Blade spring arrangement of rotary compressor

A rotary compressor, leaf spring technology, applied in rotary piston machinery, rotary piston pumps, rotary piston/swing piston pump components, etc., can solve the problem of compressed gas leakage, inconvenience, general products without structure, etc. problem, to achieve the effect of preventing the reduction of work reliability and reducing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

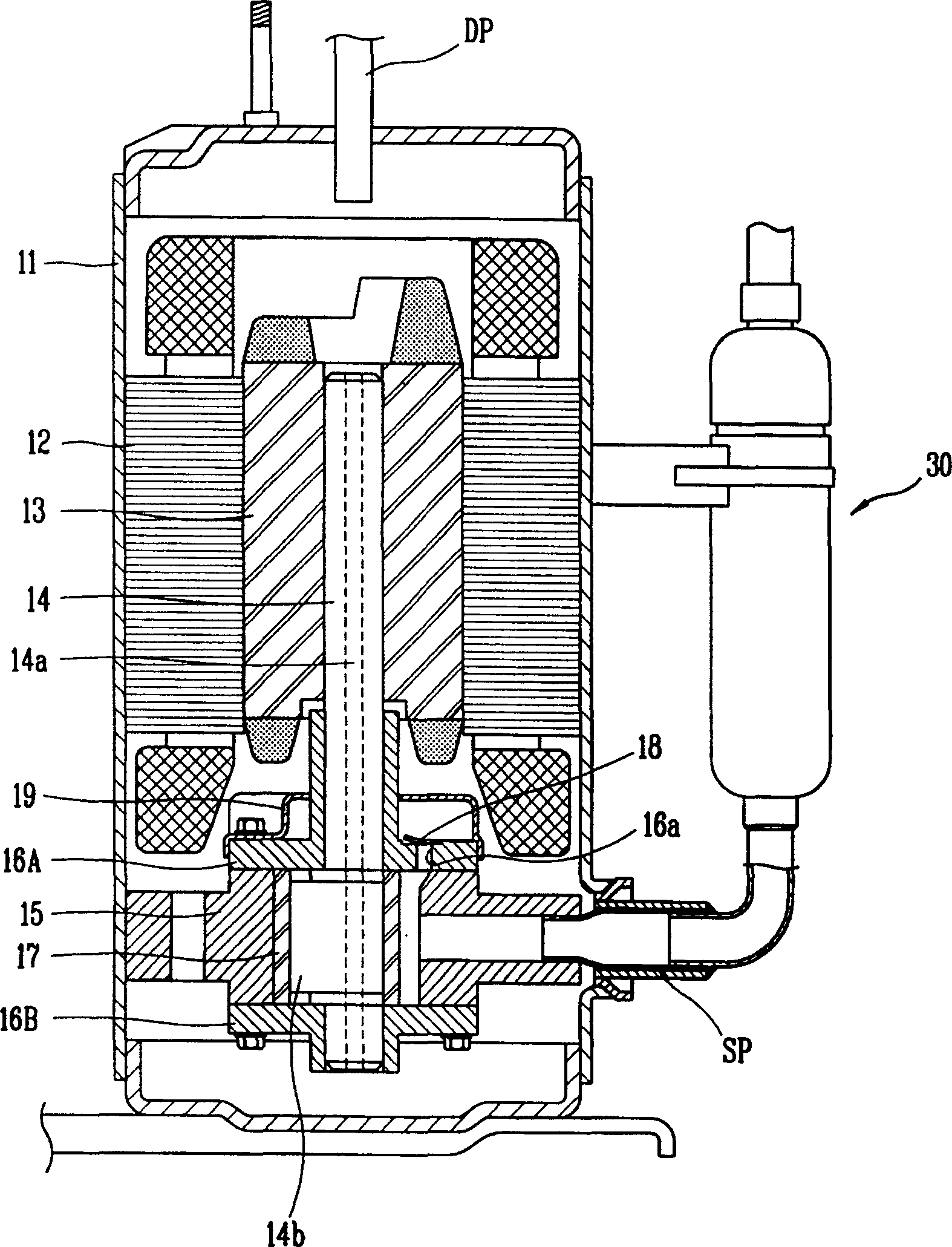

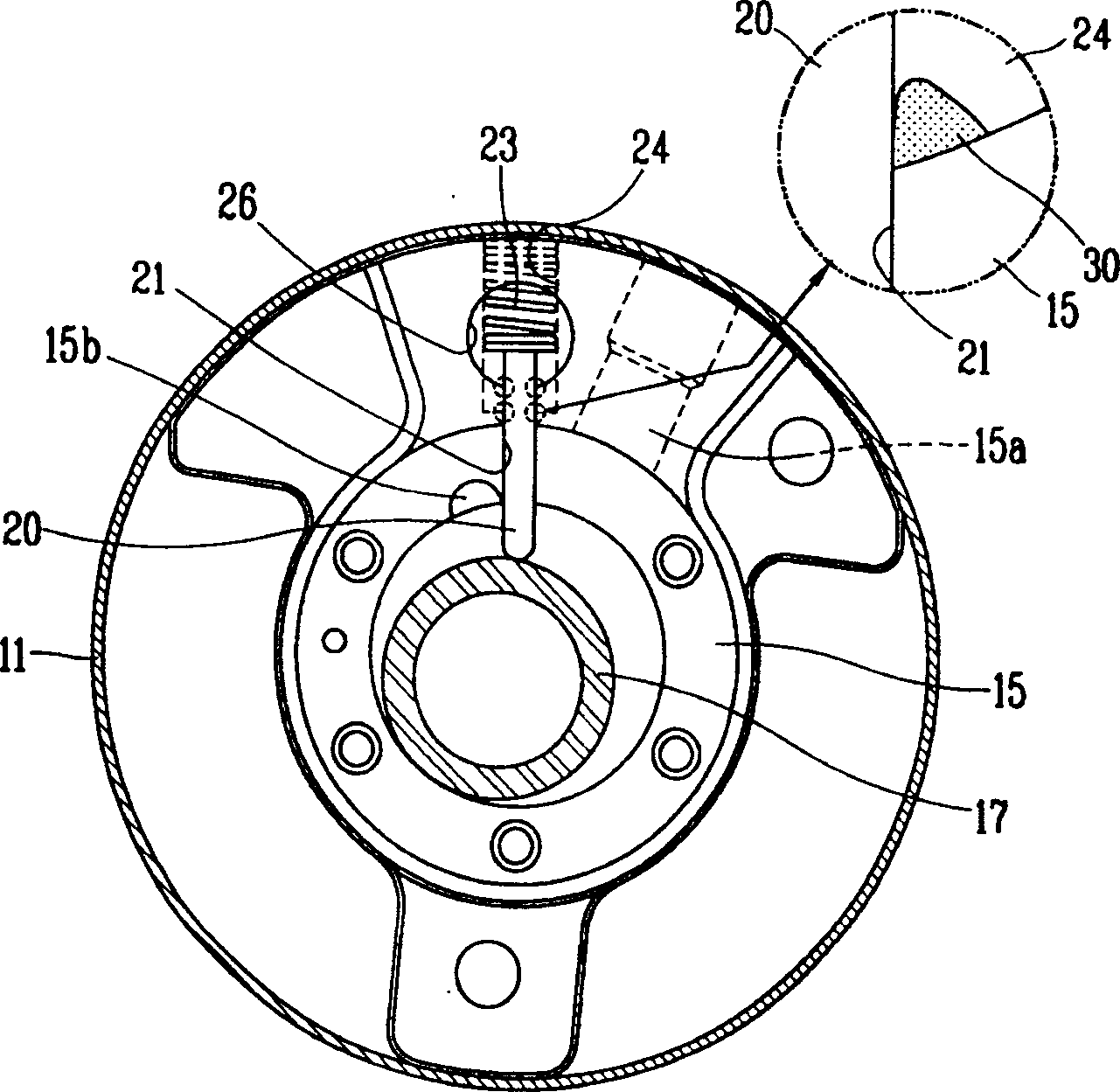

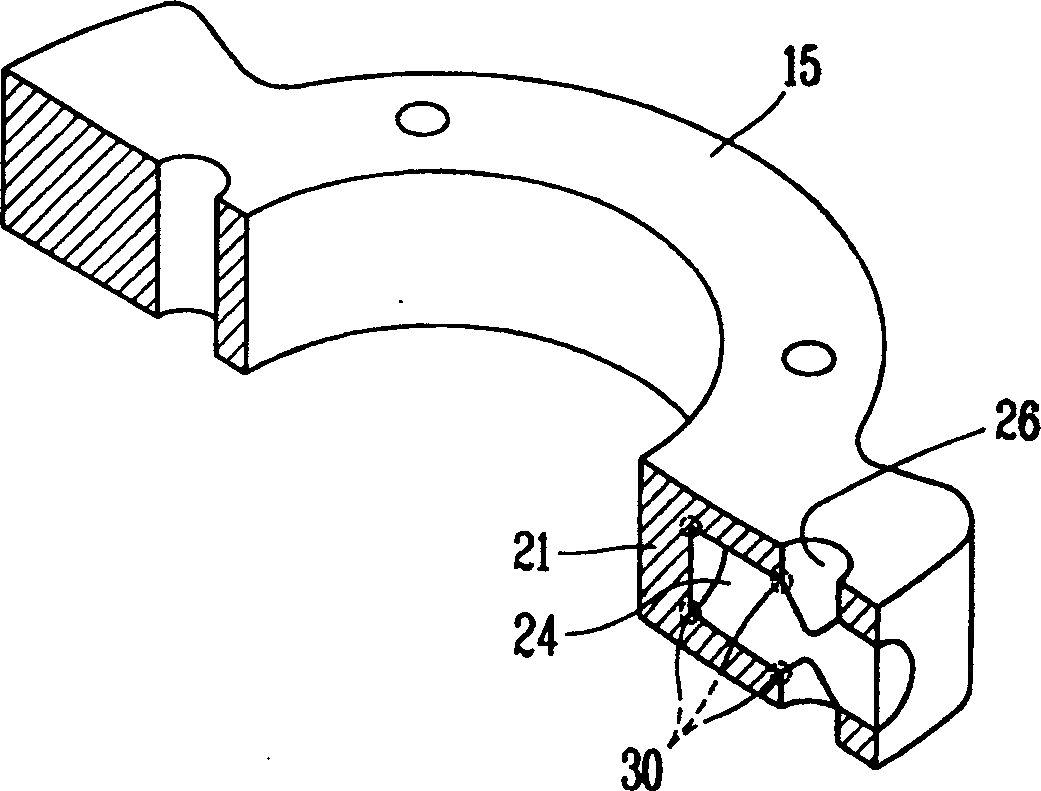

[0051] see Figure 4 to Figure 6 as shown, Figure 4 It is a schematic diagram of a rotary compressor using the vane spring mounting structure according to the present invention, showing the structure of the compression mechanism. Figure 5 , Figure 6 It is a schematic plan view of the structure and working state of the leaf spring according to the present invention.

[0052] It should be noted that, in order to highlight the key points when describing the present invention, well-known functions or configurations will not be described in detail and will be omitted.

[0053] see Figure 4 to Figure 6 As shown, the rotary compressor adopting the leaf spring arrangement structure according to the present invention includes: a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com