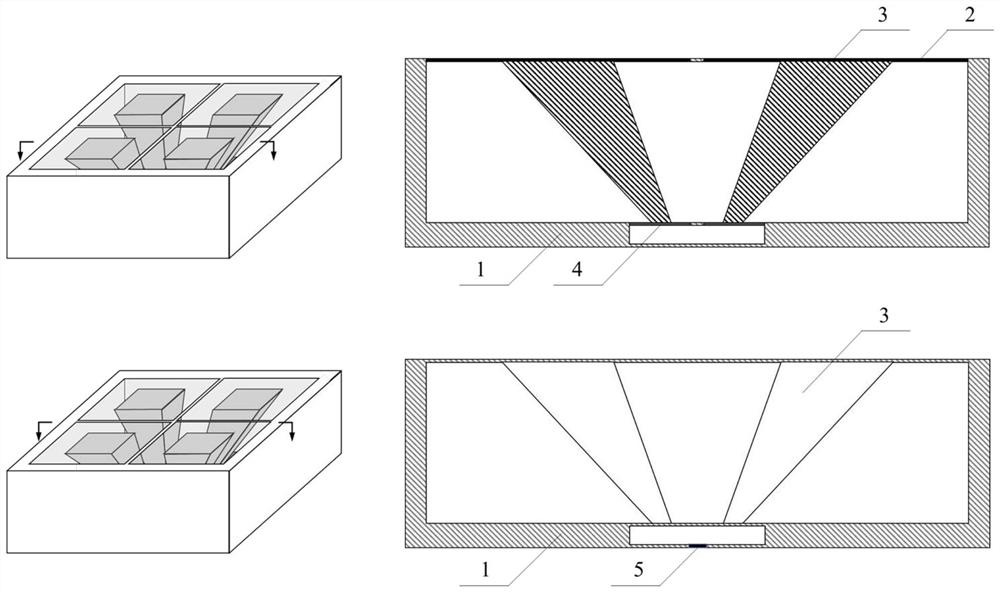

The invention provides a frequency response adjustable miniature sound pressure amplification structure which comprises a shell (1), a plurality of primary sensitive membranes (2), a plurality of connecting rods (3), a plurality of secondary sensitive membranes (4) and a terminal sensitive membrane (5), and the shell is of a rigid structure and comprises two cavity structures; the plurality of primary sensitive membranes are used as receiving ends of sound pressure signals and are fixed on the upper surface frame of the shell (1) to form a first boundary condition of peripheral fixed support; the plurality of connecting rods are respectively connected with the centers of the plurality of primary sensitive membranes and the plurality of secondary sensitive membranes, so that the primary sensitive membranes and the secondary sensitive membranes move together under the action of sound pressure; the plurality of primary sensitive membranes, the plurality of secondary sensitive membranes and the shell jointly form a first sealing cavity; a plurality of secondary sensitive membranes are fixed on the frame in the shell to form the second boundary condition of the peripheral fixed support, and form the second sealing cavity with the terminal sensitive membrane and the shell; and the terminal sensitive membranes serving as the amplification end of thea sound pressure signal is fixed on the lower surface of the shell to form a third boundary condition of the peripheral fixed support.

Owner:BEIHANG UNIV

Vibration device and apparatus including the same

PendingUS20220210577A1Improve the level ofDiaphragm materialsPiezoelectric/electrostrictive resonant transducersMetal particleAcoustics

A vibration device can include a vibration portion; a first electrode portion disposed on a first surface of the vibration portion; and a second electrode portion disposed on a second surface of the vibration portion, in which each of the first and second electrode portions include at least one of a conductive metal particle and a carbon particle.

