Semi-open type wedge-shaped horizontal sliding hydraulic clamp

A hydraulic clamp, wedge-shaped flat technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult processing, short clamp stroke, difficult to remove, etc., achieving obvious technological progress, small deformation of the clamp body, and not easy to slip. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

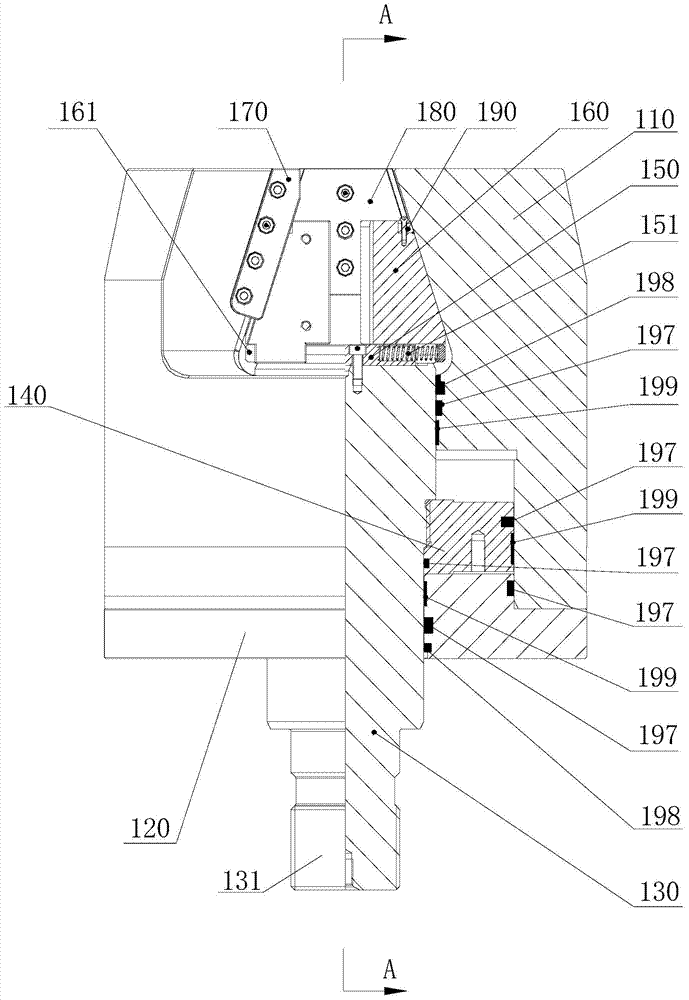

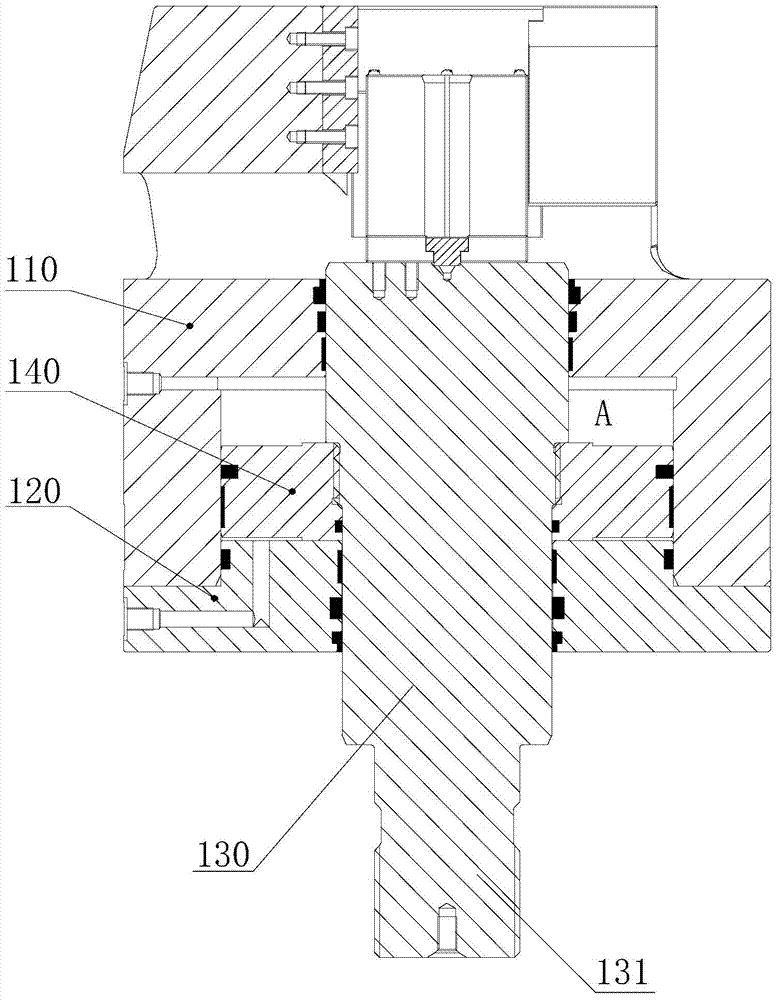

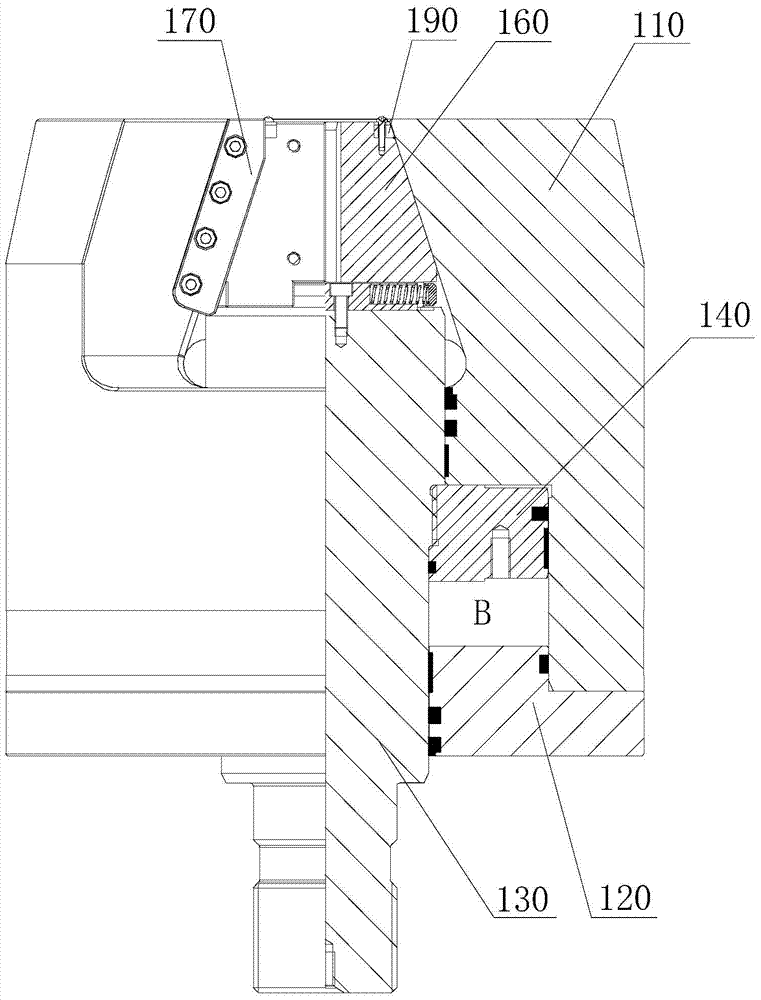

[0022] Such as Figure 1-4 As shown, a semi-open wedge-shaped flat-push hydraulic clamp includes a clamp body 110, an end cover 120, a piston rod 130, a piston 140, a guide key 150, two clamp blocks 160, two side guide plates 170, and an upper guide plate 180 and two dust-proof strips 190.

[0023] The clamp body 110 is cylindrical, with a wedge-shaped cavity at its top, and a stepped through hole communicating with the wedge-shaped cavity at its bottom and having a wide bottom and a narrow top. The bottom of the wedge-shaped cavity radially penetrates from the front side of the clamp body 110 to the On the rear side of the clip body 110, the upper part of the wedge-shaped cavity extends radially from the front side of the clip body 110 into the clip body 110, the radial length of the upper part of the wedge-shaped cavity is greater than the radius of the corresponding part of the clip body 110 and smaller The diameter of the center forms a semi-open wedge-shaped cavity, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com