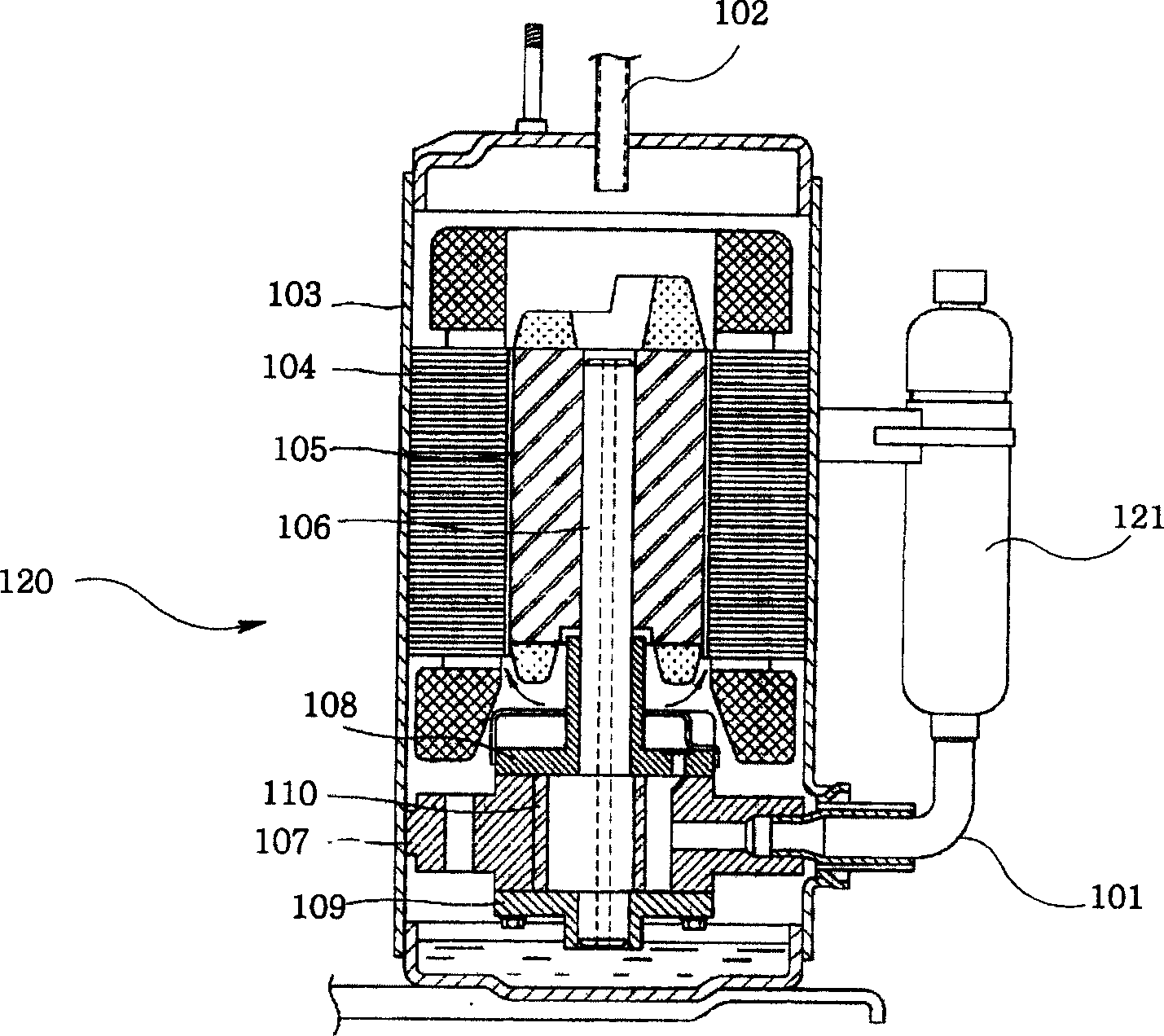

Liquid-storage tank of rotary compressor

A technology for rotary compressors and liquid storage tanks, applied to rotary piston/swing piston pump components, mechanical equipment, machines/engines, etc., to improve productivity, improve assembly engineering, and prevent poor welding and drooping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific implementation, structure, Features and their effects are described in detail below.