Owner:LG DISPLAY CO LTD

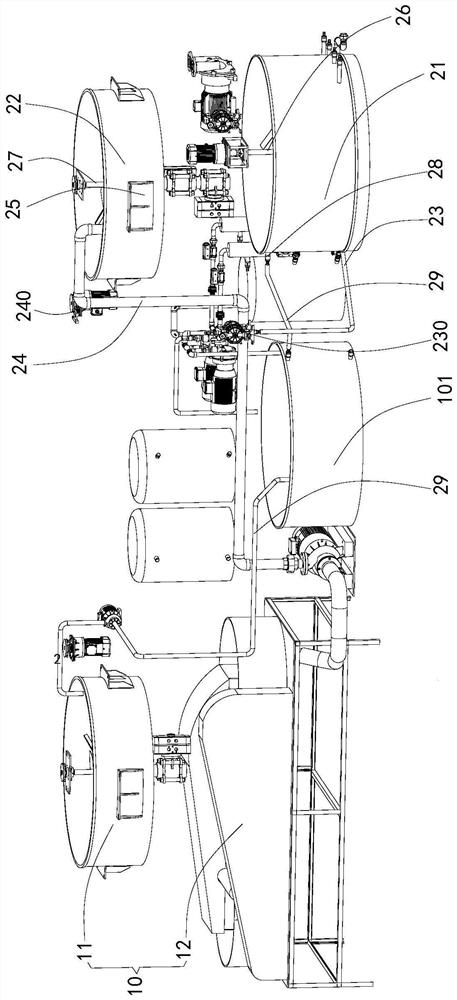

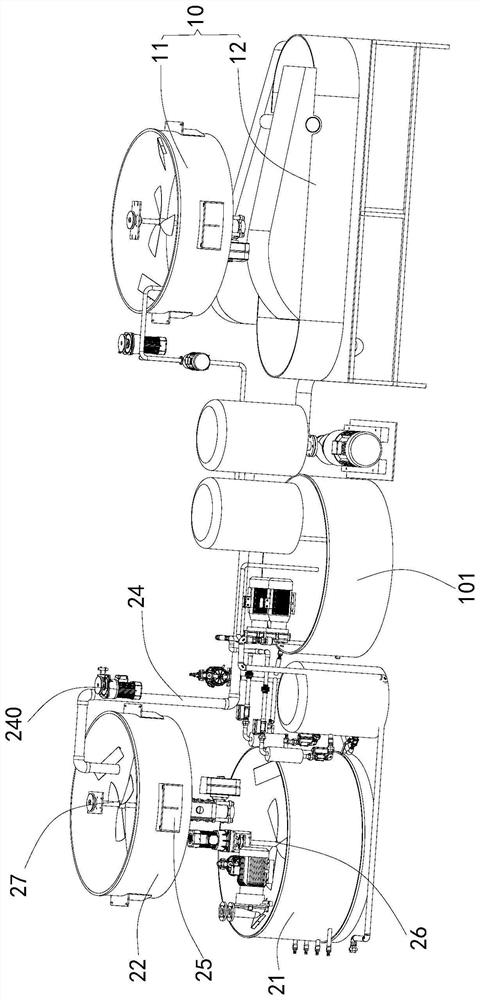

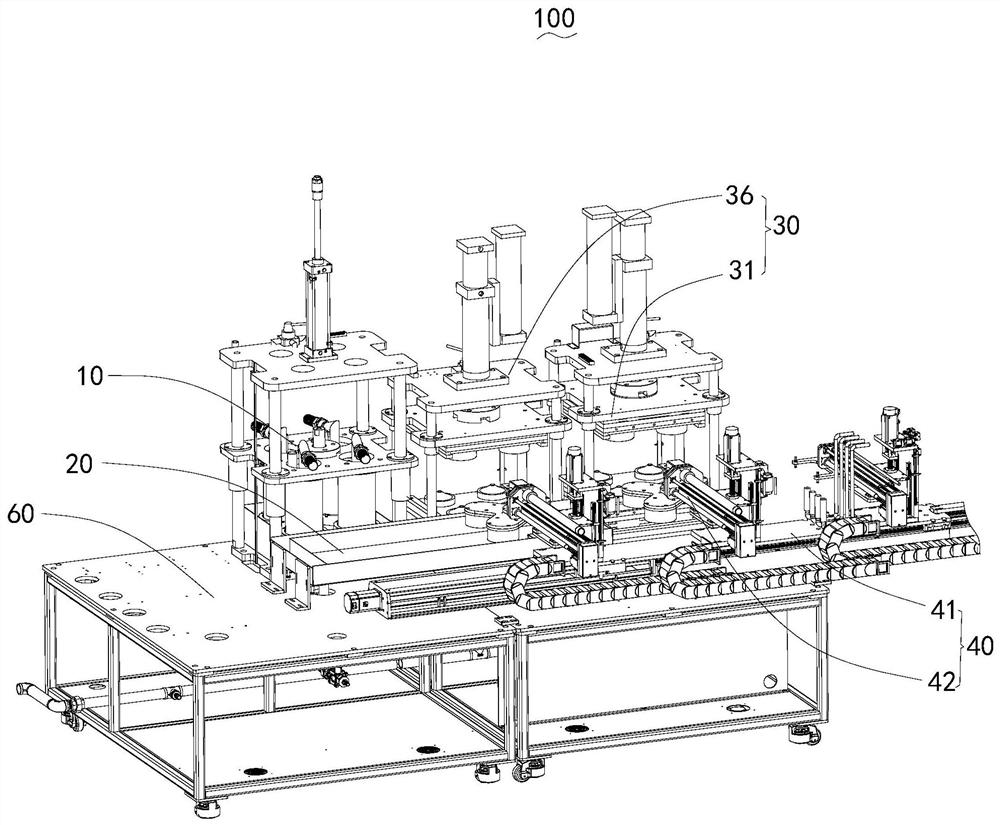

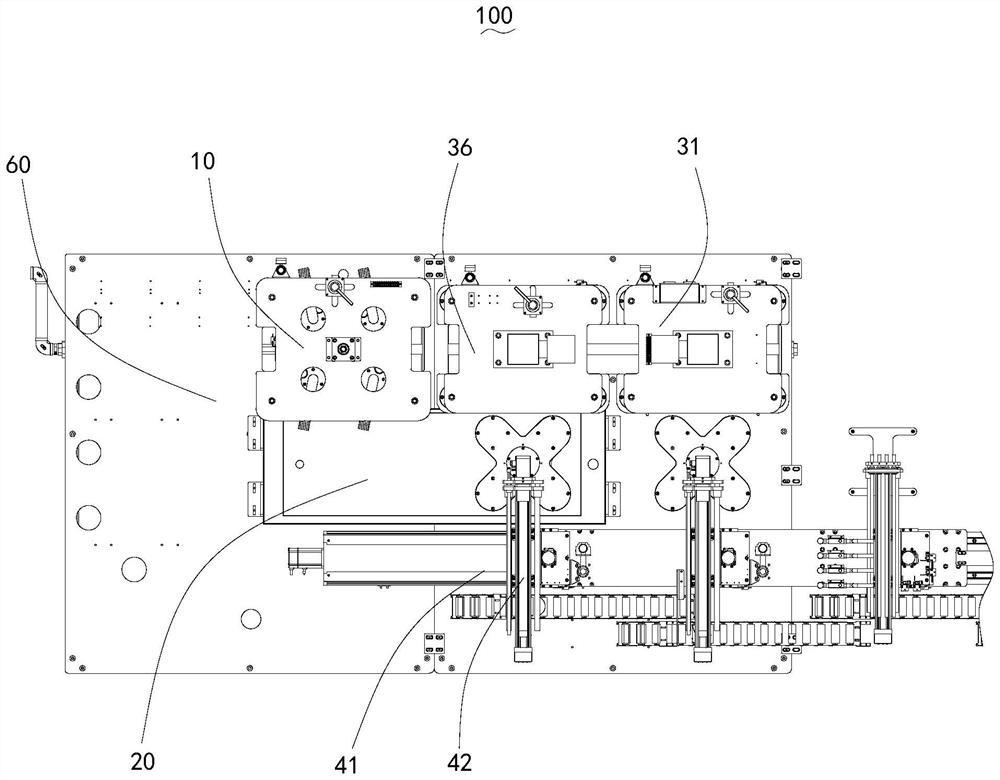

