Patents

Literature

48results about How to "Significant technological advancement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

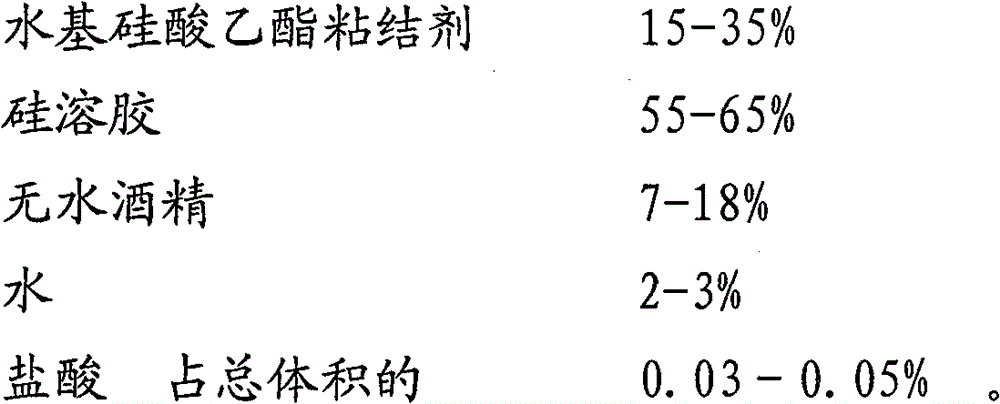

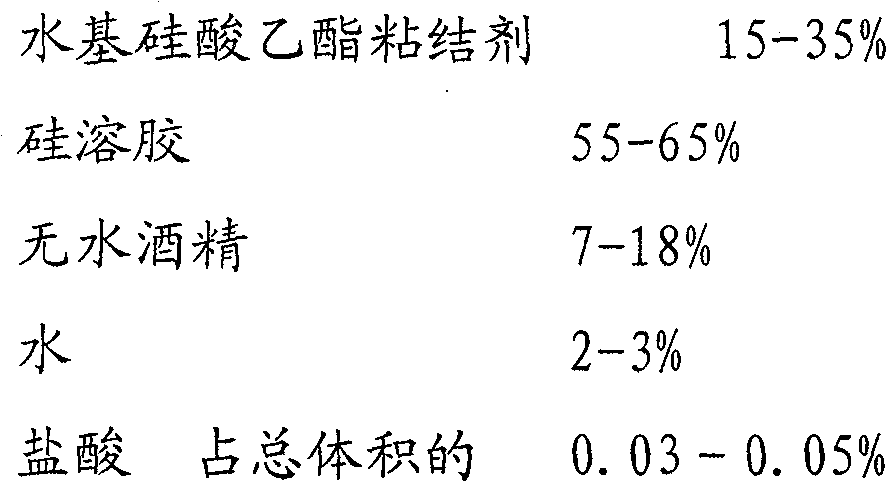

New method for manufacturing composite coating shell for precisely casting fusible patterns

InactiveCN101642798AHigh dimensional accuracyHigh refractorinessFoundry mouldsFoundry coresMetallurgyProduction cycle

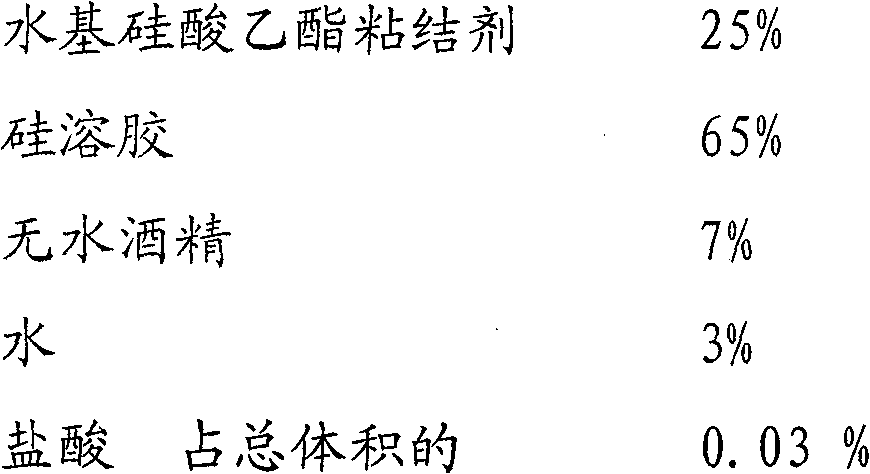

The invention relates to a new method for manufacturing a composite coating shell for precisely casting fusible patterns, and belongs to the field of precise casting. The method comprises the following steps: using water-based ethylsilicate-silica sol as a mixed binder, preparing mixed binder paint by mixing the mixed binder with refractory powders and a curing agent, painting the mixed binder paint on the surface of a fusible pattern to form a monolayer or multilayer coating bottom layer, and sequentially painting a monolayer water glass binder paint transition coating and a multilayer waterglass binder paint enhanced coating on the bottom layer, thereby forming the composite coating shell for precisely casting the fusible pattern, wherein the composite coating shell consists of a mixedbinder coating bottom layer and a water glass binder coating enhanced skin coat. The invention solves the manufacturing difficult points of the shells with complicated inner cavities, deep blind holesand deep groove parts and the problems of slow drying, long production periods, low quality and the like of the shells existing in a precise casting trade for a long time, comprehensively improves the quality of precision castings, markedly reduces the production cost, is favorable for environment protection and is a creative breakthrough for a traditional technique in the field.

Owner:武汉工控艺术制造有限公司

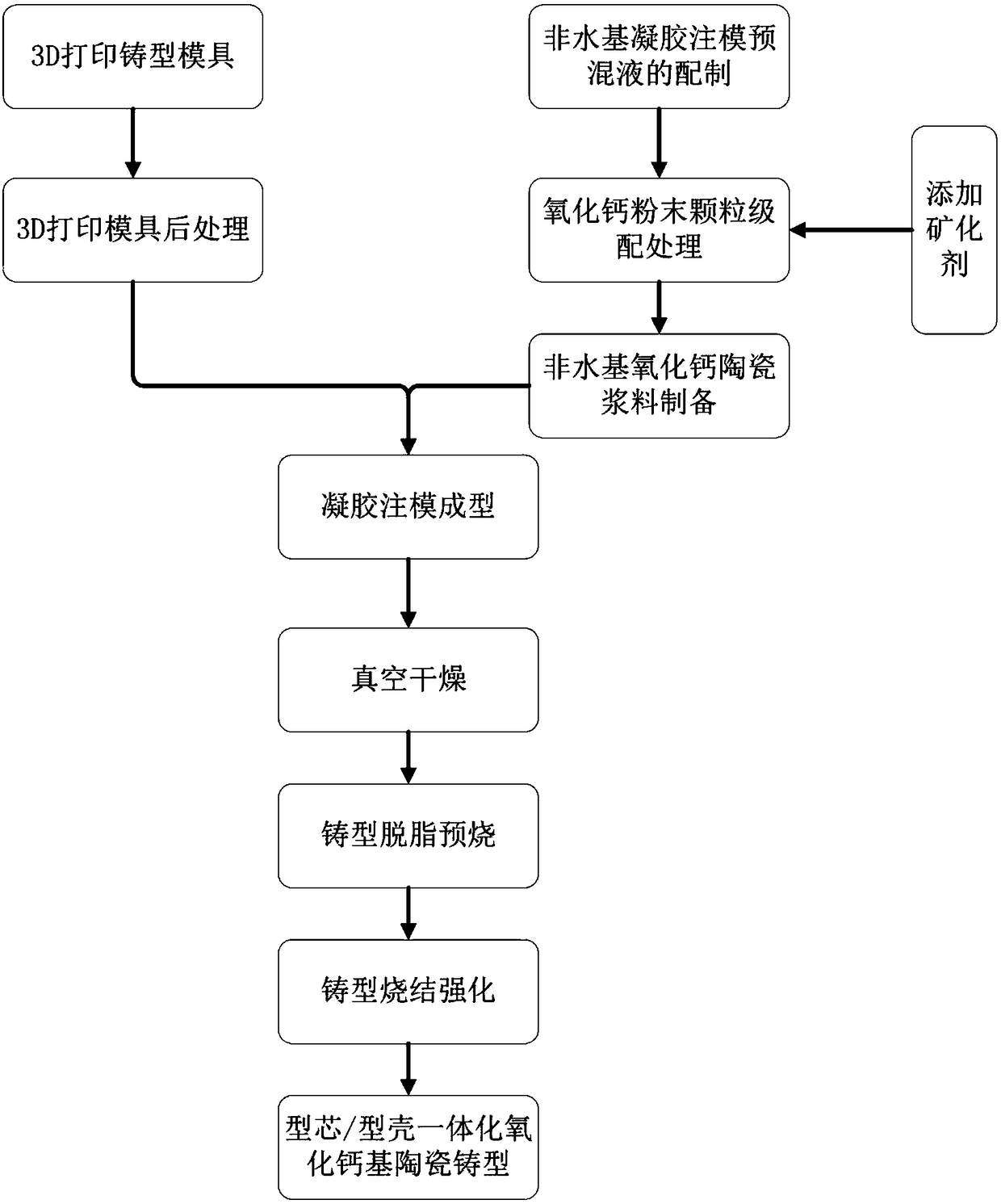

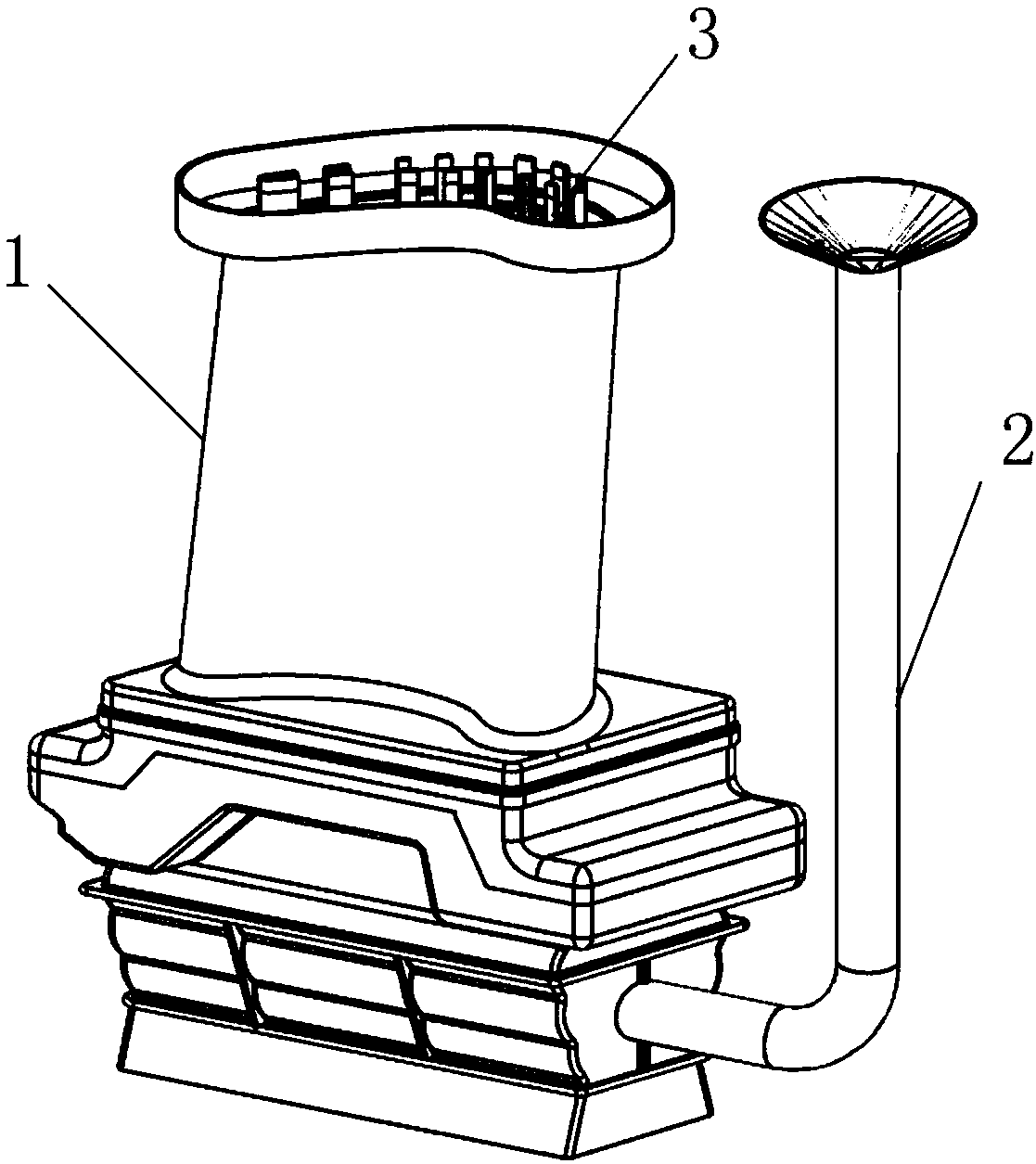

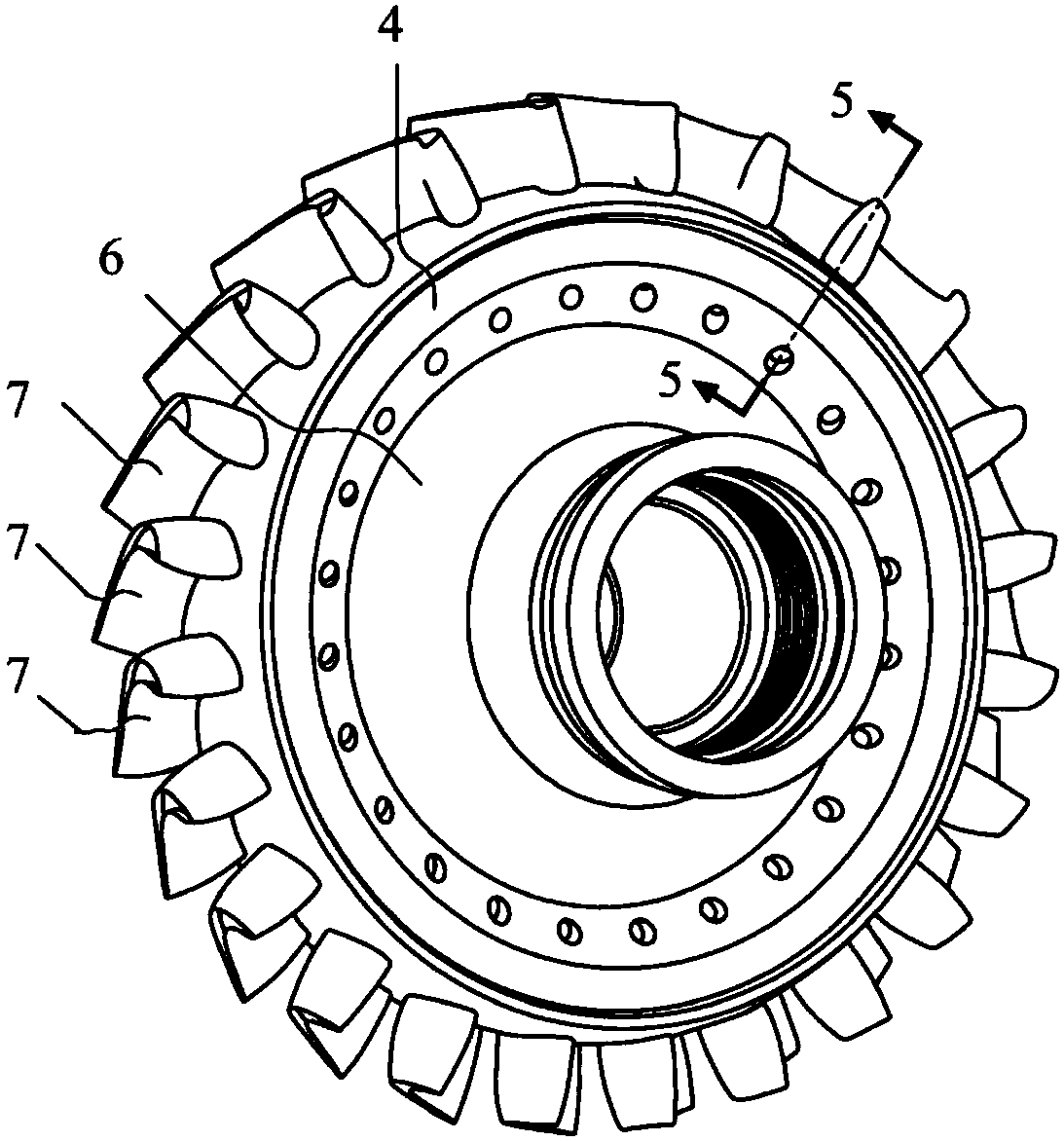

Non-water-based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and preparation method thereof

InactiveCN108059445AInhibition of hydrationImprove sintering performanceAdditive manufacturing apparatusWater basedNiobium

The invention discloses a non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and a preparation method thereof, and belongs to the technical field of rapid precision casting. The method is characterized in that a mold required for 3D printing technology rapid manufacture is used, and simultaneously a non-water-based gel injection molding technology isapplied, so that the problem of hydration of calcium oxide powder during a casting mold preparation process is effectively solved, and the method can be successfully applied to the preparation of a mold core / mold shell integrated calcium oxide-based ceramic casting mold with complex internal structural parts and components. The manufactured calcium oxide-based ceramic casting mold has good overallperformance, and can meet the casting requirements of ultrahigh-temperature alloys such as a new generation of niobium-silicon-based high-temperature alloy and active light alloys such as titanium-aluminium alloy and magnesium-aluminium alloy, and the core removal performance is extremely excellent, so that the technical problems of difficult removal and high rejection rate of silicon oxide-basedand aluminium oxide-based mold cores are solved, therefore, the non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold is a huge improvement on an existinginvestment mold precision casting and molding technology, and has broad market prospect and market value.

Owner:XI AN JIAOTONG UNIV

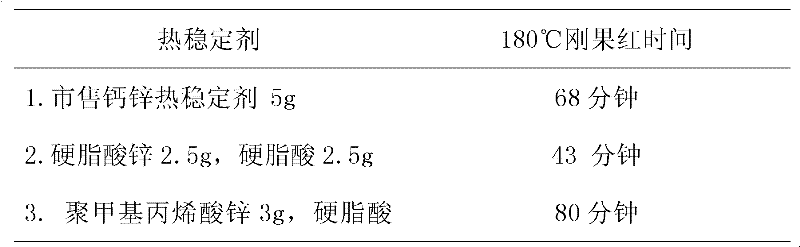

Polymer calcium zinc complex soap heat stabilizer, preparation method thereof and application thereof

The invention discloses a polymer calcium zinc complex soap heat stabilizer, which comprises the following compositions in parts by weight: 2 to 5 parts of polymer calcium zinc complex soap, 3 parts of polyol and / or polyhydric alcohol monoester, 0 to 3 parts of stearic acid soap and / or oleic soap, 0 to 1 part of epoxy compound, 0 to 0.5 parts of antioxidant and / or anti-aging agent, and 0 to 0.2 parts of fatty acid and / or lubricant. The materials are uniformly mixed and ground into a powder body at a room temperature, i.e. a finished polymer calcium zinc complex soap heat stabilizer product is obtained; and the finished polymer calcium zinc complex soap heat stabilizer product can be applied to the preparation of a chlorine-containing polymer, and can be preferably applied to the preparation of polyvinyl chloride, chlorinated polyethylene, vinylidene chloride and ACS (Acrylonitrile Chlorinated polyethylene Styrene) plastic. The polymer calcium zinc complex soap heat stabilizer provided by the invention overcomes the defects of the prior art, is safe and non-toxic, and has an excellent heat stabilizing effect.

Owner:HEBEI UNIVERSITY

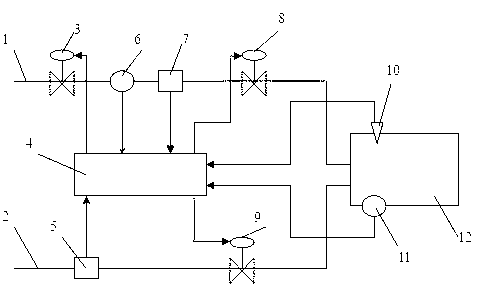

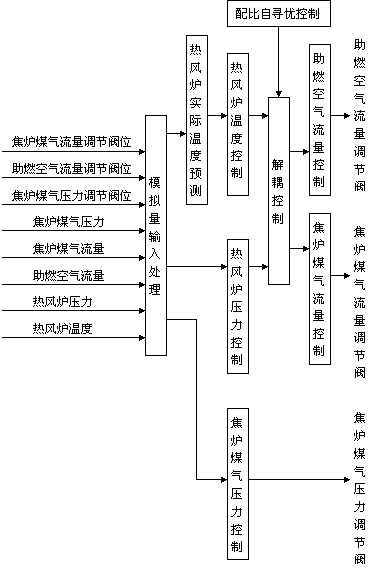

Temperature control device of flue gas desulfurizing and acid-making hot blast stove and control method

ActiveCN103307627AControl response speedOvercome temperatureFuel supply regulationTemperature controlHot air oven

A temperature control device of a flue gas desulfurizing and acid-making hot blast stove comprises a programmable controller, wherein a coke oven gas pressure regulating valve, a coke oven gas pressure sensor, a coke oven gas flow sensor and a coke oven gas flow regulating valve are mounted on a coke oven gas inlet pipeline; a combustion air flow sensor and a combustion air flow regulating valve are mounted on a combustion air inlet pipeline; a temperature sensor and a pressure sensor are mounted on the flue gas desulfurizing and acid-making hot blast stove; and the programmable controller exchanges signals with the coke oven gas pressure regulating valve, the coke oven gas pressure sensor, the coke oven gas flow sensor and the coke oven gas flow regulating valve on the coke oven gas inlet pipeline, exchanges signals with the combustion air flow sensor and the combustion air flow regulating valve on the combustion air inlet pipeline, and exchanges signals with the hot blast stove temperature sensor and the hot blast stove pressure sensor on the flue gas desulfurizing and acid-making hot blast stove. The temperature control device of the flue gas desulfurizing and acid-making hot blast stove can quickly and accurately control the temperature and the pressure of the hot blast stove, so that the hot blast stove can meet flue gas desulfurizing and acid-making requirements of a sintering machine.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

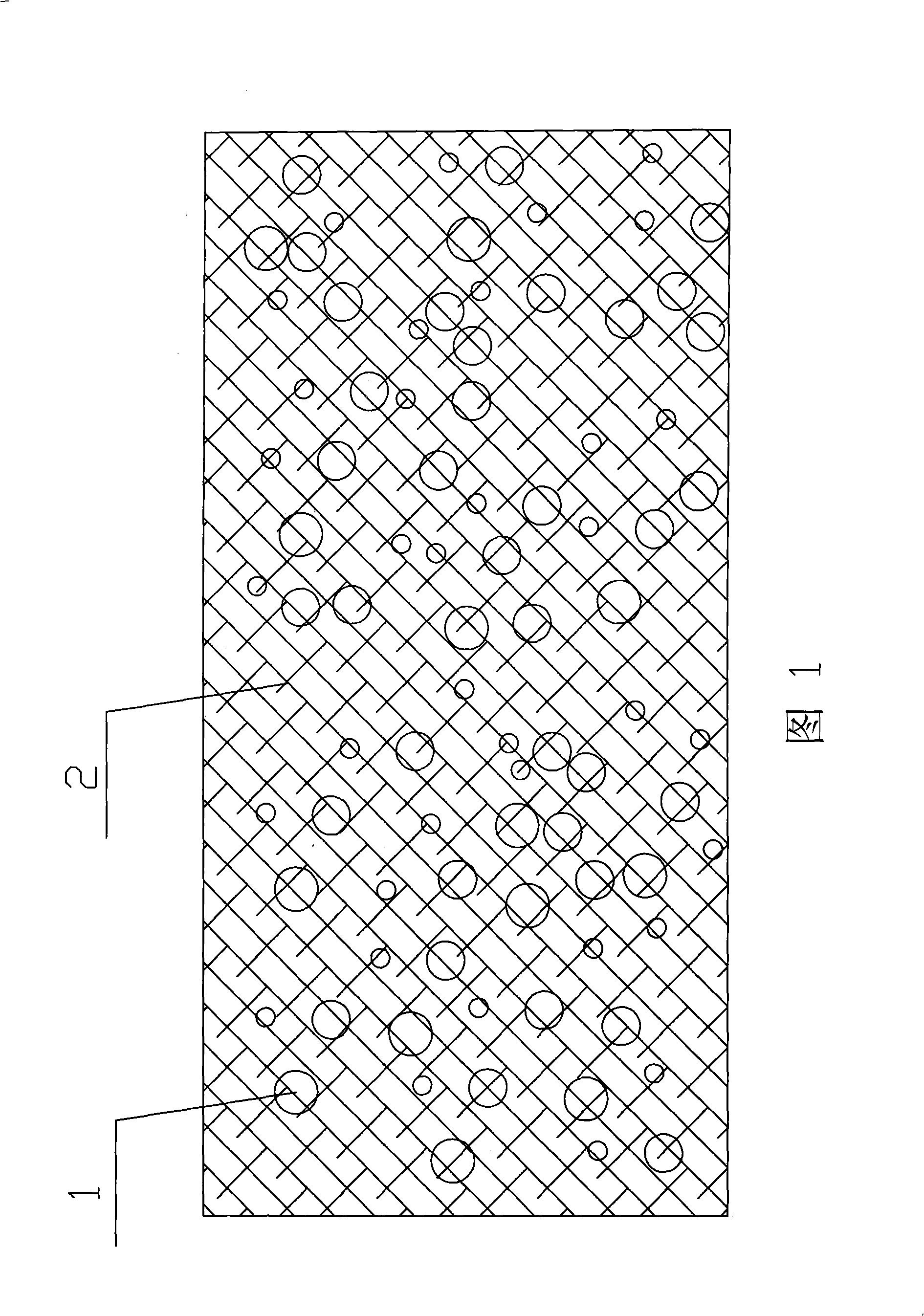

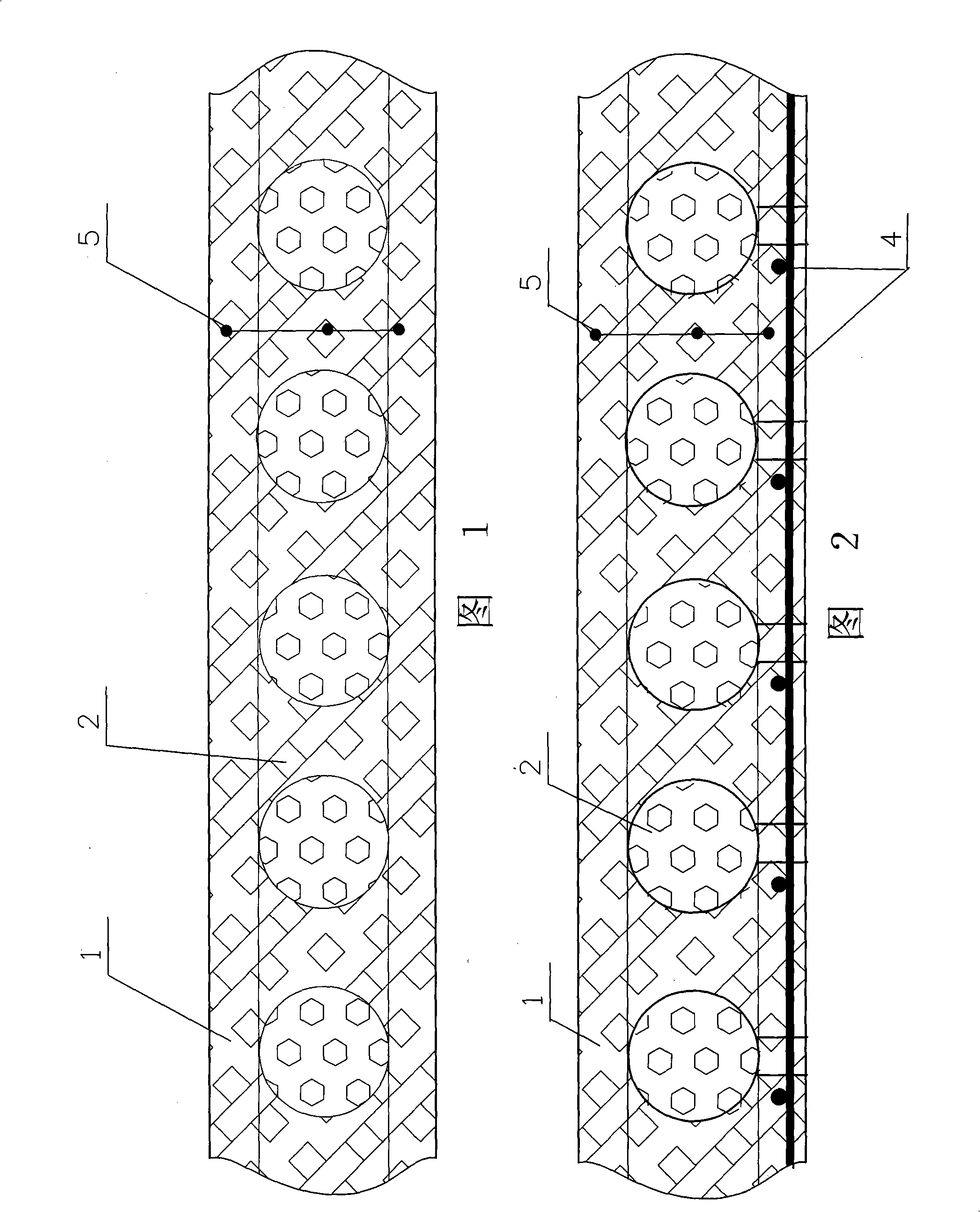

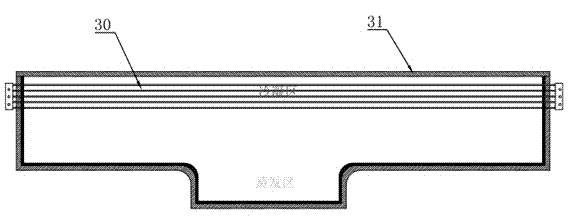

Carbon fiber autoclaved aerated concrete slab and application thereof

The invention relates to an autoclaved aerated concrete slab containing carbon fibers and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises building concrete structural slabs (1), wherein the concrete is autoclaved aerated concrete, and the concrete in the structural slabs is provided with carbon fibers (2). The product can be used as precast elements for buildings, such as floor slabs, roof slabs and wall slabs, etc.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

