Chain wheel or tooth ring production process

A production process and sprocket technology, which is applied to the production process of sprockets or gear rings, can solve the problems of low die service life, large forging machine tonnage and high product defect rate, and achieve high die service life and low forging machine tonnage. , The effect of low product defect rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the specific embodiments of the accompanying drawings.

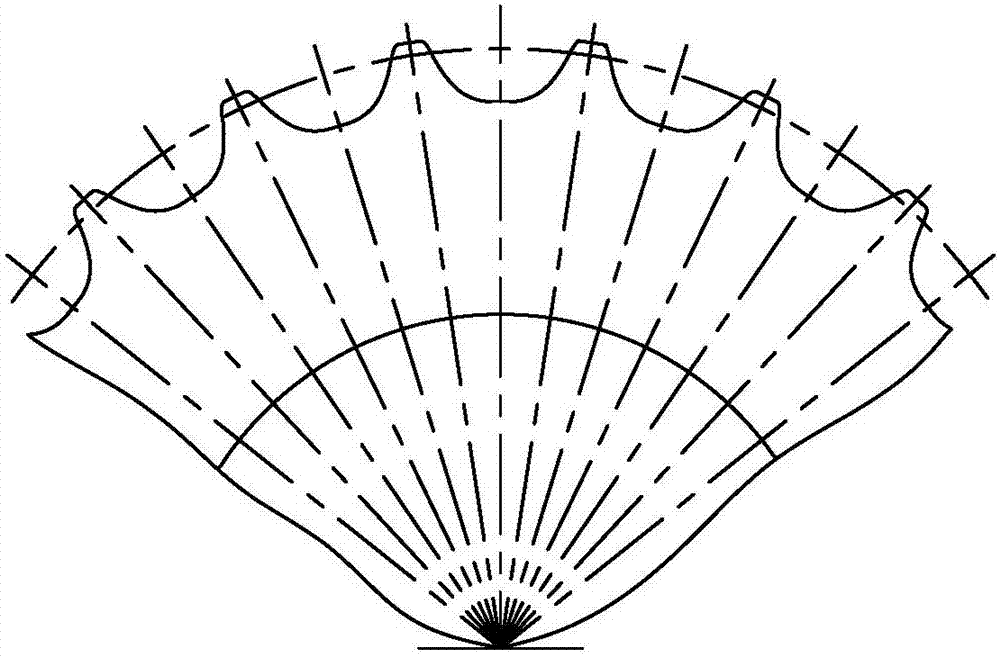

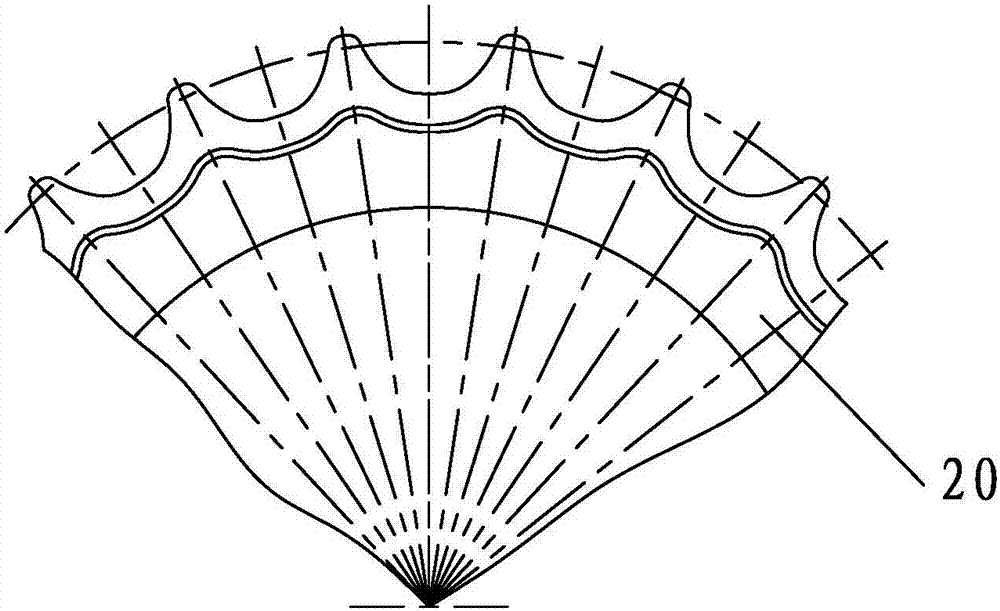

[0025] The production process provided in this embodiment can be used in the production of a sprocket or a gear ring. Since the main difference between a sprocket and a gear ring lies in the tooth shape, the sprocket is taken as an example for illustration in this embodiment.

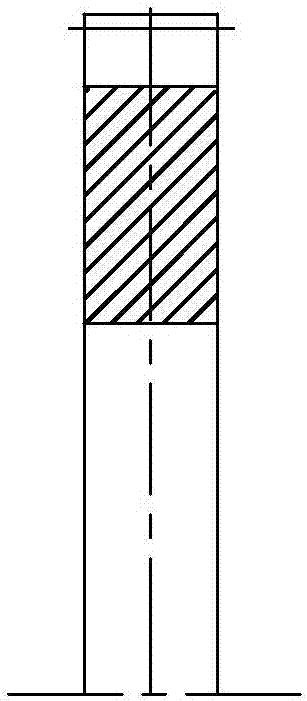

[0026] The production process of the sprocket provided in this embodiment comprises the following steps,

[0027] S1: Shape cutting, select a steel plate with the same thickness as the sprocket to be produced, use a cutting machine to perform profile cutting on the steel plate, and obtain a blank with the same outer contour shape as the sprocket or gear ring to be produced, Of course, it is necessary to make a profiling model mold before profiling cutting. Since the blank is obtained by cutting the steel plate, the edge material on the steel plate can still be used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com