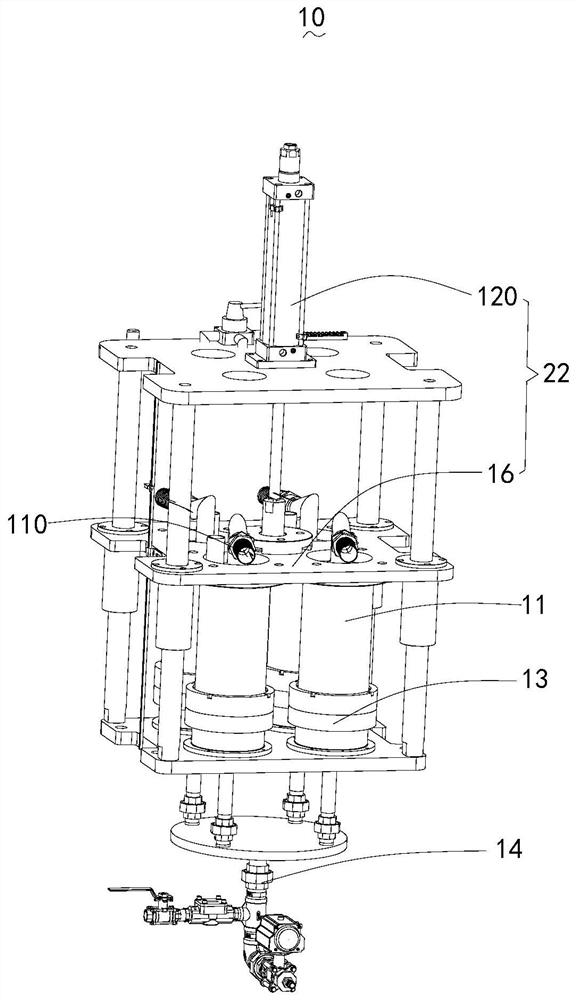

Drum paper carcass production device

PendingCN114257946ALow costConsistent concentrationDiaphragm materialsDiaphragm constructionFiberWastewater

