Non-water-based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and preparation method thereof

A technology of calcium oxide ceramics and ceramic casting molds, applied in the direction of additive processing, etc., to achieve the effects of easy removal, convenient storage and use, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

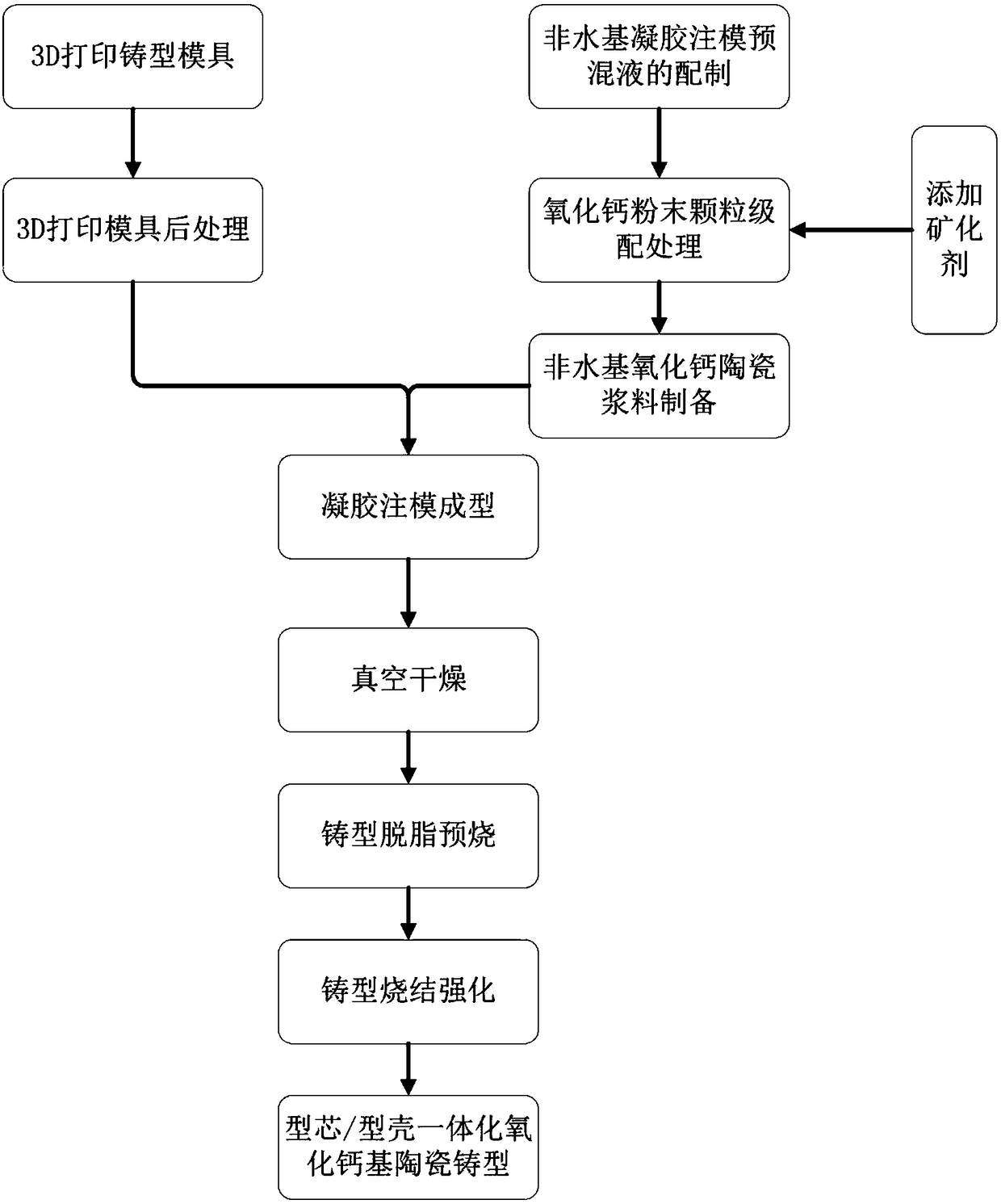

Method used

Image

Examples

Embodiment 1

[0068] A non-water-based gel injection molding method for rapidly manufacturing hollow turbine blade calcium oxide-based ceramic molds, the specific steps are as follows:

[0069] 1. Make casting resin mold

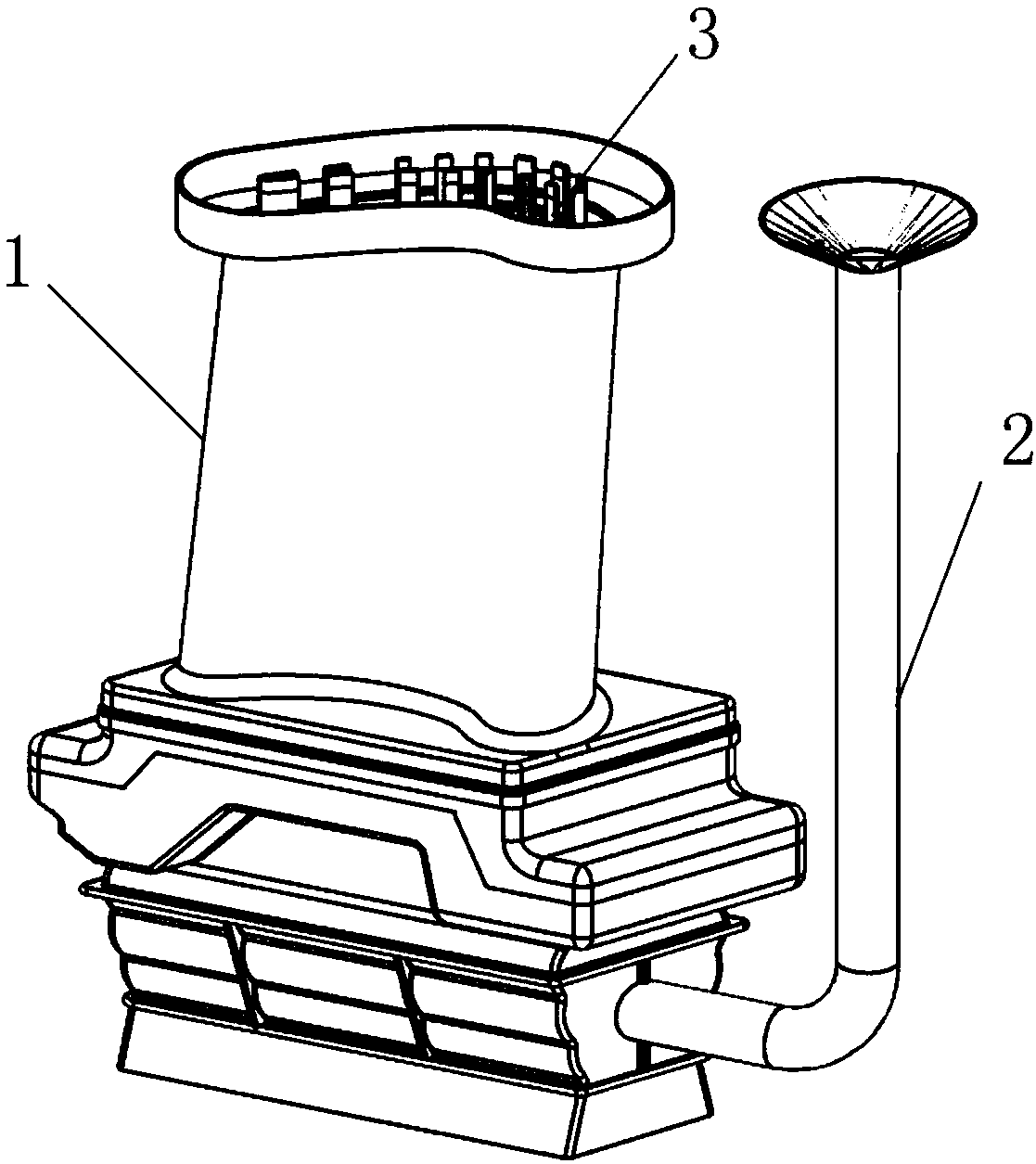

[0070] Using light-curing 3D printing technology to quickly prepare the resin prototype and casting resin mold of the hollow turbine blade; see figure 2 , wherein, 1 is the shell of the hollow turbine blade resin mold, 2 is the pouring port of the resin mold slurry, and 3 is the resin prototype of the hollow turbine blade.

[0071] 2. Prepare the non-water-based premix of the mixed system

[0072] 1) According to the mass ratio of acrylamide: N'N methylenebisacrylamide: tert-butanol = 24:1:100, a tert-butanol premix solution with an organic matter concentration of 20wt% was prepared;

[0073] 2) According to the mass ratio of acrylamide: N'N methylenebisacrylamide: ethylene glycol = 24:1:100, an ethylene glycol premix solution with an organic matter concentration of 20...

