Double-layer underwater production supporting floating barrel and installation and recycling methods thereof

A buoy, double-layer technology, applied in the field of double-layer underwater production support buoy and its installation and recovery, can solve the problem of providing mooring cables and rigid riser top tension at the same time, rigid riser top tension increase Large, rigid riser main body stress changes and other issues, to reduce performance requirements and technical requirements for installation and workover, reduce force and movement range, improve strength and fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

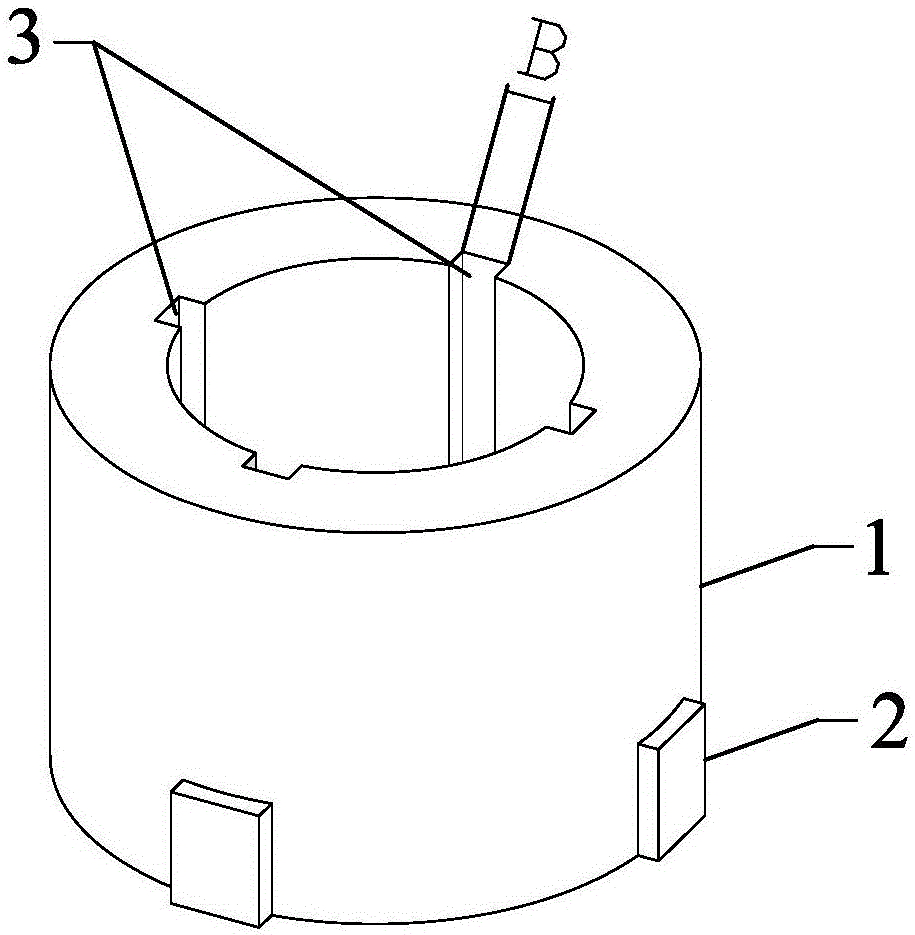

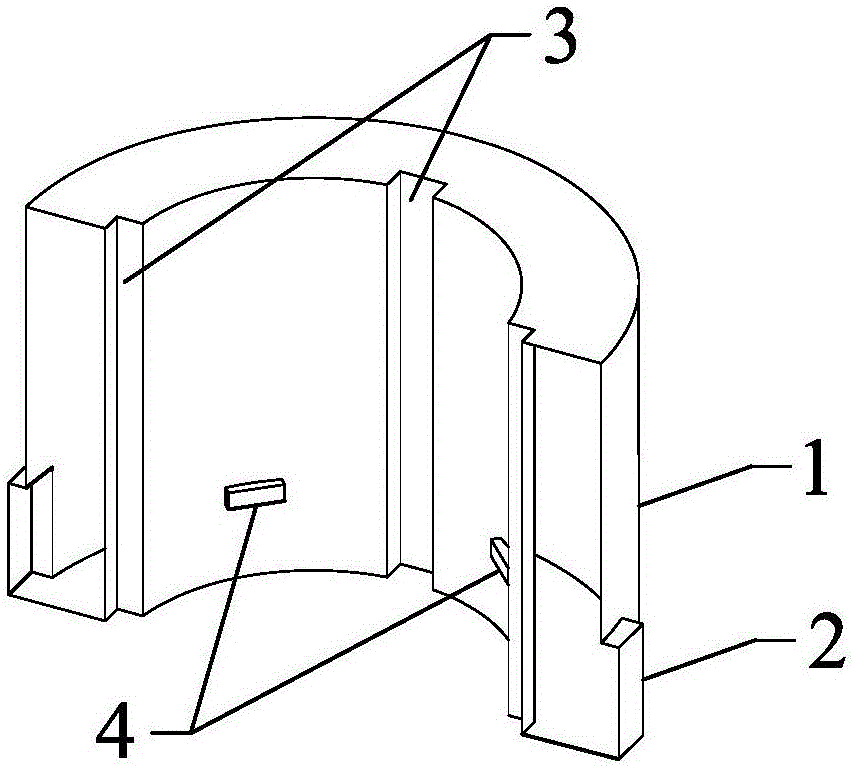

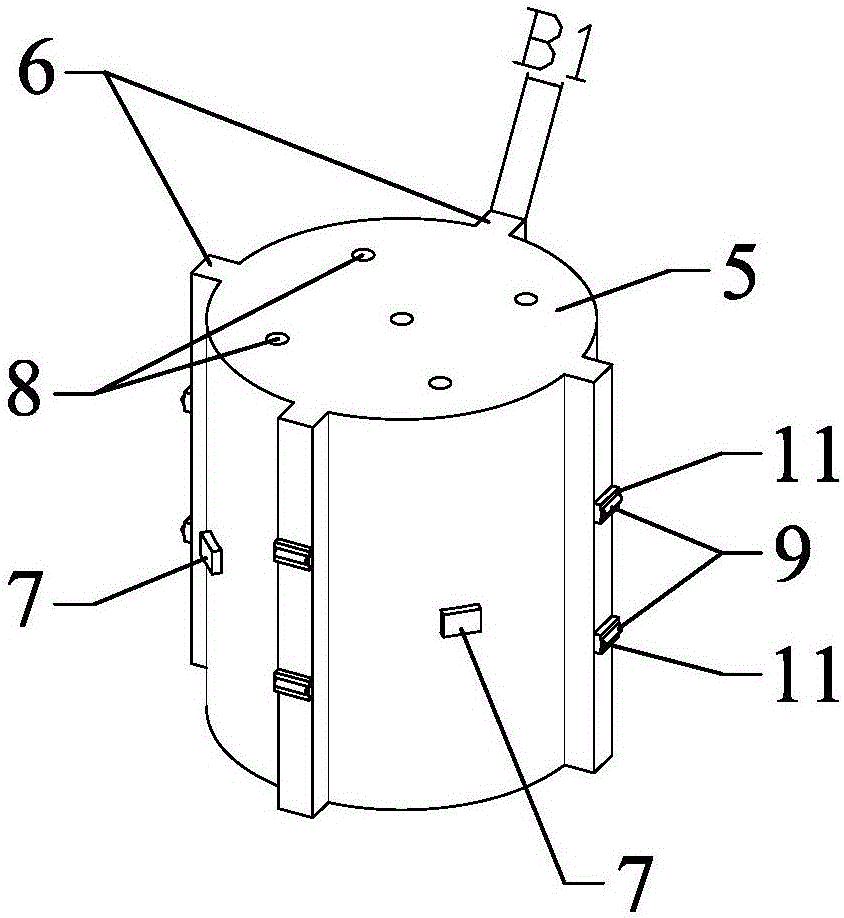

[0059] The double-layer underwater production support buoy in the present invention will be further described below in conjunction with the accompanying drawings. The illustration of the present invention takes a double-layer buoy in an ultra-deep water offshore oil and gas engineering development system with five rigid risers as an example.

[0060] Such as Figure 1-6 As shown, a double-layer underwater production support buoy includes an outer buoy 1 and an inner buoy 5; the inner buoy 5 is nested in the outer buoy 1;

[0061] The main body of the outer buoy 1 is a ring cylinder structure, the bottom edge of the outer wall of the outer buoy 1 is connected to four cantilever buoys 2, and the four cantilever buoys 2 are uniformly distributed along the circumference in a radial shape. The ends of the cantilever buoys 2 adopt a truss structure 14, The outer end of the truss structure 14 is connected to the mooring cables 15, and the outer buoy 1 is moored on the pile foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com