The invention discloses a drum paper carcass production device. The drum paper carcass production device comprises a pulping mechanism, a feeding mechanism, a pumping mechanism and a forming mechanism, the pulping mechanism comprises a pulping container, and the pulping container is used for mixing fiber materials and water and beating the mixture into fiber pulp; the feeding mechanism comprises a feeding container and a supplementing container, the feeding container is used for quantitatively providing a first volume of fiber slurry, and the supplementing container is used for quantitatively supplementing the first volume of fiber slurry to the feeding container; the material pumping mechanism is communicated with the material supply container and is used for quantitatively pumping the fiber slurry from the material supply container; the forming mechanism comprises an initial pressing component, a coloring container, a displacement assembly and a pressing assembly. According to the drum paper carcass production device, continuous feeding can be achieved, and the production efficiency is greatly improved; pigment and chemical agents do not need to be added in the early stage, no wastewater is discharged, environment friendliness is achieved, and the water treatment cost and the water resource cost are greatly saved; and the concentration of each batch of fiber pulp is consistent, so that the consistency and yield of products are ensured.

Owner:JIANGSU FENGDI TECH CO LTD

Dustproof cap-support chip integrated loudspeaker

PendingCN110691309AGuaranteed ultra-thinIncrease powerDiaphragm materialsLoudspeakerMechanical engineering

The invention discloses a dustproof cap-support chip integrated loudspeaker. The loudspeaker comprises a basin stand, a magnetic circuit system arranged at the center of the basin stand and a vibration system located at the periphery of the magnetic circuit system, wherein the vibration system comprises a sound cone and a voice coil; the outer side of the sound cone is fixed with the basin stand through a folding ring. The center of the sound cone is provided with a through hole, wherein the through hole is fixed with the voice coil, the voice coil is arranged at the periphery of the magneticcircuit system, the voice coil is connected with a support chip, the other end of the support chip is fixed on the magnetic circuit system, the magnetic circuit system sequentially comprises a magnetic sheet, magnetic steel and a magnetic bowl from top to bottom, and the magnetic bowl is arranged inside the basin stand. The loudspeaker has the beneficial effects that the support chip is designed above the voice coil and the magnetic circuit, and the characteristics of high power, low distortion and good stability are realized on the premise that the loudspeaker is ultrathin.

