Patents

Literature

36results about How to "Avoid excessive viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Concrete mixtures having high flowability

InactiveUS20070056480A1Improve liquidityAvoid excessive viscositySolid waste managementCeramicwarePolymer scienceViscosity modifier

A viscosity modifying agent is added to a concrete mixture to give the concrete desirable rheological properties. The viscosity modifying agent is incorporated into a foam admixture before it is mixed into the concrete. Because the viscosity modifying agent is a component of the foam admixture, the viscosity modifying agent is dispersed in the aqueous film that forms the foam bubbles. The viscosity modifier in the foam bubbles gives the foam beneficial rheological properties. The viscosity modifier performs more efficiently when included in the foam bubbles as compared to being mixed directly into the concrete. The foam bubbles containing the viscosity modifier can be stabilized using a fluorochemical stabilizer, which is included in the foam admixture. The foam bubbles can be further stabilized with respect to cement mixtures by including a hydration stabilizing in the cement mixture.

Owner:WELKER CHARLES D

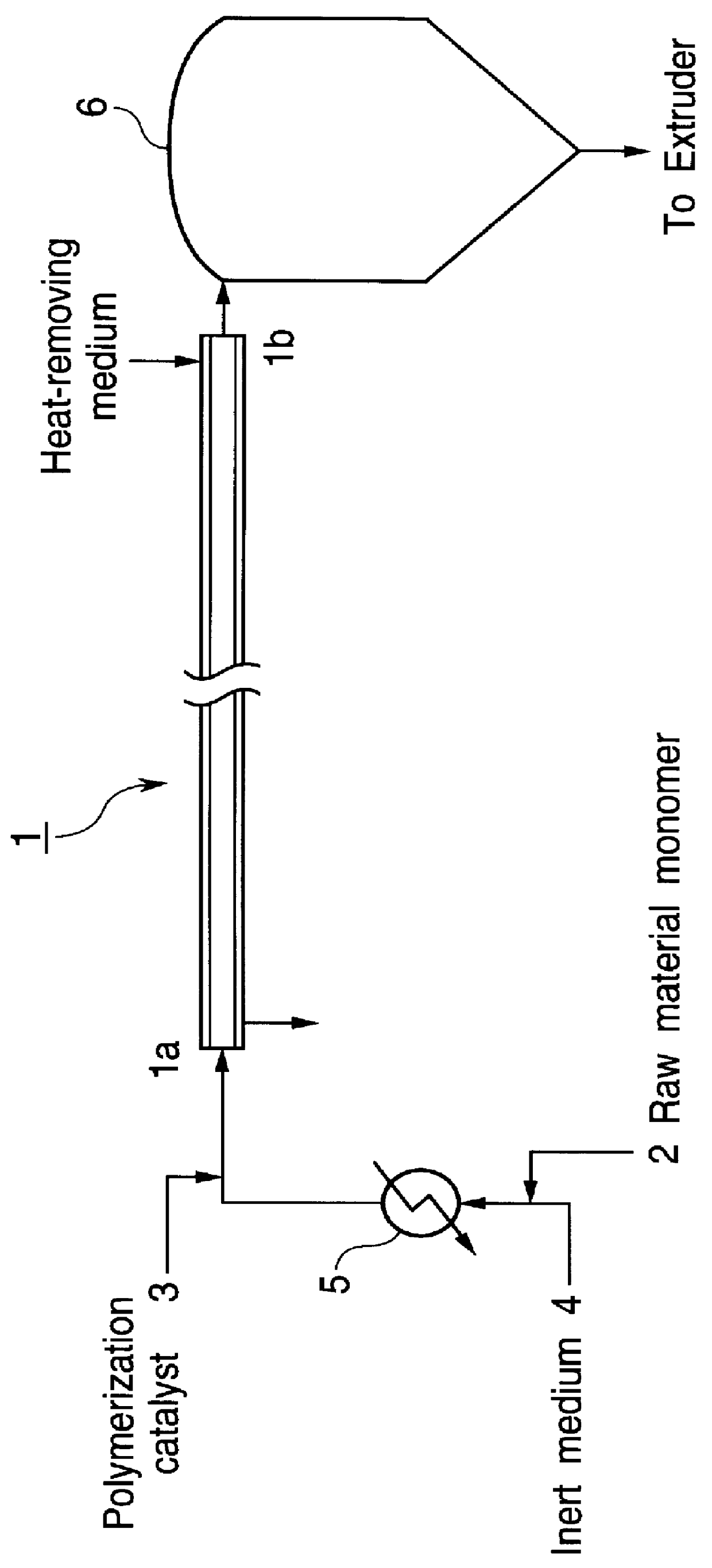

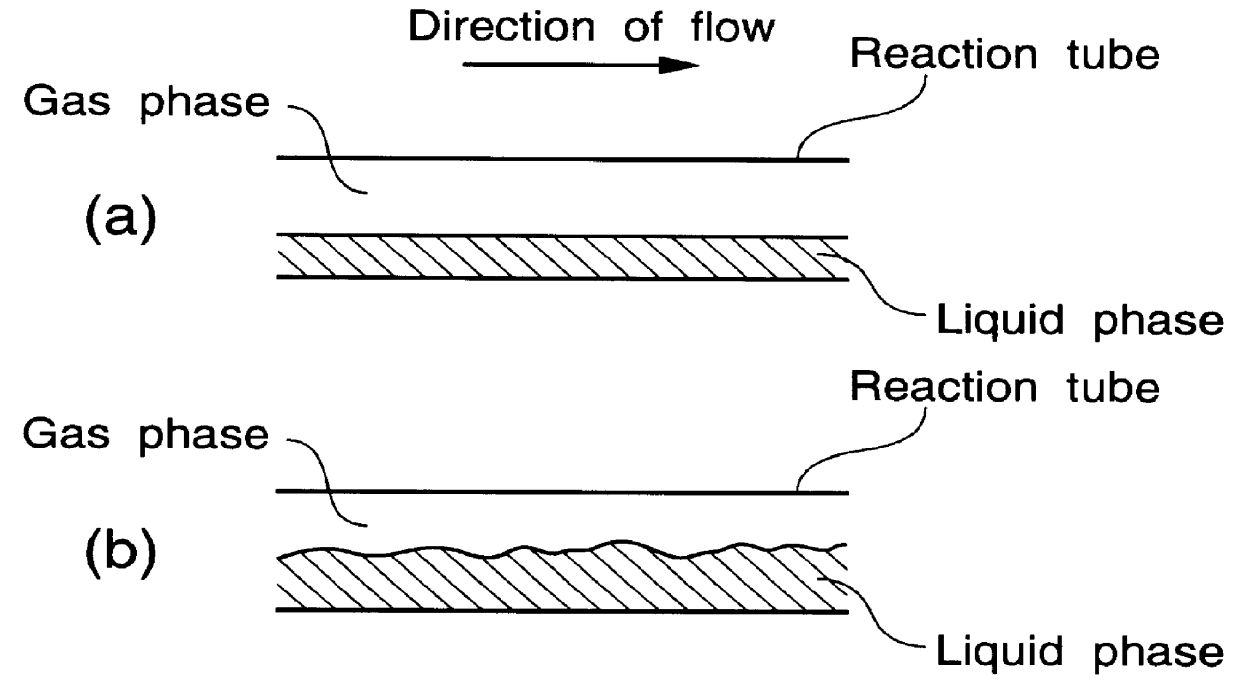

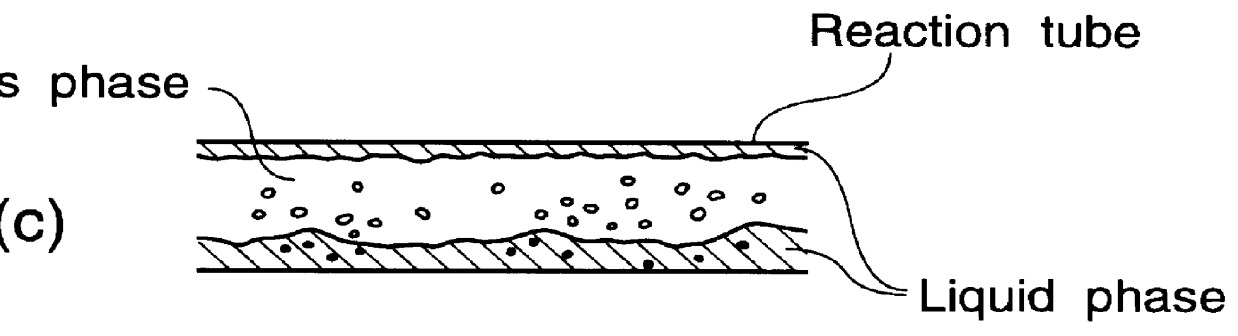

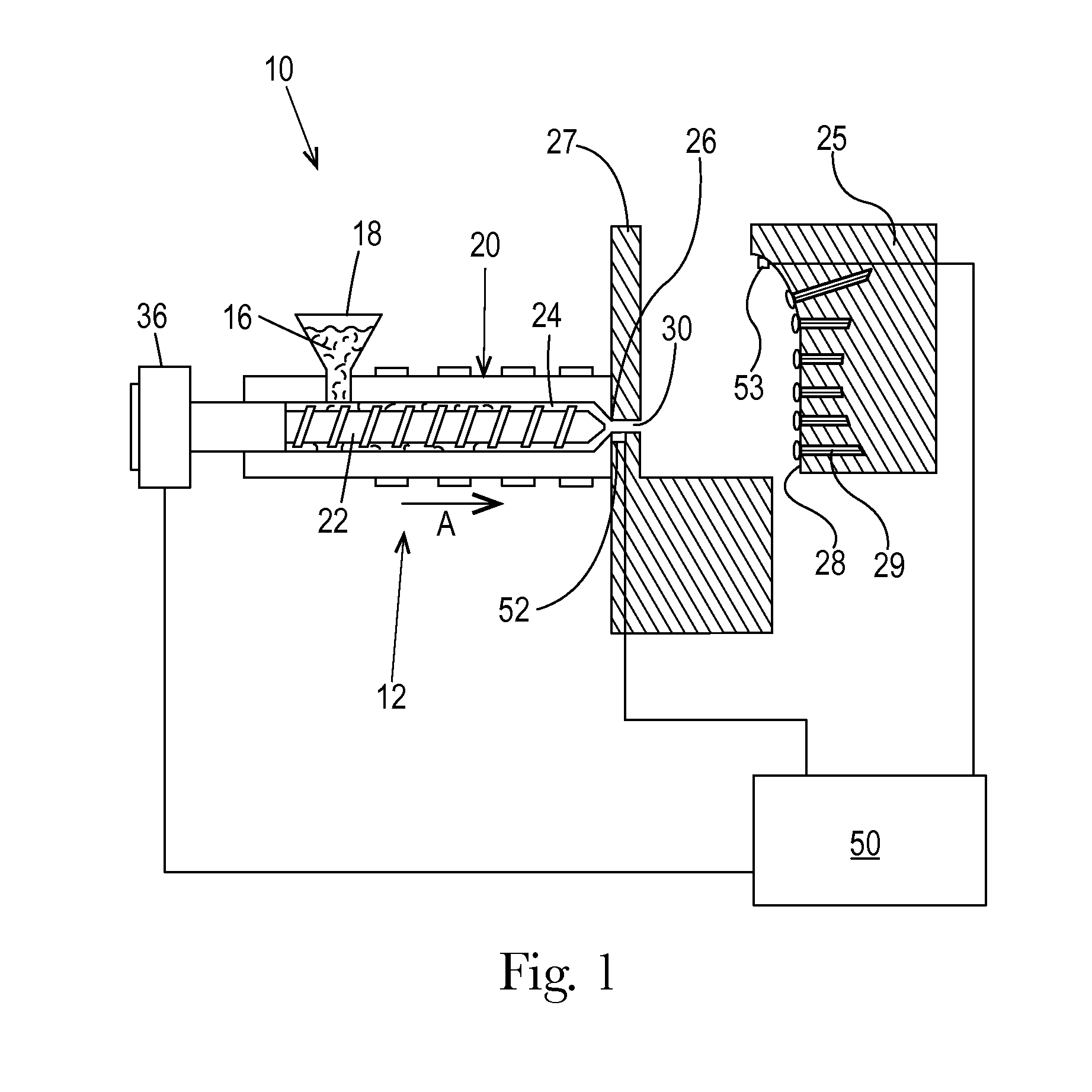

Polymerization process using separated flow

InactiveUS6111035ALow costEasy to controlChemical/physical/physico-chemical stationary reactorsPressure vessels for chemical processGas phasePolymerization catalysts

Disclosed is a polymerization process comprising feeding a monomer as a raw material, a polymerization catalyst, and optionally, an inert medium to a tubular reactor in a pressurized state; permitting a part of the raw material monomer and the inert medium fed to the reactor to form a gas phase and the remainder to form a liquid phase, so that both of the gas phase comprising the raw material monomer and / or the inert medium and the liquid phase comprising the raw material monomer and / or the inert medium are present in the reactor, wherein said liquid phase may contain a resulting polymer as a solid, and so that a gas-liquid separated flow or a gas-liquid-solid separated flow has the gas phase that is continuous in the direction of flow is formed in the reactor; and polymerizing the raw material monomer while carrying the liquid phase by the gas phase flow, wherein the ratio of a volume flow rate of the liquid phase to a volume flow rate of the gas phase at the outlet of the reactor is 0.00001 to 100,000. According to the polymerization process, polymerization can be accomplished with excellent thermal efficiency and small power energy, and besides various polymers almost free from restrictions on their properties such as viscosities and melting points can be produced.