Embodiment 2

[0089] A non-water-based gel injection molding method for quickly manufacturing a calcium oxide-based ceramic mold for a turbine engine turbine disc, the specific steps are as follows:

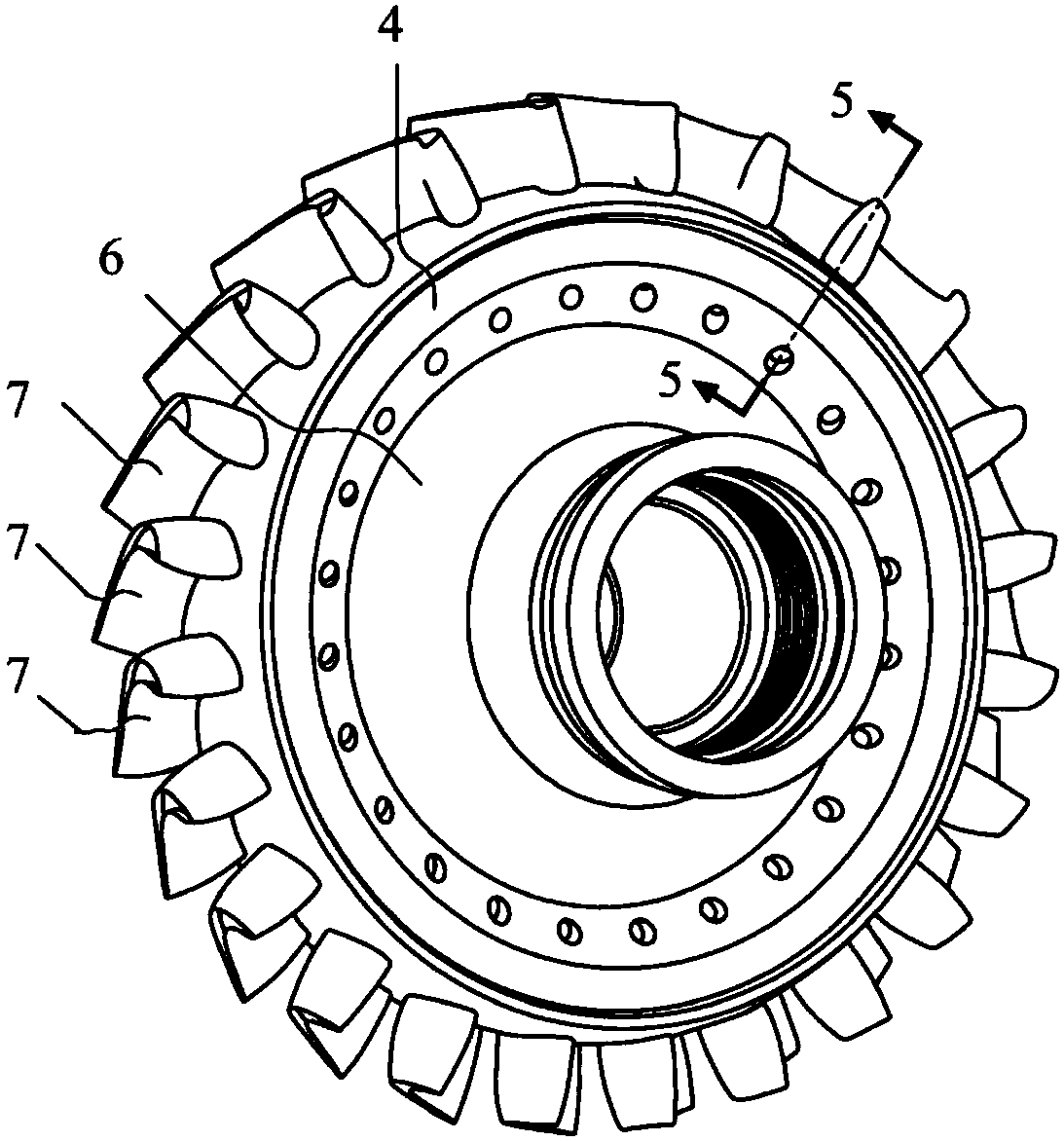

[0090] 1. Make casting molds, use 3D printing technology to quickly prepare polystyrene plastic (PS) prototypes of turbine engine turbine discs and polystyrene plastic (PS) molds for casting; see image 3 , wherein, 4 is the outer ring; 5 is the cold air hole; 6 is the wheel; 7 is the guide vane.

[0091] 2. Prepare the non-water-based premix of the mixed system

[0092] 1) According to the mass ratio of acrylamide: N'N methylenebisacrylamide: tert-butanol = 24:1:100, a tert-butanol premix solution with an organic matter concentration of 20wt% was prepared;

[0093] 2) According to the mass ratio of acrylamide: N'N methylenebisacrylamide: ethylene glycol = 24:1:100, an ethylene glycol premix solution with an organic matter concentration of 20wt% is prepared;

[0094] 3) Mix the above two premi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com