Owner:JIAXING KEYSOUND ELECTRONICS CO LTD

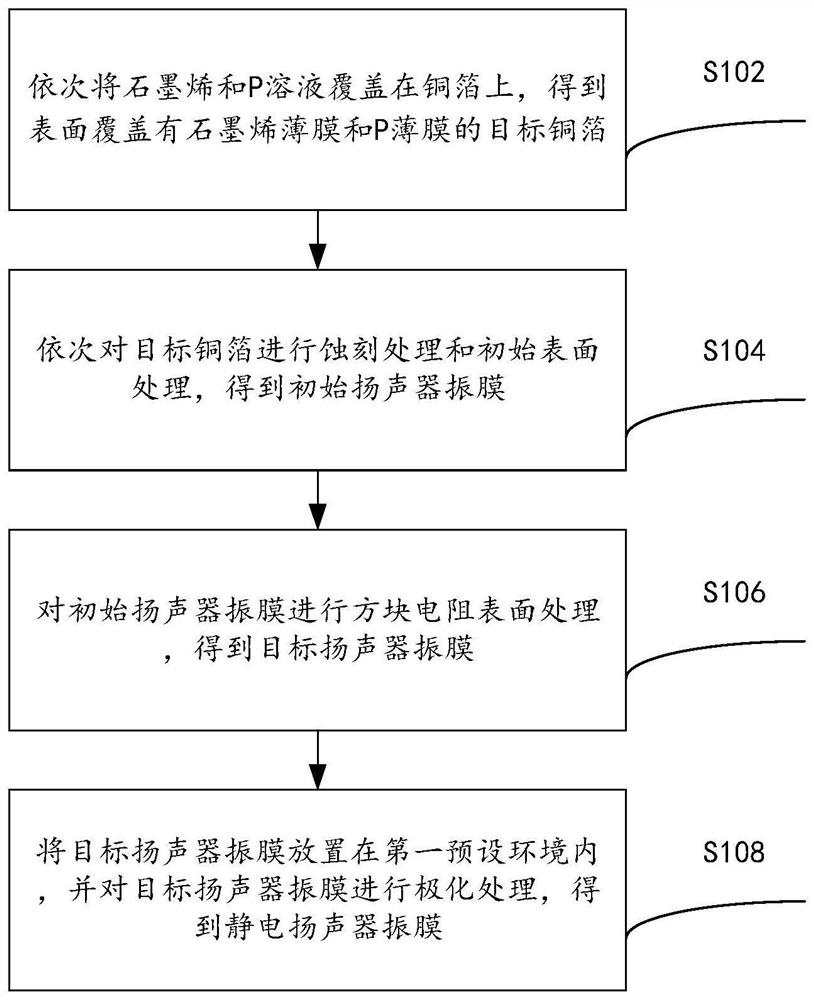

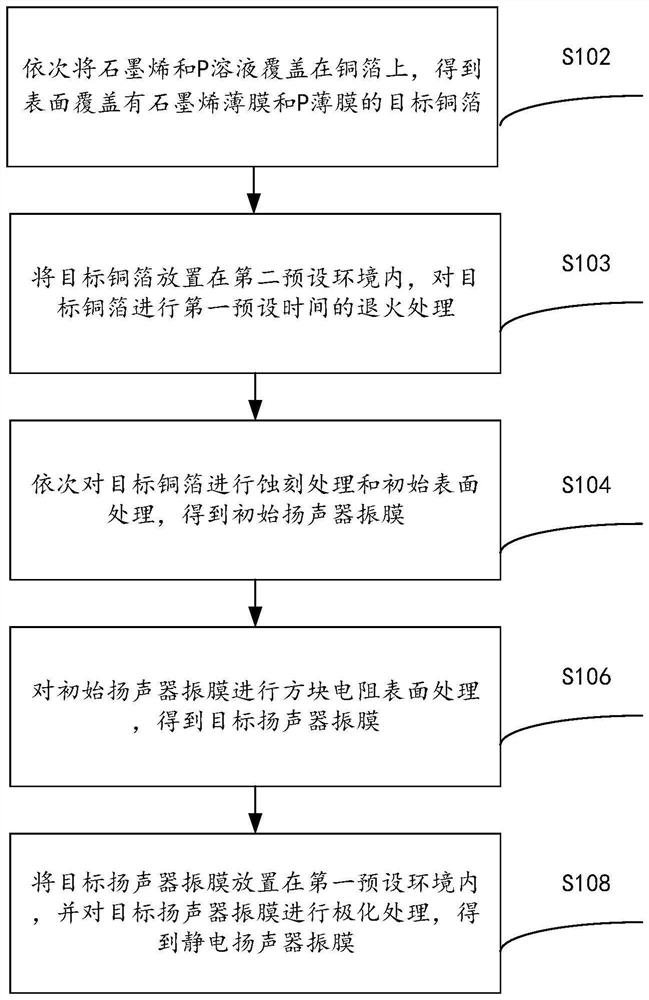

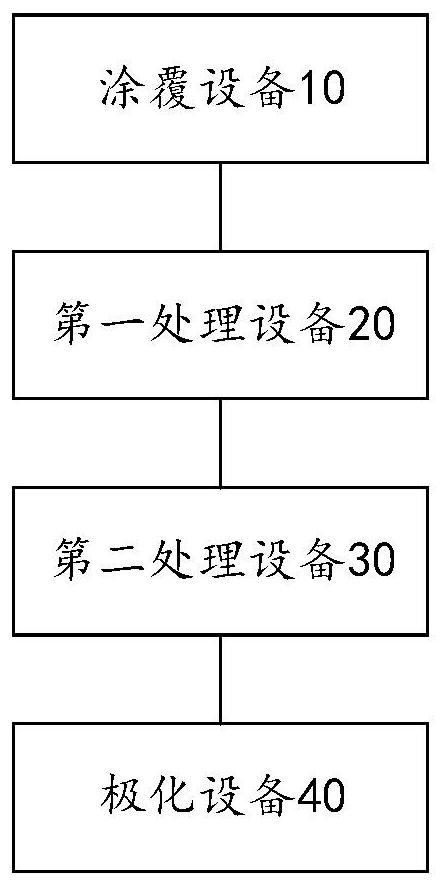

A kind of preparation method and device of electrostatic loudspeaker diaphragm

The invention provides a preparation method and device for an electrostatic speaker diaphragm, which relates to the technical field of electronic equipment, including: sequentially covering graphene and P solution on copper foil to obtain a target whose surface is covered with graphene film and P film Copper foil; perform etching treatment and initial surface treatment on the target copper foil in sequence to obtain the initial speaker diaphragm; perform square resistance surface treatment on the initial speaker diaphragm to obtain the target speaker diaphragm; place the target speaker diaphragm on the first preset In the environment, the target speaker diaphragm is polarized to obtain the electrostatic speaker diaphragm, which solves the technical problems of edge vibration distortion and phase lag of the electrostatic speaker diaphragm in the prior art.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