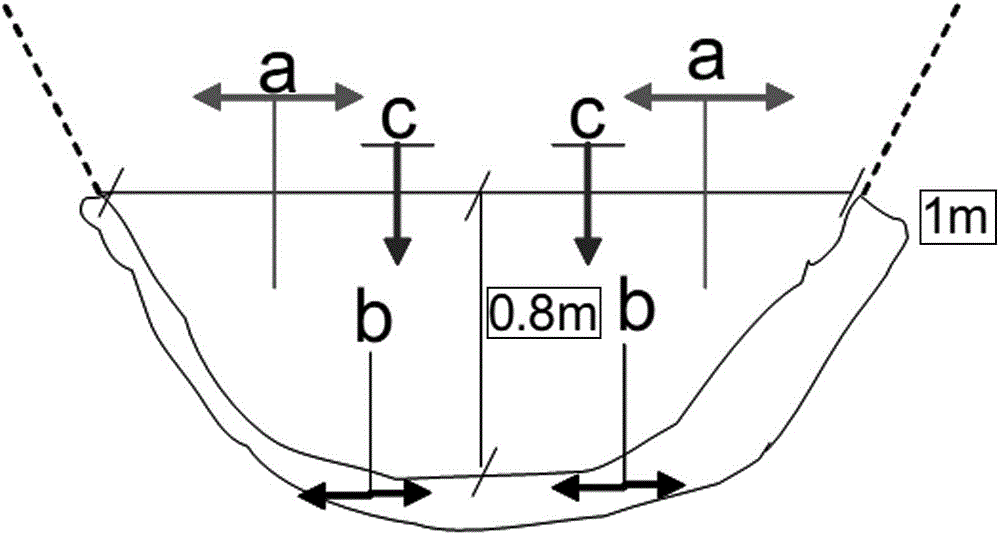

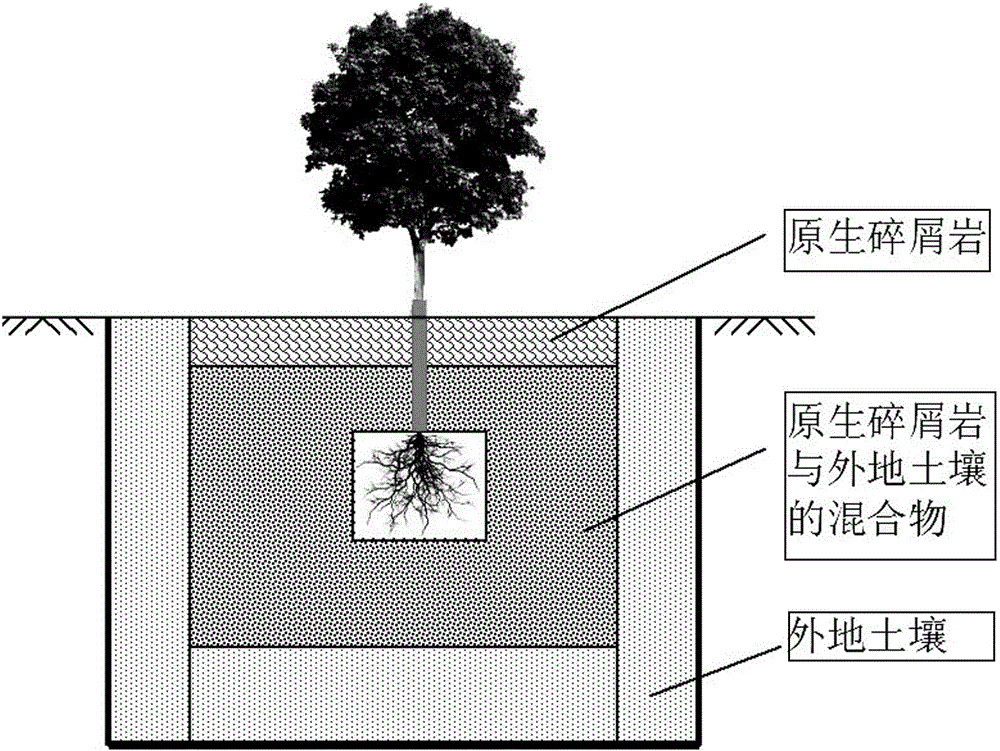

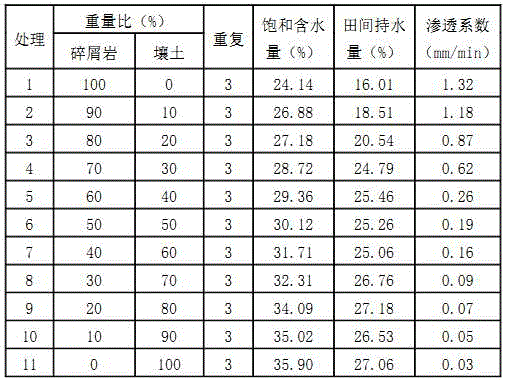

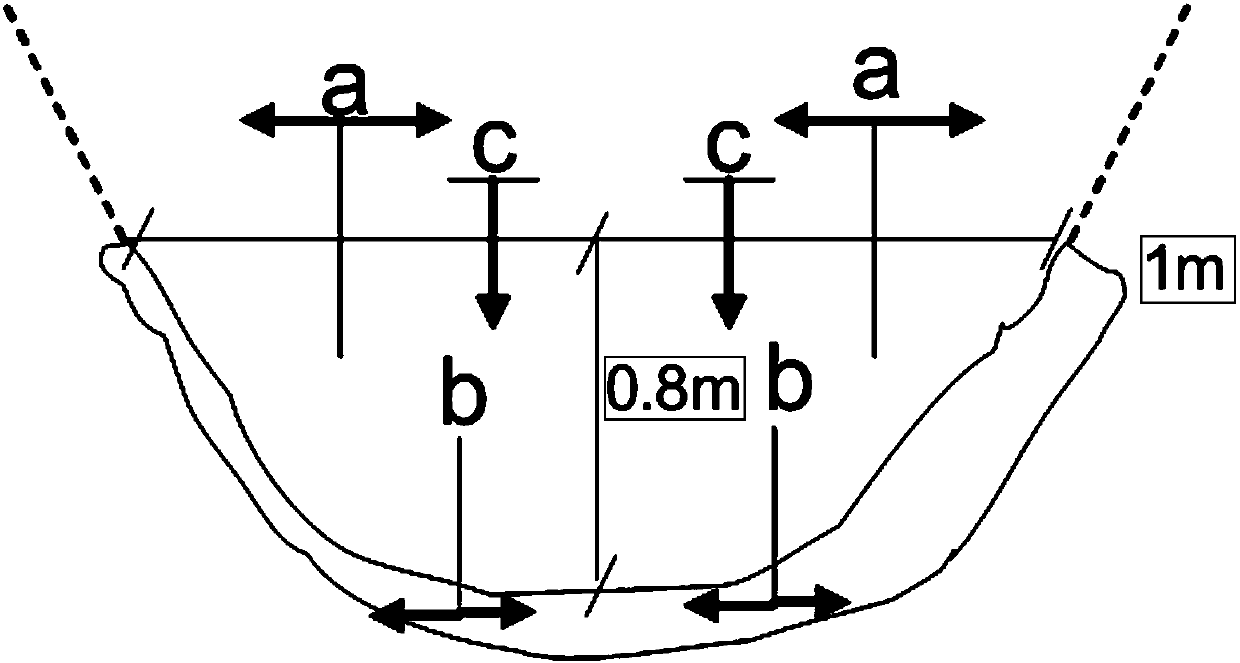

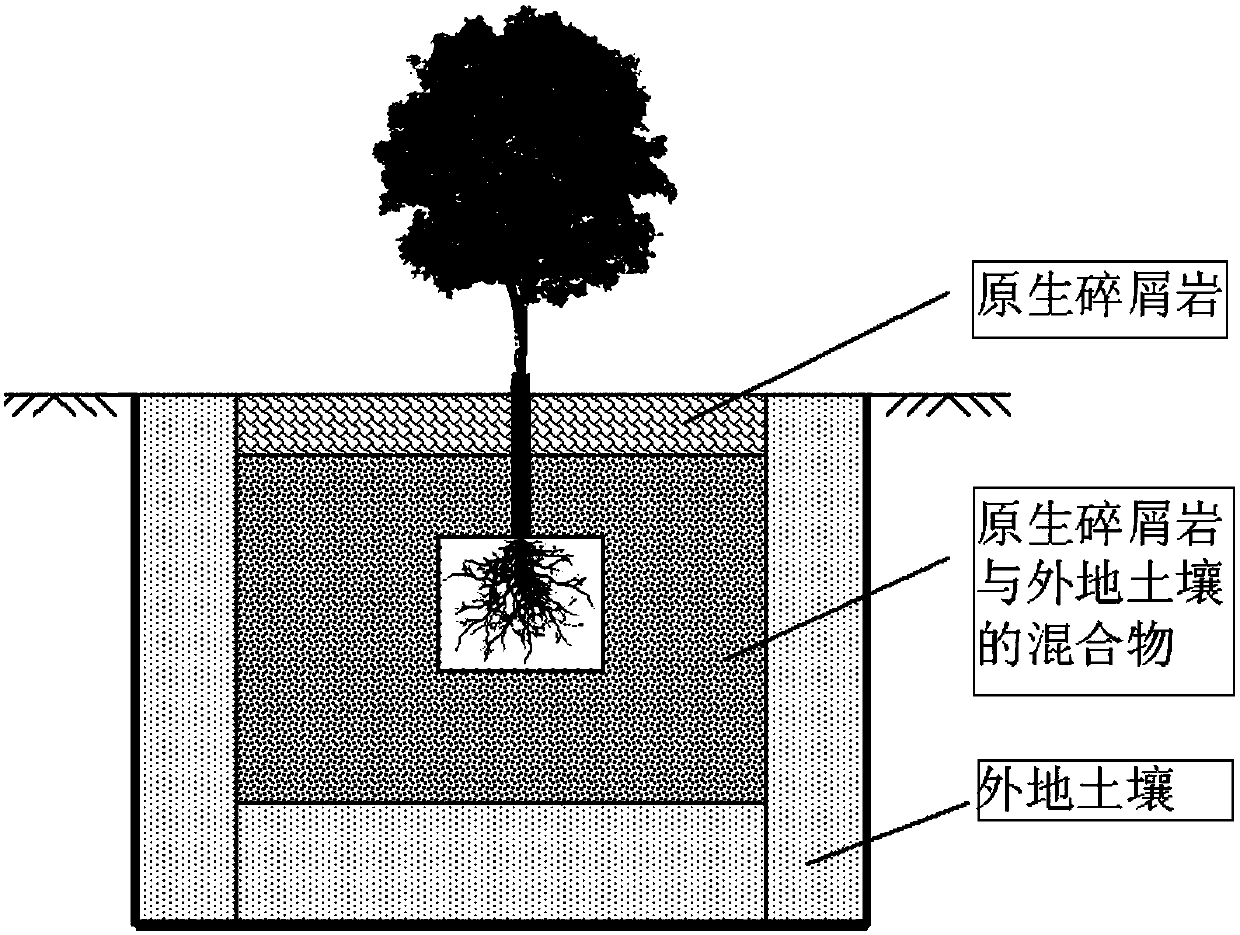

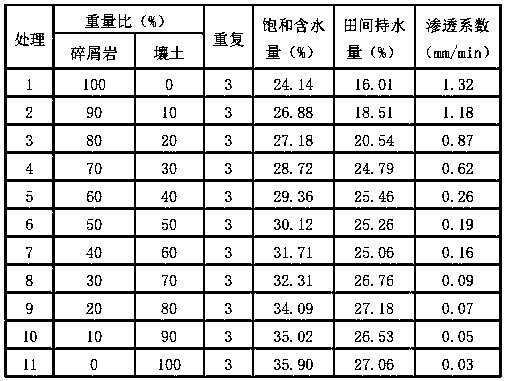

Method for rocky mountain soil dressing storage expanding afforestation

InactiveCN106068741AImprove aggregate structureIncrease effective storage capacityBio-organic fraction processingWatering devicesDrought resistanceBiological storage

The invention discloses a method for rocky mountain soil dressing storage expanding afforestation. The method comprises the steps that firstly, a special-shaped pit is dug, then, soil dressing replacement is performed and a biological storage expanding bulking agent is added into the special-shaped pit, meanwhile, supplemental irrigation water source preparation is performed, and finally, nursery stock preparation, nursery stock transplanting, rooting strengthening treatment and coverage water retention serial measures are performed to complete a rocky mountain storage expanding afforestation ecological project. The rocky mountain protoclastic granular structure can be improved, the soil reservoir effective storage is increased, the soil water storage capacity is enlarged, rainfall effectiveness and seedling drought resistance are enhanced, the natural rainfall storing and adjusting functions of a soil reservoir are brought into full play, the survival rate of rocky mountain difficulty site afforestation is increased, forest resource cultivation is accelerated, and the mountainous ecological environment is improved.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI +1

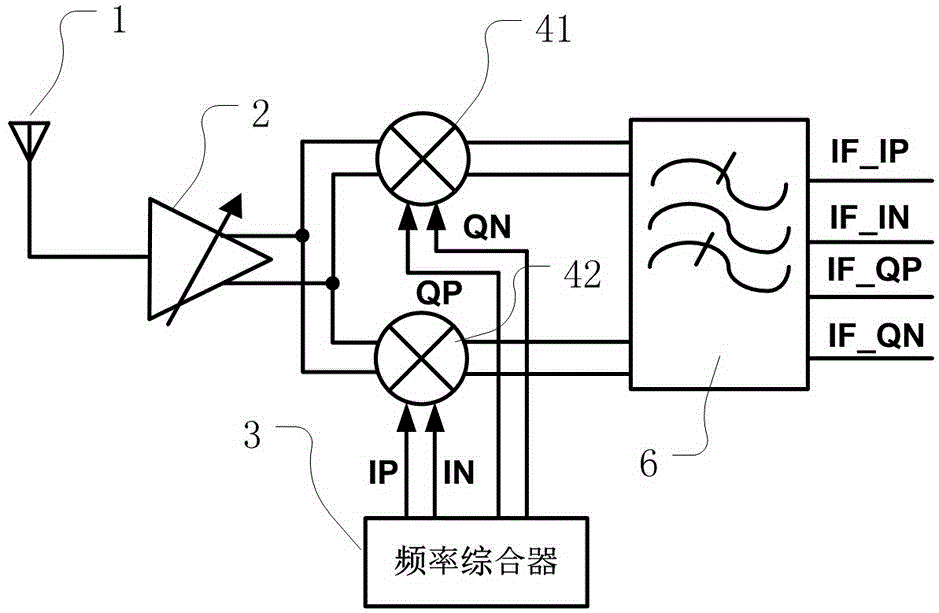

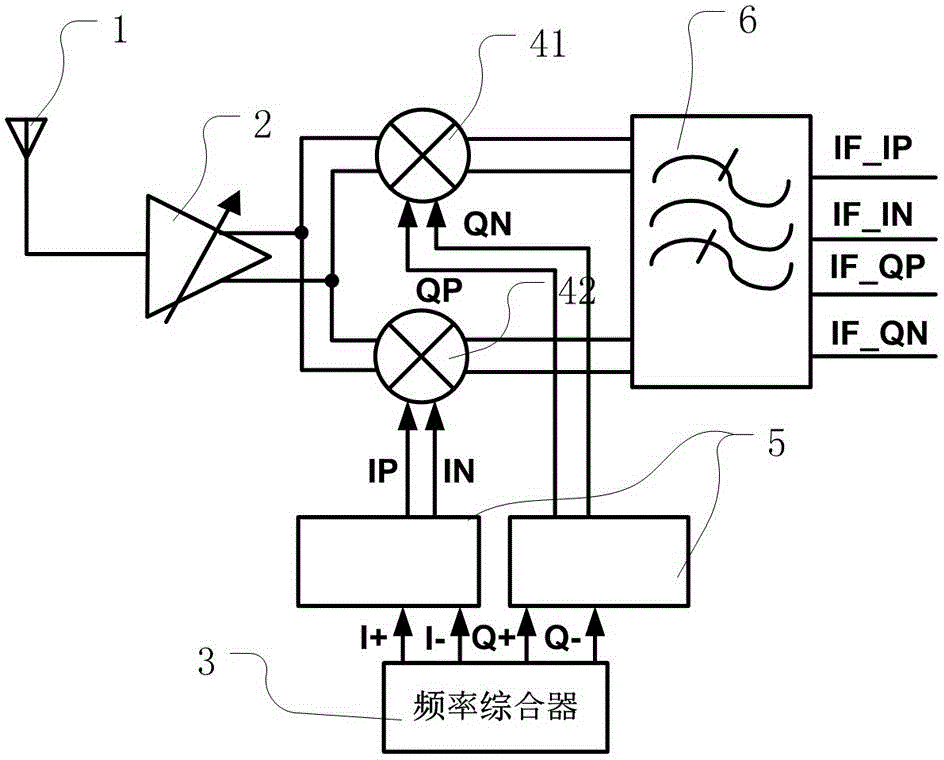

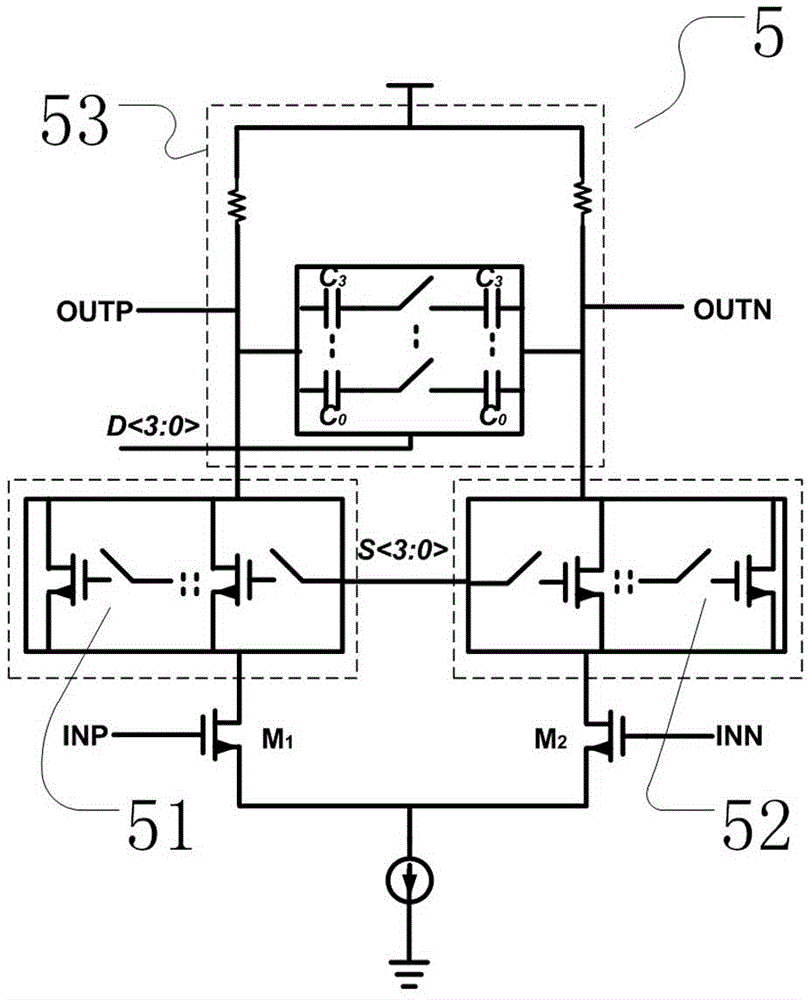

Low and medium frequency receiver with high image rejection ratio

ActiveCN103607213ASignificant technological advancementImprove image rejection ratioTransmissionPhysicsIntermediate frequency

The invention discloses a low and medium frequency receiver with a high image rejection ratio. The basic structure of the low and medium frequency receiver comprises an antenna, a low noise amplifier, a frequency synthesizer, a frequency mixer and a filter. The special structure of the low and medium frequency receiver is that an amplitude phase correction circuit is respectively connected to I and Q branches of the quadrature local oscillator signal output of the frequency synthesizer, each of the amplitude phase correction circuits is formed by two groups of CMOS amplifiers which are used for an amplitude-adjusting programmable cascade structure and a group of RC network load which is used for changing phase and is provided with a programmable capacitor array, the positive electrode and the negative electrode of any branch are connected to a group of CMOS amplifiers through a field effect transistor, and nodes between two groups of CMOS amplifiers corresponding to positive and negative electrode connection and the RC network load are outputted positive and negative electrodes after amplitude phase calibration. The low and medium frequency receiver in the scheme is applied, two branch signals are matched through amplitude and phase calibration, the image rejection ratio in the low and medium frequency receiver is raised, and the performance of the receiver is improved further.