Owner:MITSUI CHEM INC

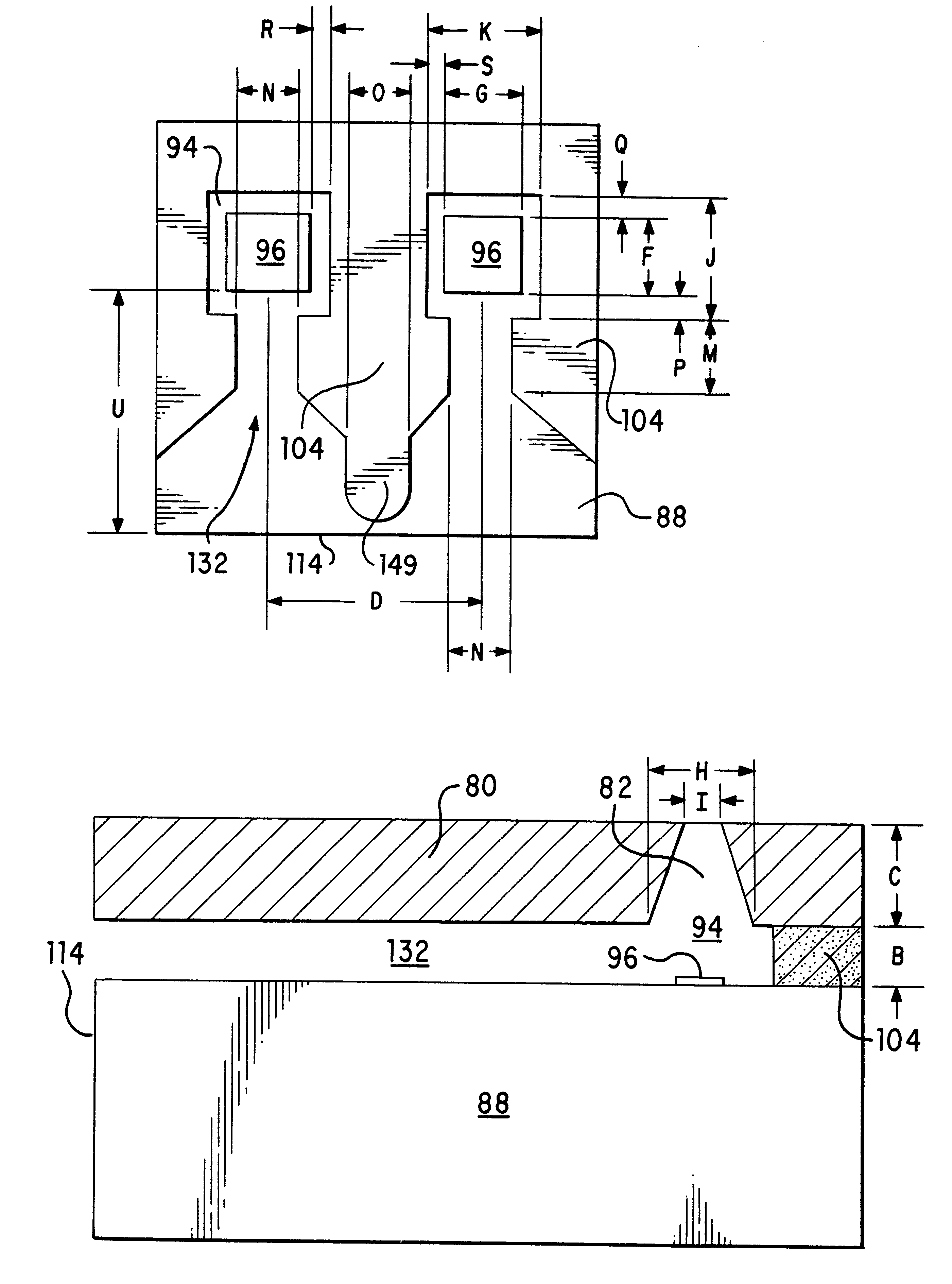

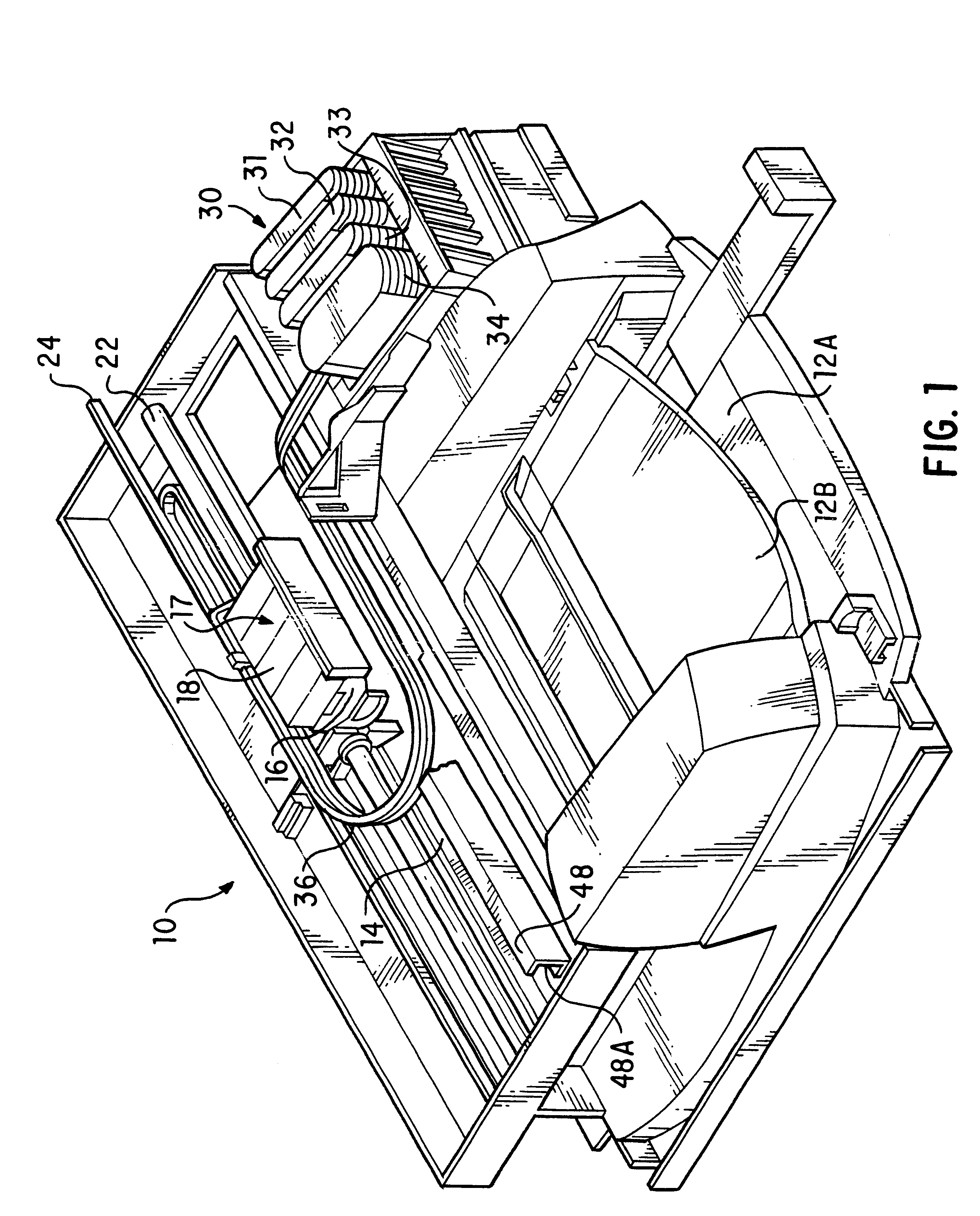

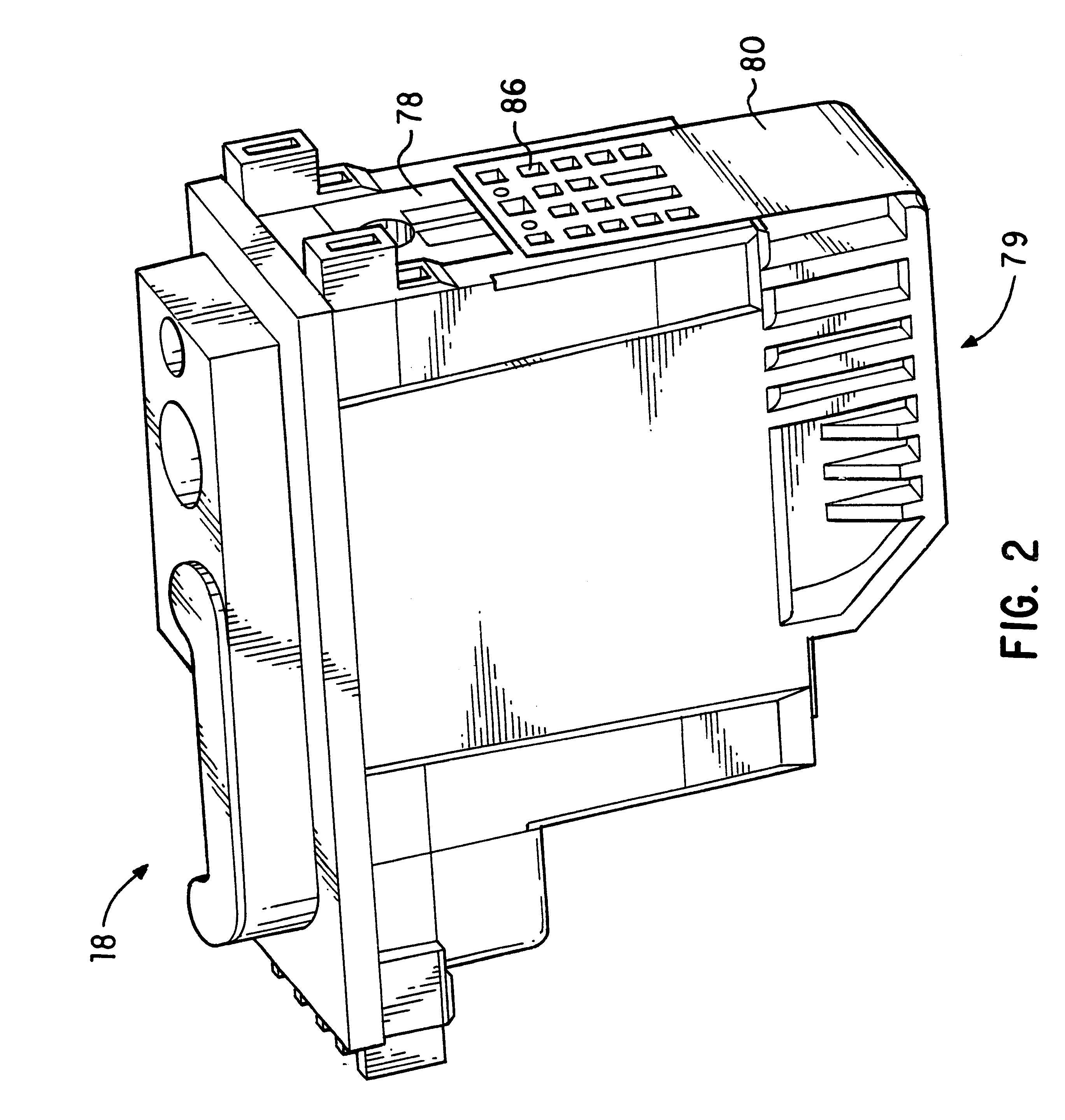

Apparatus for generating small volume, high velocity ink droplets in an inkjet printer

Disclosed is an inkjet print cartridge including an ink supply, a substrate having a plurality of individual ink ejection chambers defined by a barrier layer formed on a first surface of the substrate and having an ink ejection element in each of the ink ejection chambers, for ejecting drops of ink having a predetermined drop volume and drop velocity. The ink ejection chambers each have the same inlet channel length and are arranged in an array spaced so as to provide a predetermined resolution. A nozzle member having a plurality of ink orifices formed therein is positioned to overlie the barrier layer with the orifices aligned with the ink ejection chambers. An ink channel connects the reservoir with the ink ejection chambers. The inkjet print cartridge has several advantages of over previous printing systems in creating high quality images by using very small individual ink drops of low volume and high velocity. Highlight regions may be formed by using single low volume drops to form a dot. The individual drops are nearly invisible and can be used to form highlights with low graininess. As the density of the image increases, multi-drop dots are formed from two or more drops merging on the media to form a composite drop.

Owner:HEWLETT PACKARD DEV CO LP

Process and apparatus for making tufted article

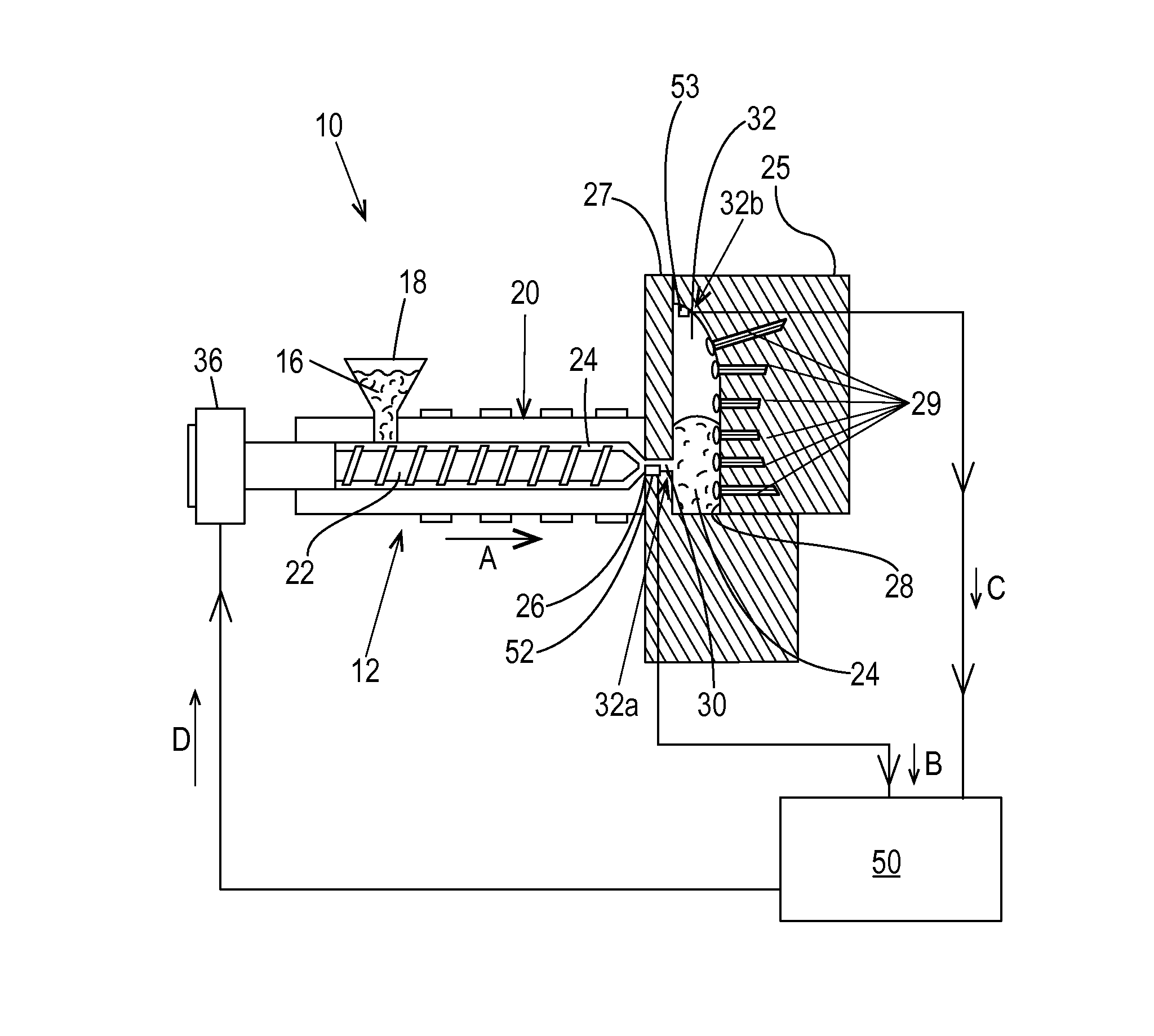

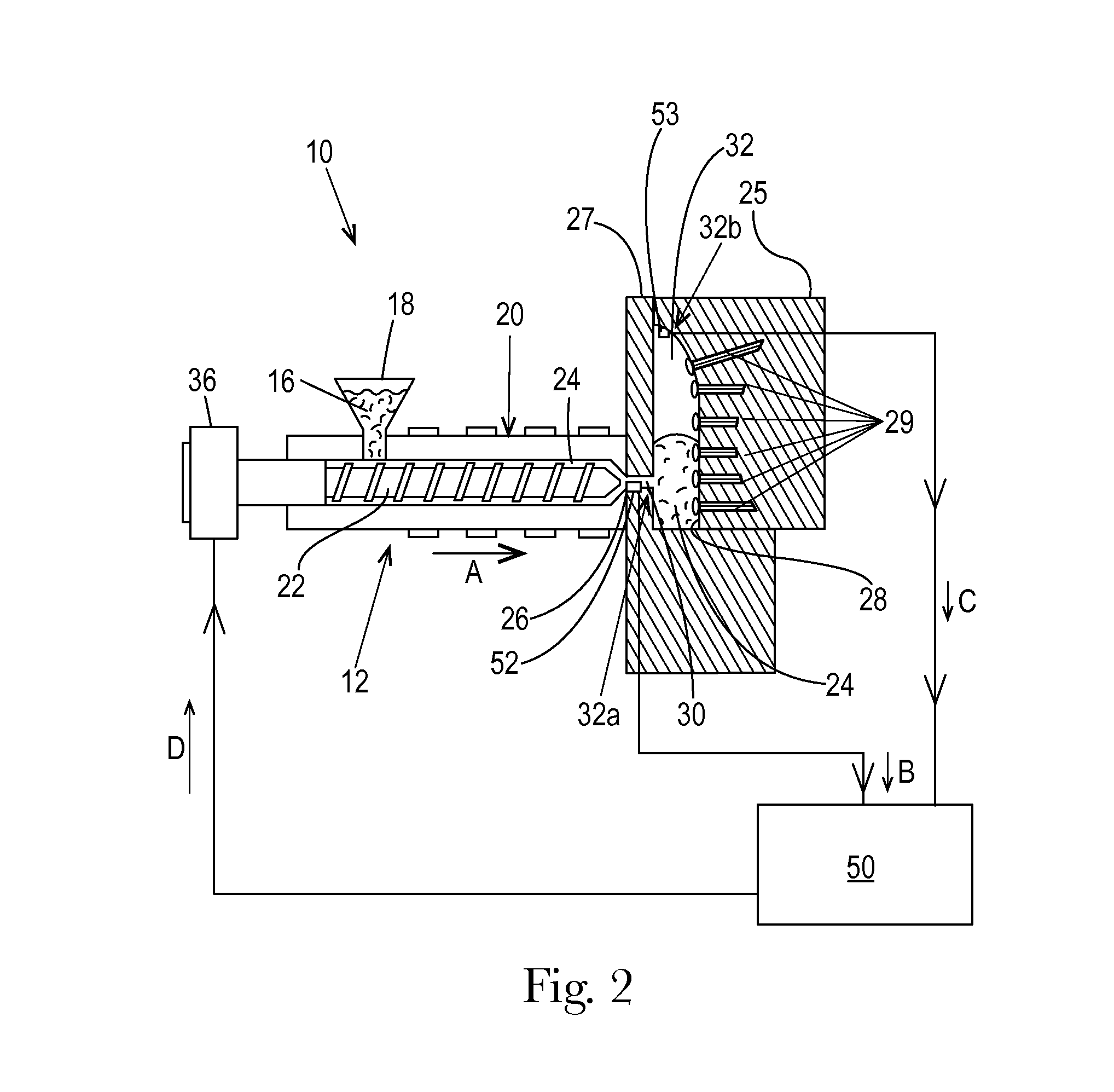

InactiveUS20150097309A1Reduce hardnessImprove thermal conductivityTailstocks/centresBrush bodiesInjection pressureEngineering

A process for making a tufted article from a thermoplastic material comprises controlling injection pressure according to a pressure-dominated algorithm including detecting at least 100 melt-pressure measurements per second upstream a front end of a mold cavity. An apparatus comprises a pressure-control mechanism for monitoring and adjusting an injection pressure according to the pressure-dominated algorithm, wherein the pressure-control mechanism comprises at least one high-frequency pressure sensor located upstream the mold cavity's front end.

