Ionic activity multi micropore ceramic filter element raw material formula and manufacturing technology thereof

A microporous ceramic and active technology, which is applied to ceramic products, clay products, and other chemical processes, can solve the problems of single purification function and inability to effectively remove heavy metal ions and bacteria, and achieve high-efficiency purification and significant technological progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

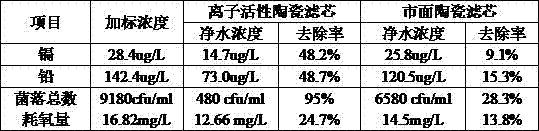

Image

Examples

Embodiment 1

[0041] Said scheme, described montmorillonite is 20%, clay is 10%, silica is 15%, feldspar is 15%, pore-forming agent is 15%, adhesive is 5%, catalyst one is 15%; Catalyst two 5%.

Embodiment 2

[0043] The above scheme, the montmorillonite is 25%, the clay is 10%, the silica is 25%, the feldspar is 10%, the pore-forming agent is 15%, the adhesive is 2%, the catalyst one is 10%; the catalyst two 3%.

Embodiment 3

[0045] In the above scheme, in the step b, the various raw materials are ground for the first time for about 20 hours, and after adding the catalyst disulfuric acid solution, the second grinding is about 2 hours, and the temperature for calcining the green body in the step d is 1150 The calcination time is 10 hours, and the montmorillonite still maintains a high ion activity after being calcined at a high temperature of 1000 degrees, so it has an efficient purification effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com