Owner:SHANGHAI PANCHIP MICROELECTRONICS CO LTD

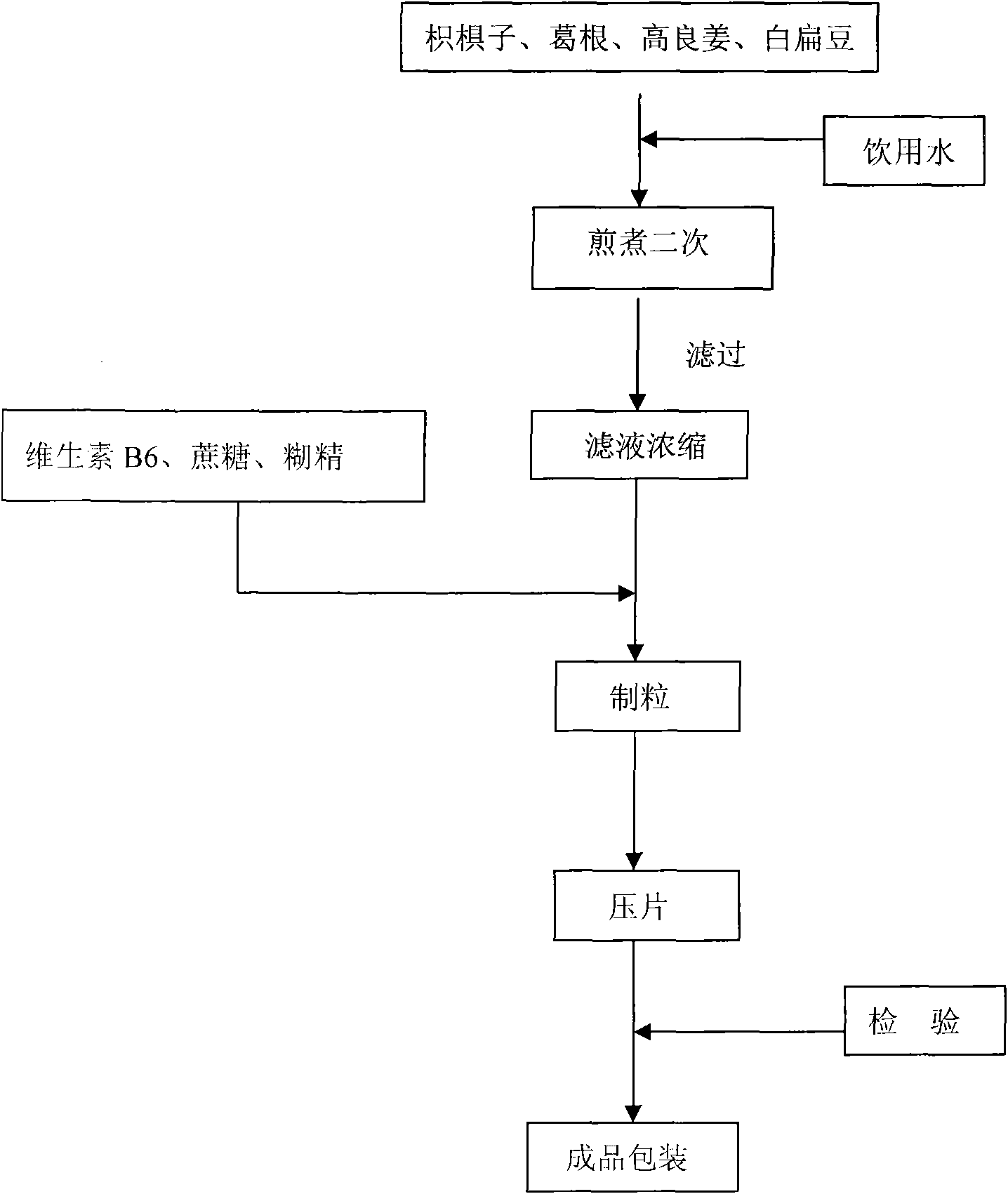

Drinking sugar and manufacturing method thereof

InactiveCN101647508ARelieve vomitingRelieve muscle crampsNervous disorderConfectioneryFunctional foodSucrose

The invention relates to a drinking sugar and a manufacturing method thereof, and belongs to the filed of functional foods. The drinking sugar is prepared from natural Chinese medicinal main materialswhich are homologous Chinese herbal and foods and respectively honey tree fruit, kudzuvine root, lesser galangal rhizome and white hyacinth bean, and accessories of vitamin B6, white granulated sugarand dextrin; and the formula of the drinking sugar comprises 30 to 50g of honey tree fruit, 1,050 to 1,100g of kudzuvine root, 30 to 50g of lesser galangal rhizome, 30 to 50g of white hyacinth bean,45 to 75g of vitamin B6, 100 to 200g of sucrose and 100 to 200g of dextrin, wherein the weight percentage of the Chinese medicinal main materials, the vitamin B6, the sucrose and the dextrin is 75:5:10:10; and the Chinese medicinal main materials are decocted and condensed into thick paste, and the thick paste is evenly mixed with the accessories to prepare drinking sugar tablets. The drinking sugar gives full play to synergic and complementary effects of the Chinese medicinal main materials and the vitamin B6 in the aspects of relieving alcohol, protecting liver and nourishing stomach, and isintroduced with a proper amount of sucrose, so the small-dosage sugar tablets with good mouthfeel can quickly discharge the alcohol out of the body, eliminate the deposit of residual alcohol in the liver and the stomach, have the effects of protecting the liver, strengthening the stomach and keeping health, and also have the same effects if nondrinkers eat the sugar tablets in daily life.

Owner:武汉海纳药业有限公司

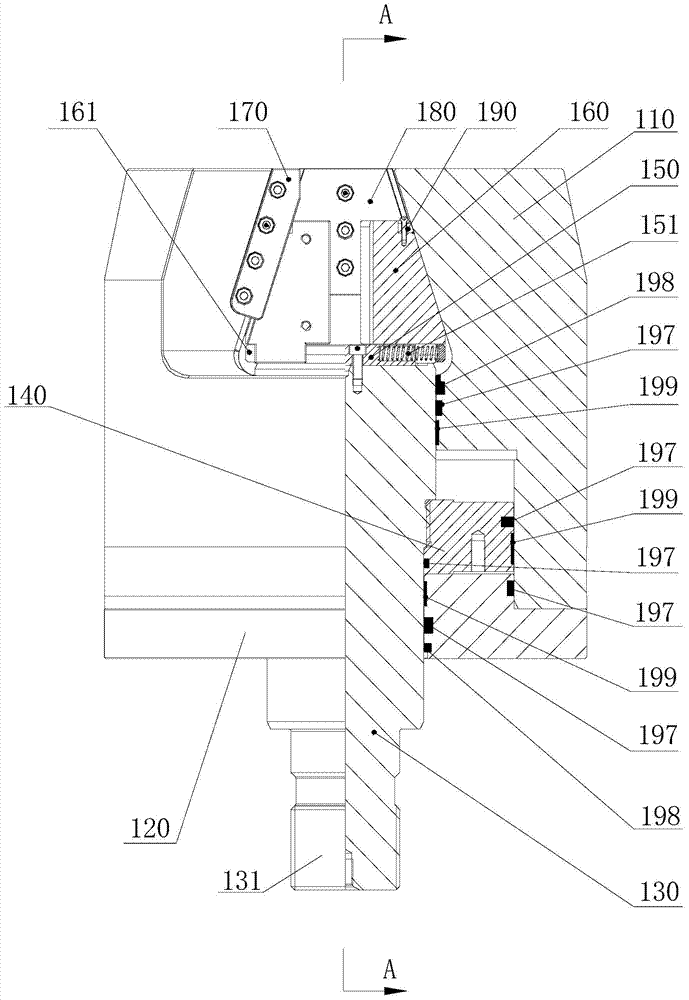

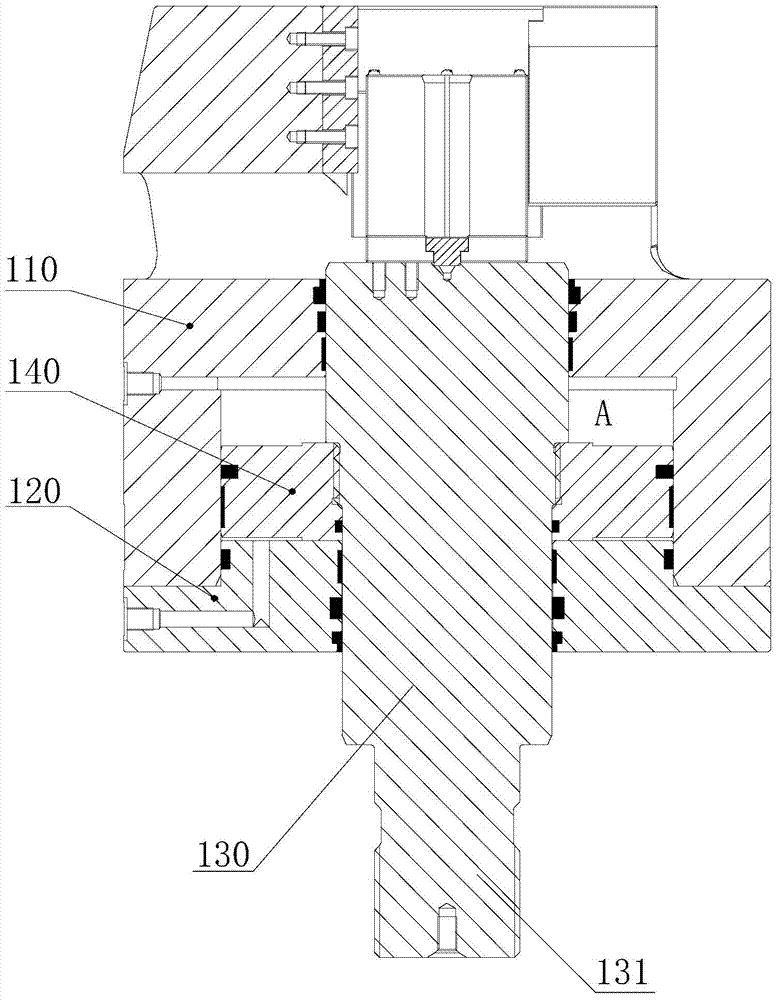

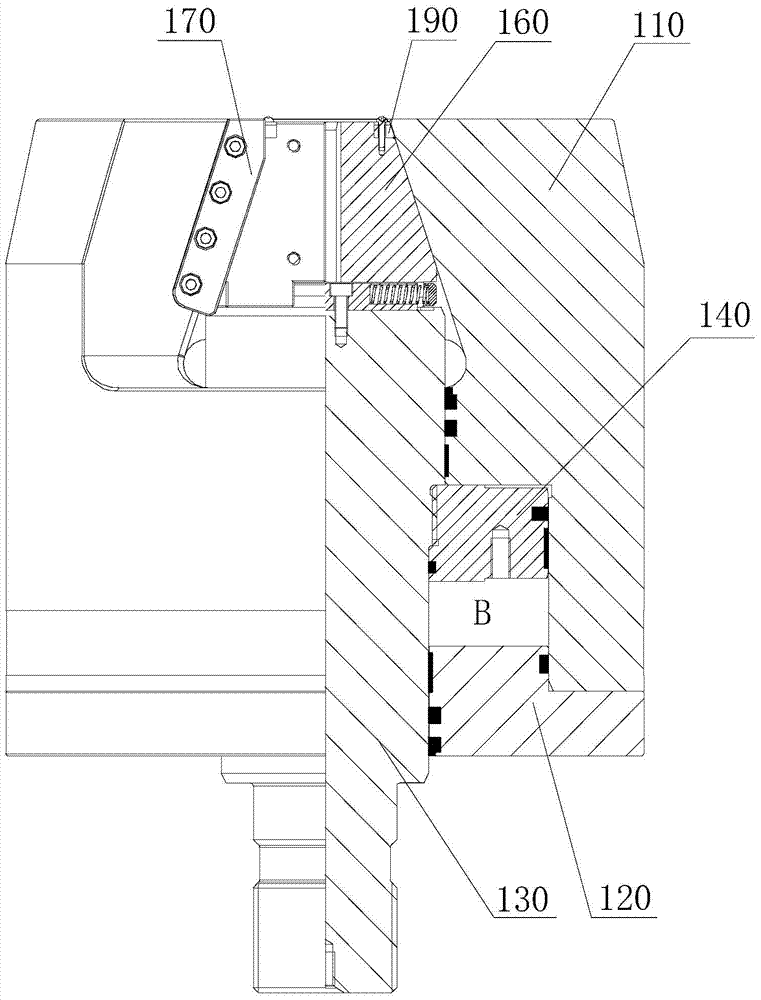

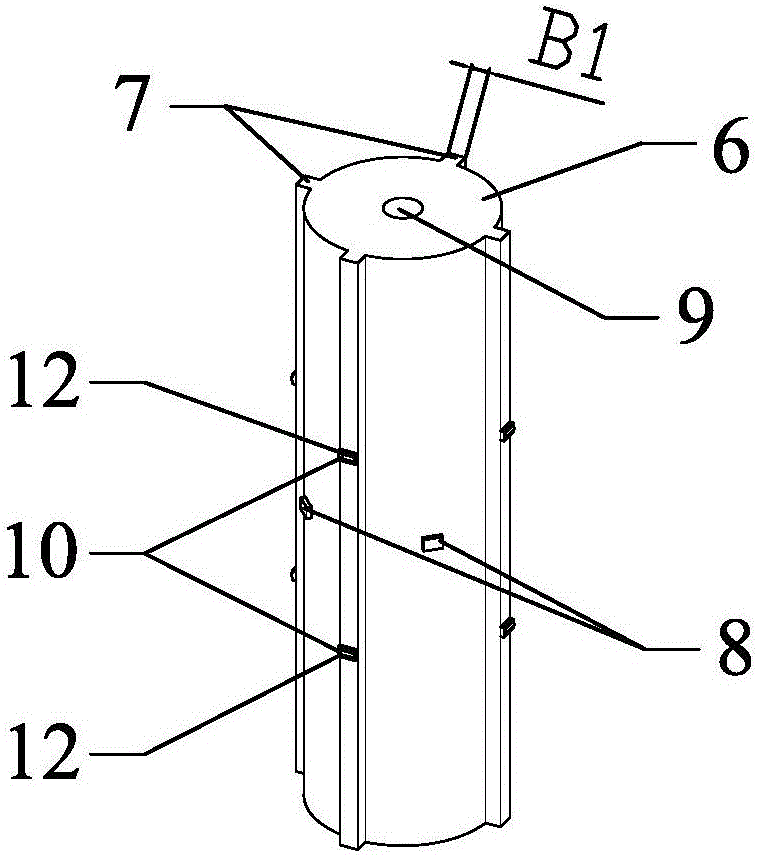

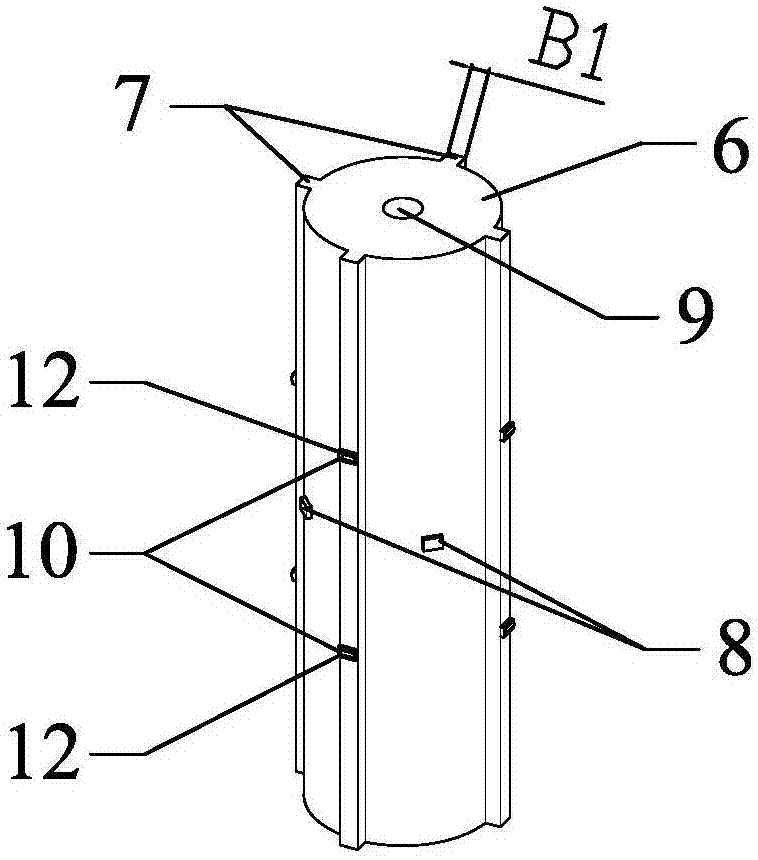

Semi-open type wedge-shaped horizontal sliding hydraulic clamp

The invention relates to a semi-open type wedge-shaped horizontal sliding hydraulic clamp, comprising a clamp body, an end cover, a piston rod, a piston, a guide key, two clamping blocks, two side guide plates, an upper guide plate and two dustproof strips. The clamp disclosed by the invention is convenient to replace and easy to clean; the clamp body has high rigidity and hardly deforms or slip in a test; the clamp can meet conventional large-batch tensile tests, also can meet the test requirements of dynamostatic universal and repeated tensile and compression tests, and has obvious technical advantages.

Owner:胡伟萍 +1

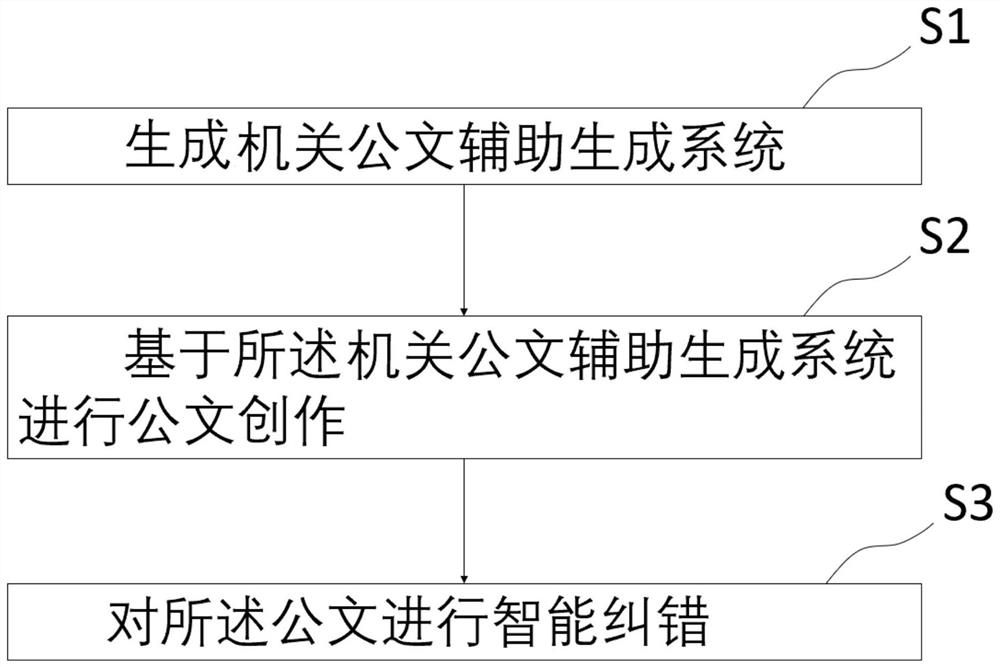

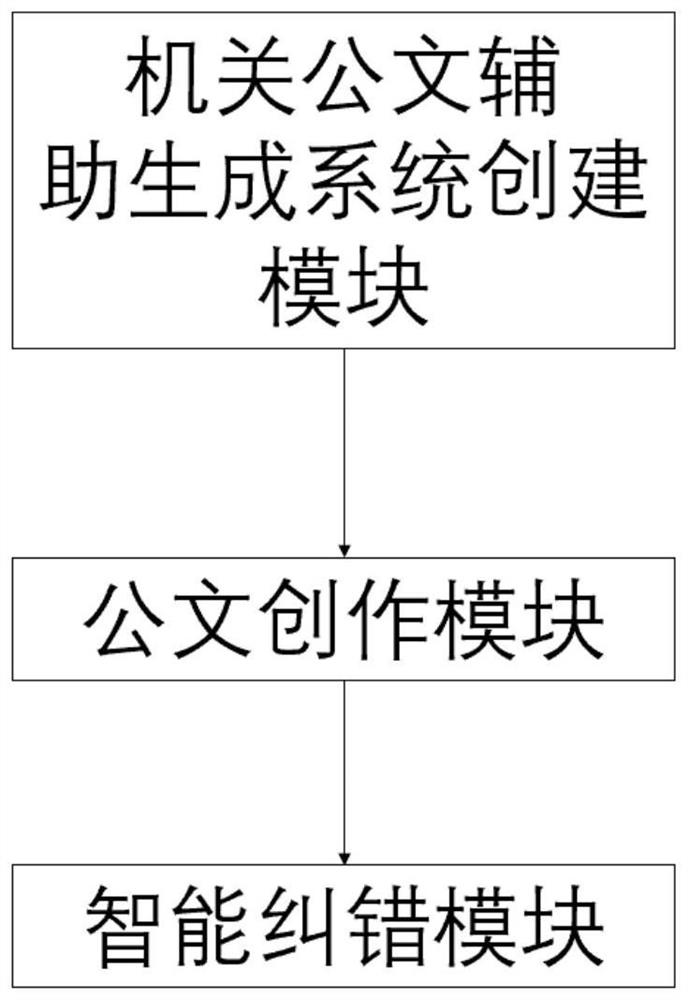

Organization official document auxiliary generation method, device and system

PendingCN113254574ASignificant technological advancementSignificant practicalityData processing applicationsNatural language data processingText corpusComputer-aided

The invention provides an organization document auxiliary generation method. The method comprises the following steps: generating an organization document auxiliary generation system; performing official document creation based on an organization official document auxiliary generation system; and performing intelligent error correction on the official document. The organ document auxiliary generation device comprises an organ document auxiliary generation system creation module; an official document creation module; and an intelligent error correction module. A corpus-based computer-aided writing system is constructed by utilizing the large-capacity storage, rapid processing and convenient man-machine interaction capabilities of a computer, sentence patterns and example sentences from a real corpus are recommended to a user in real time in a man-machine interaction form, assistance is provided for the core activity of sentence making, the technical blank of a corpus-based computer-aided writing system is filled up, the problems that in the prior art, provided information is not accurate, the efficiency is low, and writing auxiliary services are not in place and incomplete are solved by adopting the one-stop intelligent official document writing auxiliary method, and the writing requirement is comprehensively met.

Owner:河北地质大学

Autoclaved aerated concrete, steel reinforced concrete composite structure and application thereof

InactiveCN101294429AReduce weightReduce floor pressureConstruction materialFloorsFloor slabReinforced concrete

The invention relates to a composite structure of autoclaved aerated concrete and reinforced concrete and an application thereof. The prior precast slabs have large specific gravity, resulting in high weight of buildings and very high cost of foundations. The autoclaved aerated concrete has low specific gravity but poor strength, so as not to be used as supporting parts. The inventive product comprises a building concrete structure member (1) containing reinforced steel bars, wherein the low stress part at the middle of the concrete structure member uses autoclaved aerated concrete (2). The product can be used as precast elements for buildings, such as floor slabs and roof slabs, etc.