Owner:THE PROCTER & GAMBLE COMPANY

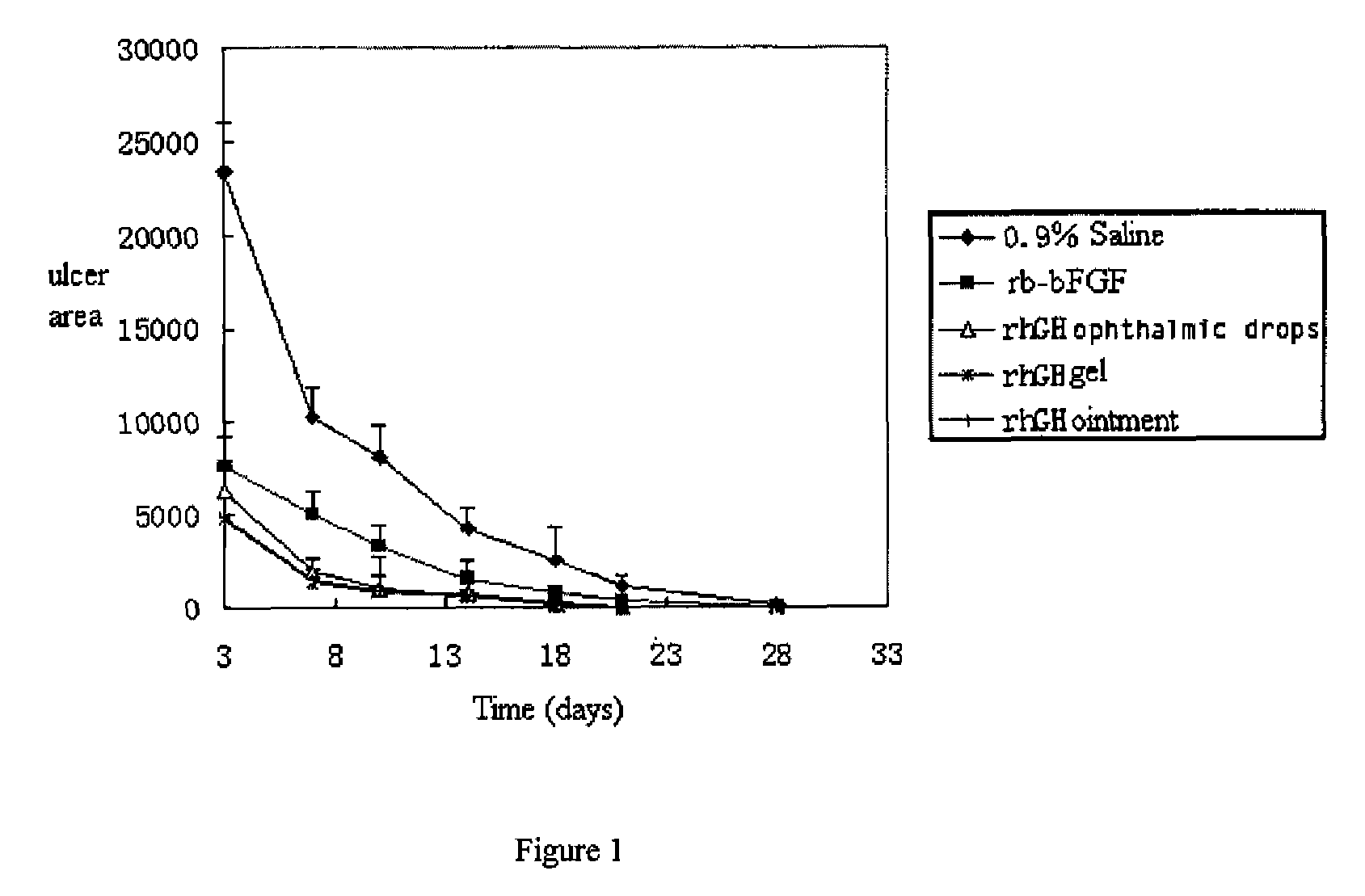

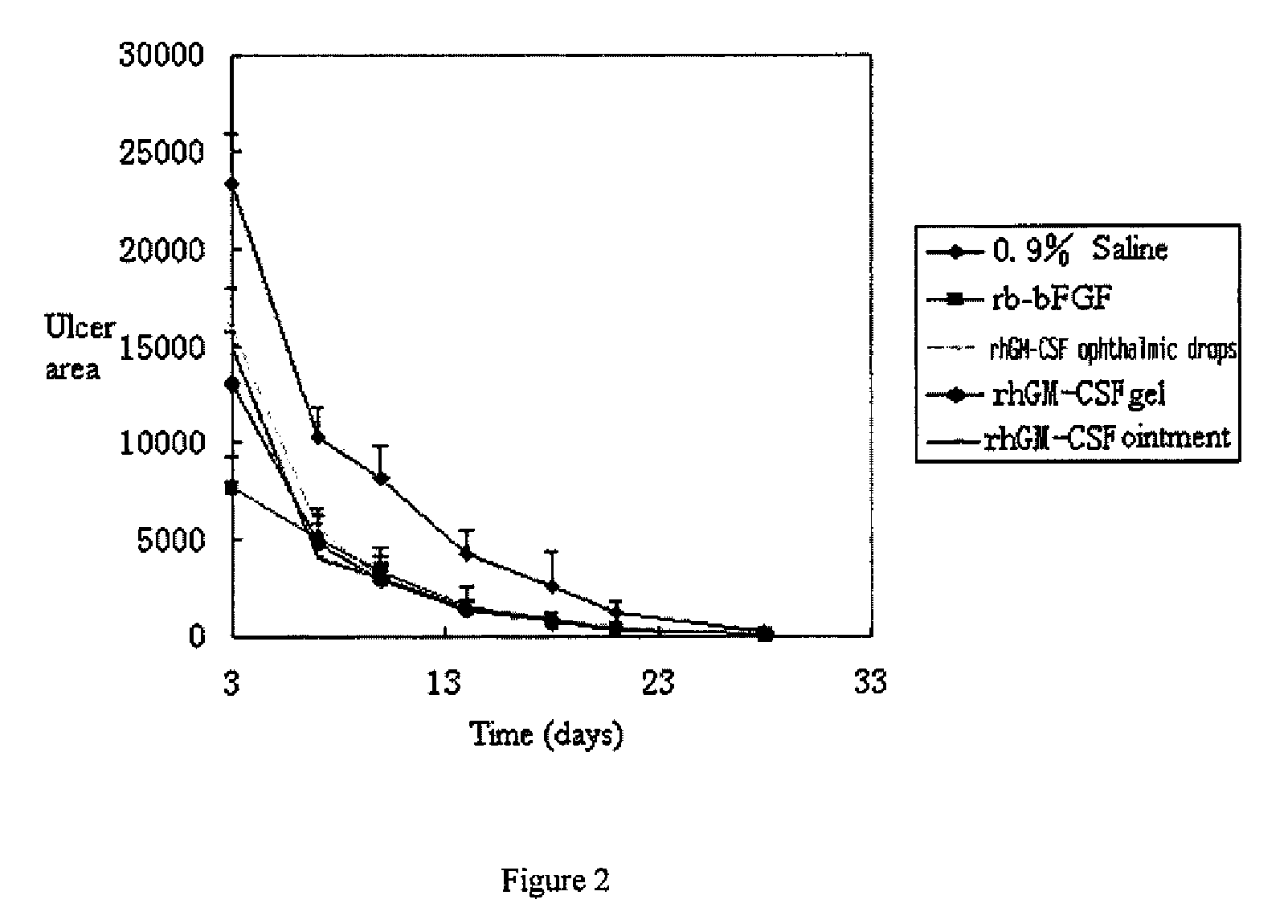

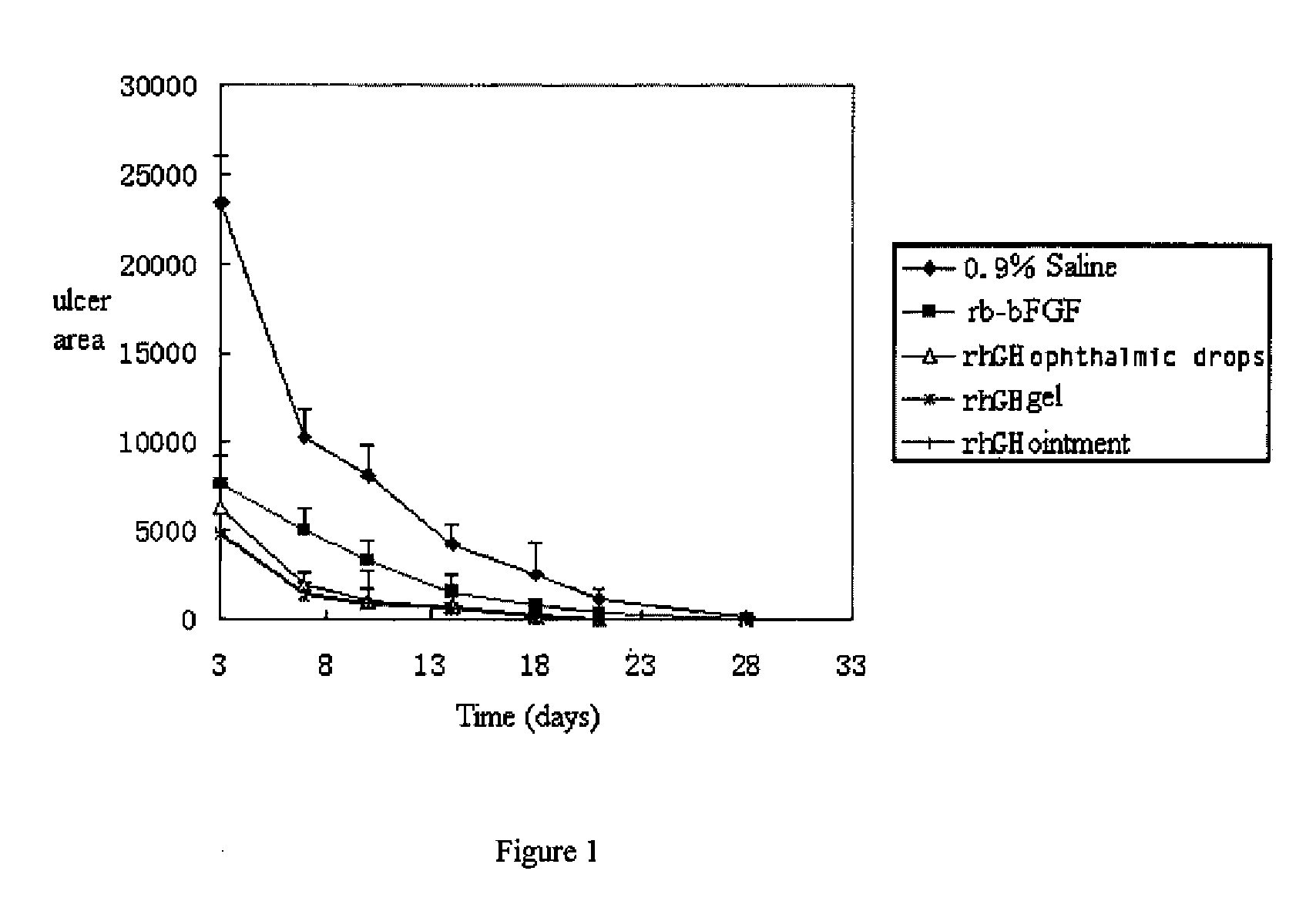

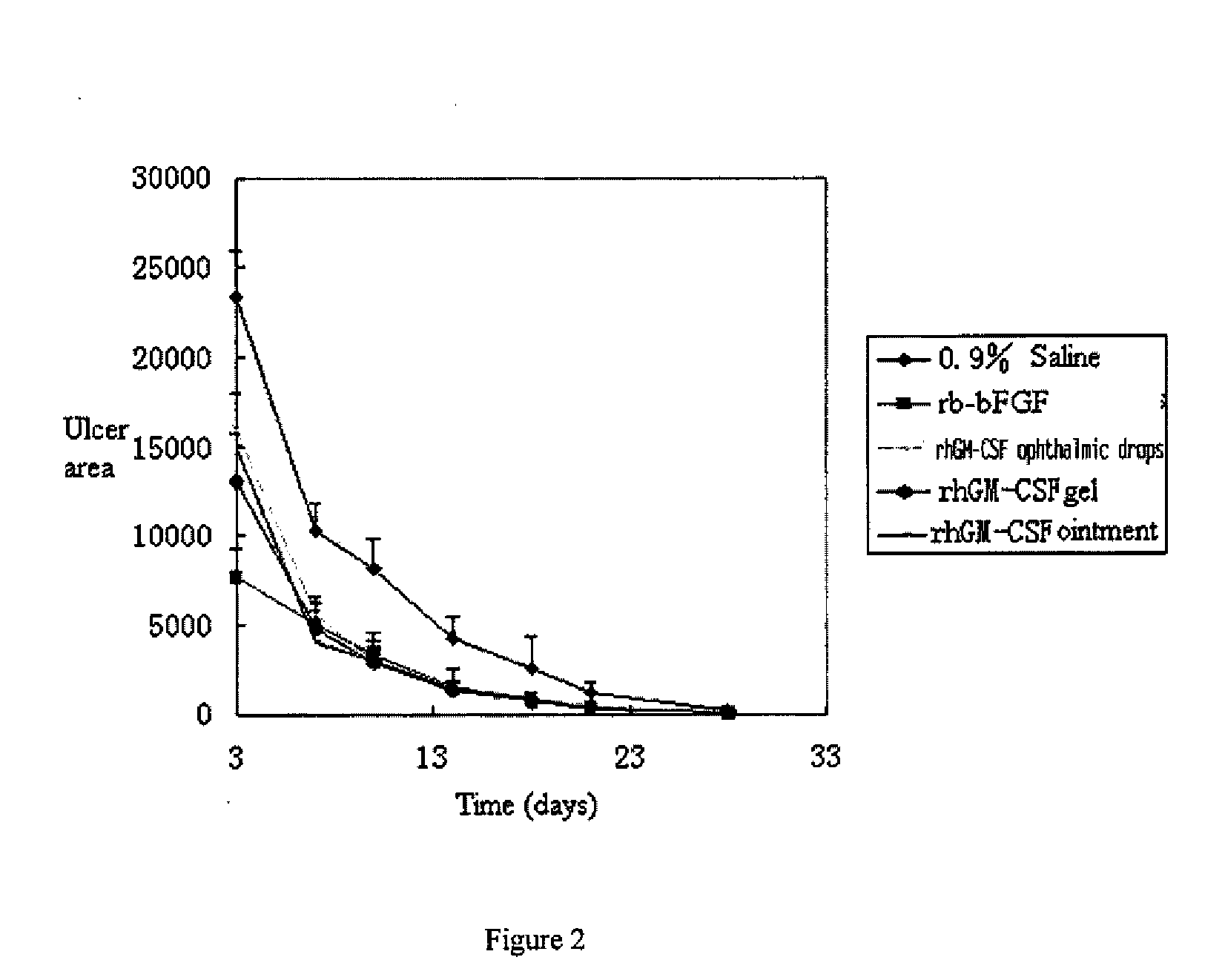

Ophthalmic hGM-CSF preparation

InactiveUS7858582B2Avoid excessive viscosityBenefit to drugSenses disorderPeptide/protein ingredientsGynecologyHuman growth hormone

Owner:CHANGCHUN GENESCIENCE PHARM CO LTD

Method for Obtaining White Sugar from Cane Juice

InactiveUS20120216799A1Requires low equipmentReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsFruit juicePhosphoric acid

The invention relates to a method for obtaining white sugar from cane juice, characterized in that it involves: obtaining sugar colors of between 300 and 150 ICUMSA units, with a sulphite content no greater than 5 ppm and an ash content no greater than 0.2% in the case of white sugar and in the case of refined sugar with colors less than 40 UI, less than 5 ppm sulphites and less than 0.04% ash, using fewer chemical products and devices and comprising the formation of reducing sugars; as well as optimizing the production time, reducing deterioration, making the process and the chemical products more efficient and preventing SO2 contamination. The method is characterized in that it simplifies the traditional method of obtaining white sugar using elemental sulfur, eliminating prealkalinization and sulphiting and the respective machinery and equipment and reducing the number of chemical products, such as lime, phosphoric acid, sulfur and activated carbon, in order to aggregate only sodium metabisulphite optionally complemented with monosodium phosphate in juice with pH values of 4 to 6.6 prior to any process involving the clarification of juice, cane syrup or molten liquor.