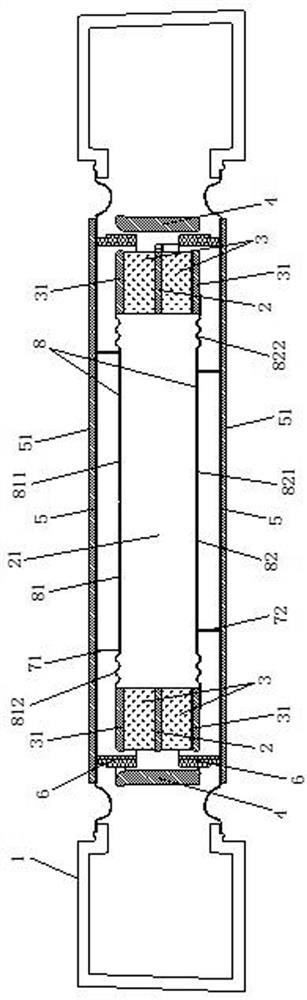

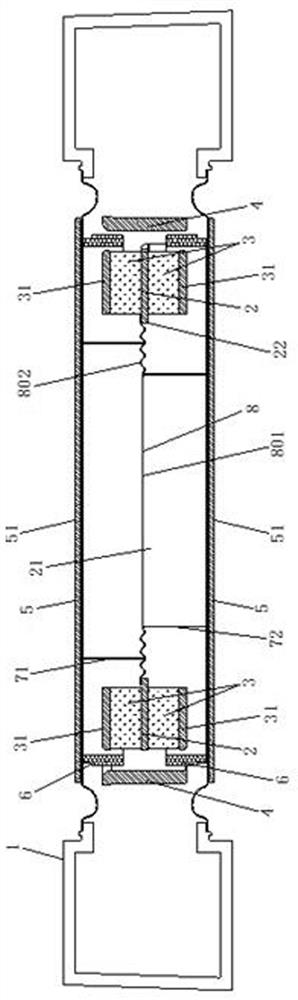

Sounder and electronic product including the sounder

ActiveCN111901734BImprove polarizationSolve the problem of asymmetric elastic distributionDiaphragm materialsEngineeringAcoustics

The invention discloses a sounder and an electronic product including the sounder, comprising: a housing; a magnetic circuit system located in the housing; the magnetic circuit system includes a side magnetic part and a central magnetic part; the central magnetic part includes a Support plate; and two central magnets located on both sides of the support plate; the central magnetic part is a central hollow structure; two sets of vibration components are located on both sides of the support plate, each set of vibration components includes a diaphragm and a voice coil; sound The device also includes a centering structure located on the inner side of the central hollow edge of the central magnetic part. The centering structure includes two ring skeletons respectively connected and fixed on the central parts of the two diaphragms. The adjacent ends of the two ring skeletons are connected and fixed with elastic supports. The outer edge of the elastic support is connected and fixed on the central magnetic part of the hollow edge. The invention can reduce the polarization generated when the double-diaphragm vibrates in the two-way sounder structure, reduce product distortion, and improve product performance and stability.

Owner:GOERTEK INC

Microphone with double back polar plates and manufacturing method thereof

PendingCN114422930AImprove adhesionImprove yieldDiaphragm materialsLayered productsElectrical connectionEngineering

The microphone comprises a substrate, a first sacrificial layer, a lower back polar plate, a second sacrificial layer, a vibrating diaphragm, a third sacrificial layer and an upper back polar plate which are sequentially stacked from bottom to top, the first conductive channel downwards penetrates through the second sacrificial layer from the surface of the second sacrificial layer to the lower back electrode plate; the second conductive channel penetrates through the third sacrificial layer and is connected with the first conductive channel; the first electrode and the third electrode are isolated from each other and located on the upper back pole plate, the first electrode is electrically connected with the lower back pole plate through the second conductive channel and the first conductive channel, and the third electrode is electrically connected with the upper back pole plate. According to the microphone with the double back polar plates, the electrode on the lower back polar plate and the electrode of the vibrating diaphragm are connected to the upper back polar plate when the vibrating diaphragm and the upper back polar plate layer are deposited, so that the adhesive force between the conductive channel and the lower back polar plate and the vibrating diaphragm is improved, and the yield and the reliability of a device are improved.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