Owner:哈尔滨工业大学空间钢结构幕墙有限公司

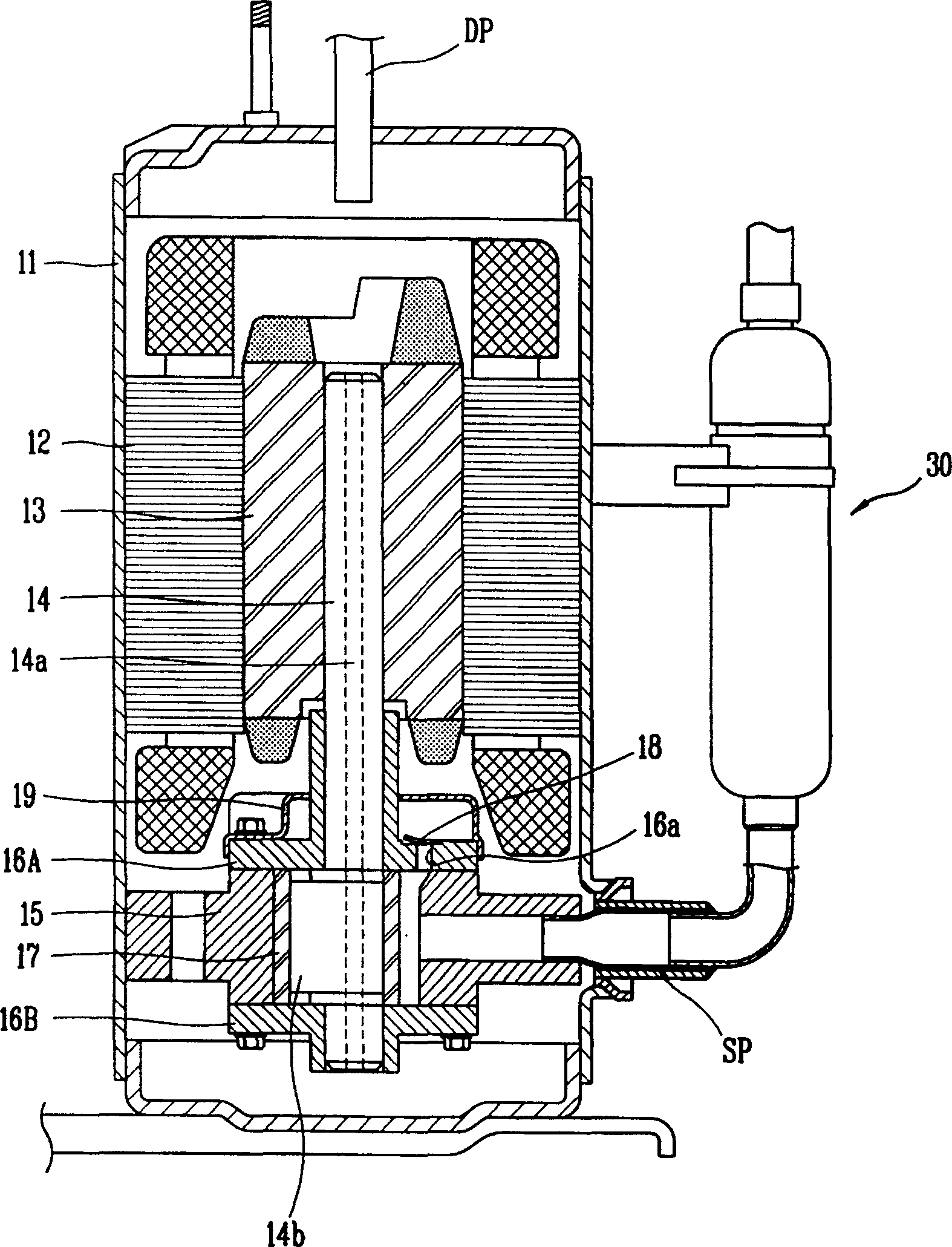

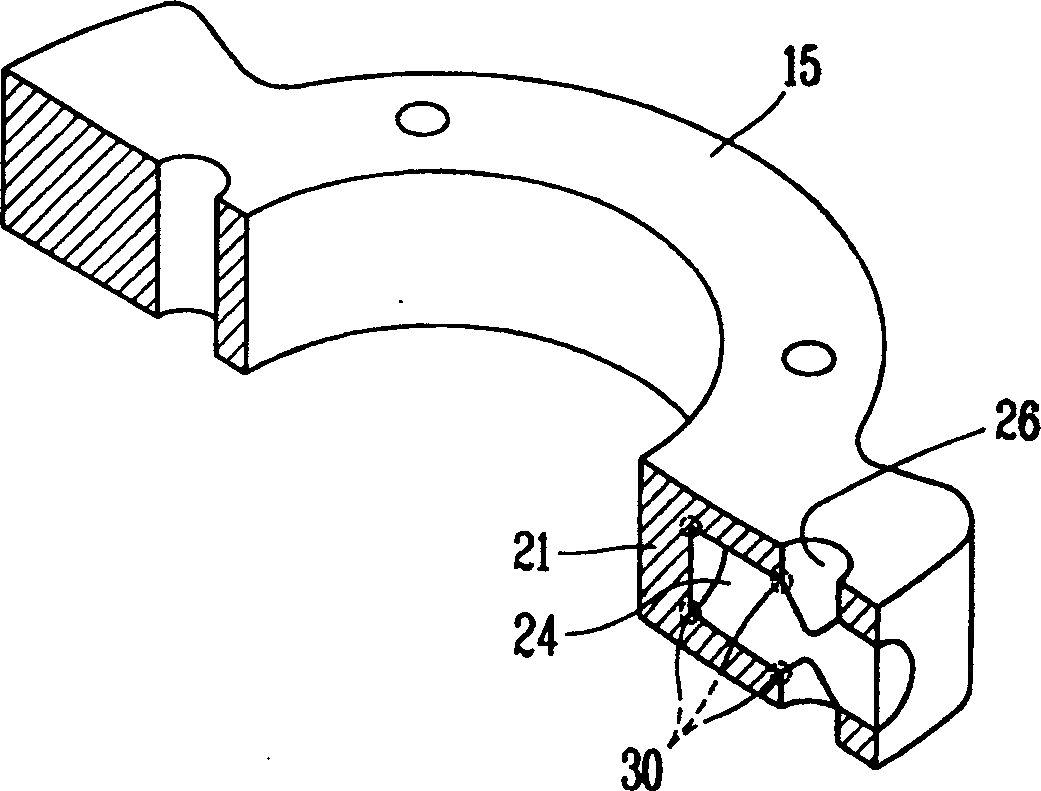

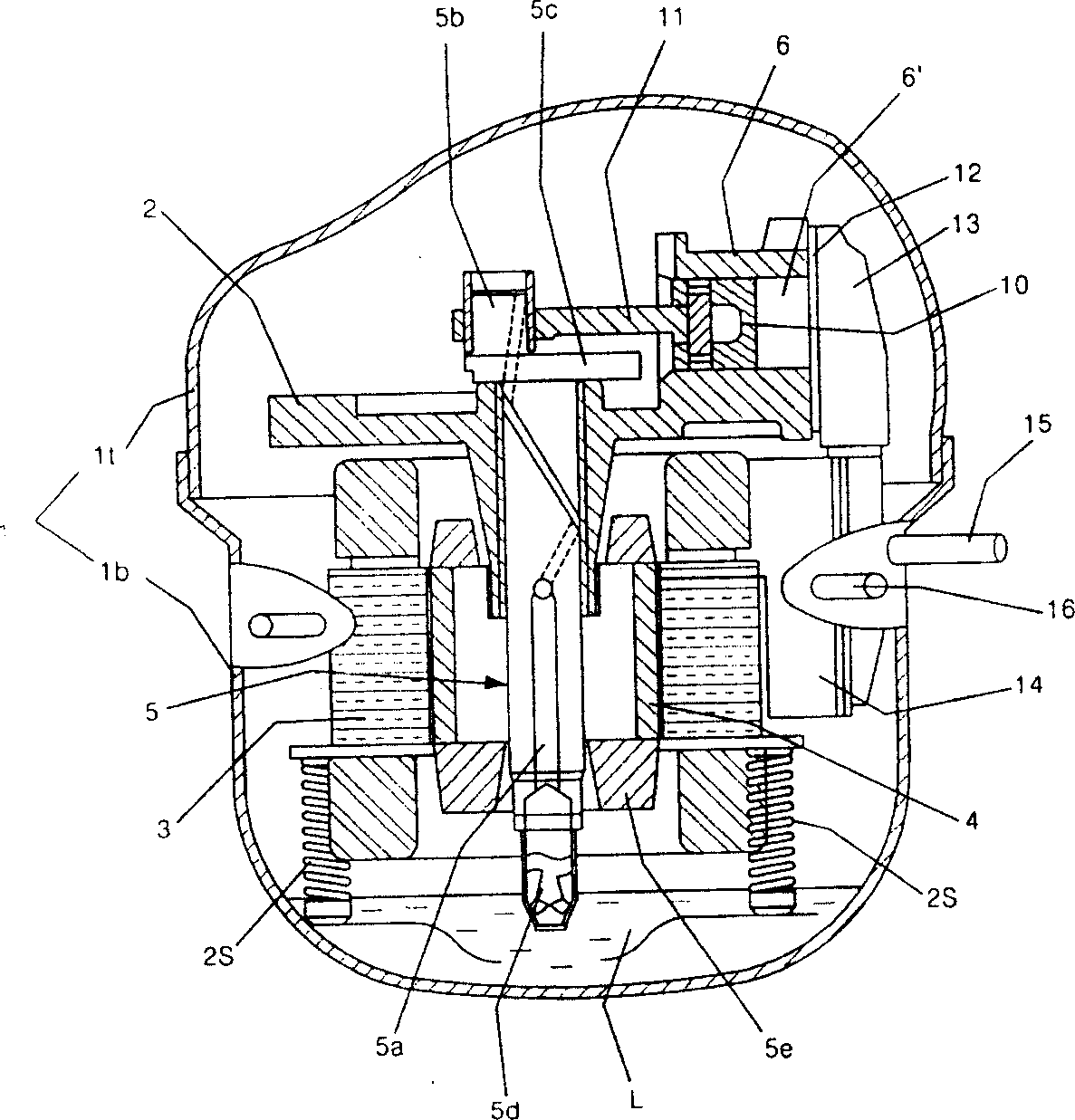

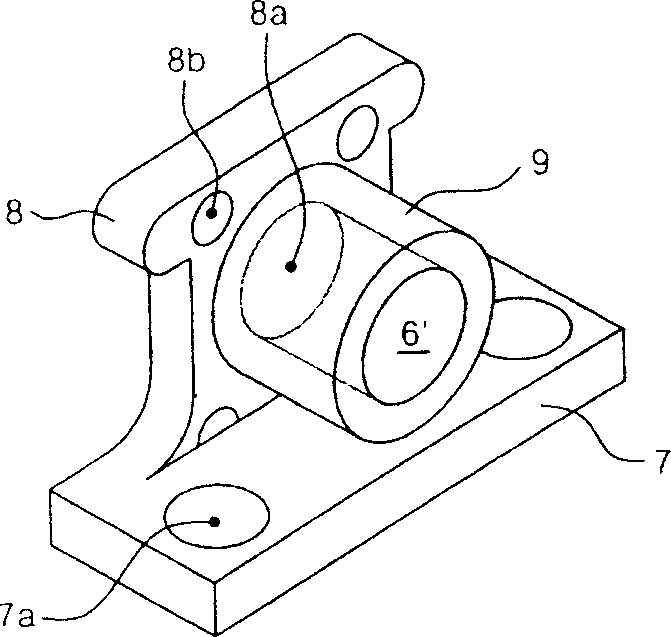

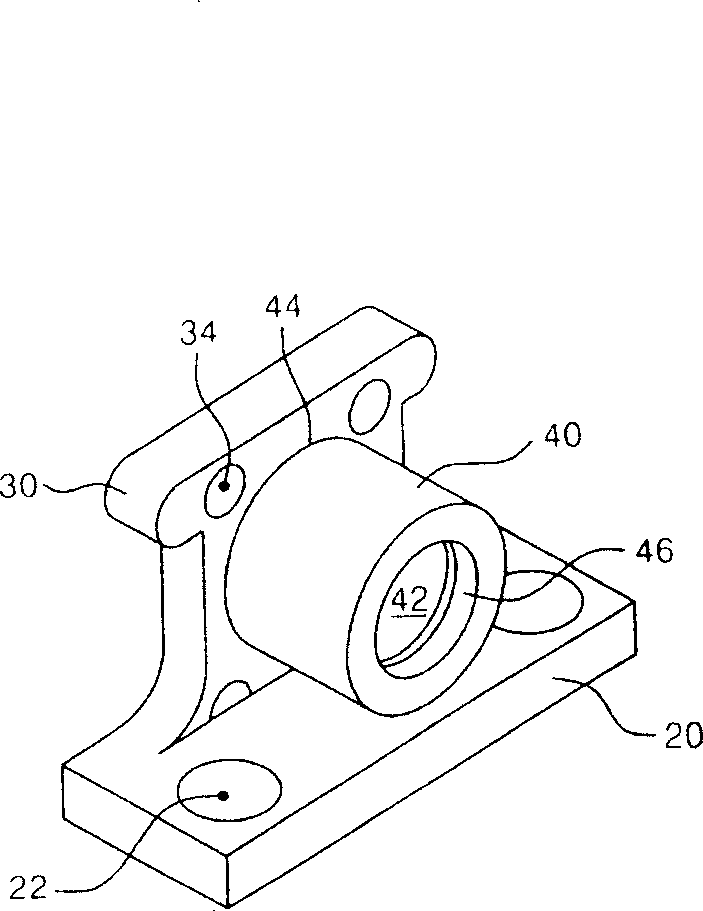

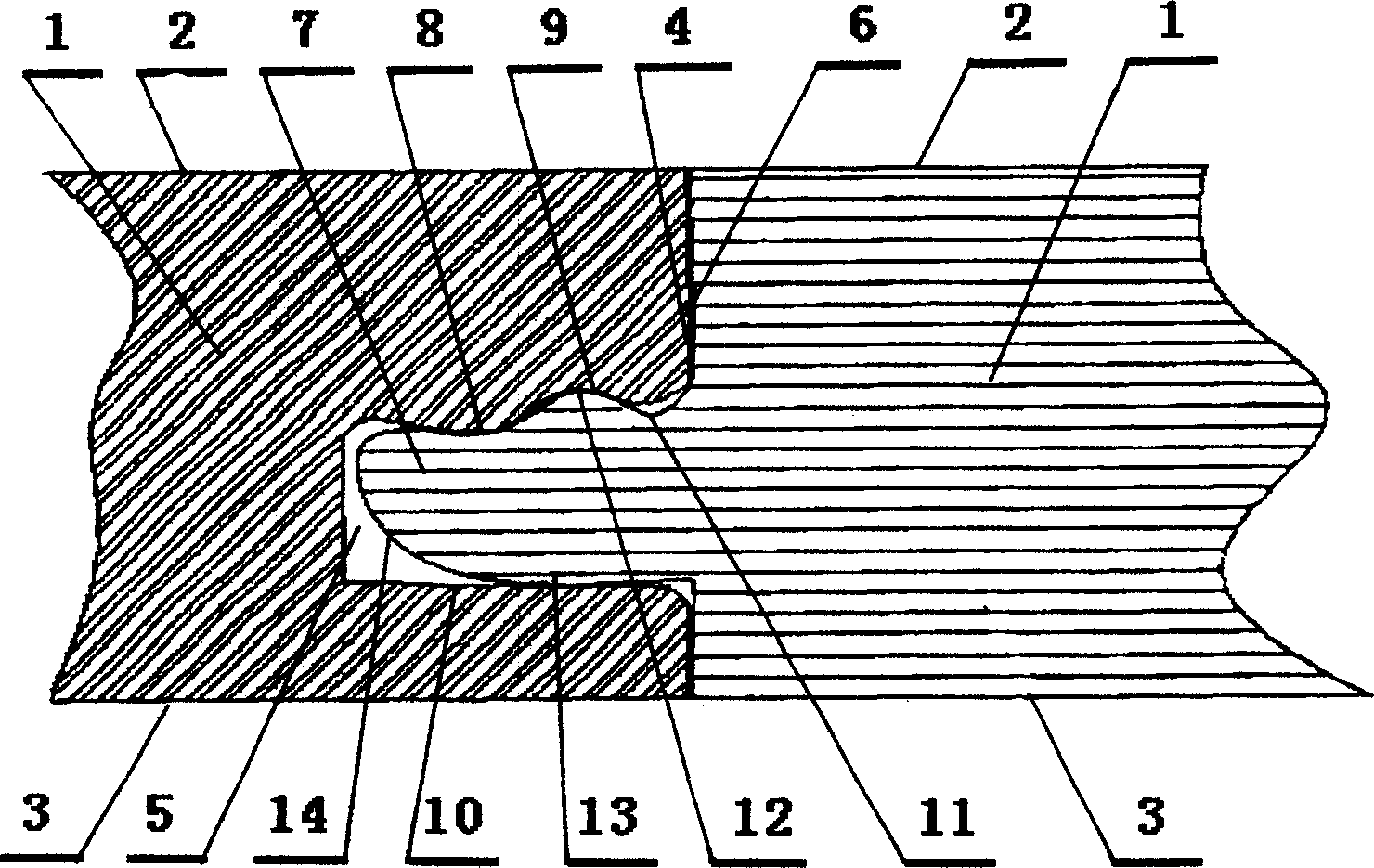

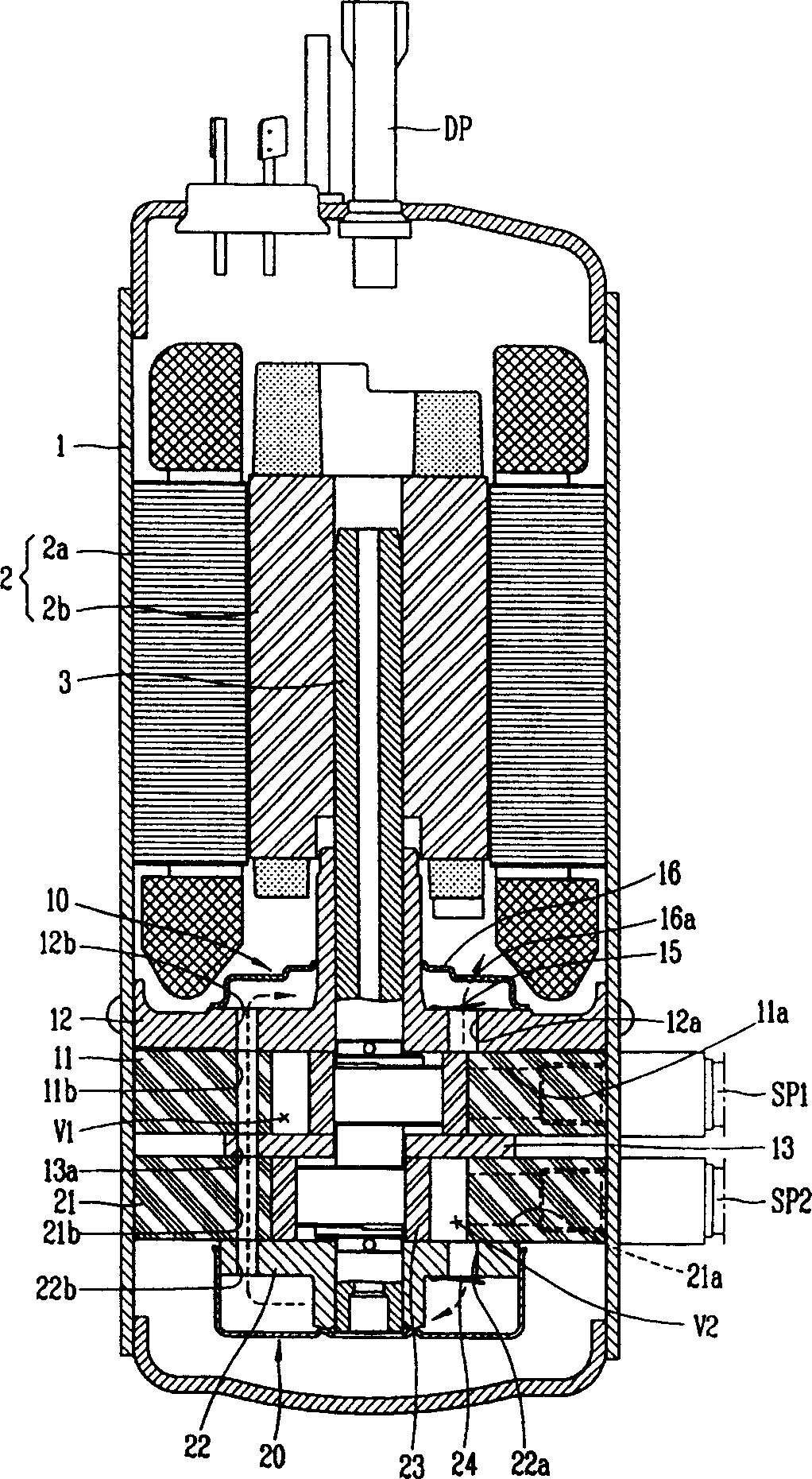

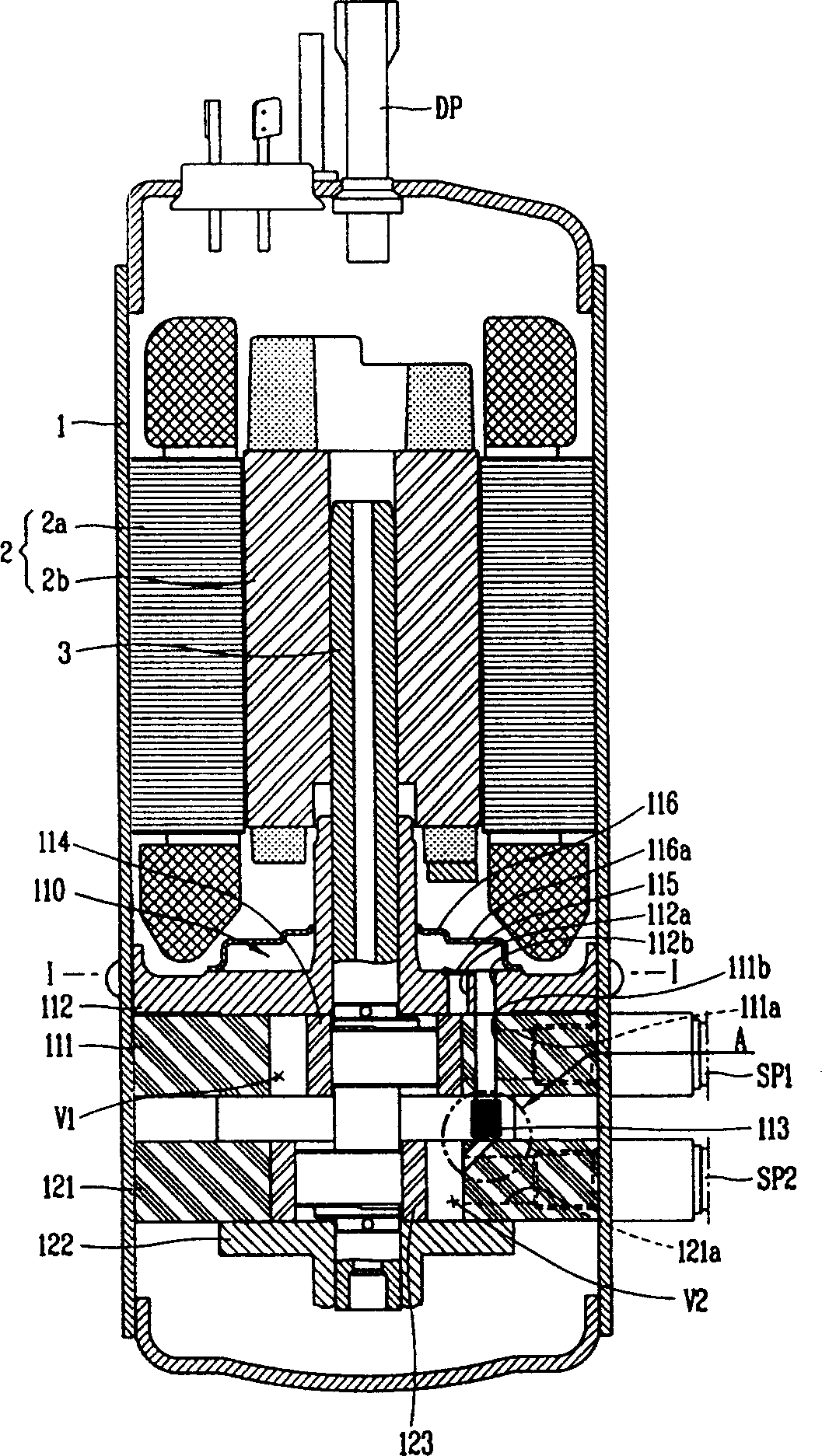

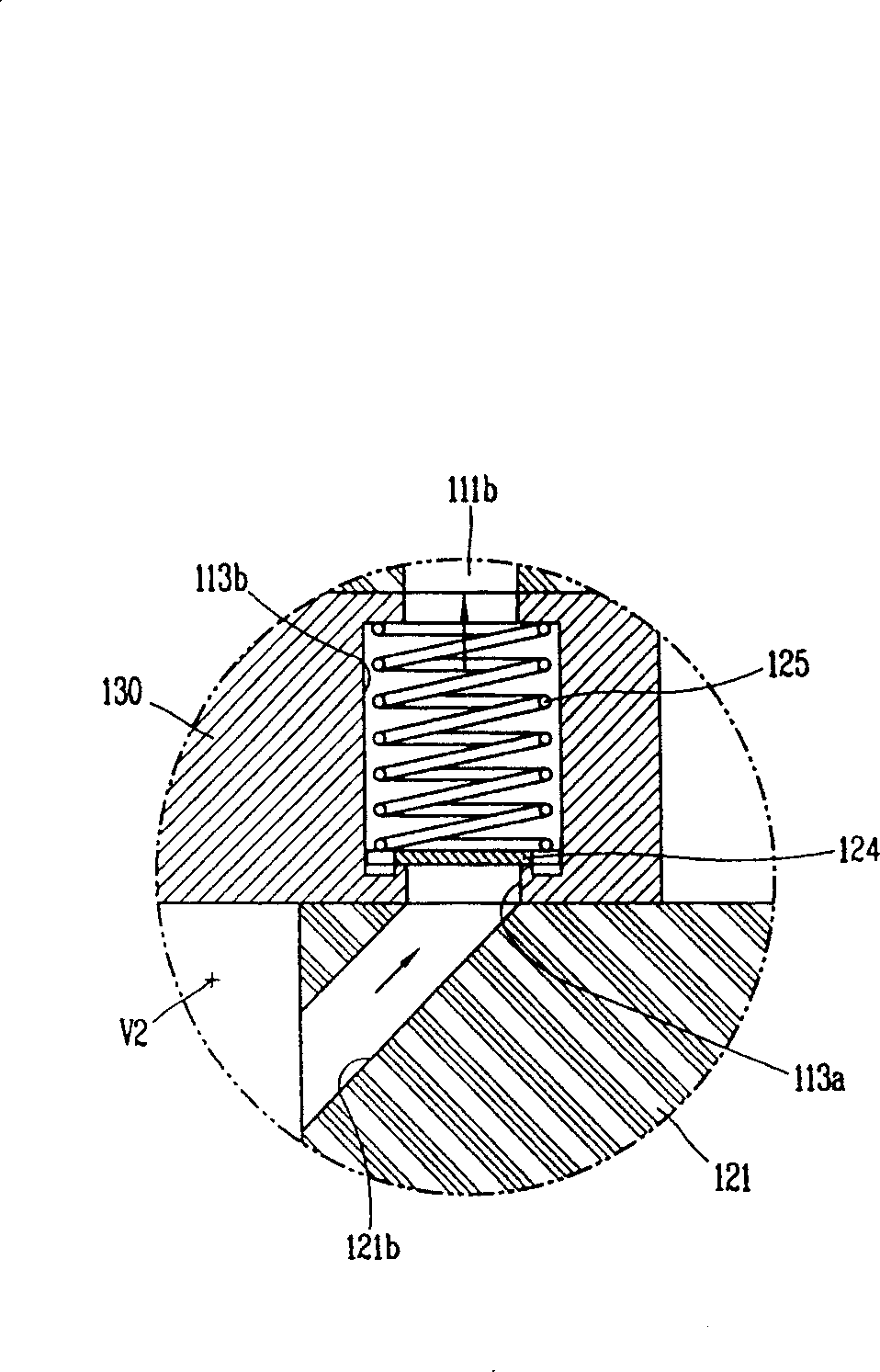

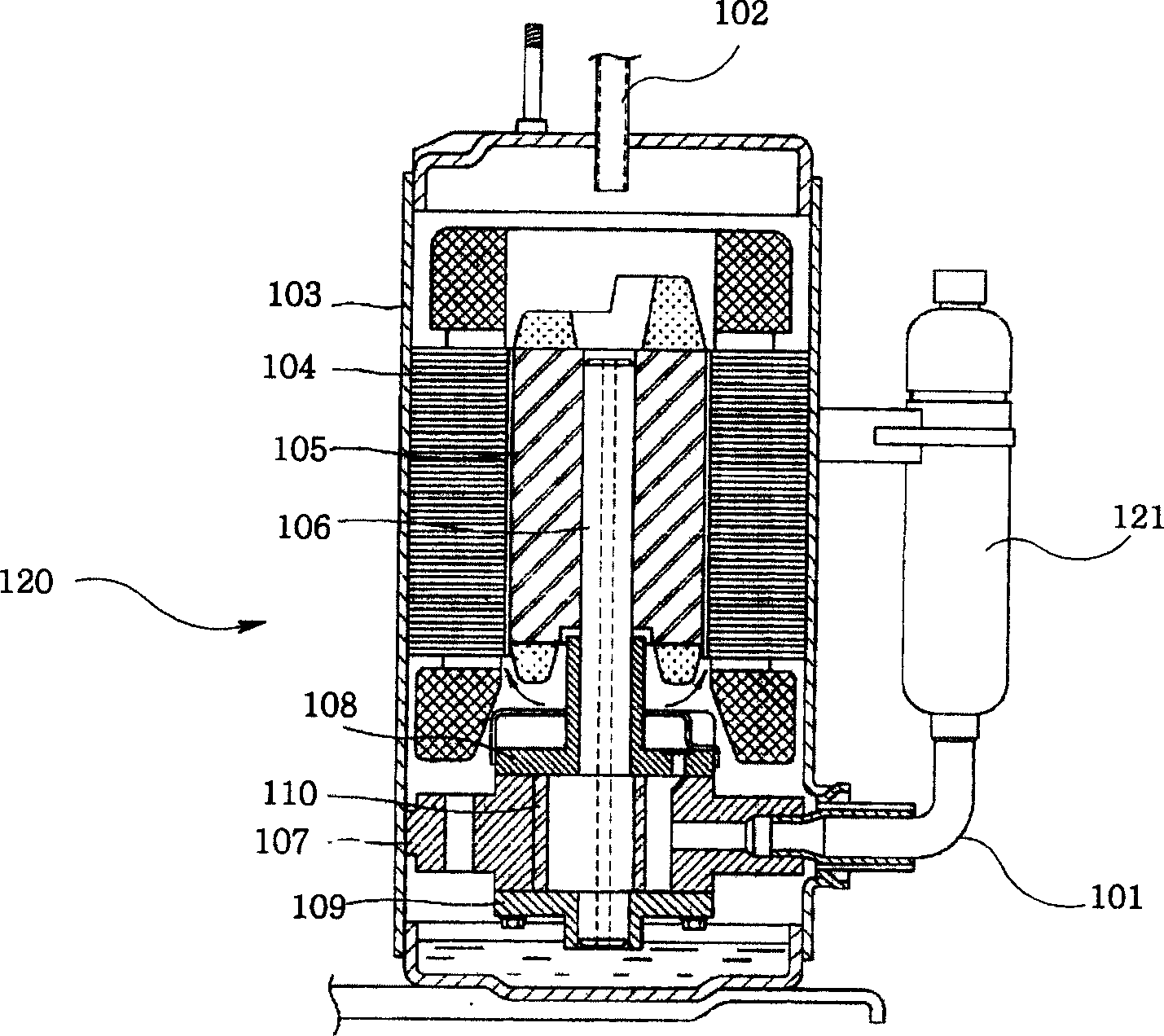

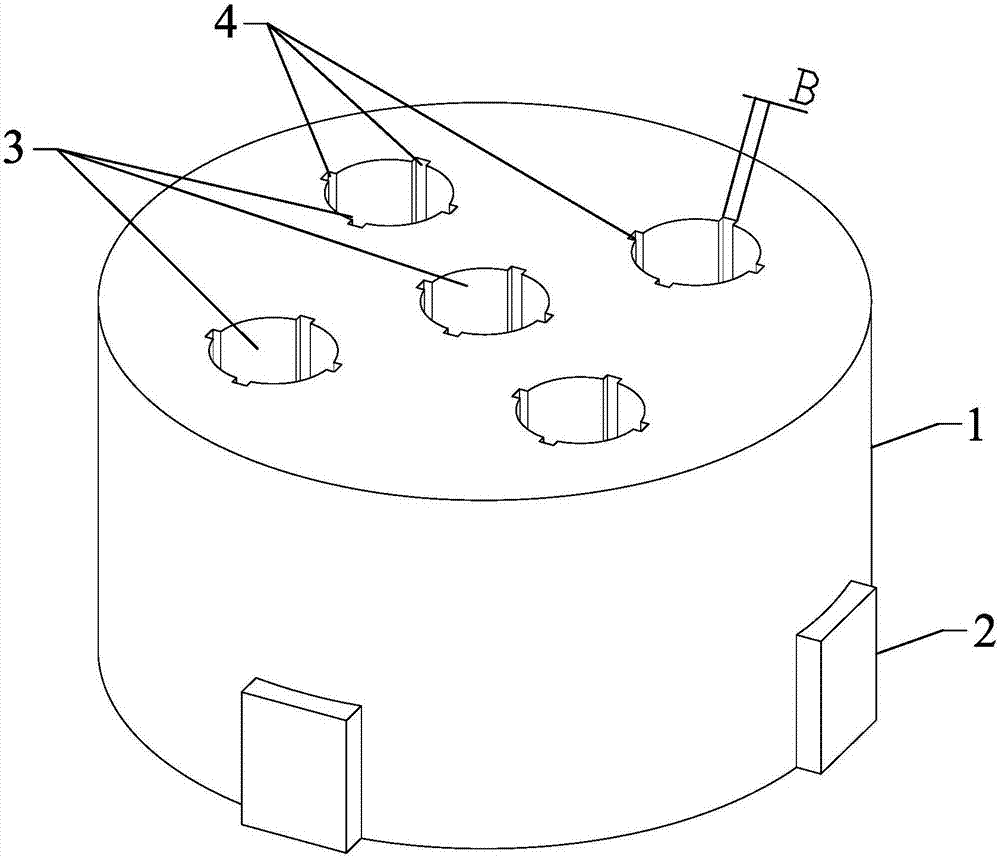

Blade spring arrangement of rotary compressor

InactiveCN1896531APrevents reduction in operational reliabilityReduce burrsRotary piston pumpsRotary piston liquid enginesEngineeringPiston