Owner:BOLANOS MARIO ALAVES

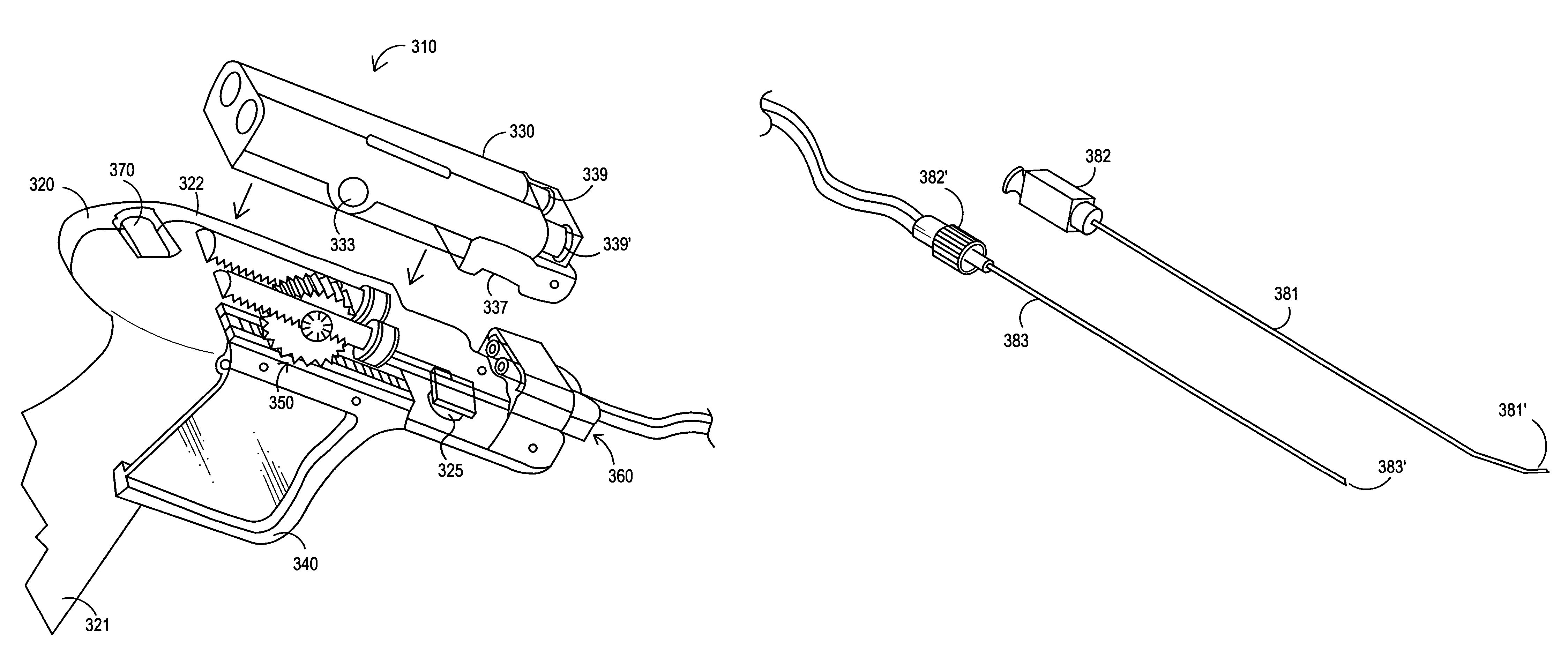

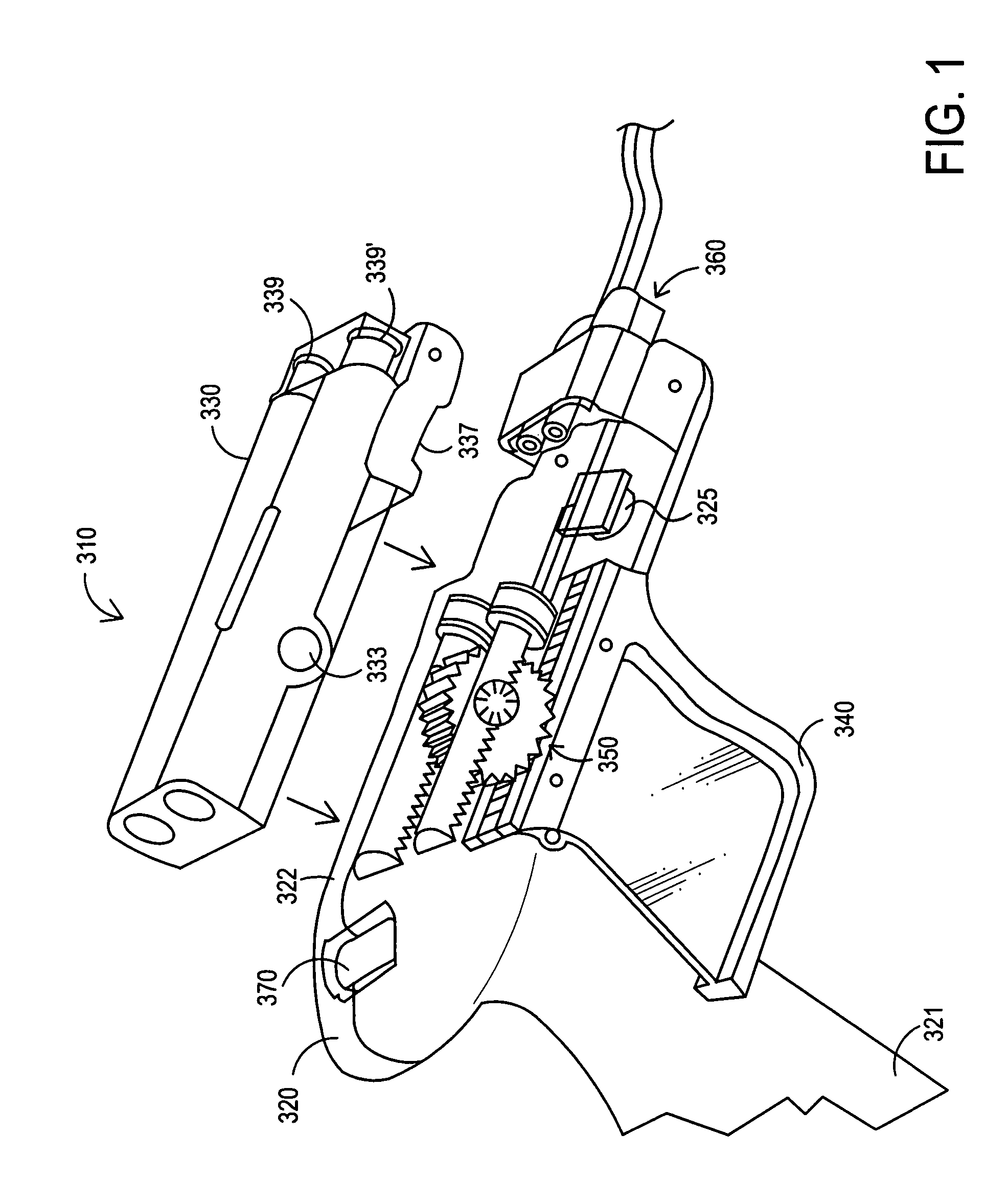

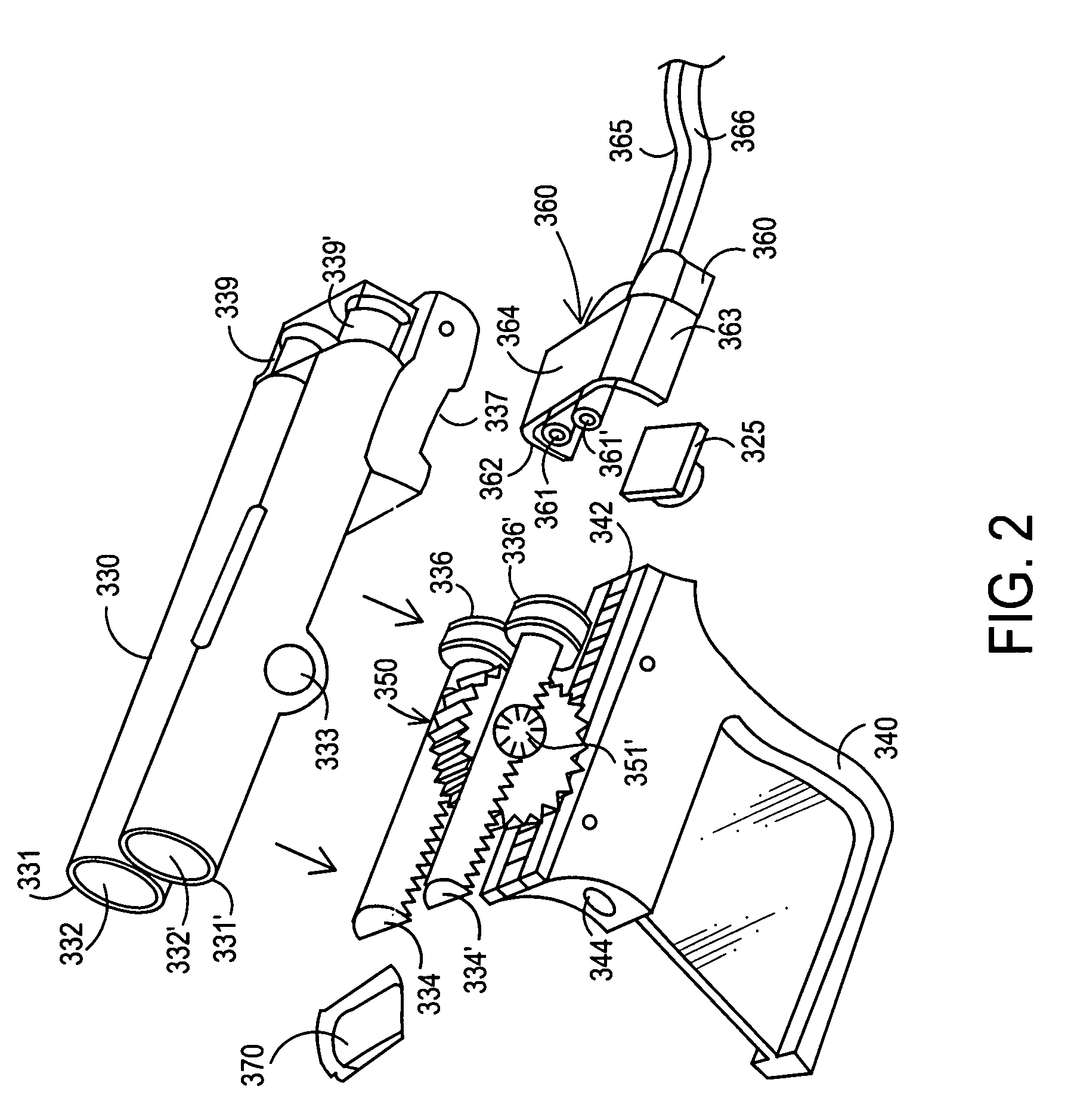

Apparatus and method for delivery of biologic sealant

ActiveUS8047407B2Restore hydrostatic pressureFacilitate extended pain reliefLiquid surface applicatorsSurgical adhesivesEngineeringSealant

A device for delivery of biologic materials, comprising: a cartridge having at least two cylinder bores for fluids to be delivered, wherein each cylinder includes an exit port for a fluid, a plunger within each cylinder for pushing the fluids out of the cylinder, a housing adapted to receive the cartridge, wherein the housing or cartridge includes an adaptor to receive and lock a manifold that operably connects to the exit ports of the cartridge, at least two toothed rams, wherein each toothed ram is at least partially within a cylinder bore, a trigger connected to the housing, wherein the trigger includes a toothed drive rack, a toothed wheel assembly that cooperates with the toothed drive rack and with the toothed rams, as well as methods of making the device, methods of using the device to treat discs, kits including the device.

Owner:PAUZA KEVIN

Concrete mixtures having high flowability

InactiveUS7621995B2Improve liquidityAvoid excessive viscositySolid waste managementCeramicwareHydration reactionPolymer science

A viscosity modifying agent is added to a concrete mixture to give the concrete desirable rheological properties. The viscosity modifying agent is incorporated into a foam admixture before it is mixed into the concrete. Because the viscosity modifying agent is a component of the foam admixture, the viscosity modifying agent is dispersed in the aqueous film that forms the foam bubbles. The viscosity modifier in the foam bubbles gives the foam beneficial rheological properties. The viscosity modifier performs more efficiently when included in the foam bubbles as compared to being mixed directly into the concrete. The foam bubbles containing the viscosity modifier can be stabilized using a fluorochemical stabilizer, which is included in the foam admixture. The foam bubbles can be further stabilized with respect to cement mixtures by including a hydration stabilizing in the cement mixture.