Drum paper carcass forming device

The invention discloses a drum paper carcass forming device. The drum paper carcass forming device comprises a forming mechanism and a forming mechanism, wherein the forming mechanism is used for receiving fiber pulp and forming the fiber pulp into an initial pressing piece; the coloring mechanism is arranged on one side of the forming mechanism and used for containing coloring liquid; the shifting mechanism comprises a shifting driving part and a mechanical arm installed on the shifting driving part, and the mechanical arm is driven by the shifting driving part to move so as to move the primary pressing piece into the coloring mechanism to be colored and then move the colored primary pressing piece; and the pressing mechanism is used for receiving the colored primary pressing piece and pressing and forming the colored primary pressing piece. According to the drum paper carcass forming device, the drum paper carcass is dyed after being formed, no chemical component is added into the pigment, and the pigment is not in direct contact with the environment, so that the drum paper carcass forming device is environment-friendly, and the water treatment cost is greatly saved.

Owner:JIANGSU FENGDI TECH CO LTD

Vibration-generating apparatus and vehicle including the same

PendingUS20220210530A1High-quality soundPrivacy protectionMicrophonesDiaphragm materialsSound sourcesNoise removal

A vibration-generating apparatus, includes: a microphone apparatus disposed at an object including a plurality of regions, the microphone apparatus being configured to receive noise near the object, a sound processing circuit configured to: receive a sound source signal and a noise signal corresponding to the noise, generate a noise removal signal having an antiphase of the noise signal, and generate a vibration driving signal, based on the sound source signal and the noise removal signal, and a vibration apparatus disposed at the object to vibrate based on the vibration driving signal to vibrate the object.

Owner:LG DISPLAY CO LTD

Coil extension element

ActiveUS11051111B2Improve acoustic performanceReduce Harmonic DistortionDiaphragm materialsLoudspeakersEngineeringLoudspeaker

A dynamic loudspeaker driver comprising a magnet-system; a membrane; the membrane being movably mounted with respect to the magnet-system; at least one voice coil attached to the membrane and operatively coupled with the magnet-system, wherein the voice coil comprises an upper edge facing the membrane and a lower edge being arranged opposite the upper edge of the voice coil; at least one voice coil extension element comprising an upper surface facing the membrane and a lower surface facing the upper edge of the voice coil, wherein the lower surface of the voice coil extension element is attached the upper edge of the voice coil while the upper surface of the voice coil extension element is attached to the membrane.

Owner:SOUND SOLUTIONS INTERNATIONAL COMPANY LTD

Vibrating device and equipment comprising same

PendingCN114697834ADiaphragm materialsPiezoelectric/electrostrictive resonant transducersMetal particleMechanical engineering

The invention relates to a vibration device and equipment comprising the same. A vibration device includes a vibration portion, a first electrode portion disposed at a first surface of the vibration portion, and a second electrode portion disposed at a second surface of the vibration portion, where the first electrode portion and the second electrode portion include at least one of conductive metal particles and carbon particles.