This invention is blade spring setting structure of rotating type compressor. It can reduce the formation of trimmings along the blades moving track when assembling the blade spring. It can also prevent reliability from decreasing. The rotating type compressor includes air cylinder setting inside of outer casing; the first and second bearings attaching to both side faces of air cylinder. They cut through the rotating shaft, which is connected to driving electric engine; rotating piston inside of air cylinder. It connects to rotating shaft eccentric part and moves the refrigerant gas at the same time of eccentrically rotating; blades setting through the blade housing part. They carry out straight-line motion along radial direction in pace with the eccentric rotation of rotating piston. The blades also separate the interior of air cylinder into absorbing space and compressing space; blade spring setting inside of the lubricating oil-supplying hole, which communicates to blade housing part along the axial direction of rotating shaft. The blade spring can provide elasticity which makes blades contact with the rotating piston.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

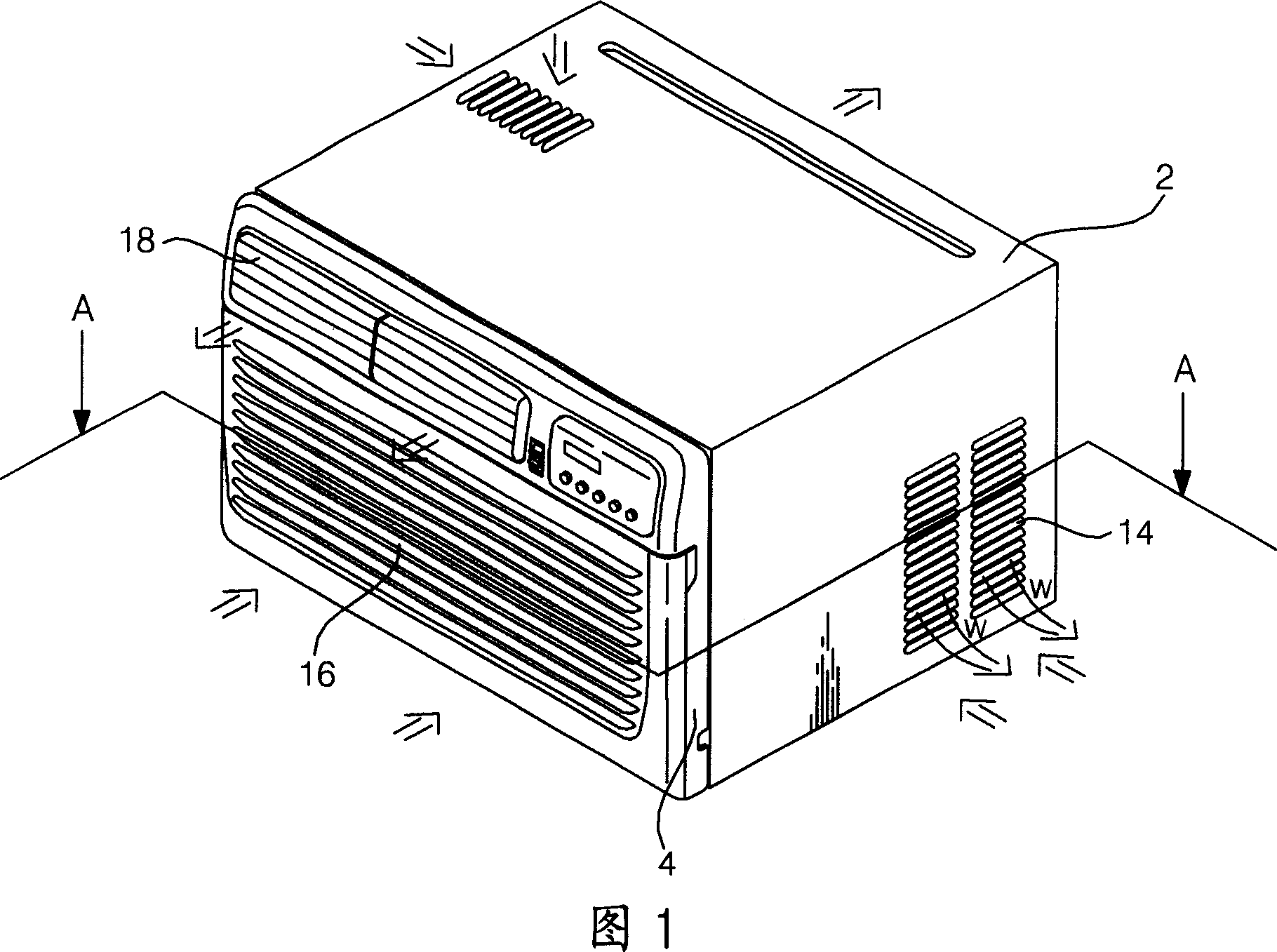

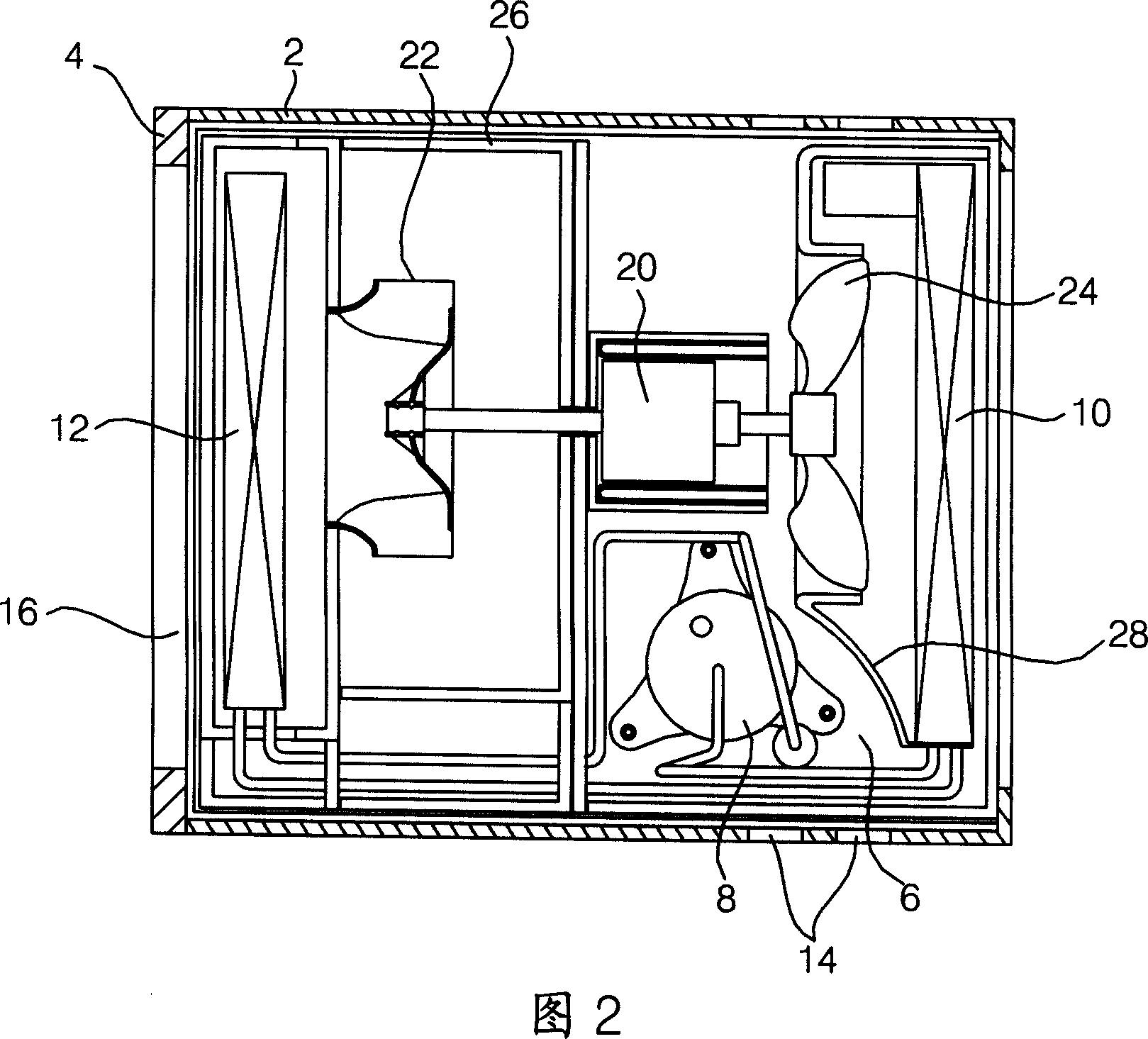

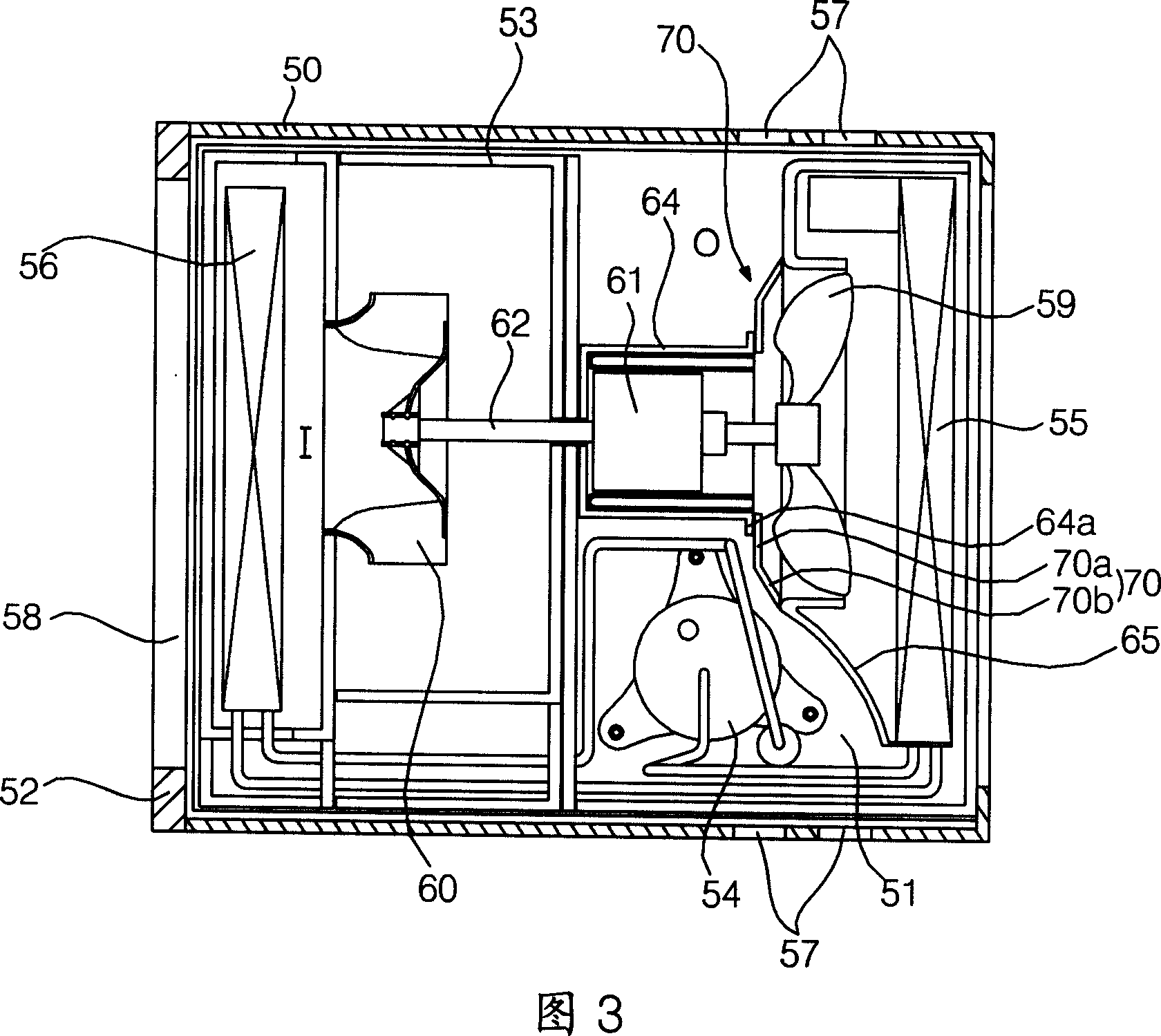

Integral air conditioner

InactiveCN1955580ASignificant technological advancementPrevent splashLighting and heating apparatusAir conditioning systemsEngineeringWater collection

An integral air-conditioner consists of frame with indoor unit and outdoor unit and setting air suction opening on said frame, forming water collection tray at bottom surface of said body frame and setting condensed water splash proof unit in front of internal side on said air suction opening for avoiding condensed water collected in water collection tray to be splashed out from said air suction opening.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Cylinder of closed compressor

InactiveCN1896515AIncrease frictionReduce wearPositive displacement pump componentsPositive-displacement liquid enginesWorking fluidFriction force

This invention is a kind of air cylinder of hermetic compressor. It includes air cylinder base; air cylinder body and breaking section. The air cylinder base is to connect to the frame; the said air cylinder body is above the said air cylinder base and has compressing chamber cutting through the interior. The valve components, which control working fluid to get in and out, are mounted at one end; the said breaking section is at the lowest point side of the said compressing chamber. It can reduce friction of pistons, which move along the inner face of the said compressing chamber.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

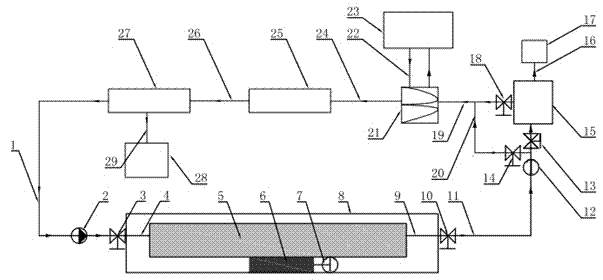

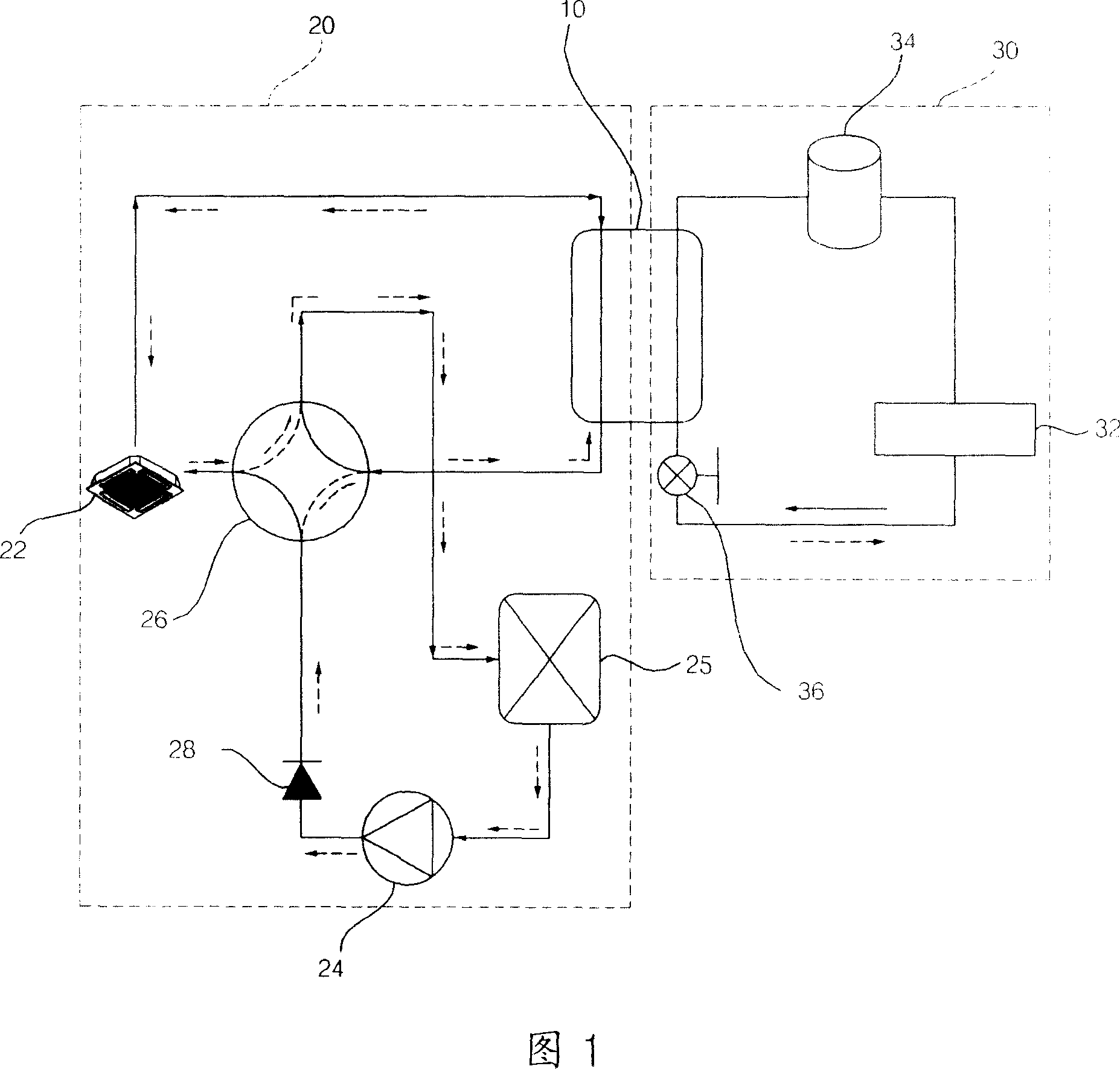

Cold and heat continuously-supplying system and method based on server waste heat and solar energy

ActiveCN103940146AIncrease productionImprove cooling effectDigital data processing detailsClimate change adaptationLithium bromideSolar water

The invention discloses a cold and heat continuously-supplying system and method based on server waste heat and solar energy. The system comprises a water supply pipe, a circulating pump, a first electric check valve, an inlet connecting pipe, a micro-channel panel heat pipe heat exchanger, a local heat source, a first temperature sensor, a server, an outlet connecting pipe, a second electric check valve, an outlet main pipeline, a second temperature sensor, a third electric check valve, a fourth electric check valve, a hot water tank, a hot water pipe, a heat user, a fifth electric check valve, a solar water supply pipe, a bypass pipe, a steam generator, a heat medium pipe, a solar heat collecting field, a steam pipeline, a lithium bromide refrigerator, a cold water pipe, a cold storage device, a fresh air unit and a refrigerating conveying pipe. The waste heat in the server is utilized, stepped heating for solar supplied water is achieved, and the steam amount and the refrigerating capacity are improved. Cold and heat continuous supply is ensured through the cold storage device and the hot water tank, the cooling rate is improved, meanwhile, the energy utilization efficiency of the system is improved, and energy consumption is greatly reduced.

Owner:ZHEJIANG UNIV

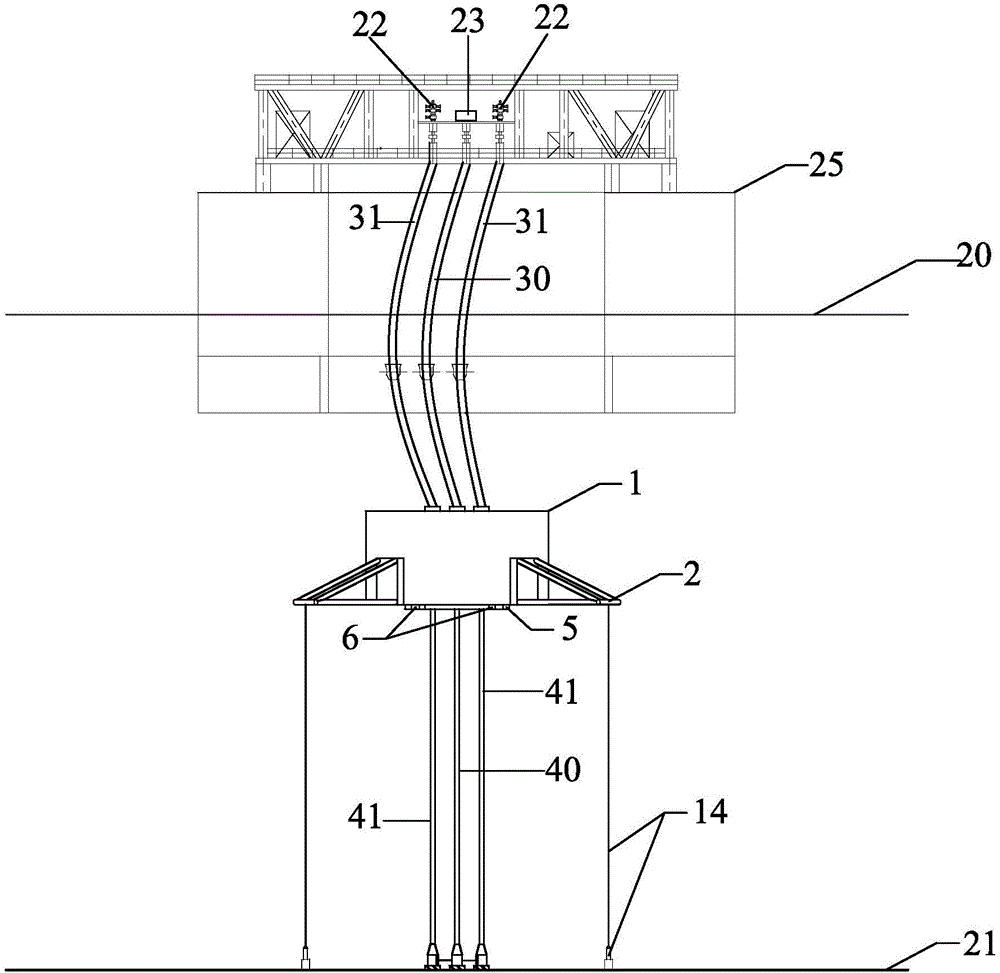

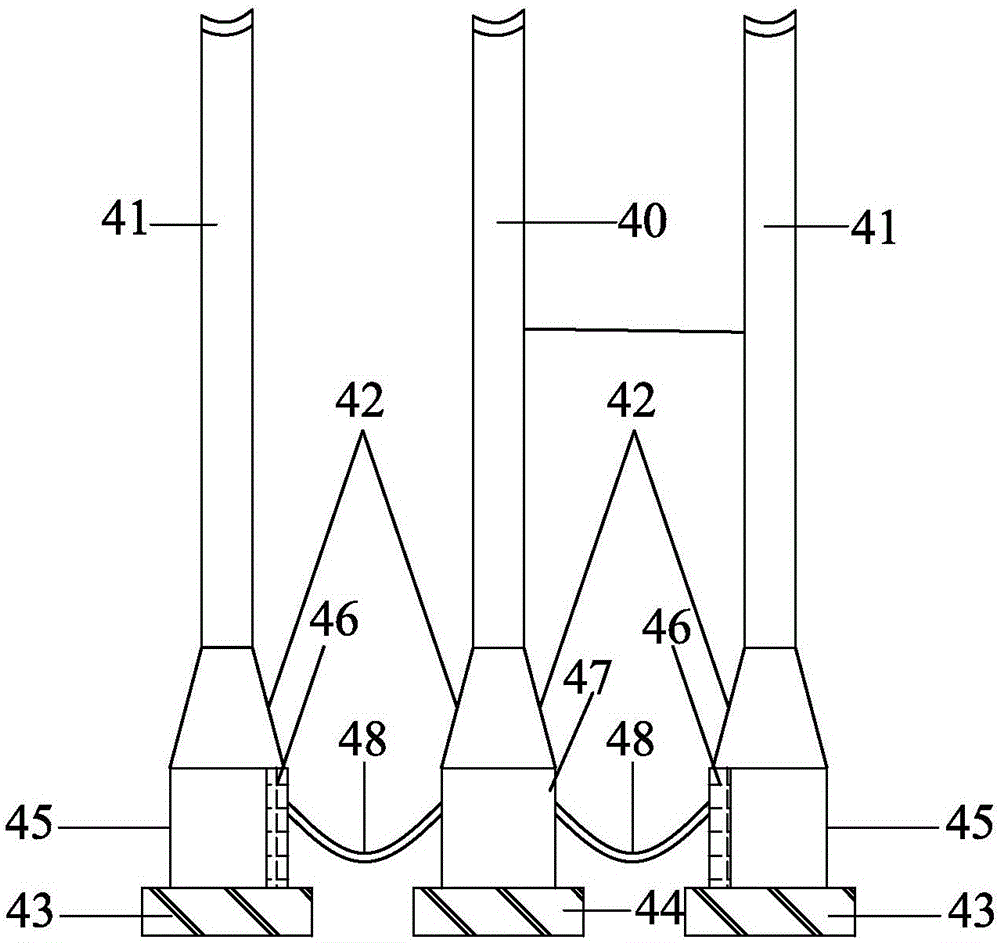

Underwater integrated type system for vertical pipe production and conveying and mounting method thereof

ActiveCN106697208ASignificant technological advancementAvoid asymmetryVessel partsFloating buildingsVertical tubeMarine engineering

The invention discloses an underwater integrated type system for vertical pipe production and conveying and a mounting method thereof. The system comprises a vertical pipe production assembly, a vertical pipe control assembly, a combination pontoon and a mooring device. The combination pontoon comprises an outer-layer pontoon body and inner-layer pontoon bodies, and the inner-layer pontoon bodies are embedded into the outer-layer pontoon body in a sleeved mode. The outer-layer pontoon body is responsible for supplying cable mooring tensile force, and all the inner-layer pontoon bodies are each responsible for supplying top tensile force to a single corresponding rigid production vertical pipe or rigid protection pipe, so that vertical stress and motion decoupling of the mooring device and all the vertical pipes are achieved, stress and motion decoupling between all the vertical pipes are also improved, and the requirement of in-place performance of the rigid production vertical pipes is improved. According to the underwater integrated type system for vertical pipe production and conveying and the mounting method thereof, a lower-section pipe cable of a flexible control pipe cable is uniformly integrated and assembled in the rigid protection pipe, and thus the problem of complex galloping damage is avoided; and the inner-layer pontoon bodies can freely rise and fall along the outer-layer pontoon body, and thus the thermal expansion requirement of the rigid production vertical pipes is met.