Owner:WELKER CHARLES D

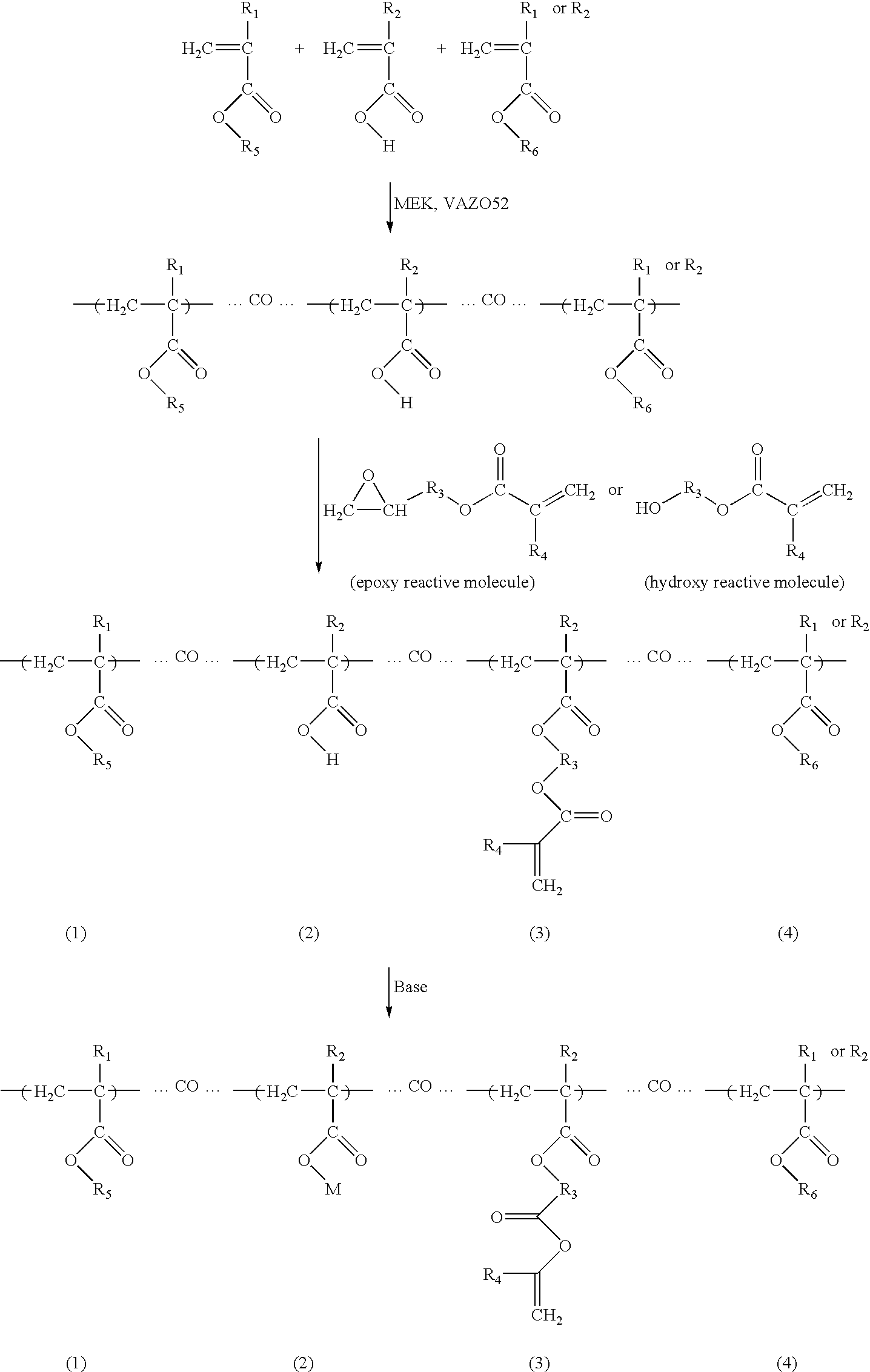

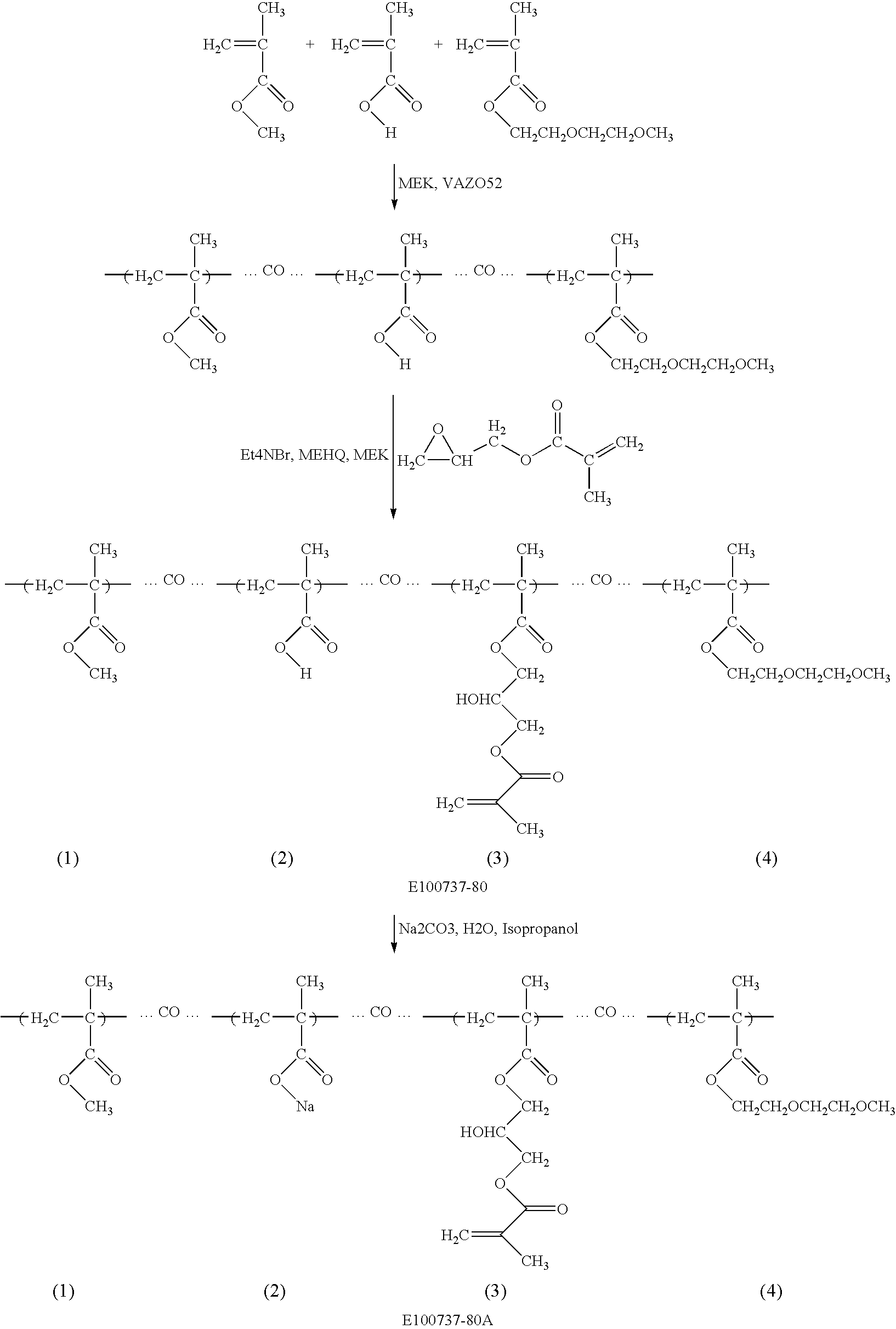

Ink jet printable hydrogel for sensor electrode applications

The present invention provides an ink jet printable hydrogel composition comprising: (a) one or more cross-linkable ionic polymers wherein said polymer is a copolymer, interpolymer or mixture thereof; (b) initiation system; and (c) solvent; wherein said cross-linkable ionic polymers can be selected from photocross-linkable polymers, thermally cross-linkable polymers, photocross-linkable and thermally cross-linkable polymers, and mixtures thereof; and with the proviso that the composition has a viscosity of less than about 100 mPa·s.

Owner:EI DU PONT DE NEMOURS & CO

External preparation, method of producing the same and usage for the same

InactiveUS20090156482A1Facilitated DiffusionRegulate expressionOrganic active ingredientsSenses disorderHuman growth hormoneMedicine

The present invention provides an external preparation and the method for produce the same, in which said external preparation comprises recombinant human growth hormone or recombinant human granulocyte macrophage-stimulating factor and pharmaceutical acceptable carriers. The present invention also relates to application and usage method in preparing medicaments for treatment of various lesions and ulcer, especially corneal lesion and corneal ulcer.

Owner:CHANGCHUN GENESCIENCE PHARM CO LTD

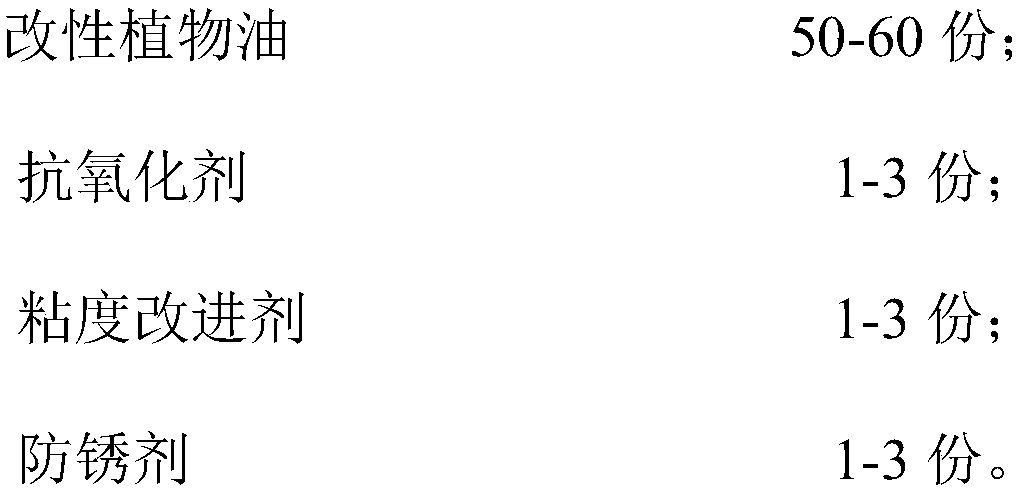

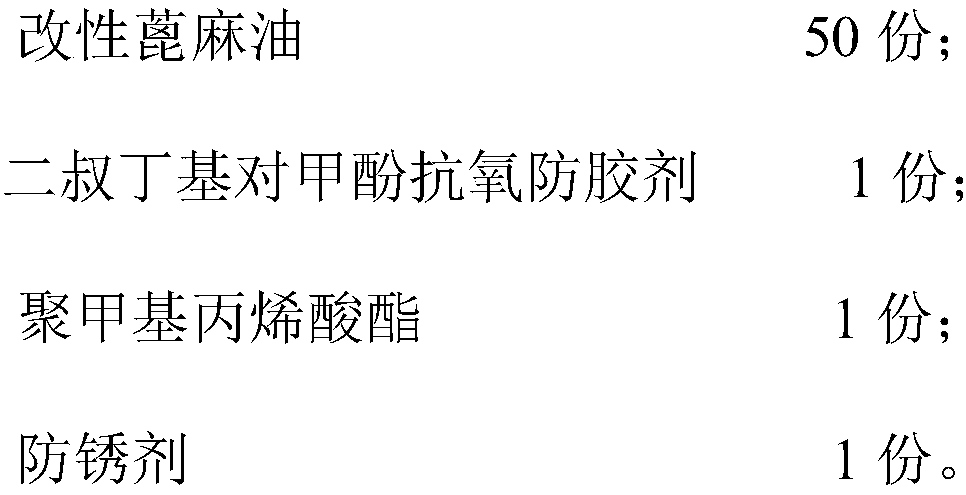

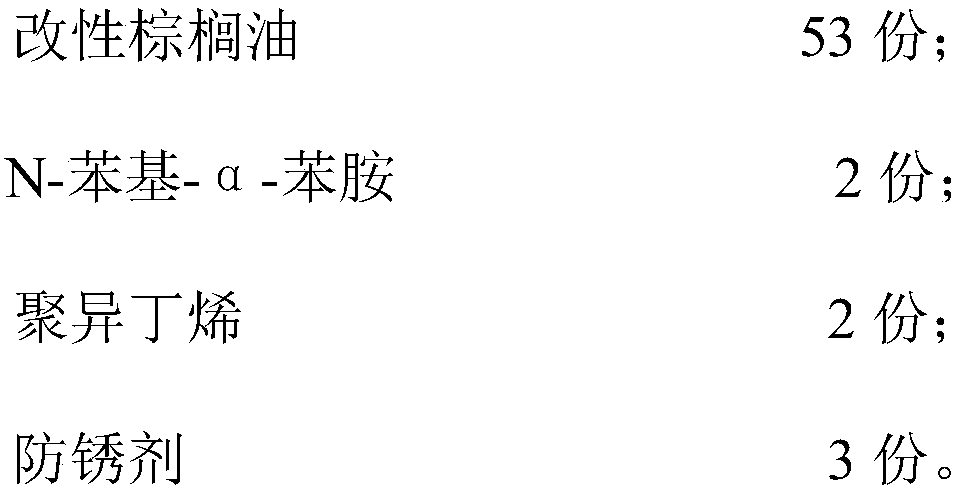

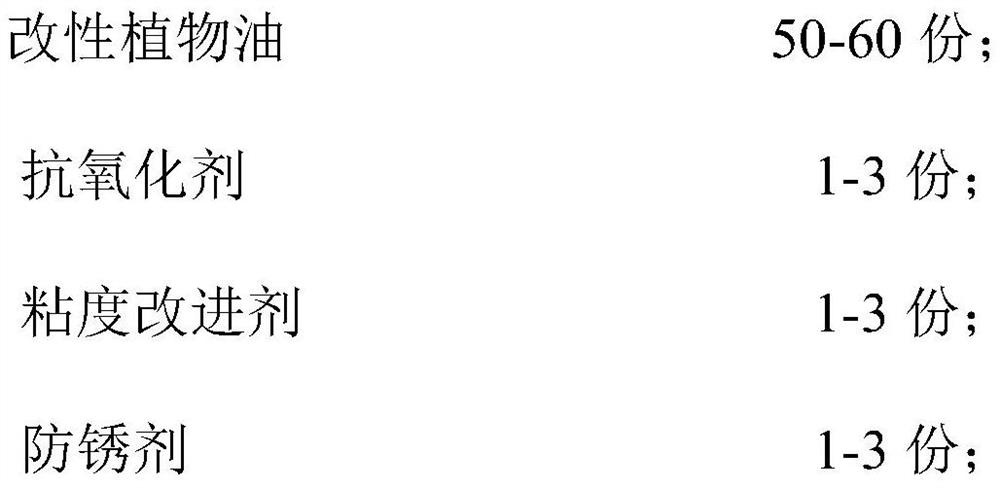

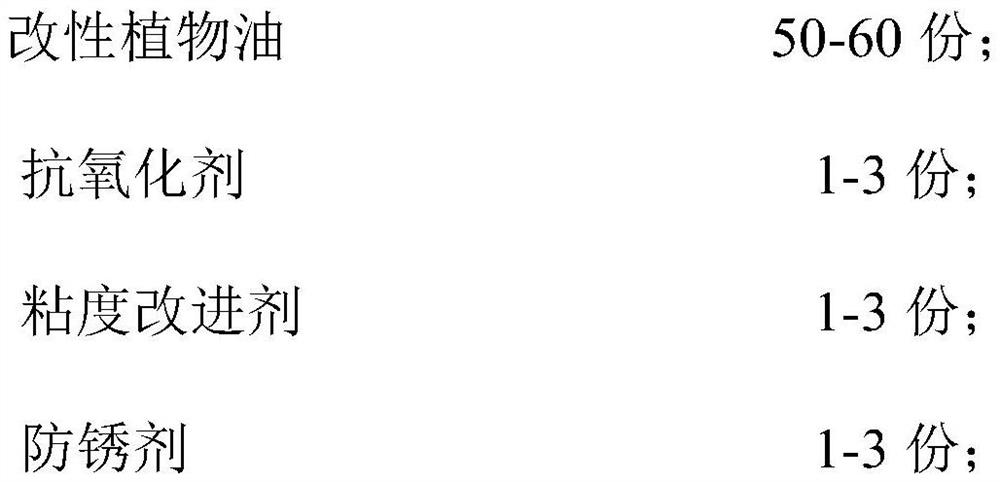

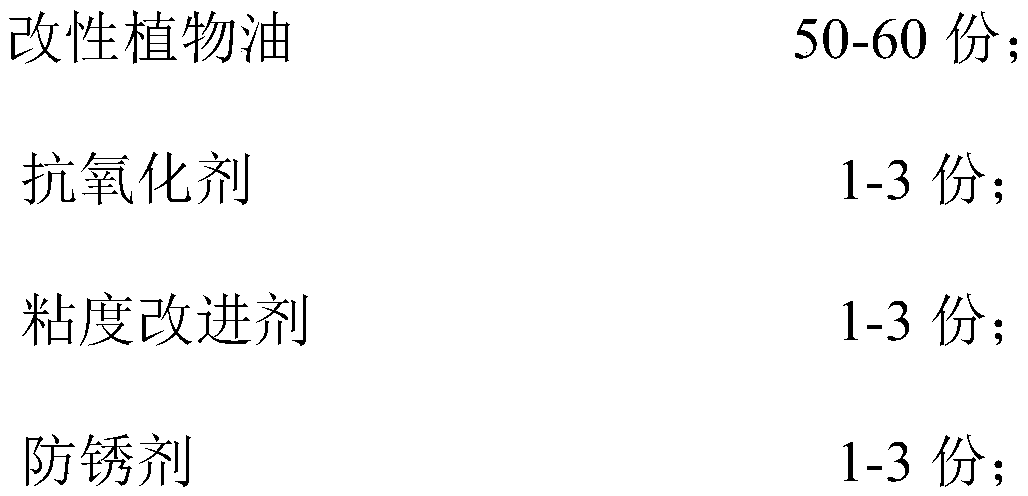

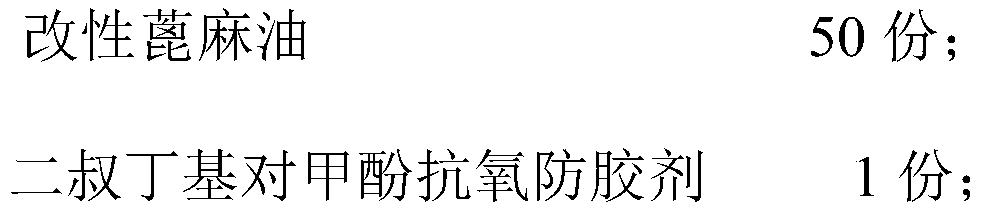

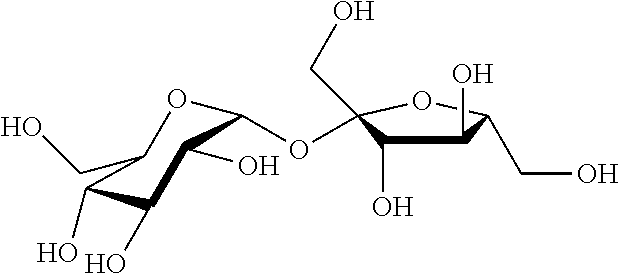

Biodegradable environmentally-friendly lubricating oil and preparation method thereof

ActiveCN108130172ASimple manufacturing methodRaw materials are easy to getLubricant compositionVegetable oilPhosphate

The invention discloses biodegradable environmentally-friendly lubricating oil. The lubricating oil is characterized by comprising the following raw materials in parts by weight: 50-60 parts of modified vegetable oil, 1-3 parts of an antioxidant, 1-3 parts of a viscosity modifier, and 1-3 parts of a rust inhibitor; the modified vegetable oil is prepared by performing hydrosilylation on methyl hydrogen silicone oil and vegetable oil and performing interesterification on the methyl hydrogen silicone oil modified vegetable oil and a phosphate ester compound; and the rust inhibitor is obtained byperforming an esterification reaction on polylactic acid and dodecenylsuccinic acid. The biodegradable environmentally-friendly lubricating oil disclosed by the invention has better viscosity-temperature performance, a more remarkable lubricating effect and more excellent oxidation stability than those of lubricating oil disclosed in the prior art, is biodegradable, and causes less pollution to the environment.

Owner:JIANGSU SHUANGJIANG ENERGY TECH CO LTD

Method for treating tailing slurries with Caro's acid

InactiveUS6090297AMinimize decomposition and hydrolysisEfficient dilutionPeroxyhydrates/peroxyacidsSulfur compoundsCyanideSlurry

A process for treating precious metal tailing slurries with Caro's acid, in which the Caro's acid is accompanied by reduced amounts of Caro's acid mist, is disclosed. The hot Caro's acid-containing mixture, formed by reaction of concentrated sulfuric acid and hydrogen peroxide, is quenched with water to reduce or eliminate the Caro's acid mist. The resulting cooled and diluted mixture is introduced into a precious metal tailings slurry to reduce the amount of cyanide values in the slurry.

