Reinforced composite floor board and method of increasing its work surface fastening force

A technology for strengthening composite and working surfaces, applied in the direction of floors, buildings, building structures, etc., can solve the problems affecting the overall flatness of the floor, affecting the service life of the floor, and raised arches, so as to enhance the reliability of work and extend the working life The effect of increasing the service life and increasing the clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method of the present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

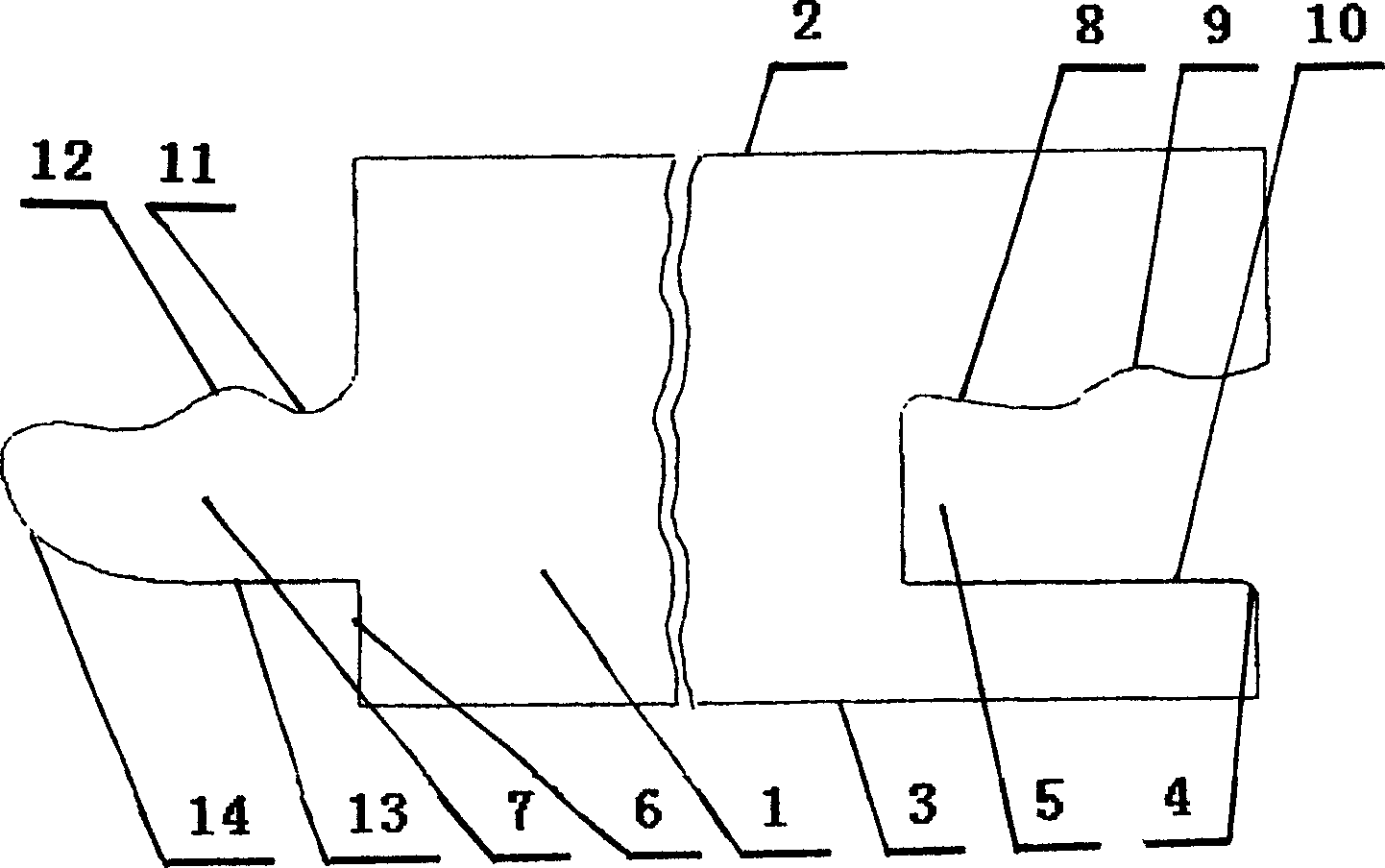

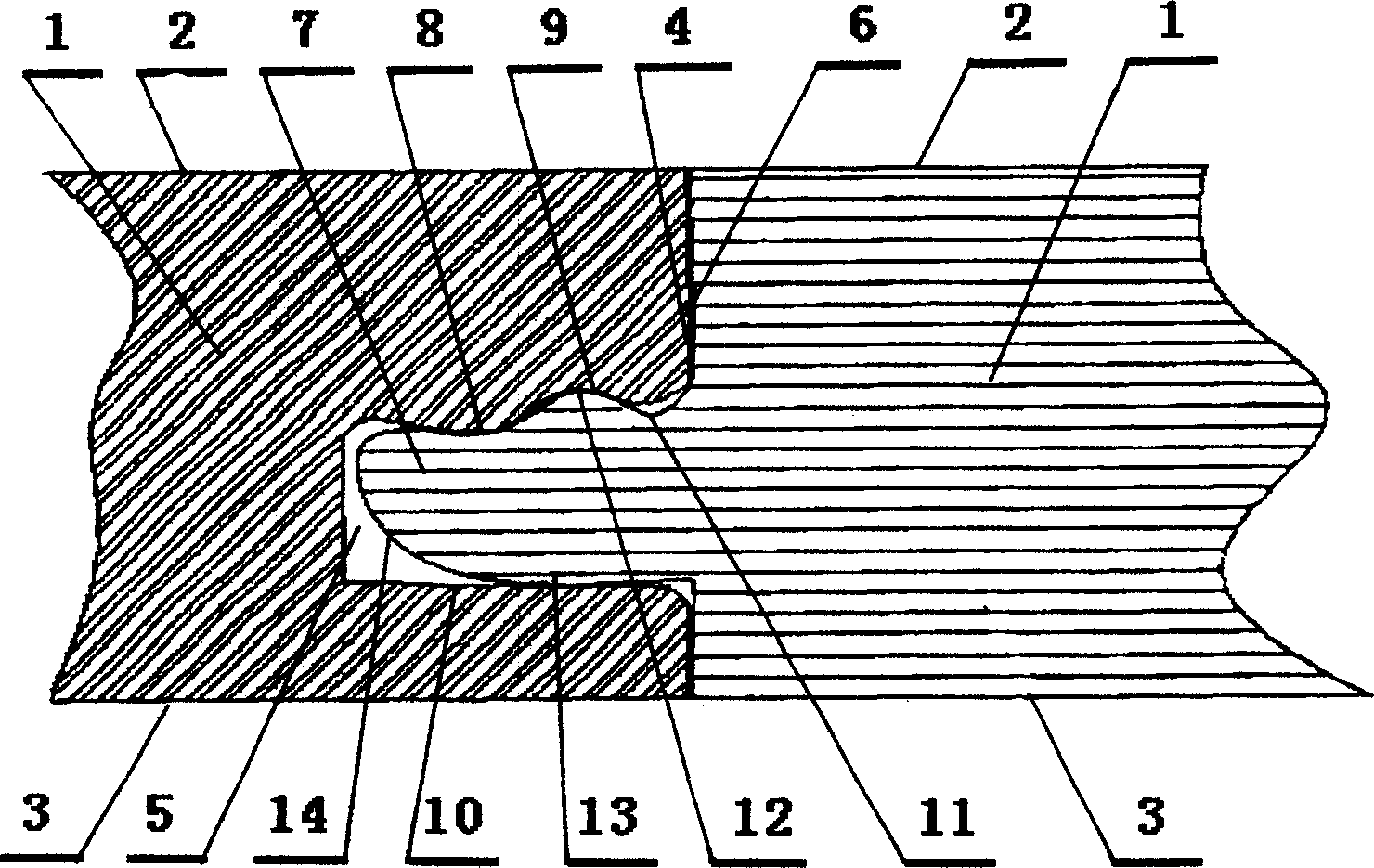

[0015] exist figure 1 and figure 2 Among them, the compound floor in the form of groove and tenon structure manufactured by the method of the present invention, the lock is arranged on the groove surface of the working groove near the working surface of the wear-resistant layer and the tenon surface of the working tenon, and on the working groove The other groove surface close to the moisture barrier layer is set flat, the initial section of the other tenon surface close to the moisture barrier layer is set flat, and the top end is set in an R arc shape for easy introduction. When fighting, you must rely on external force to enter the buckle. The composite floor manufactured based on the method of the present invention is mainly composed of a substrate 1 , a wear-resistant layer 2 and a moisture barrier layer 3 . A working groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com