Owner:DALIAN UNIV OF TECH

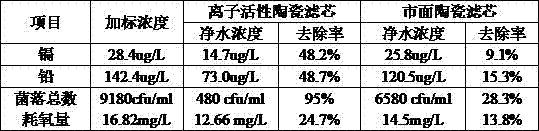

Ionic activity multi micropore ceramic filter element raw material formula and manufacturing technology thereof

InactiveCN107089836ASignificant technological advancementEfficient purificationOther chemical processesCeramicwareManufacturing technologyChemical adsorption

The invention relates to the technical field of ceramic filter element manufacture, and particularly relates to an ionic activity multi micropore ceramic filter element raw material formula. A filter element is prepared from, by weight, 20-30% of montmorillonite, 10-30% of clay, 10-30% of silicon earth, 10-30% of feldspar, 15-30% of pore-forming agents, 2-10% of tackiness agents, 10-20% of first catalyzer and 0.5-10% of second catalyzer. The formula has the advantages that a traditional ceramic filter element has single physical adsorption, and the ionic activity ceramic filter element by contrast, has physical and chemical adsorption and has remarkable technological progressiveness; through the raw material formula and the manufacturing technology process, the activity of ion particles which are distributed on the filter element evenly is retained effectively, and the technical difficulty that the ionic activity of the montmorillonite vanishes after the montmorillonite is subjected to 1000 DEG C high temperature calcination and loses crystal water in the prior art is solved. The ionic activity ceramic filter element plays an ionic bond electrostatic attraction part in the water purification process, pulls in and intercepts heavy metal ions in water, catches and inhibits and kills malignant bacteria, and accordingly has an efficient purification function.

Owner:邱和忠

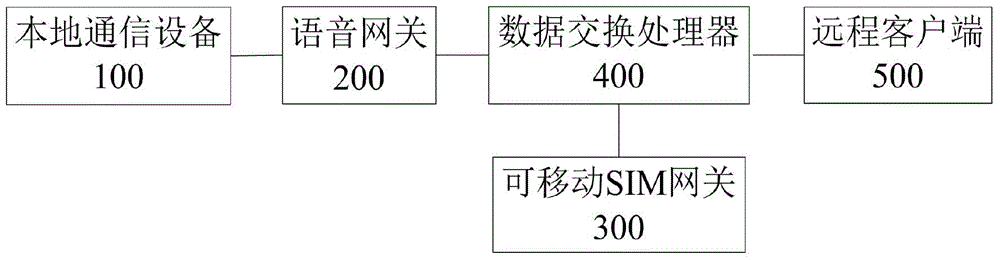

Method and system for realizing long-distance communication by using mobile SIM gateway

InactiveCN104883748ASignificant technological advancementEasy to useInterconnection arrangementsConnection managementTraffic capacityInternet network

The invention relates to a method and system for realizing long-distance communication by using a mobile SIM gateway. With a mobile SIM gateway and a voice gateway, SIM card authentication data are transmitted to a local base station operator authentication system or mobile base station authentication remotely by an internet network based on SIM gateway access, so that an SIM card is registered to the local base station remotely; and then a local communication service with continuous communication is realized by an APP or other terminals. Therefore, an objective of roaming flow and telephone charge saving is achieved.

Owner:安锦锋

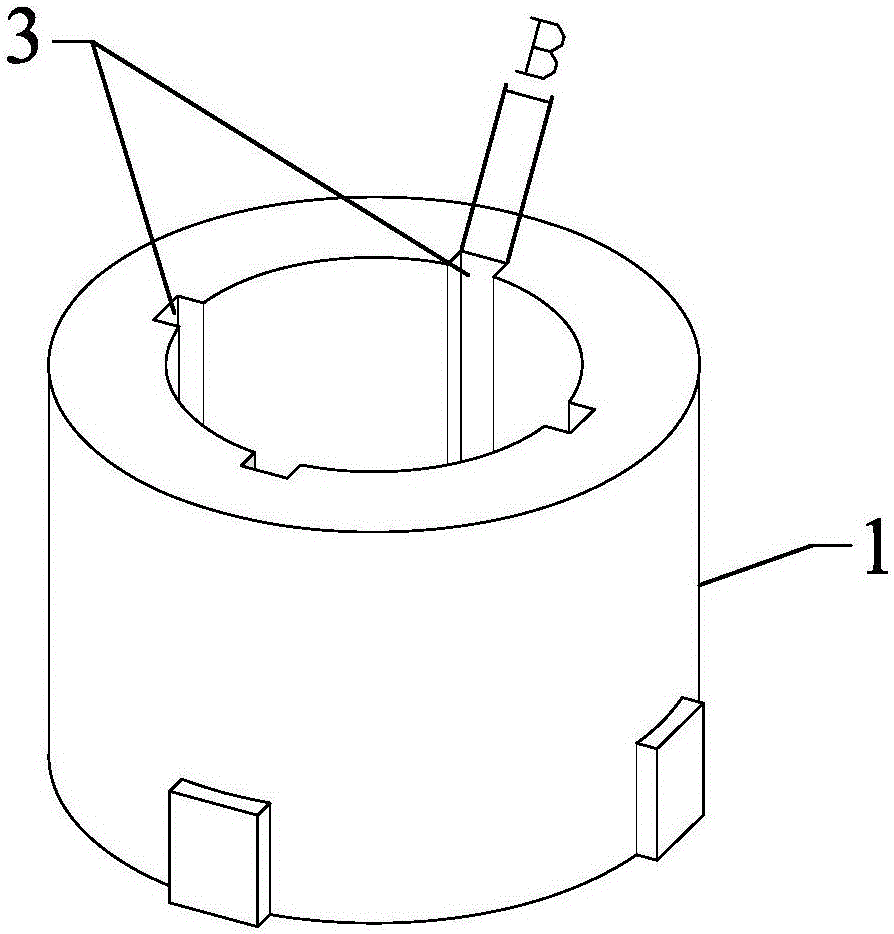

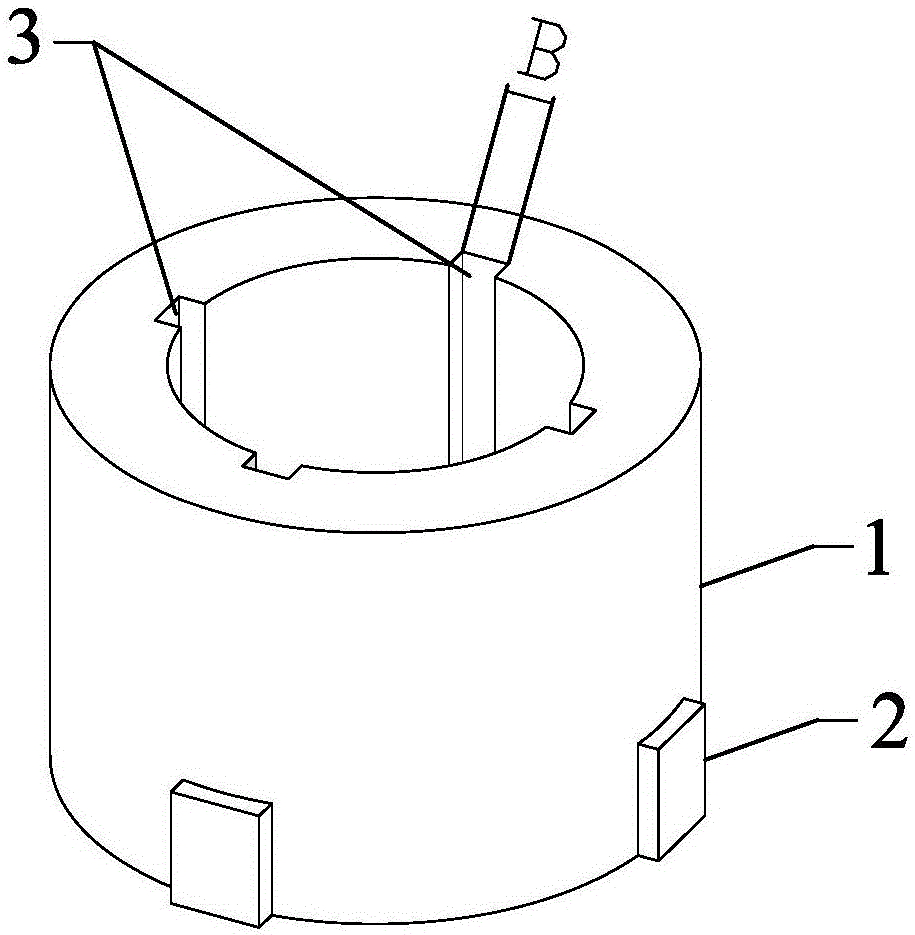

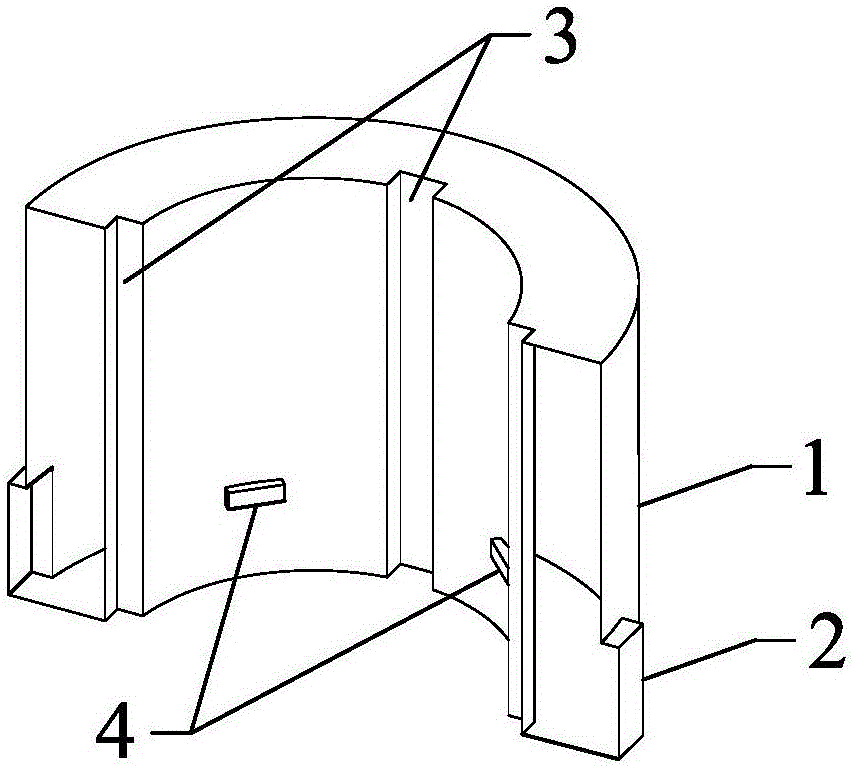

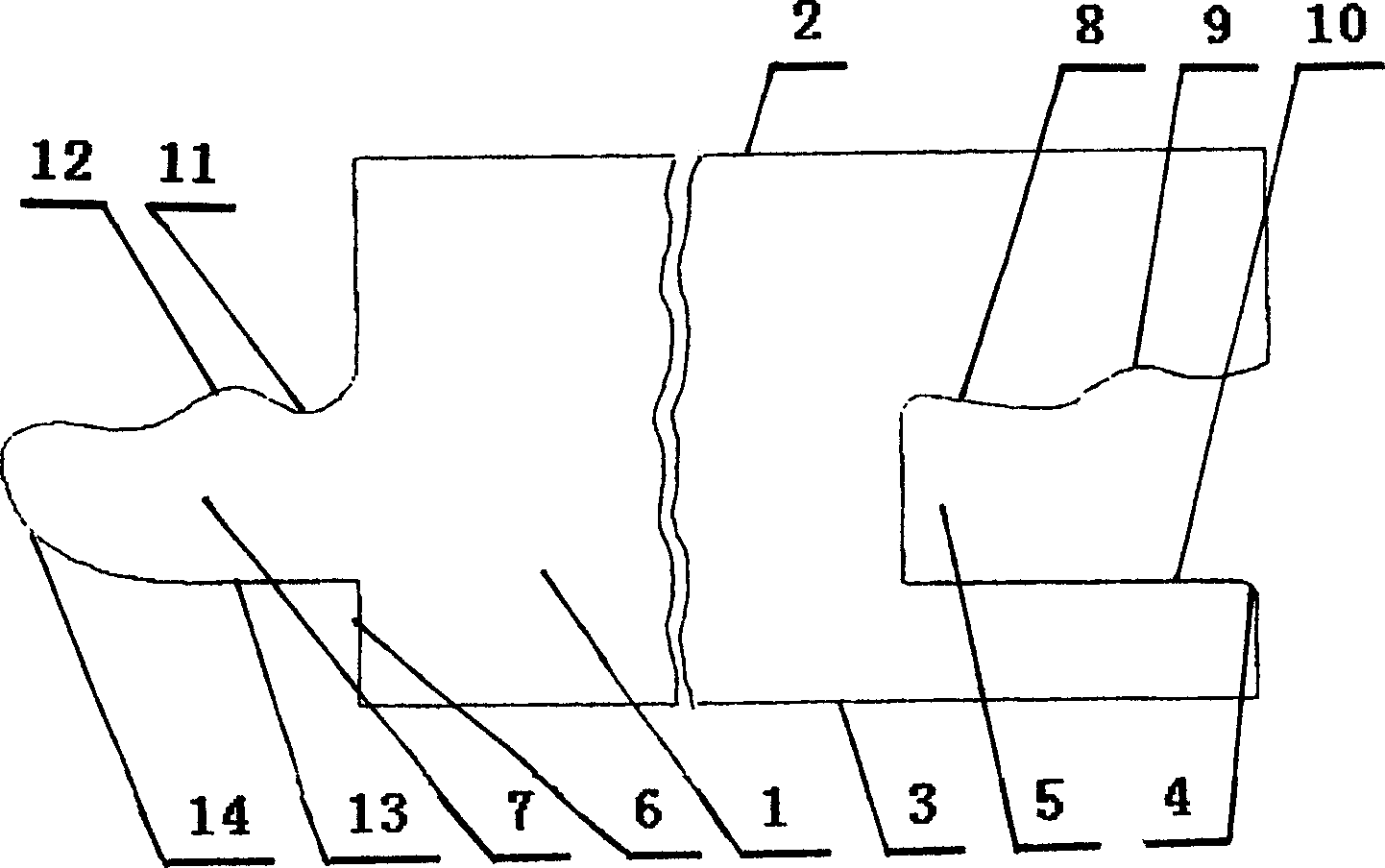

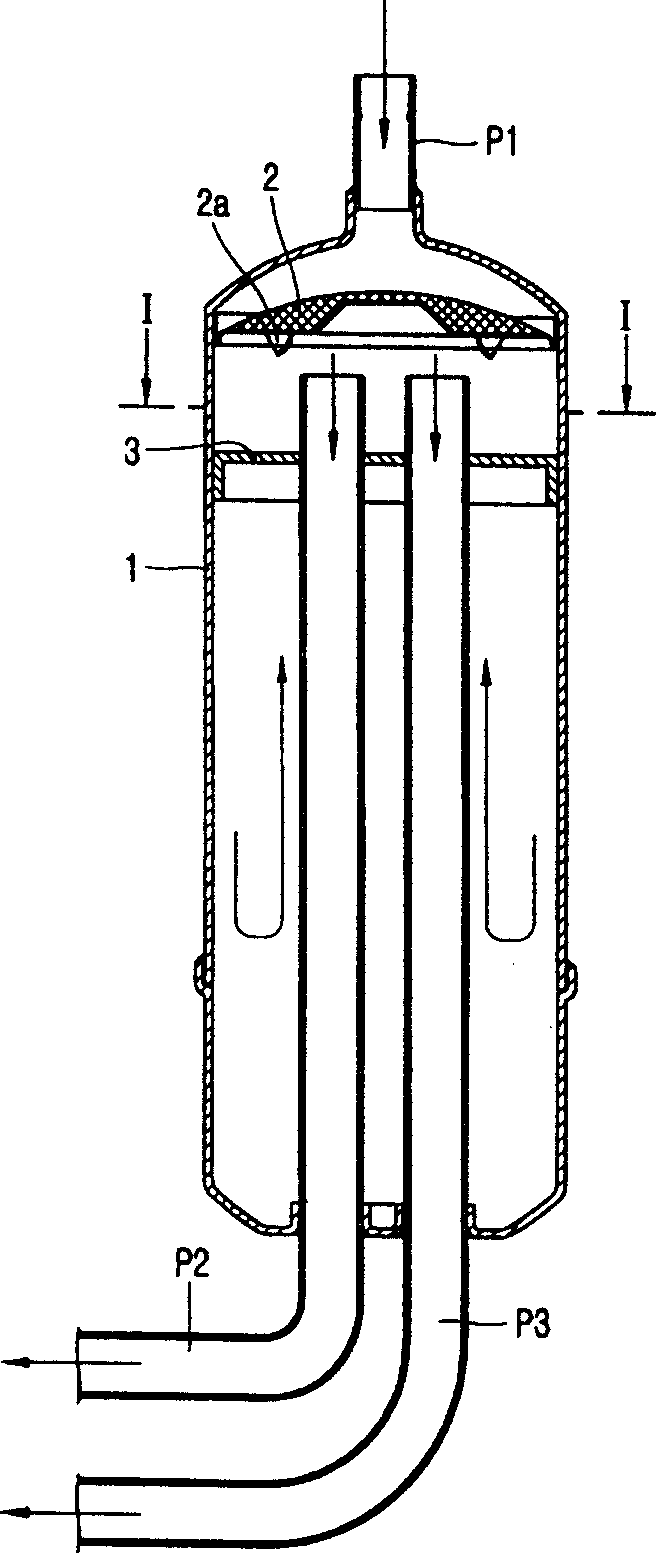

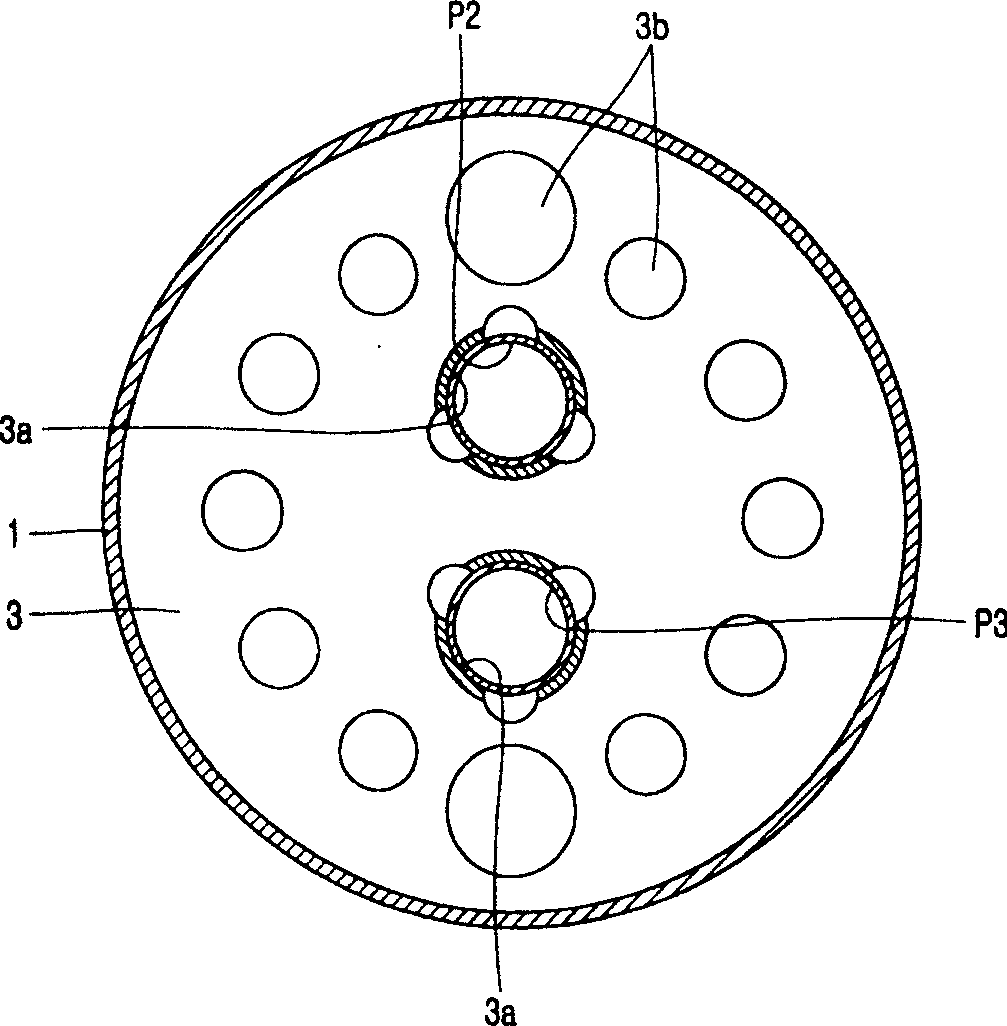

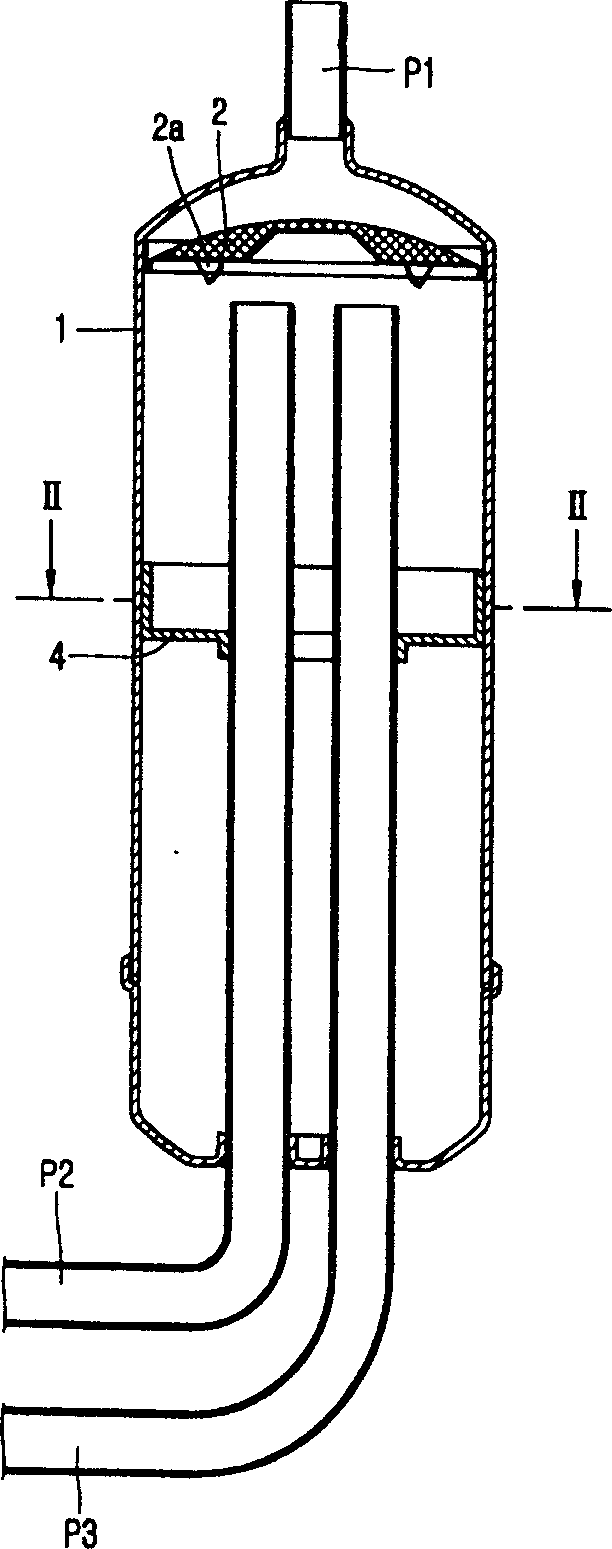

Riser self-tensioning type underwater production support buoy and mounting and recycling method thereof

ActiveCN106585910ASignificant technological advancementMeet the requirements of practical engineering applicationsVessel partsFloating buildingsBuoyUltimate tensile strength

The invention discloses a riser self-tensioning type underwater production support buoy and a mounting and recycling method thereof. The riser self-tensioning type underwater production support buoy comprises an outer layer buoy and inner layer buoys, wherein the plurality of inner layer buoys are embedded in the outer layer buoy. As the outer layer buoy is in charge of providing a tensioning force of a mooring cable and the inner layer buoys provide top tensioning forces of rigid risers, the riser self-tensioning type underwater production support buoy can conveniently provide desired top tensioning forces of the rigid risers and the mooring cable at the same time; and requirements of practical engineering application can be only satisfied by using the riser self-tensioning type underwater production support buoy in a super deep water ocean oil and gas engineering development system. As vertical motions and stresses of the rigid risers and the outer layer buoy are decoupled, the stress and motion amplitudes of the rigid risers can be reduced to be the benefit of improving the strengths and fatigue performances of the rigid risers. When the buoy is biased, secondary distribution of the top tensioning forces among the rigid risers can be avoided to be the benefit of improving the strengths and fatigue performances of the rigid risers so that the rigid risers satisfy use requirements.