Owner:FMC CORP

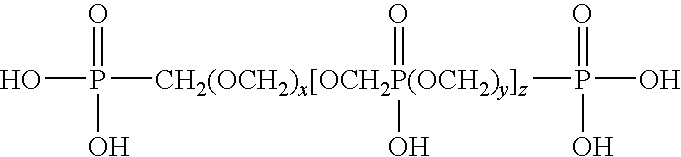

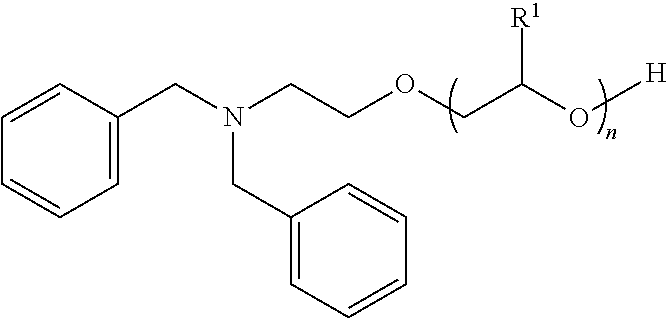

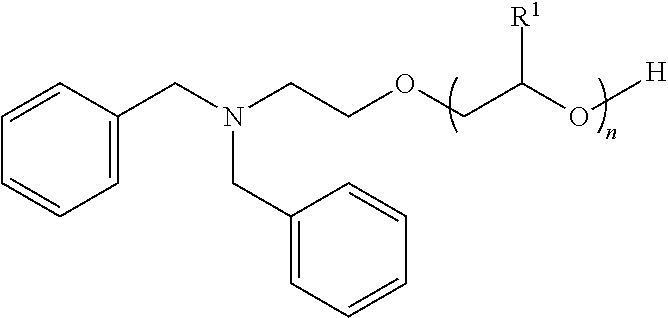

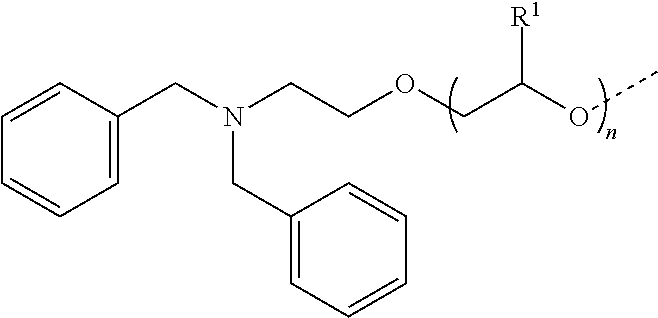

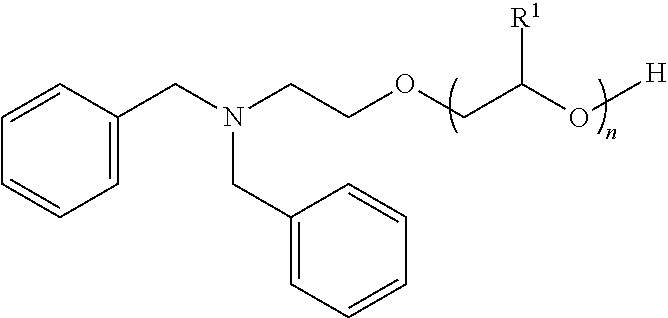

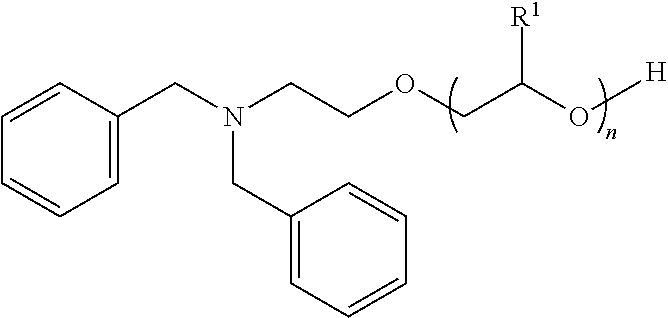

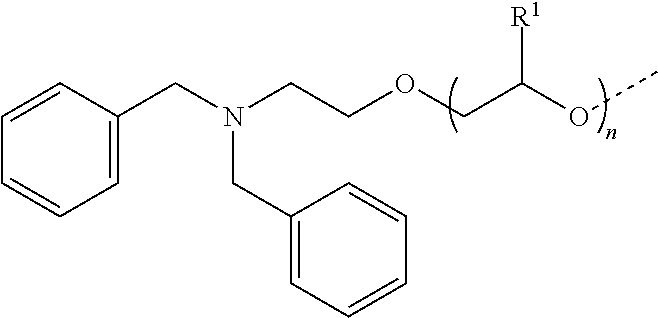

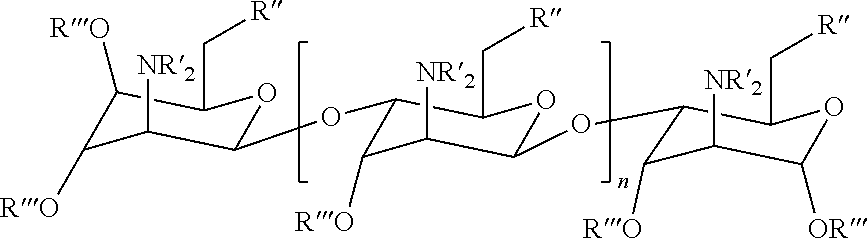

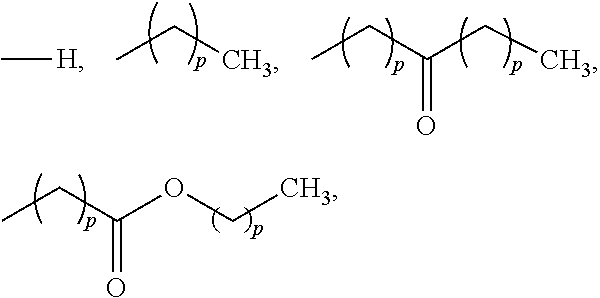

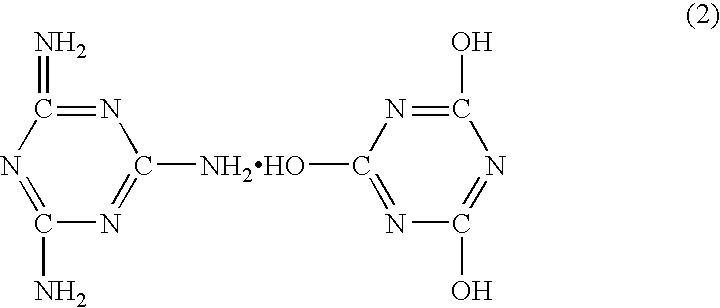

Dibenzylamine hydrophobe

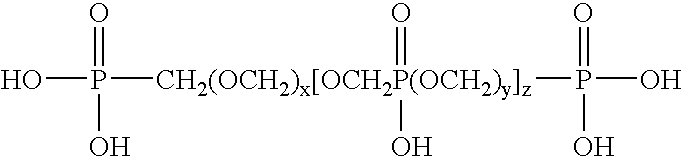

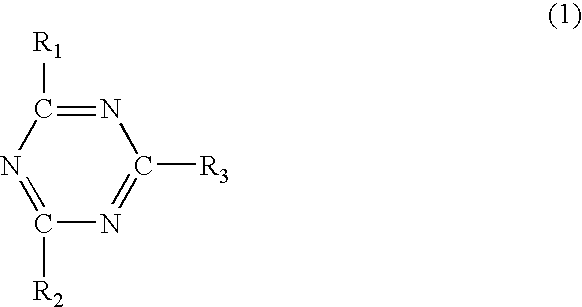

ActiveUS20130281639A1Avoid excessive viscosityOrganic compound preparationCoatingsMethyl groupHydrophobe

The present invention relates to a compound characterized by the following formula:wherein each R1 is independently methyl or ethyl; and n 1 to 10. The compound is useful in preparing hydrophobically modified alkylene oxide urethane polymers, which are useful as rheology modifiers for coatings formulations.

Owner:ROHM & HAAS CO

Modified vegetable oil and preparation method thereof

InactiveCN111675810APromote degradationImprove thermal stabilityLubricant compositionTrans esterificationVegetable oil

The invention discloses a preparation method of modified vegetable oil. The method comprises the following steps: 1) modifying vegetable oil with methyl hydrogen-containing silicone oil: adding methylhydrogen-containing silicone oil into a flask provided with a constant-temperature feeding funnel and a condensation pipe, replacing air in the flask with nitrogen or inert gas, opening condensate water, adding a catalyst, vegetable oil and isopropanol, stirring, heating to 80-85 DEG C, keeping the temperature for 6-7 hours, and performing reduced pressure distillation to remove low-volatility substances, thereby obtaining hydrogen-containing silicone oil modified vegetable oil; and 2) ester exchange: adding methyl hydrogen-containing silicone oil modified vegetable oil prepared in the step 1) and (2R,3S)-2,3,4-trihydroxyl-3-methylbutyl dihydrogen phosphate into an organic solvent, heating to 95-105 DEG C within 30-40 minutes under a vacuum pressure of 200 mbar; making the mixture carry out reactions for 2-3 hours under stirring at a stirring speed of 800-1000 rpm, and then carrying out rotary evaporation at 50-60 DEG C to remove low-volatility substances. The lubricating oil preparedfrom the modified vegetable oil is good in chemical stability, has an extreme pressure anti-wear effect, does not need to be added with an extreme pressure anti-wear agent additionally, is economicaland environment-friendly, and avoids the problem of overlarge viscosity caused by using a large amount of auxiliaries.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

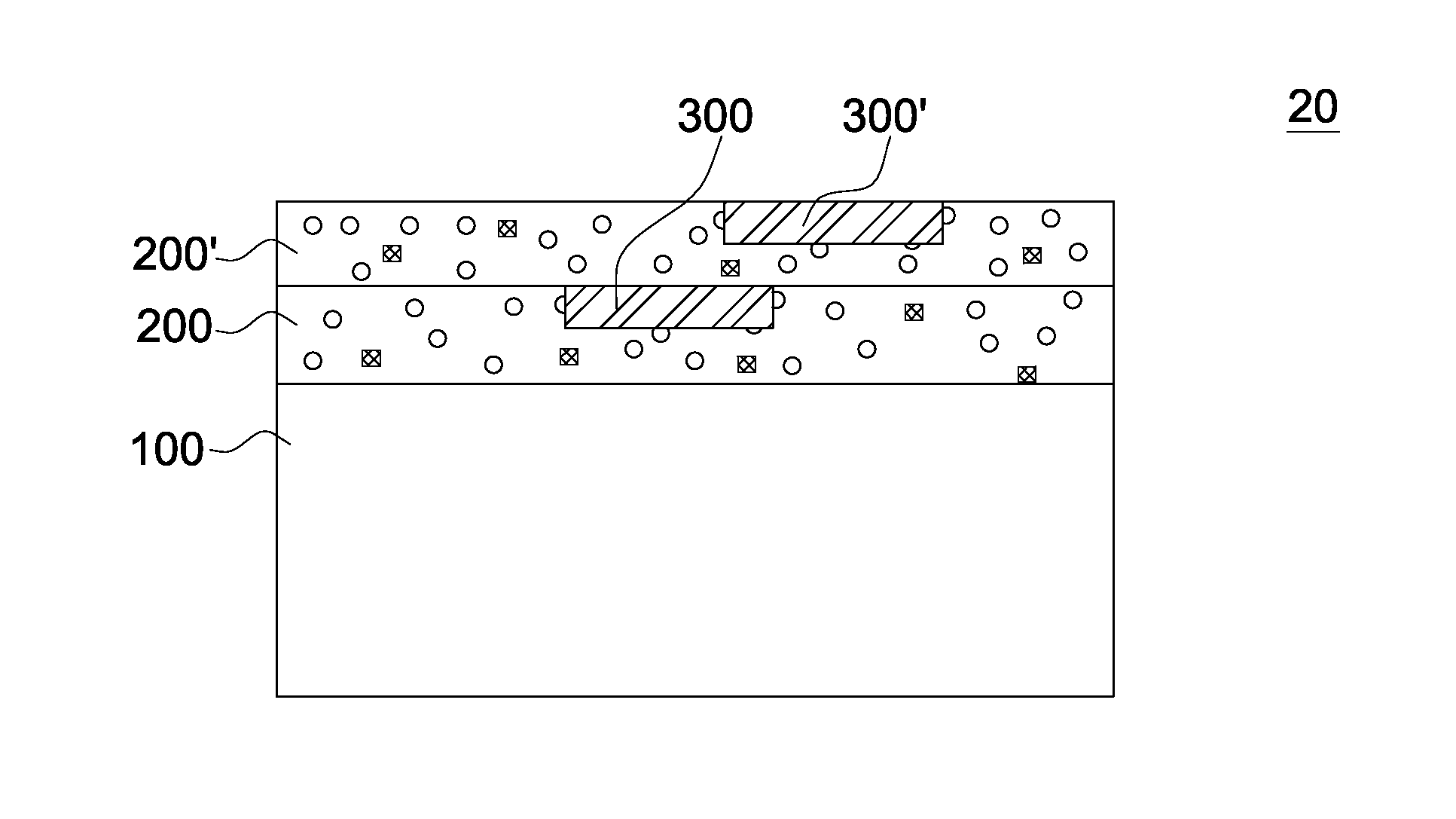

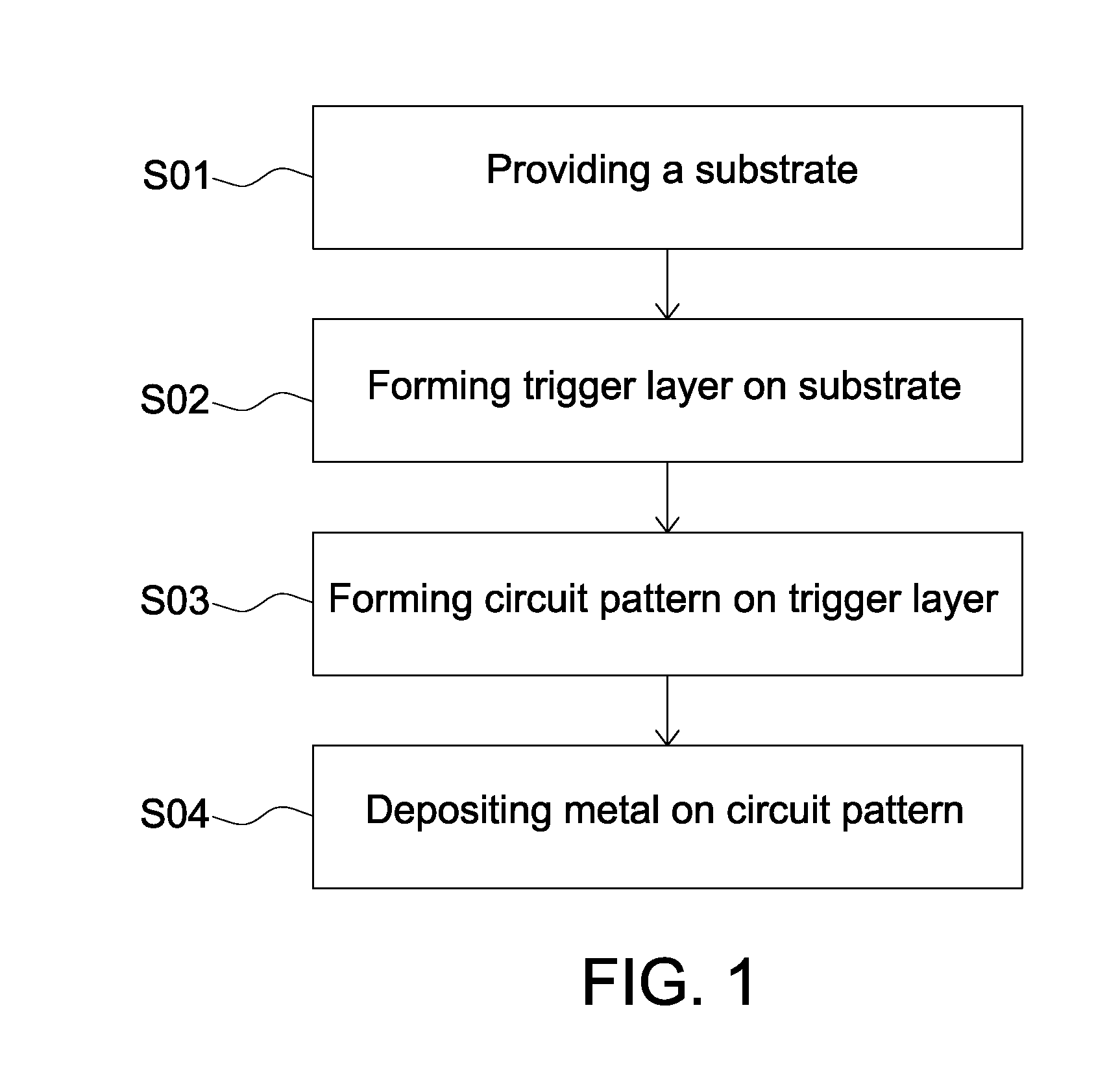

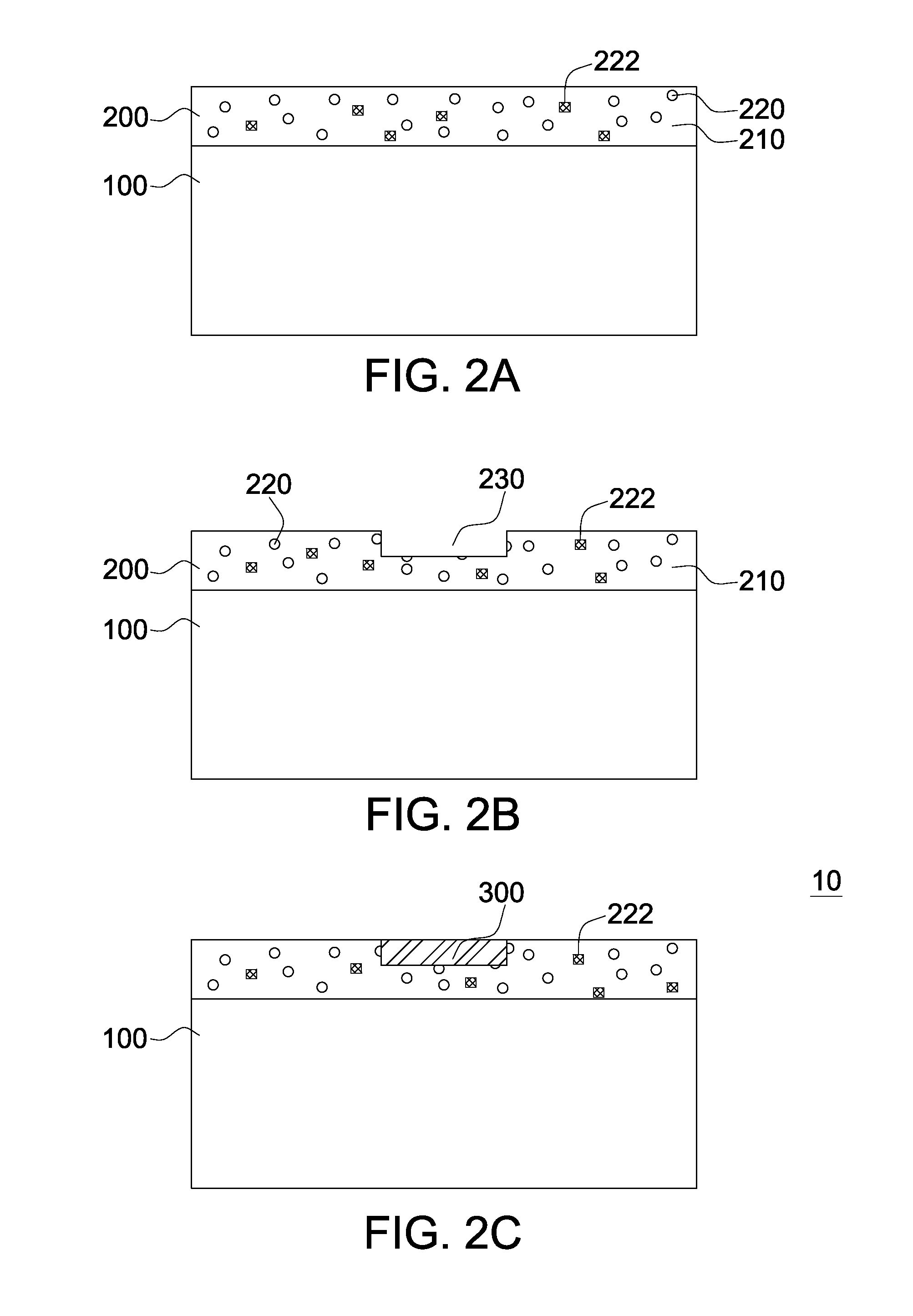

Method for forming metal circuit, liquid trigger material for forming metal circuit and metal circuit structure