Owner:LG DISPLAY CO LTD

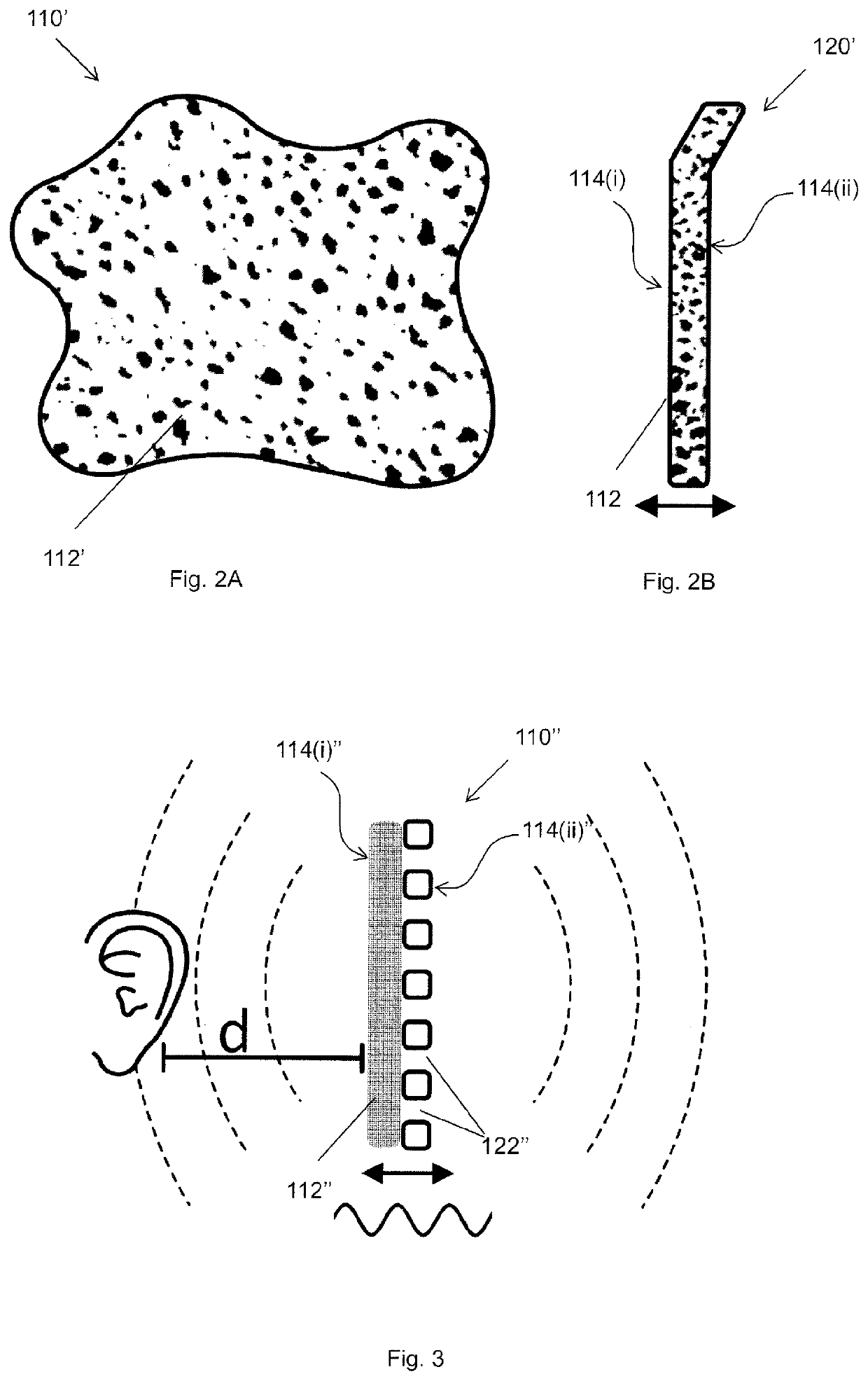

Dipole loudspeaker for producing sound at bass frequencies

PendingUS20220210543A1Excellent sound absorption qualityAvoid less frictionDiaphragm materialsLoudspeakersBass (sound)Loudspeaker

A dipole loudspeaker for producing sound at bass frequencies. The dipole loudspeaker includes: a diaphragm having a first radiating surface and a second radiating surface, wherein the first radiating surface and the second radiating surface are located on opposite faces of the diaphragm; a drive unit configured to move the diaphragm at bass frequencies such that the first and second radiating surfaces produce sound at bass frequencies, wherein the sound produced by the first radiating surface is in antiphase with sound produced by the second radiating surface; a frame, wherein the diaphragm is suspended from the frame via one or more suspension elements, wherein the frame is configured to allow sound produced by the first radiating surface to propagate out from a first side of the dipole loudspeaker and to allow sound produced by the second radiating surface to propagate out from a second side of the dipole loudspeaker. The diaphragm includes a region of porous material having a specific airflow resistance in the range 5-5000 Pa·s / m, wherein the diaphragm is configured to permit airflow through at least part of said region of porous material from the first radiating surface of the diaphragm to the second radiating surface of the diaphragm.

Owner:PSS BELGIUM

Coil extension element

ActiveUS20190052972A1Improve acoustic performanceReduce Harmonic DistortionDiaphragm materialsLoudspeakersEngineeringLoudspeaker

A dynamic loudspeaker driver comprising a magnet-system; a membrane; the membrane being movably mounted with respect to the magnet-system; at least one voice coil attached to the membrane and operatively coupled with the magnet-system, wherein the voice coil comprises an upper edge facing the membrane and a lower edge being arranged opposite the upper edge of the voice coil; at least one voice coil extension element comprising an upper surface facing the membrane and a lower surface facing the upper edge of the voice coil, wherein the lower surface of the voice coil extension element is attached the upper edge of the voice coil while the upper surface of the voice coil extension element is attached to the membrane.

Owner:SOUND SOLUTIONS INTERNATIONAL COMPANY LTD

Popular searches

Printed circuit aspects Piezoelectric/electrostrictive transducers Printed circuit manufacture Transducer diaphragms Non-linear optics Input/output processes for data processing Electrostatic transducer microphones Diaphragm mounting/tensioning Measurement devices Electrostatic transducer loudspeakers

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com