Owner:DALIAN UNIV OF TECH

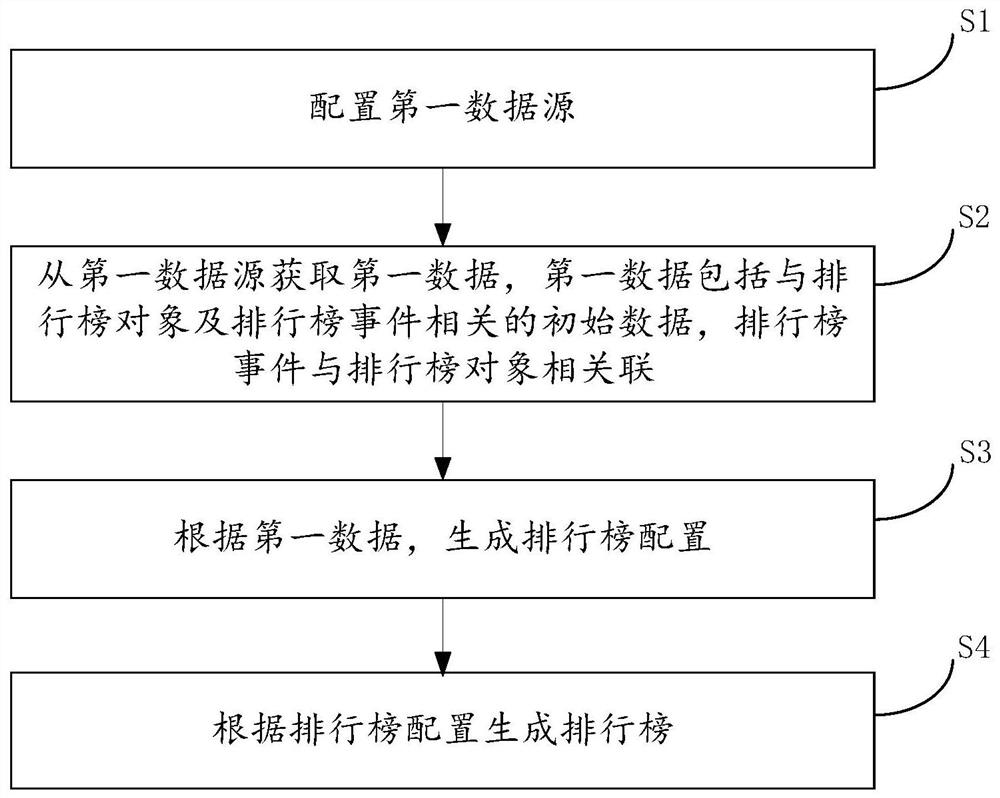

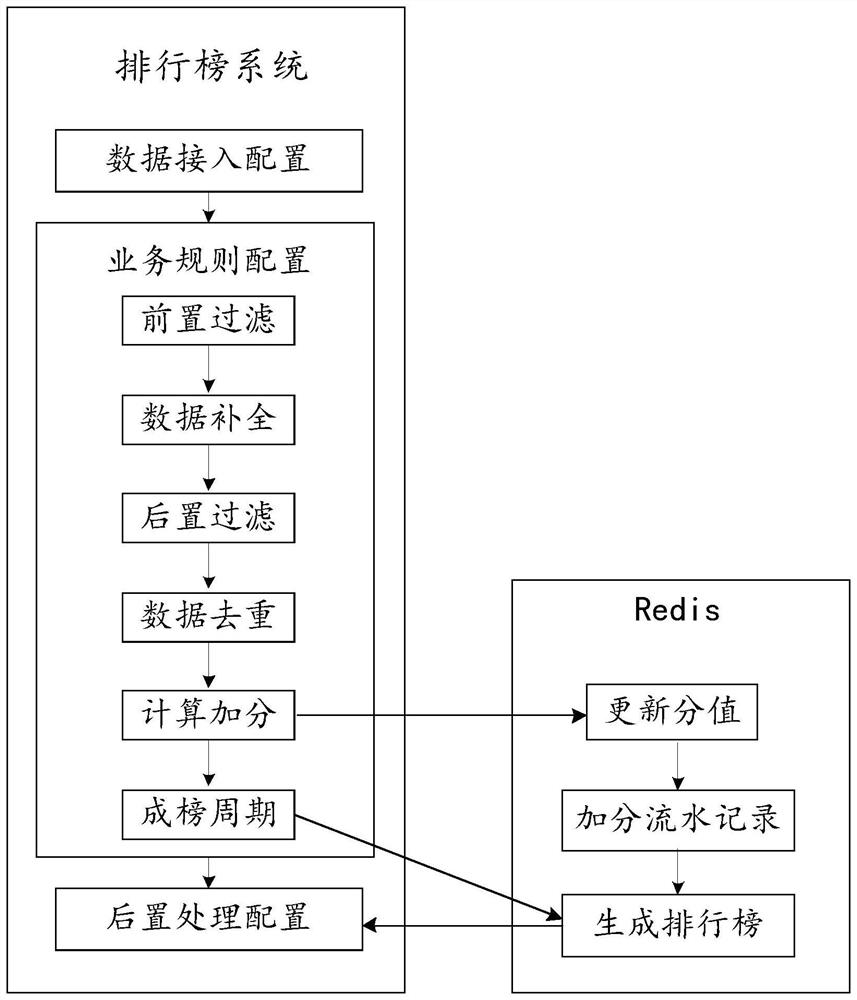

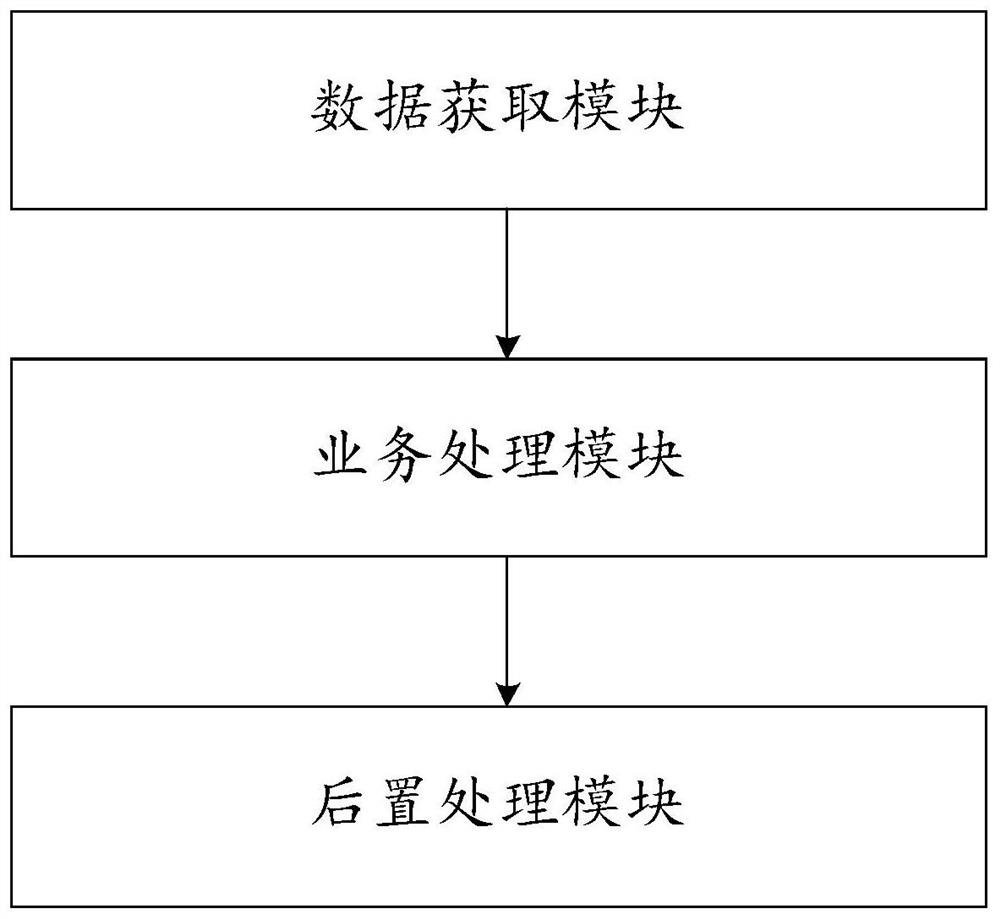

Ranking list system and method for generating ranking list

PendingCN112799644ASignificant technological advancementSignificant practicalityInterprogram communicationSoftware designData packData source

The invention proposes a method for generating a ranking list. The method comprises the steps: configuring a first data source, obtaining first data from the first data source, obtaining the first data from the first data source, enabling the first data to comprise initial data related to a ranking list object and a ranking list event, enabling the ranking list event to be related to the ranking list object, generating a ranking list configuration according to the first data, and generating the ranking list according to the ranking list configuration. The invention further provides a ranking list system, wherein the system has expandability, and requirements of different types of ranking lists are flexibly met in a configuration mode, so that manpower and material resources needed by development of different types of ranking lists are reduced, and the development cost is reduced; meanwhile, the development period is shortened, and the ranking list generation efficiency is improved.

Owner:GUANGZHOU BAIGUOYUAN NETWORK TECH

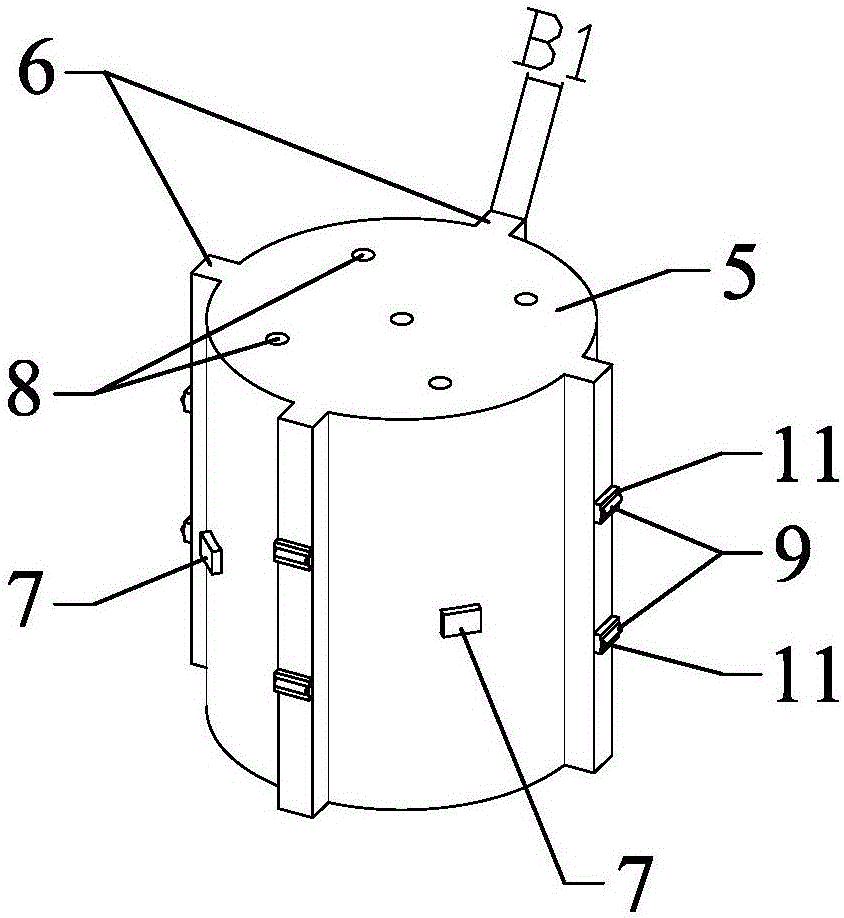

Double-layer underwater production supporting floating barrel and installation and recycling methods thereof

ActiveCN106522896ASignificant technological advancementMeet the requirements of practical engineering applicationsFluid removalUltimate tensile strengthSeabed

The invention discloses a double-layer underwater production supporting floating barrel and installation and recycling methods thereof. The floating barrel comprises an outer floating barrel body and an inner floating barrel body, wherein the inner floating barrel body is nested in the outer floating barrel body. The outer floating barrel body is used for providing tension force of mooring cables, the inner floating barrel body is used for providing top tension force required by a rigid vertical pipe, accordingly, the double-layer floating barrel can conveniently and separately provide the top tension force required by the rigid vertical pipe and the mooring cables, and by applying the double-layer floating barrel in an ultra-deep ocean oil-gas project development system, the requirement for practical project application can be met. The perpendicular movement and stress of the rigid vertical pipe and the outer floating barrel body are decoupled, so that the stress and movement amplitude of the rigid vertical pipe are reduced, and the strength and fatigue performance of the rigid vertical pipe can be improved advantageously. The outer floating barrel body is moored on a seabed through the four mooring cables, when any one of the cables breaks off and fails, the other three cables can still maintain stability of the outer floating barrel body, and safety of the oil-gas development system is ensured.

Owner:DALIAN UNIV OF TECH

Reinforced composite floor board and method of increasing its work surface fastening force

InactiveCN1847580AGuaranteed clamping forceExtended service lifeFlooringEngineeringMechanical engineering

The present invention is method of increasing the fastening force of the working surface of composite floor to prolong the service life of the composite floor and the floor thus produced. The floor features that the preliminary shafts are set in the surface of the work groove near the wearing layer and the surface of the work tongue, that the surface of the work groove near the damp-proof layer and the surface of the work tongue near the damp-proof layer are even whereas the top of the work tongue is circular for convenient insertion, and that the work surface produces powerful clamping force to make the floor impact resistant without arching, flat and long in service life.

Owner:上海格林德斯木业有限公司

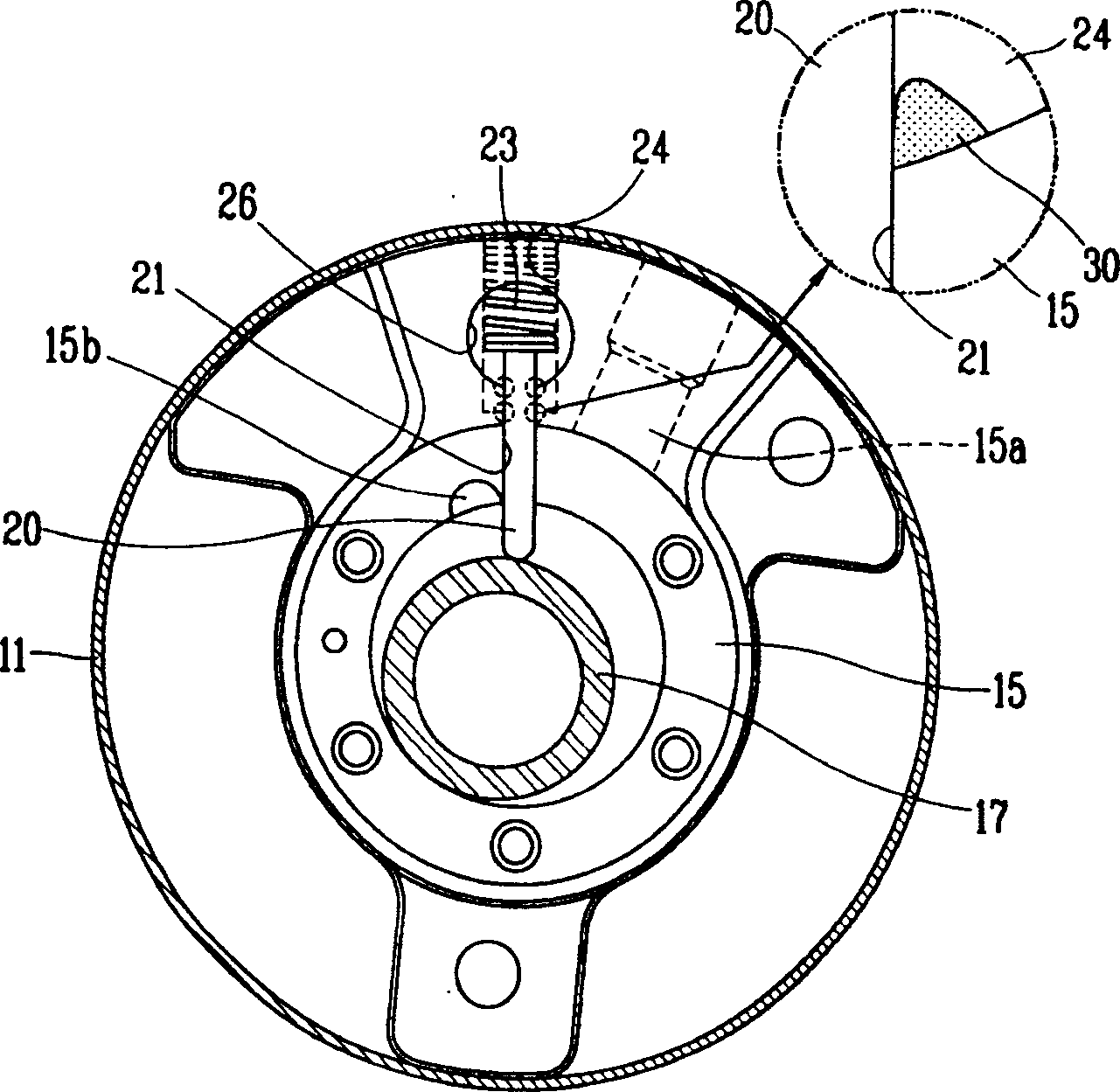

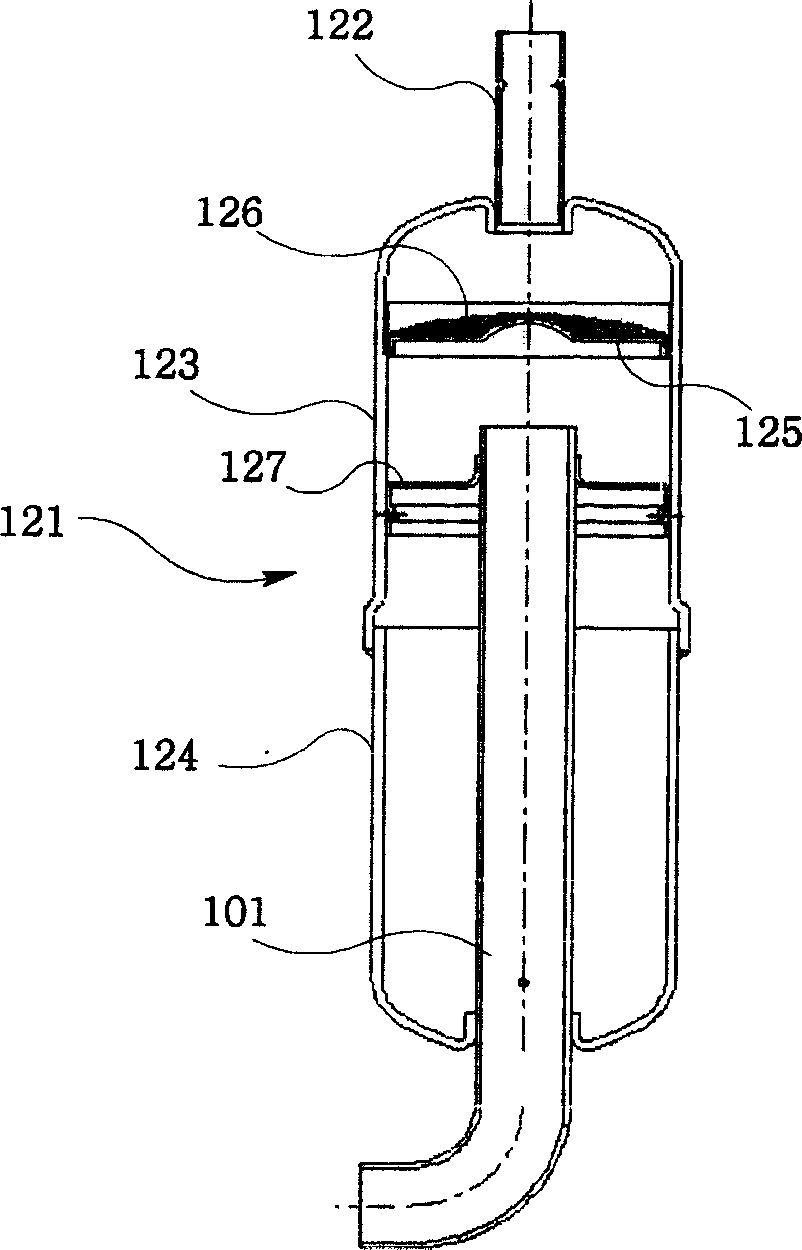

Vibration-noise absorber of liquid-storage tank for compressor

InactiveCN1896534AReduce vibration noiseSignificant technological advancementRotary/oscillating piston pump componentsLiquid fuel engine componentsLiquid storage tankEngineering

This invention relates to a kind of liquid-storage tank vibrating noise decreasing device for compressor. One end of air guiding pipe inserts into outer casing that has refrigerant circulating pipe. The other end of air guiding pipe connects to compressor absorbing hole. The liquid storage tank separates refrigerants flowing into the said outer casing into gaseous refrigerant and liquid refrigerants. In order to support air-guiding pipe, the end of air guiding pipe is set with reinforced materials.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