ActiveUS20150122533A1Avoid excessive viscosityRadiation applicationsConductive materialSemiconductor materialsLiquid state

A metal circuit structure, a method for forming a metal circuit and a liquid trigger material for forming a metal circuit are provided. The metal circuit structure includes a substrate, a first trigger layer and a first metal circuit layer. The first trigger layer is disposed on the substrate and includes a first metal circuit pattern. The first metal circuit layer is disposed on the first circuit pattern and is electrically insulated from the substrate. The composition of the first trigger layer includes an insulating gel and a plurality of trigger particles. The trigger particles are at least one of organometallic particles, a chelation and a semiconductor material having an energy gap greater than or equal to 3 eV. The trigger particles are disposed in the insulating gel, such that the dielectric constant of the first trigger layer after curing is between 2 and 6.5.

Owner:IND TECH RES INST

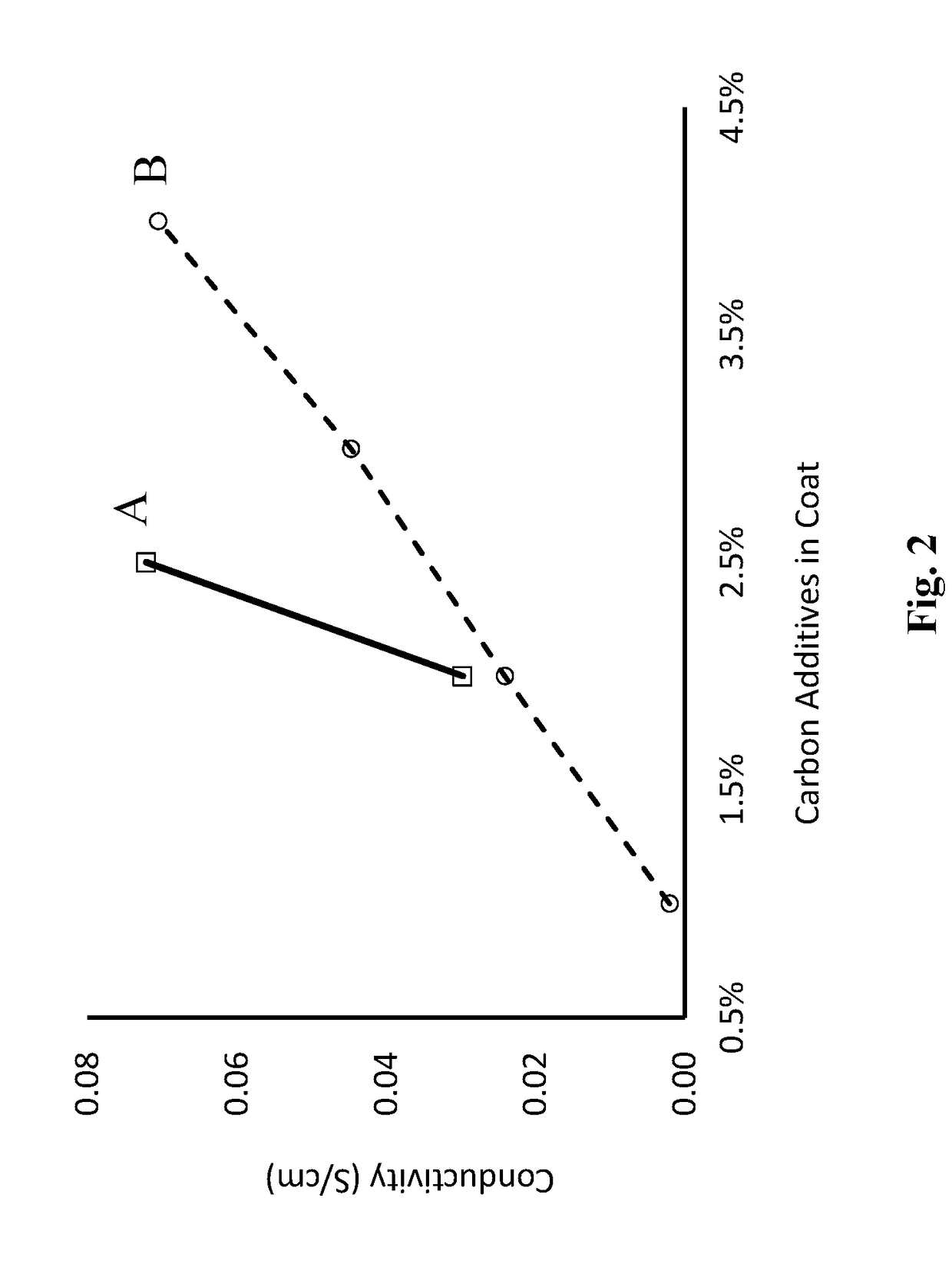

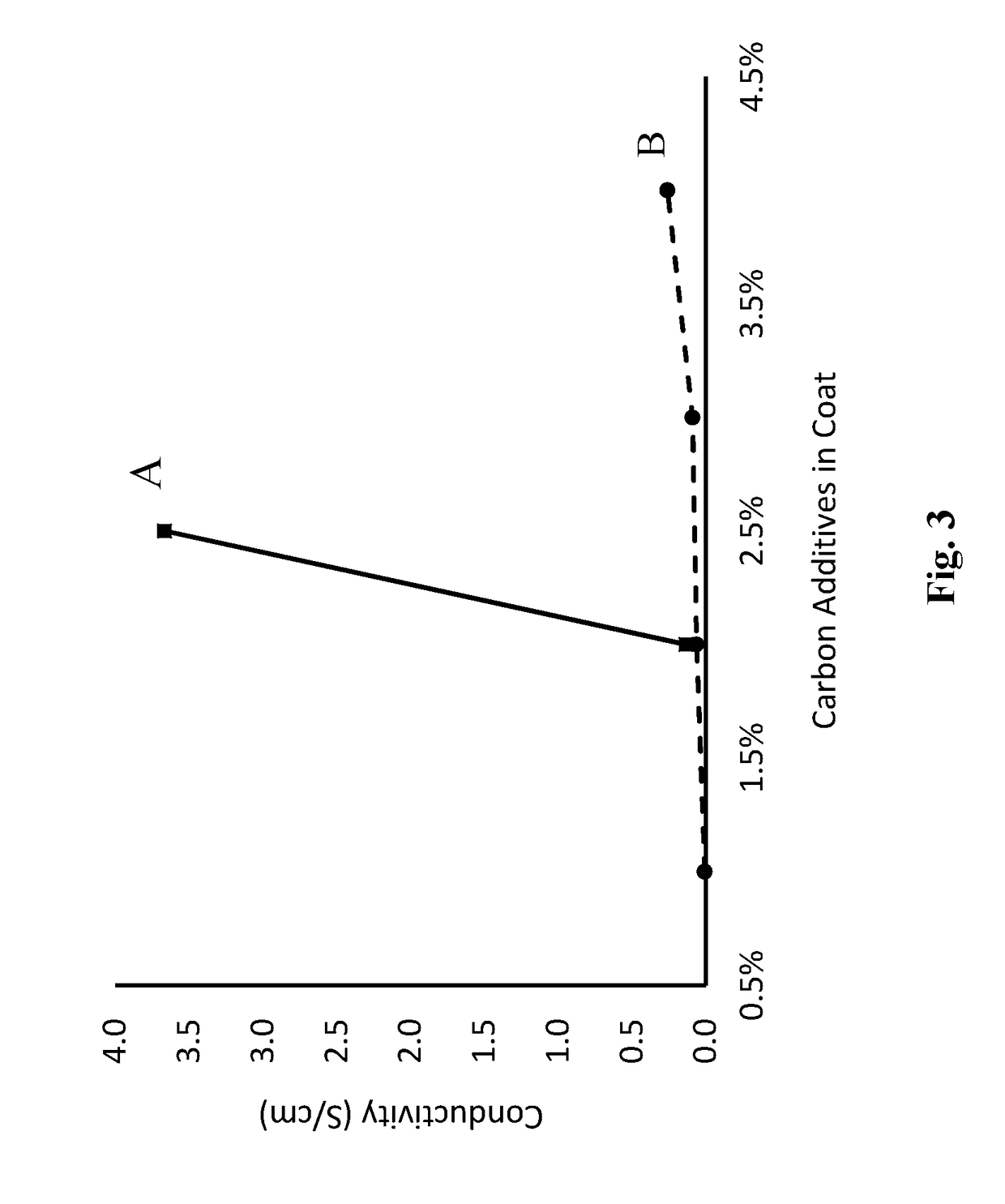

Electrode Slurries Containing Halogenated Graphene Nanoplatelets, and Production and Uses Thereof

InactiveUS20180201740A1Remain stableHigh energy densityMaterial nanotechnologySolid electrolytesHalogenBromine

This invention provides process for forming a binder slurry, which process comprises:A) mixing halogenated graphene nanoplatelets and one or more polar solvents to form a nanoplatelet slurry, and combining the nanoplatelet slurry and one or more binders to form a binder slurry; orB) combining i) a nanoplatelet slurry comprising halogenated graphene nanoplatelets in a polar solvent with ii) one or more binders to form a binder slurry.The halogenated graphene nanoplatelets comprise graphene layers and are characterized by having, except for the carbon atoms forming the perimeters of the graphene layers of the nanoplatelets, (a) graphene layers that are free from any element or component other than sp2 carbon, and (b) substantially defect-free graphene layers, wherein the total content of halogen in the nanoplatelets is about 5 wt % or less calculated as bromine and based on the total weight of the nanoplatelets.

Owner:ALBEMARLE CORP

Dibenzylamine hydrophobe

ActiveUS8791201B2Avoid excessive viscosityOrganic compound preparationCoatingsHydrophobeMethyl group

The present invention relates to a compound characterized by the following formula:wherein each R1 is independently methyl or ethyl; and n 1 to 10. The compound is useful in preparing hydrophobically modified alkylene oxide urethane polymers, which are useful as rheology modifiers for coatings formulations.

Owner:ROHM & HAAS CO

Polymeric additives for reducing the viscosity loss on tinting

PendingUS20200262965A1Suitable for useLess viscosity lossPolyurea/polyurethane coatingsPolymer scienceViscosity

The presently claimed invention relates to a composition comprising polyurethane polymer and diluents, which is used as an additive in coating formulations, in particular water-borne paint and coating formulations, for reducing the effect of the viscosity loss caused by the addition of colorants / pigment pastes thereby improving the viscosity stability in tinted coating formulations as well as the method for preparing the composition.

Owner:BASF AG

A kind of biodegradable environmental protection lubricating oil

ActiveCN108130172BPromote degradationImprove thermal stabilityLubricant compositionVegetable oilButanedioic acid

The invention discloses a preparation method of modified vegetable oil. The method comprises the following steps: 1) modifying vegetable oil with methyl hydrogen-containing silicone oil: adding methylhydrogen-containing silicone oil into a flask provided with a constant-temperature feeding funnel and a condensation pipe, replacing air in the flask with nitrogen or inert gas, opening condensate water, adding a catalyst, vegetable oil and isopropanol, stirring, heating to 80-85 DEG C, keeping the temperature for 6-7 hours, and performing reduced pressure distillation to remove low-volatility substances, thereby obtaining hydrogen-containing silicone oil modified vegetable oil; and 2) ester exchange: adding methyl hydrogen-containing silicone oil modified vegetable oil prepared in the step 1) and (2R,3S)-2,3,4-trihydroxyl-3-methylbutyl dihydrogen phosphate into an organic solvent, heating to 95-105 DEG C within 30-40 minutes under a vacuum pressure of 200 mbar; making the mixture carry out reactions for 2-3 hours under stirring at a stirring speed of 800-1000 rpm, and then carrying out rotary evaporation at 50-60 DEG C to remove low-volatility substances. The lubricating oil preparedfrom the modified vegetable oil is good in chemical stability, has an extreme pressure anti-wear effect, does not need to be added with an extreme pressure anti-wear agent additionally, is economicaland environment-friendly, and avoids the problem of overlarge viscosity caused by using a large amount of auxiliaries.

Owner:JIANGSU SHUANGJIANG ENERGY TECH CO LTD

Fabric softener composition

ActiveUS20180334639A1Less viscosity lossGood flexibilityOrganic detergent compounding agentsDetergent mixture composition preparationViscosityOrganic chemistry

A liquid fabric softener composition and processes for making and using same. In particular a liquid fabric softener composition comprising a structurant providing the desired viscosity which remains stable over time.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method and use for fluorine-containing microemulsion

ActiveUS20130213270A1High molecular weightAvoid excessive viscosityOther chemical processesTransportation and packagingPolymer scienceEmulsion

A microemulsion consisting of water, peroxidic fluoropolyether carboxylate and oil is provided. When the microemulsion is used in homopolymerization, binary copolymerization or multi-component copolymerization of fluorine-containing olefin monomers, an emulsion with a low viscosity and a particle diameter of 30-200 nm can be obtained.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