[0036] The following detailed description will be given in conjunction with the accompanying drawings of the embodiments of the present invention.

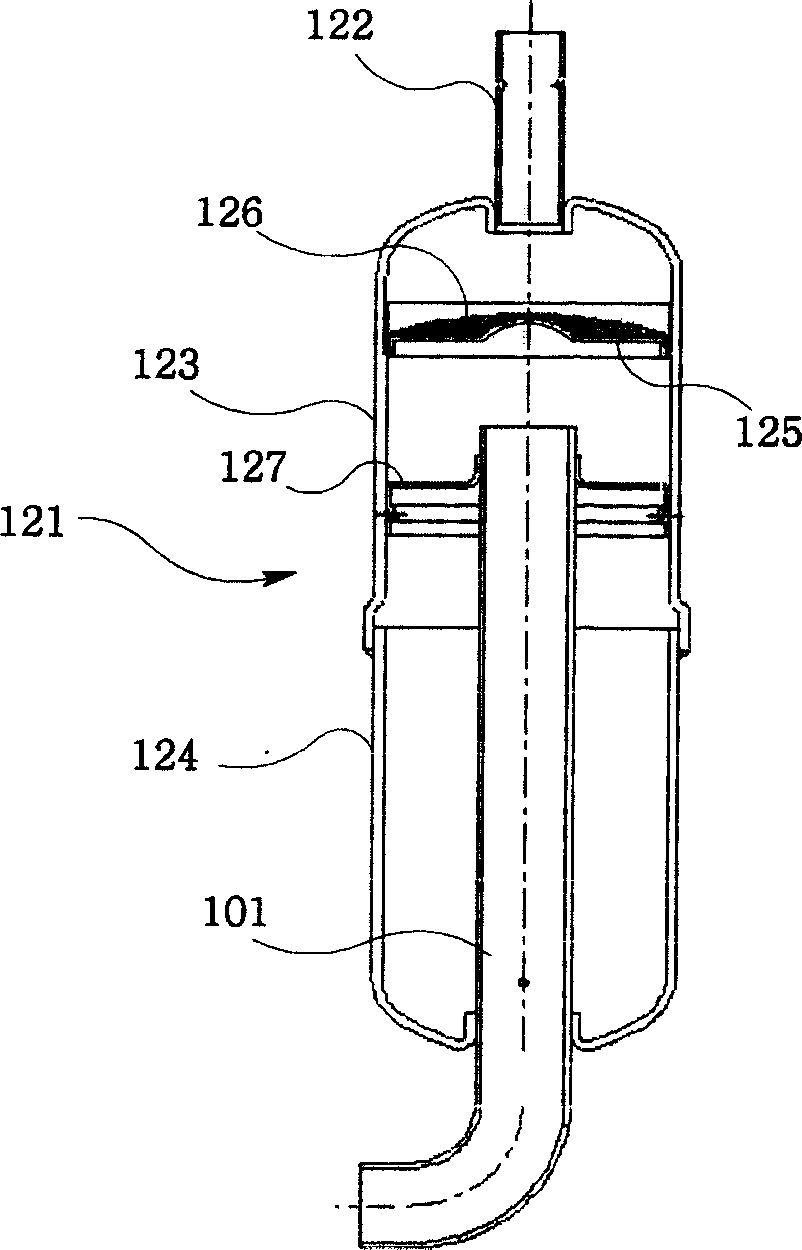

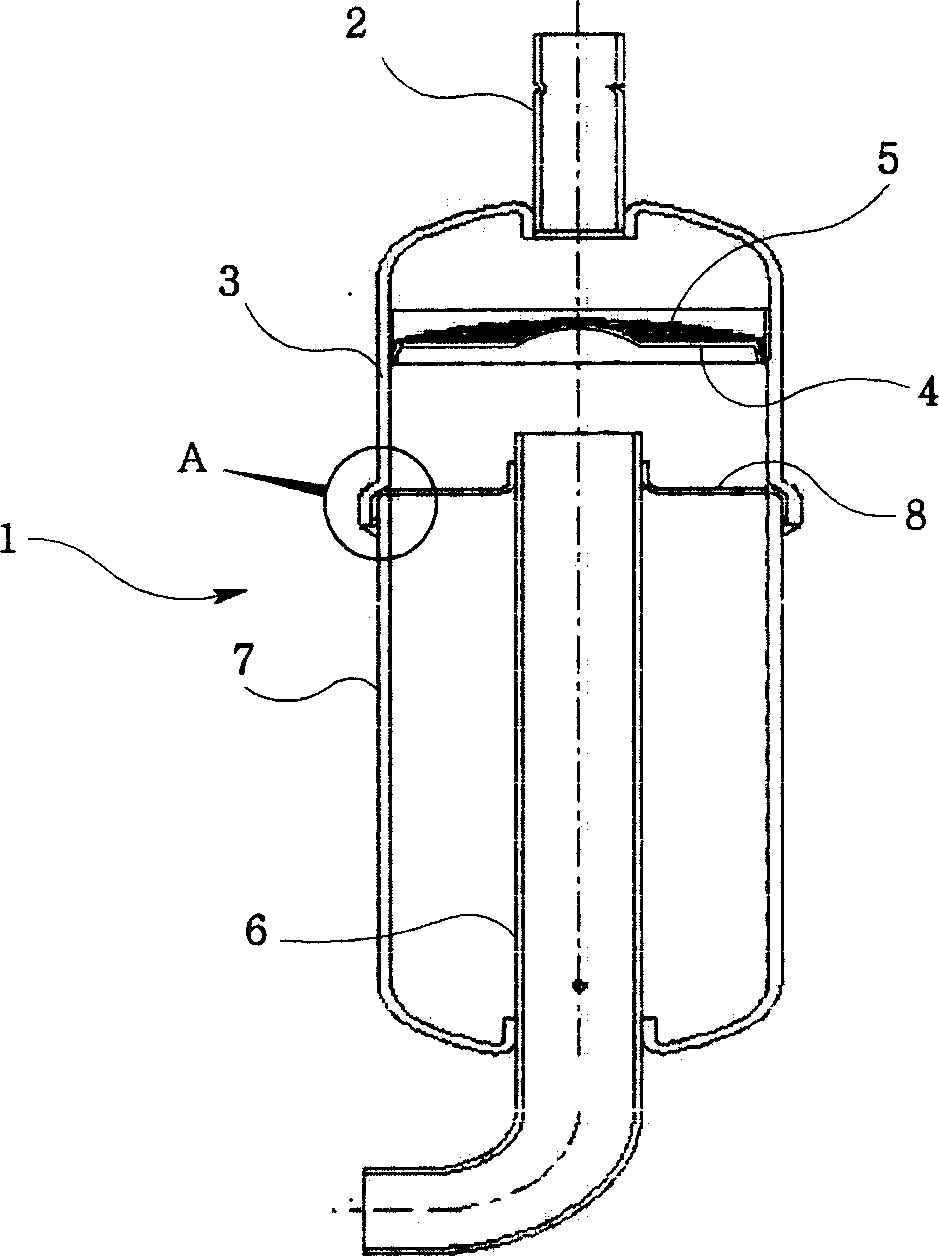

[0037] image 3 Shown is a longitudinal sectional view of the rotary compressor liquid storage tank according to the present invention, Figure 4 Shown is an enlarged cross-sectional view of the storage tank suction pipe holder according to the present invention, Figure 5 is to expand image 3 Sectional view of part A, Image 6 Illustrated is image 3 Longitudinal sectional view of another embodiment.

[0038] The liquid storage tank 1 of this rotary compressor is an upper cap 3 provided with a refrigerant inflow pipe 2 in the upper part; it is provided in the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com