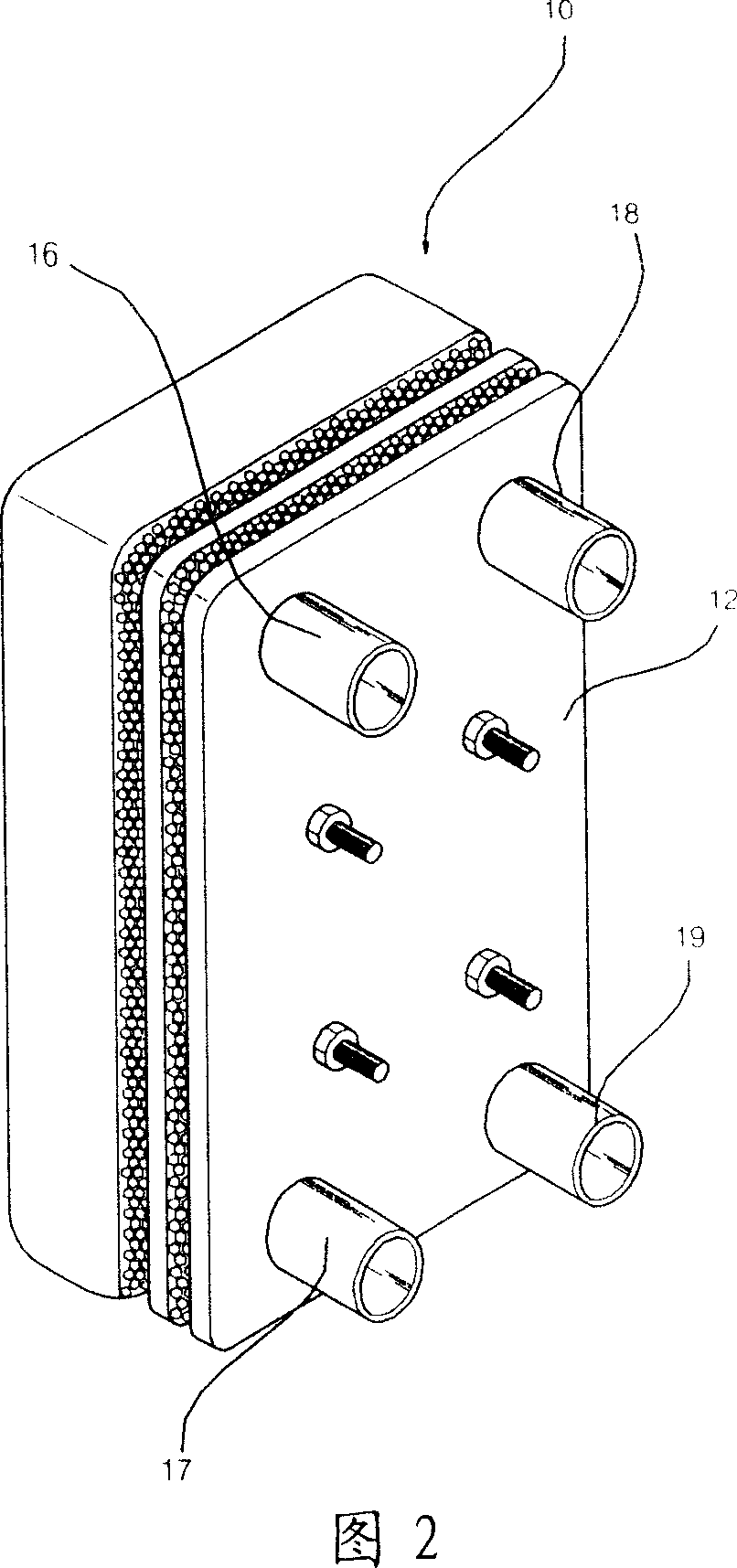

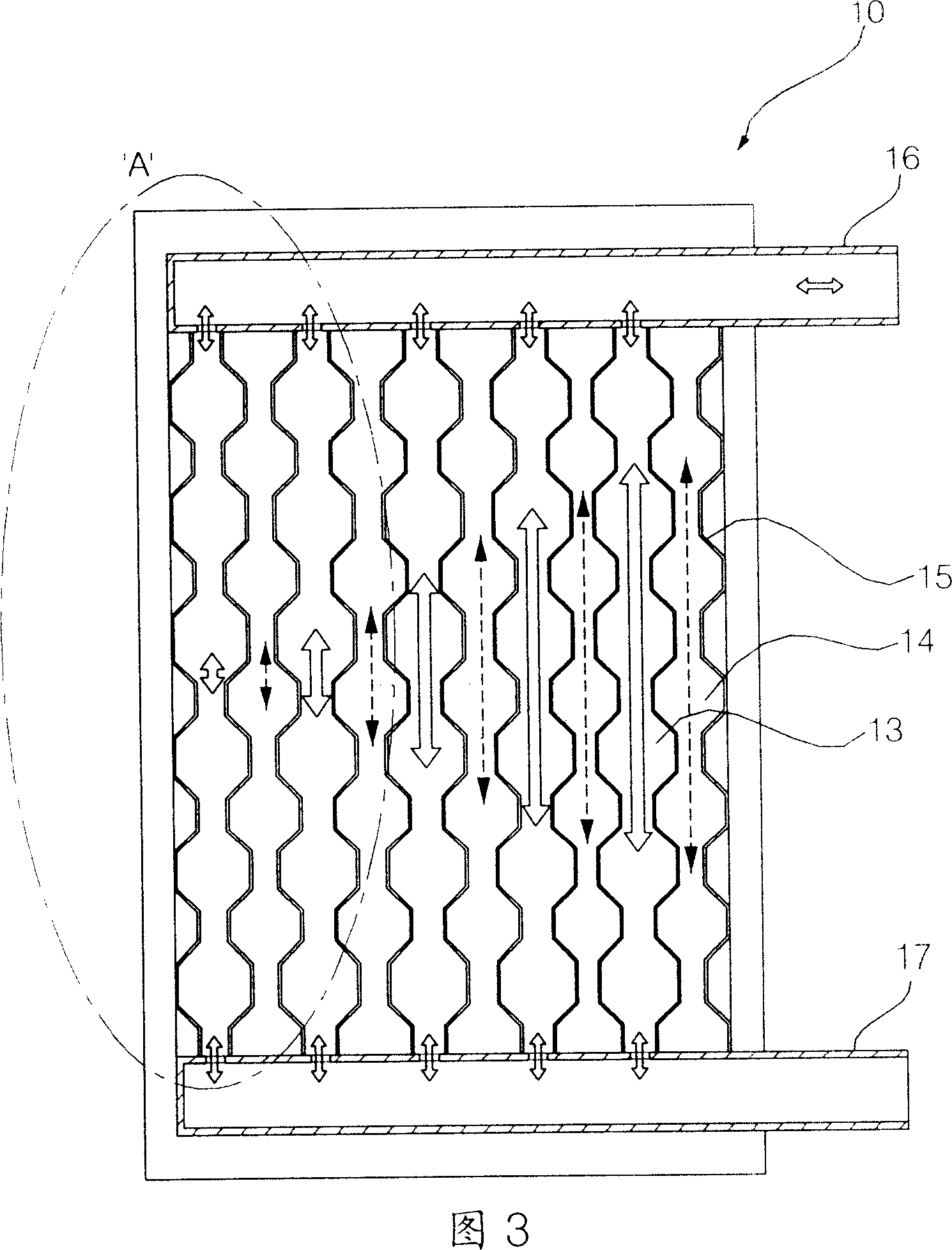

Disk type heat exchanger

InactiveCN1959327AImprove heat exchange efficiencySignificant technological advancementHeat exchanger casingsStationary plate conduit assembliesPlate heat exchangerEngineering

A heat exchanger of tray type consists of multiple heat exchange box formed by arranging the first and the second heat exchange media channels alternatively, the first and the second heads set on said box and used for supplying or recovering the first heat exchange media, the third and the fourth heads set on said box and used for supplying or recovering the second heat exchange media, heat exchange media equally distributing unit for distributing two said medias equally in two said channels.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

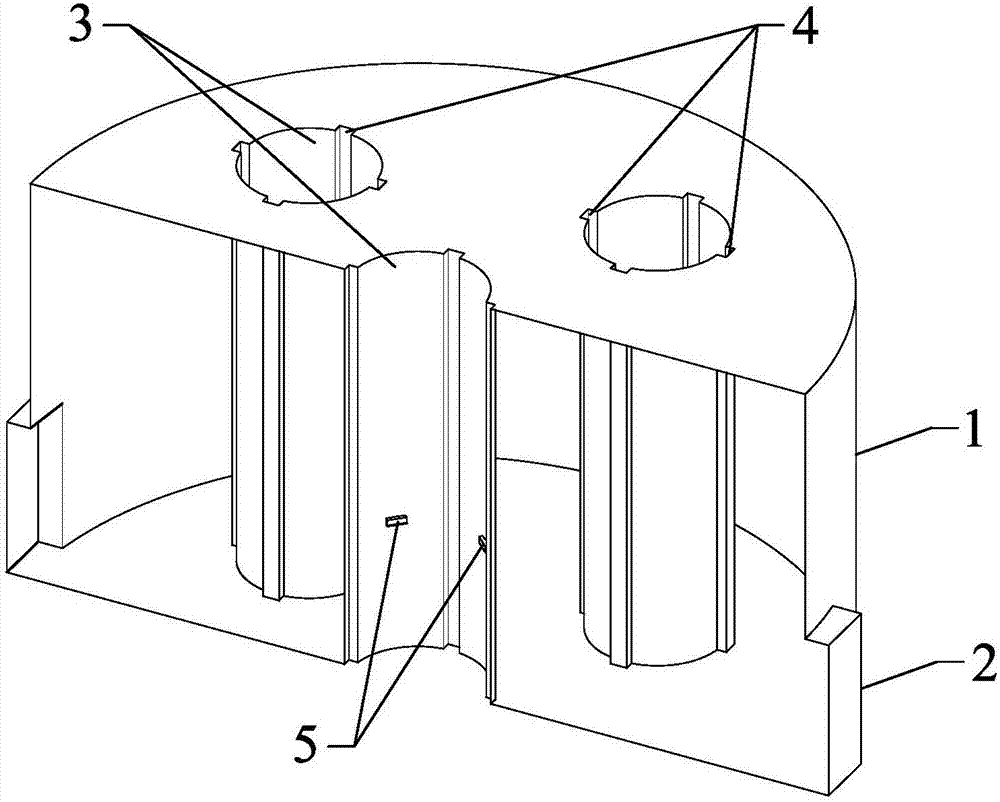

Discharging structure of reciprocating rotary compressor

InactiveCN1896543ASignificant technological advancementReduce in quantityRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsInterior spaceGyration

This is a kind of air discharging structure of twin rotating compressor. It includes the first and second air cylinders, which absorb and compress refrigerants; intermediate bearing separating the inner space of the two air cylinders; main bearing and assistant bearing respectively setting at upper and lower sides of the air cylinders at both sides. They not only seal the inner space of two air cylinders, but also support the rotating shaft, which transfers the driving force of driving electric engine; many rotating pistons, which connect to the rotating shaft and carries out gyration. They compress refrigerants with each throttle valves; the first discharging passage, which is in the main bearing and is used for discharging the refrigerants compressed by the first air cylinder; the second discharging passage, which forms by connecting the second air cylinder, intermediate bearing, the first air cylinder and the said main bearing. This invention decreases the number of mufflers and reduces the material cost.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

New method for manufacturing composite coating shell for precisely casting fusible patterns

InactiveCN101642798BQuality improvementImprove protectionFoundry mouldsFoundry coresWater basedMonolayer

The invention relates to a new method for manufacturing a composite coating shell for precisely casting fusible patterns, and belongs to the field of precise casting. The method comprises the following steps: using water-based ethylsilicate-silica sol as a mixed binder, preparing mixed binder paint by mixing the mixed binder with refractory powders and a curing agent, painting the mixed binder paint on the surface of a fusible pattern to form a monolayer or multilayer coating bottom layer, and sequentially painting a monolayer water glass binder paint transition coating and a multilayer waterglass binder paint enhanced coating on the bottom layer, thereby forming the composite coating shell for precisely casting the fusible pattern, wherein the composite coating shell consists of a mixedbinder coating bottom layer and a water glass binder coating enhanced skin coat. The invention solves the manufacturing difficult points of the shells with complicated inner cavities, deep blind holes and deep groove parts and the problems of slow drying, long production periods, low quality and the like of the shells existing in a precise casting trade for a long time, comprehensively improves the quality of precision castings, markedly reduces the production cost, is favorable for environment protection and is a creative breakthrough for a traditional technique in the field.

Owner:武汉工控艺术制造有限公司

A kind of method for afforestation of stony mountainous land with alien soil expansion and storage

InactiveCN106068741BImprove the ecological environmentIncrease effective storage capacityBio-organic fraction processingWatering devicesBiological storageEcological environment

The invention discloses a method for rocky mountain soil dressing storage expanding afforestation. The method comprises the steps that firstly, a special-shaped pit is dug, then, soil dressing replacement is performed and a biological storage expanding bulking agent is added into the special-shaped pit, meanwhile, supplemental irrigation water source preparation is performed, and finally, nursery stock preparation, nursery stock transplanting, rooting strengthening treatment and coverage water retention serial measures are performed to complete a rocky mountain storage expanding afforestation ecological project. The rocky mountain protoclastic granular structure can be improved, the soil reservoir effective storage is increased, the soil water storage capacity is enlarged, rainfall effectiveness and seedling drought resistance are enhanced, the natural rainfall storing and adjusting functions of a soil reservoir are brought into full play, the survival rate of rocky mountain difficulty site afforestation is increased, forest resource cultivation is accelerated, and the mountainous ecological environment is improved.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI +1

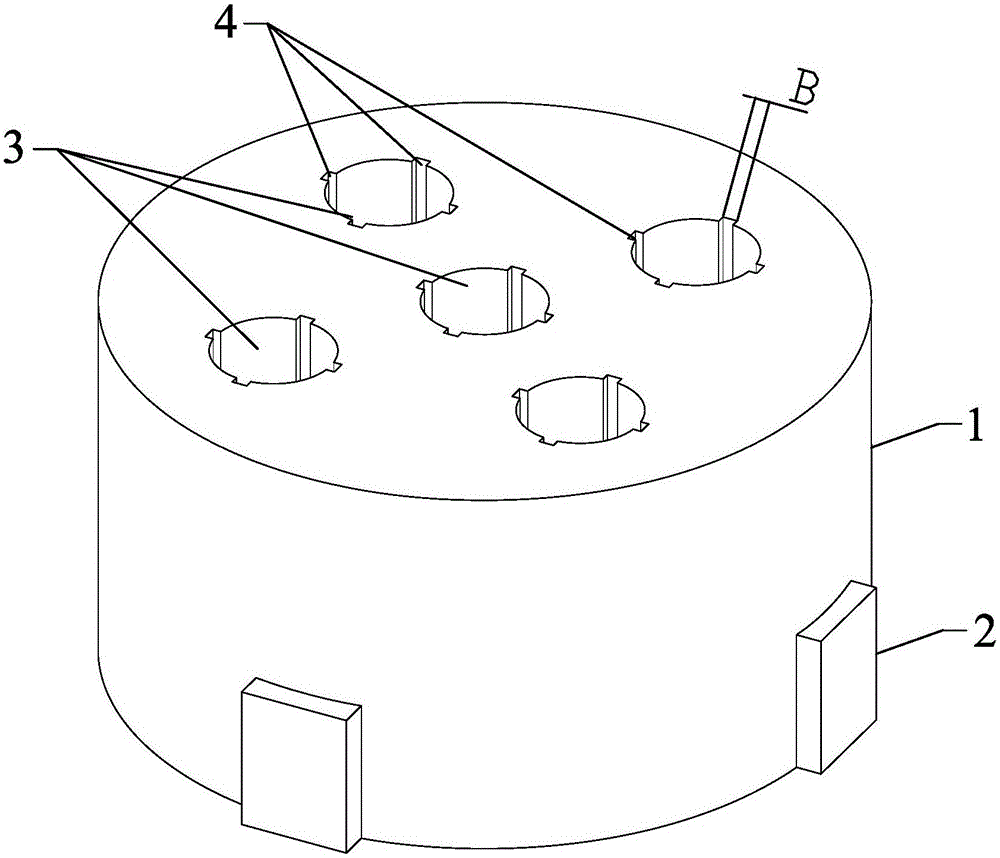

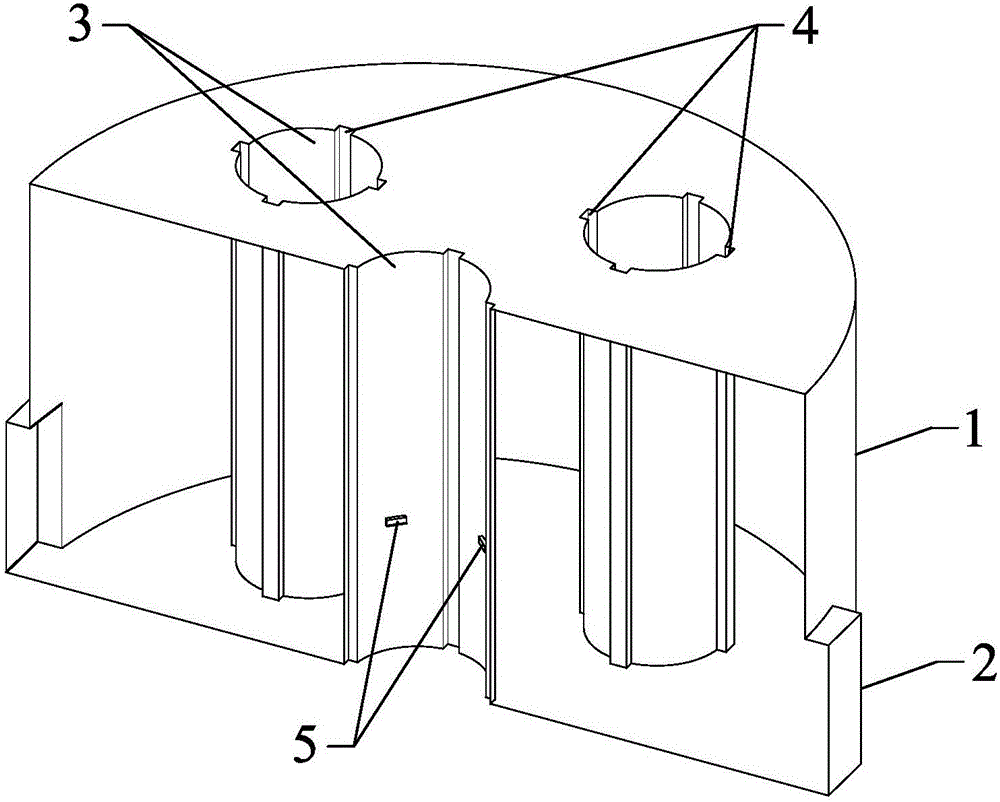

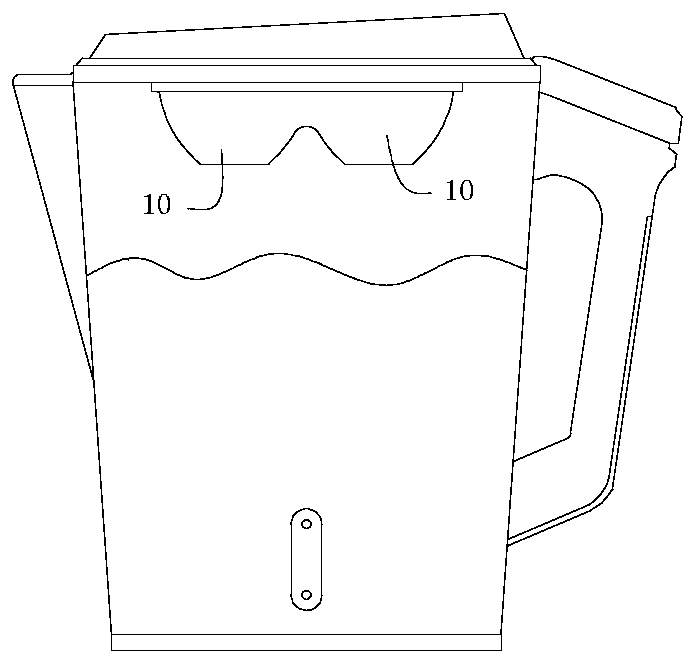

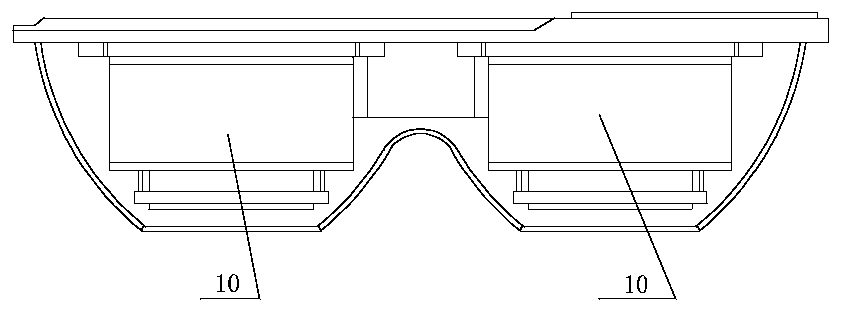

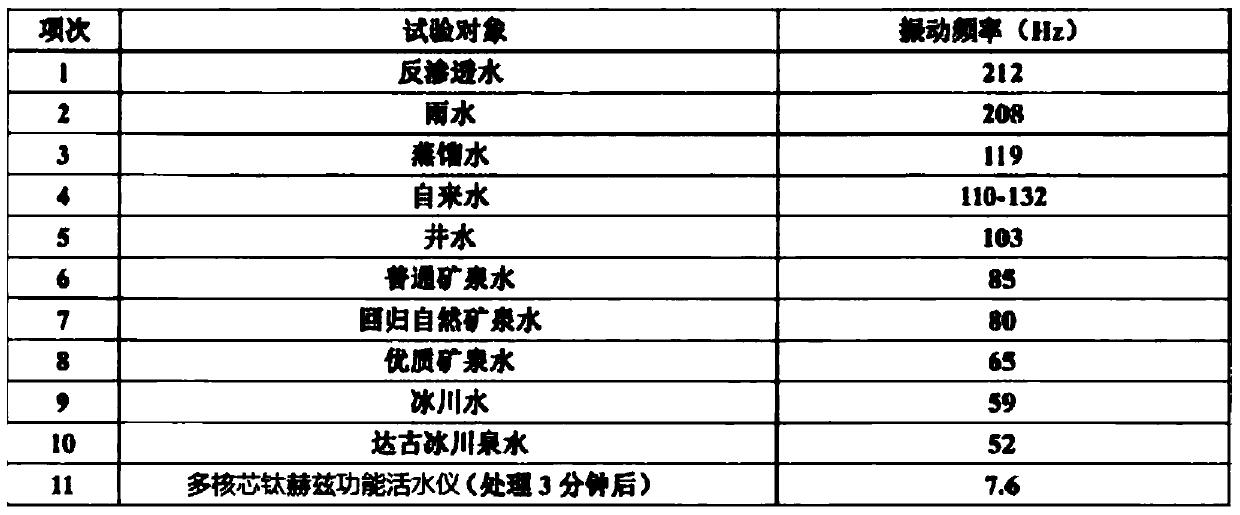

Multi-core titanium Hertz function water activating instrument and water activating method thereof

InactiveCN110304684AShorten the timeImprove activation efficiencyWater/sewage treatment with mechanical oscillationsResonanceDiiron Trioxide

The invention belongs to the technical field of water activating devices or water activating equipment and particularly relates to a multi-core titanium Hertz function water activating instrument anda water activating method thereof. The multi-core titanium Hertz function water activating instrument comprises two or more titanium Hertz activating cores, functional components include a first functional group and a second functional group, and the ratio of the mass components, namely gypsum rubrum, raw gypsum, agate and quartz, of the first functional group is 1:0.35:0.26:1.05; and the ratio ofthe mass components, namely selenomethionine, metasilicic acid, magnetic ferric oxide nanoparticles and titanium dioxide nanoparticles, of the second functional group is 0.56:0.24:1.05:1.24. A multi-core resonance structure and the corresponding water activating treatment method are adopted, thus the water activating time can be shortened from thirty minutes of existing equipment to three minutes, the energy saving rate can reach 90%, the activating efficiency is improved by about ten times, and significant technological advancement is realized.

Owner:东莞市淳萃知识产权服务有限公司

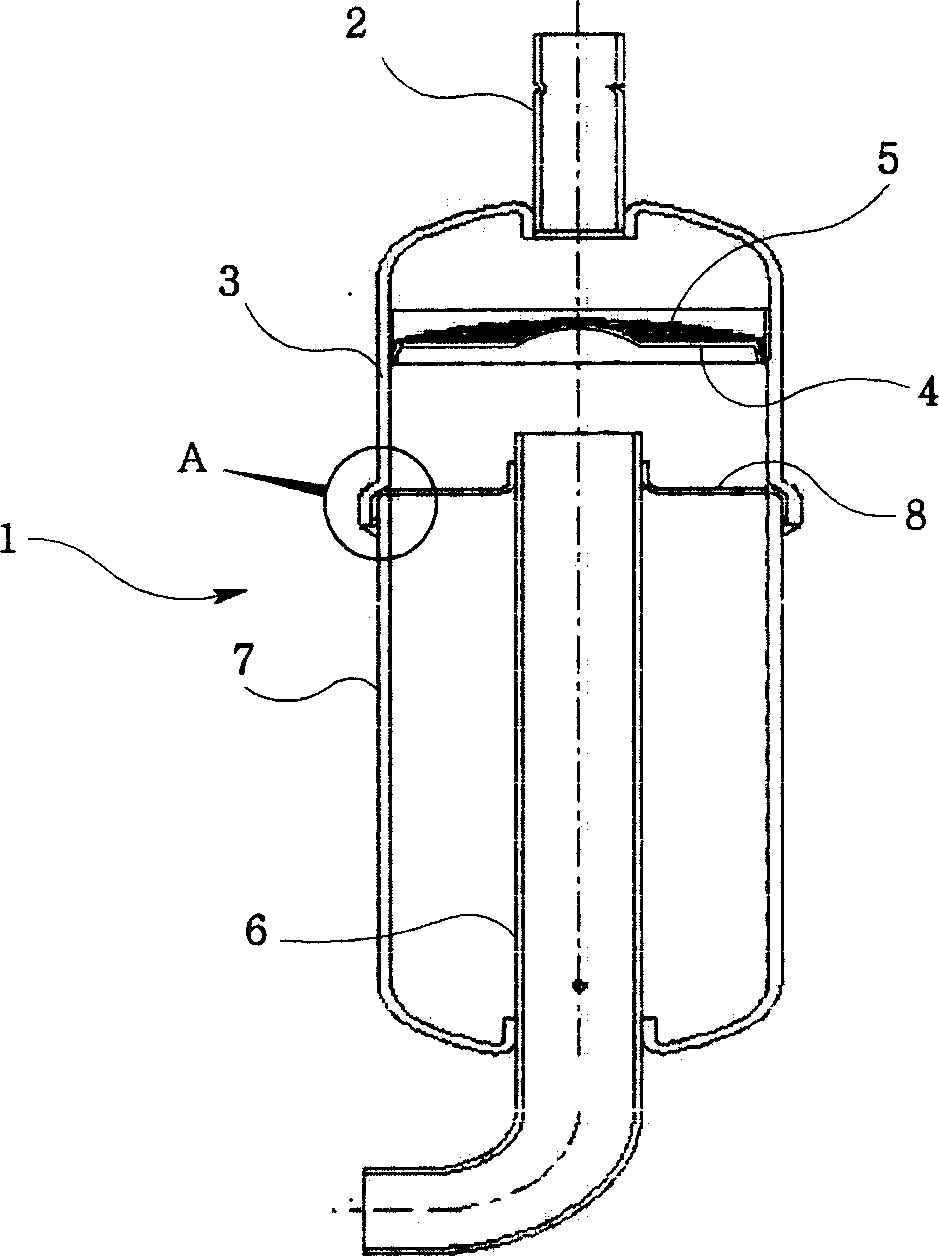

Liquid-storage tank of rotary compressor

InactiveCN1896530AImprove noiseImprove assembly engineeringRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigerantEngineering

This is a kind of liquid -storage tank of rotating type compressor. It includes upper cap, the upper side of which is set with refrigerants feeding pipe; and screen, which is set at the upper side of the inner side of upper cap and supported by screen support. It is used to separate refrigerant liquid; lower cap welding at the lower end part of the said upper cap; vertical part cutting through the lower part center of lower cap; L-flexible type feeding pipe connecting to compressor through horizontal part; feeding pipe fixer supporting the upper side of L-flexible type feeding type. It is between the upper cap and lower cap. They assembled together by welding so as to fixing more firmly in the liquid storage tank

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

A standpipe self-tensioning underwater production support buoy and its installation and recovery method

ActiveCN106585910BSignificant technological advancementMeet the requirements of practical engineering applicationsVessel partsFloating buildingsBuoyUltimate tensile strength

The invention discloses a riser self-tensioning type underwater production support buoy and a mounting and recycling method thereof. The riser self-tensioning type underwater production support buoy comprises an outer layer buoy and inner layer buoys, wherein the plurality of inner layer buoys are embedded in the outer layer buoy. As the outer layer buoy is in charge of providing a tensioning force of a mooring cable and the inner layer buoys provide top tensioning forces of rigid risers, the riser self-tensioning type underwater production support buoy can conveniently provide desired top tensioning forces of the rigid risers and the mooring cable at the same time; and requirements of practical engineering application can be only satisfied by using the riser self-tensioning type underwater production support buoy in a super deep water ocean oil and gas engineering development system. As vertical motions and stresses of the rigid risers and the outer layer buoy are decoupled, the stress and motion amplitudes of the rigid risers can be reduced to be the benefit of improving the strengths and fatigue performances of the rigid risers. When the buoy is biased, secondary distribution of the top tensioning forces among the rigid risers can be avoided to be the benefit of improving the strengths and fatigue performances of the rigid risers so that the rigid risers satisfy use requirements.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com