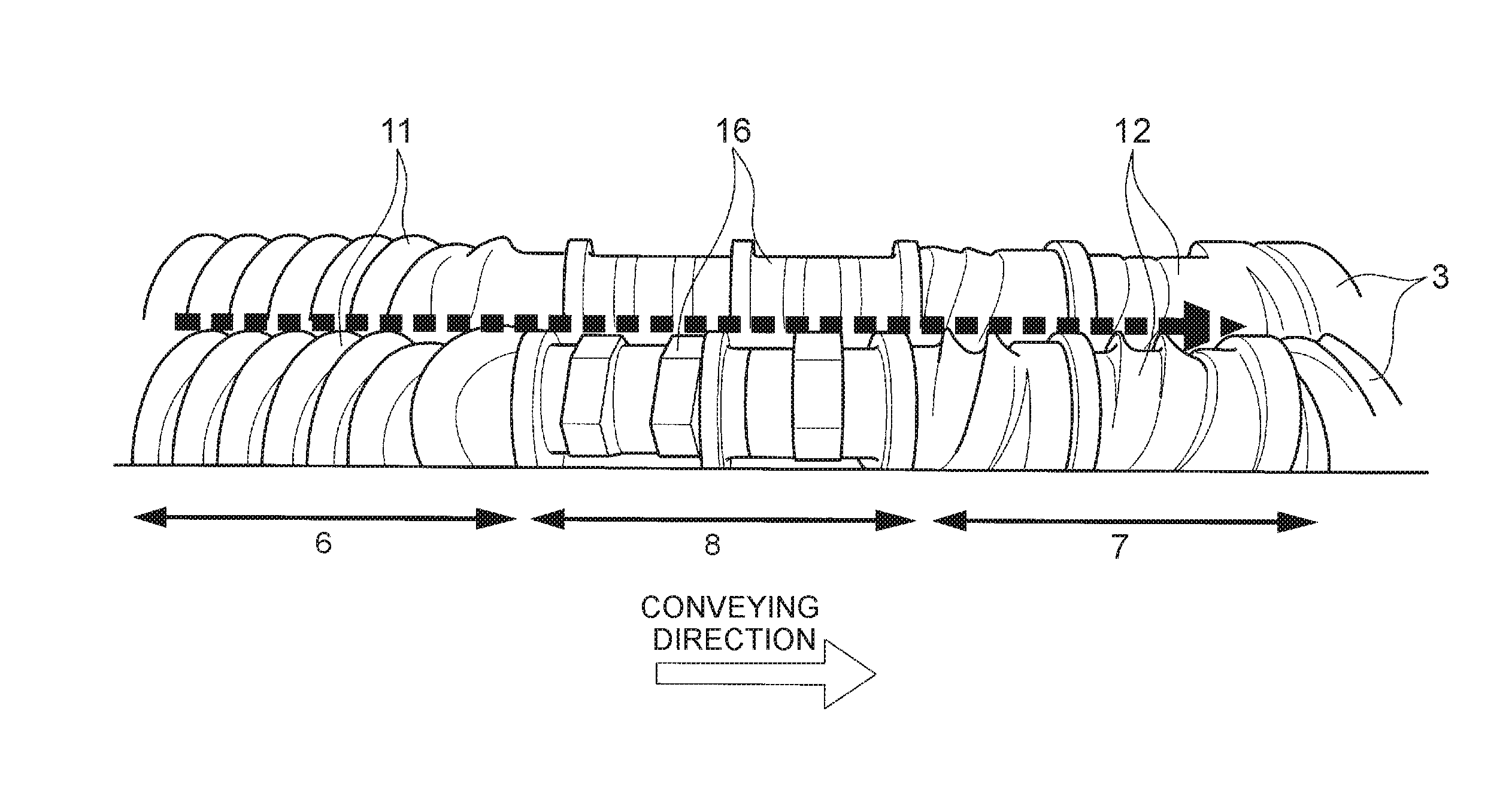

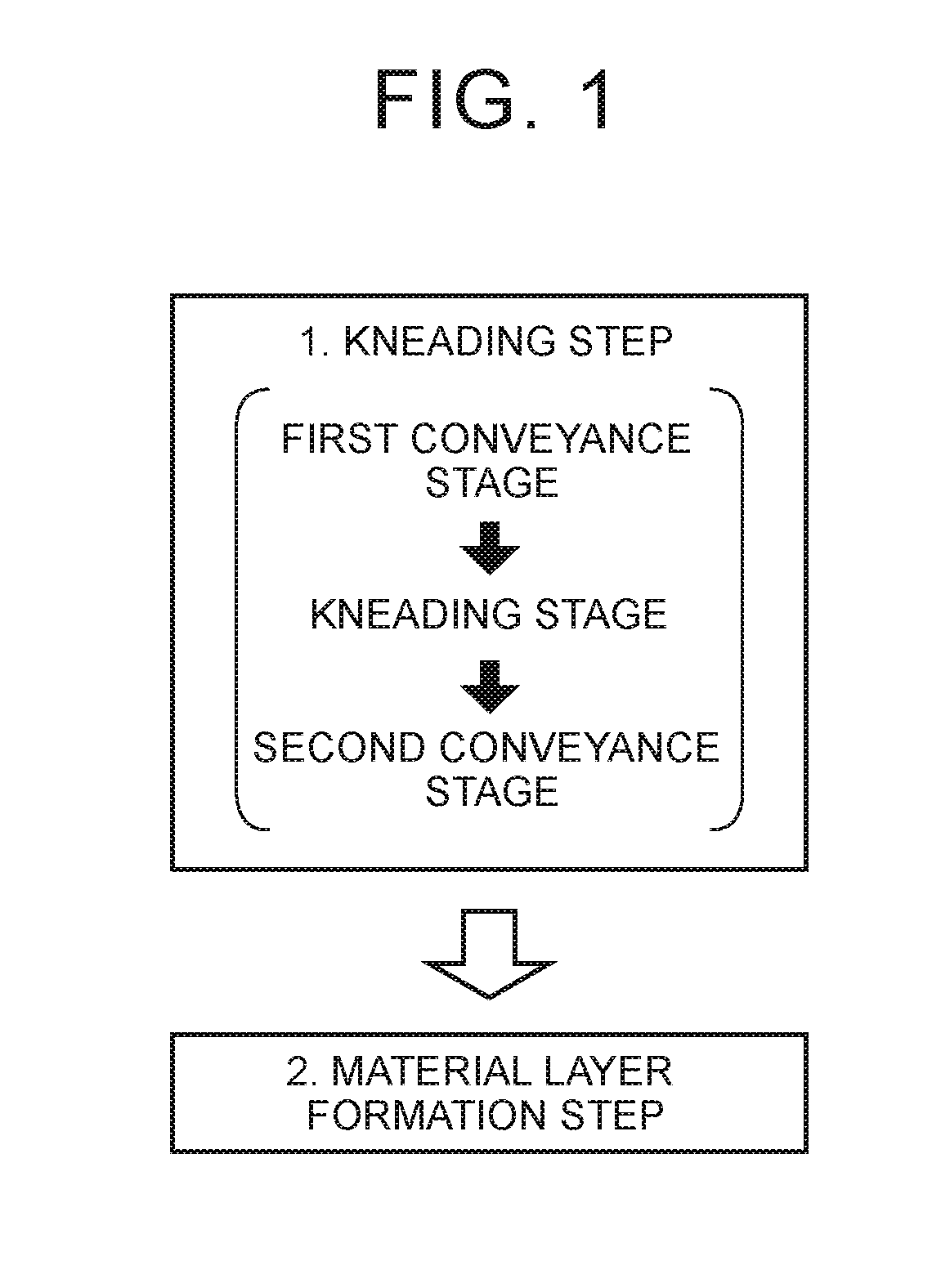

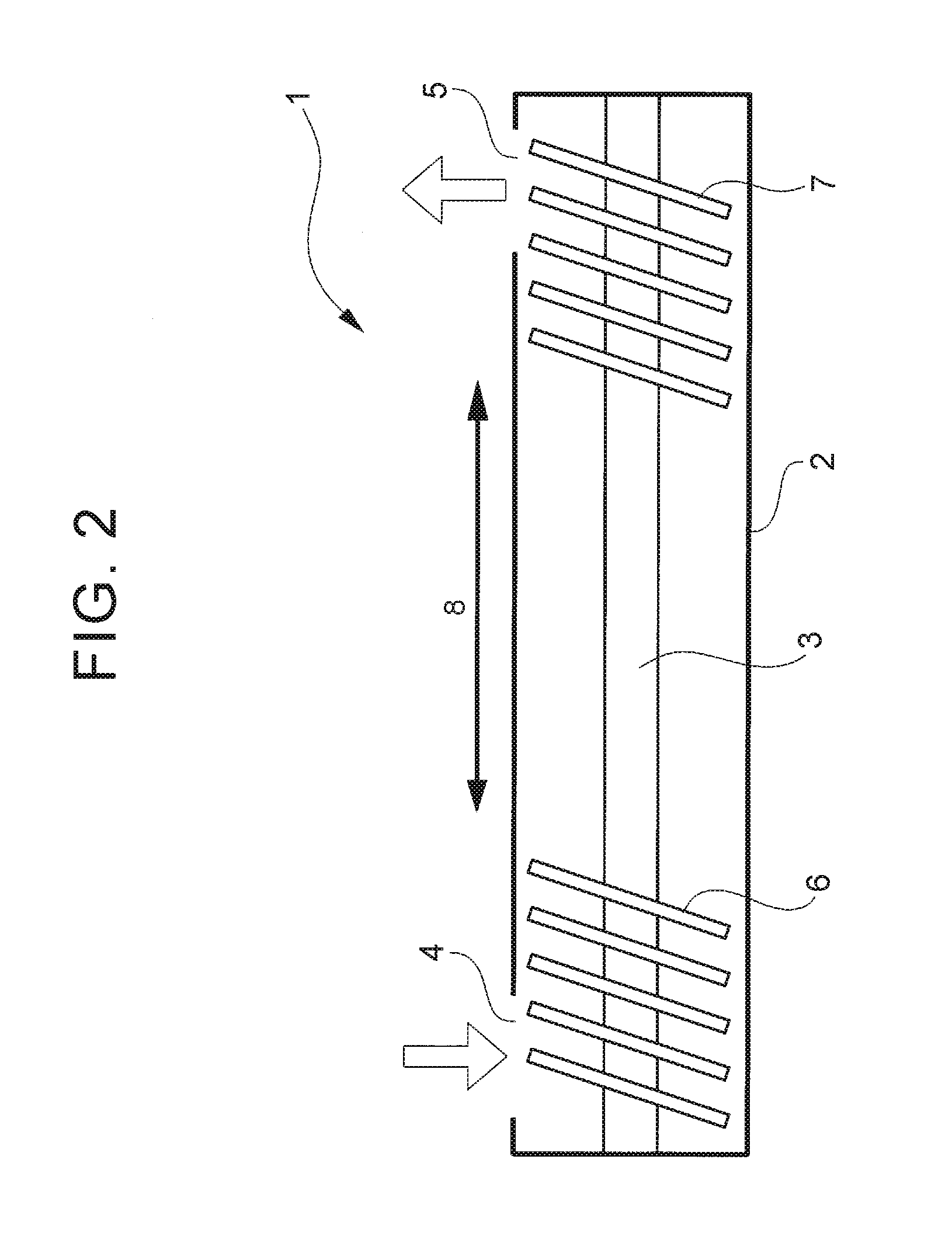

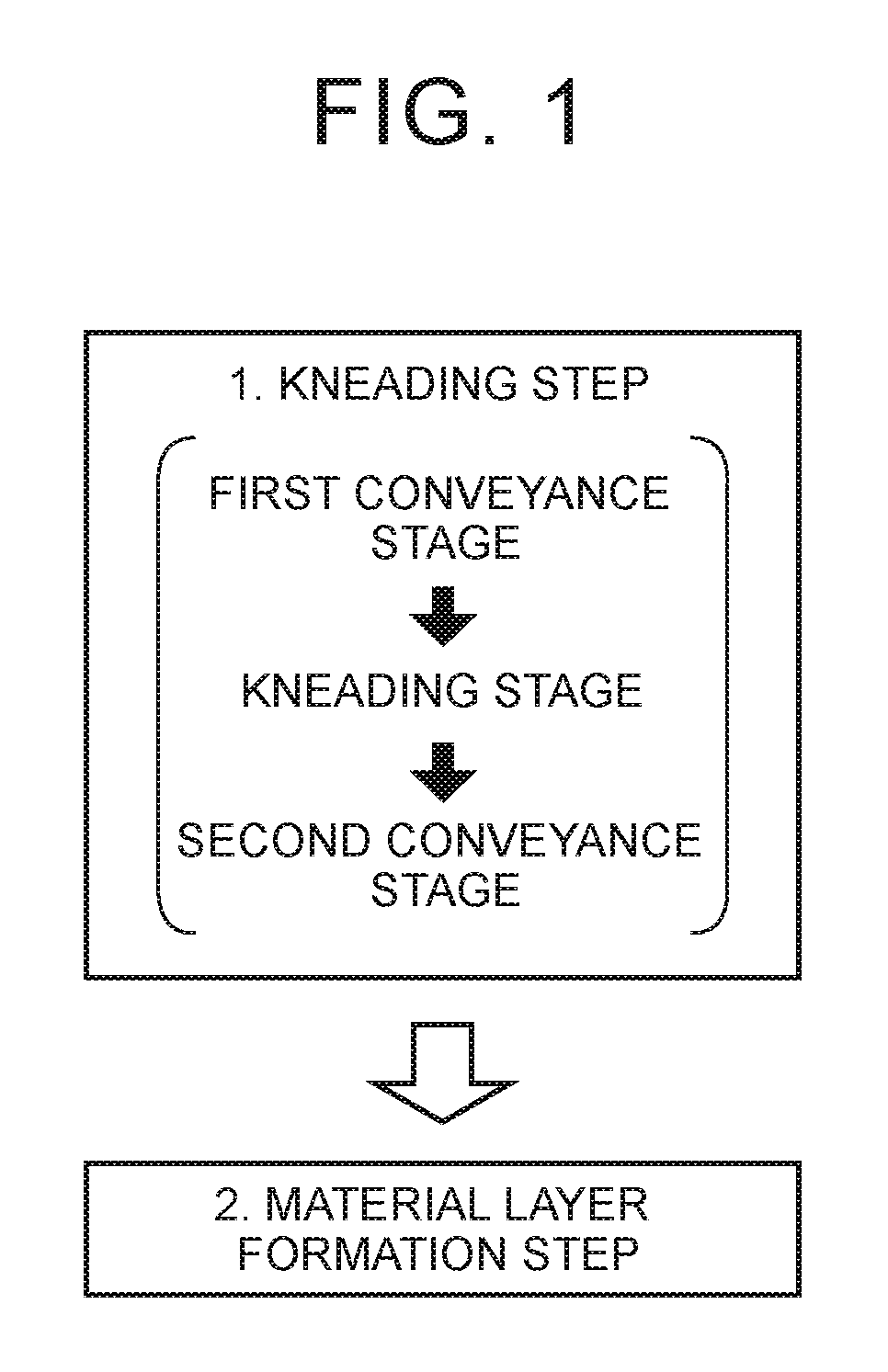

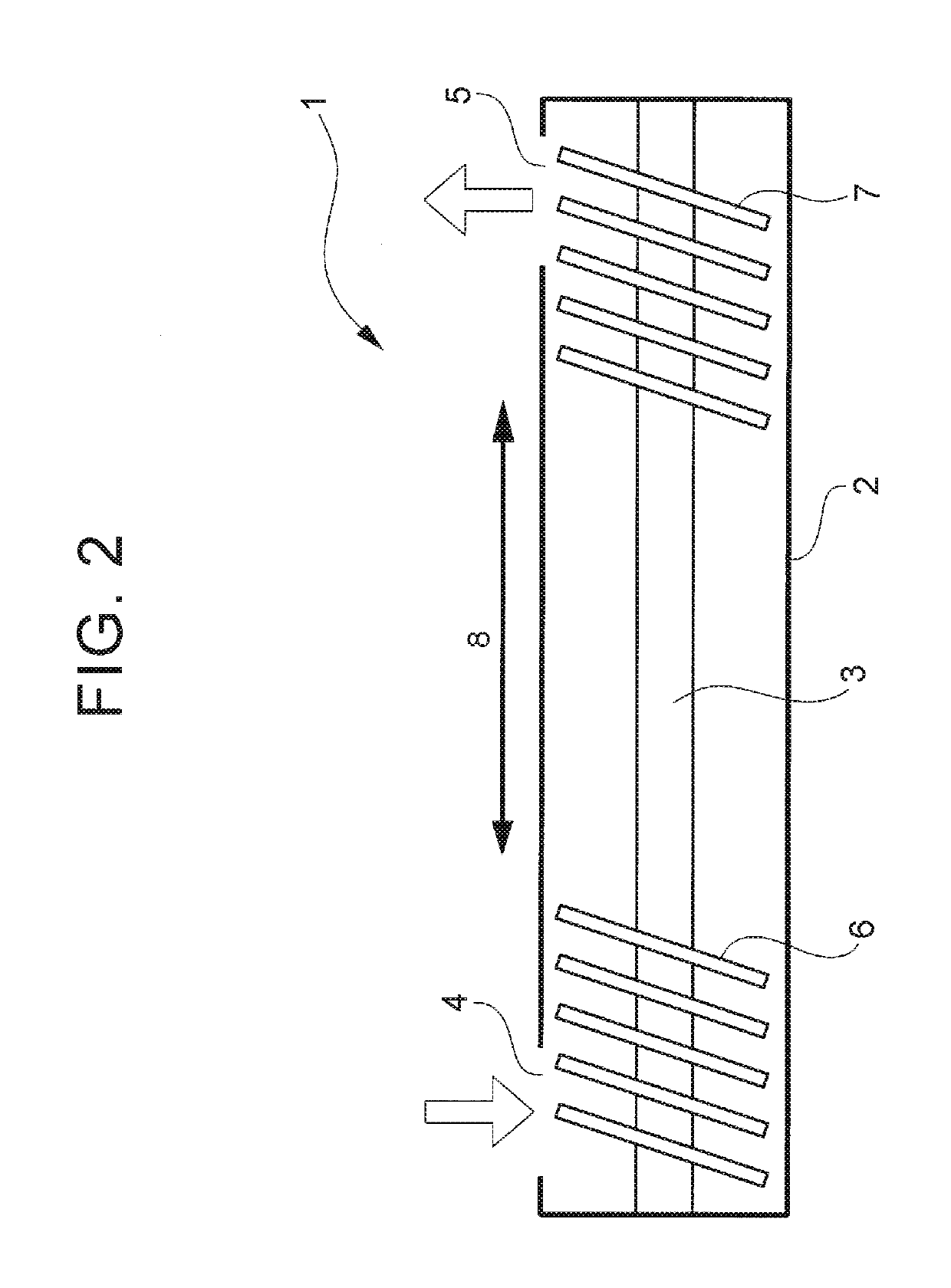

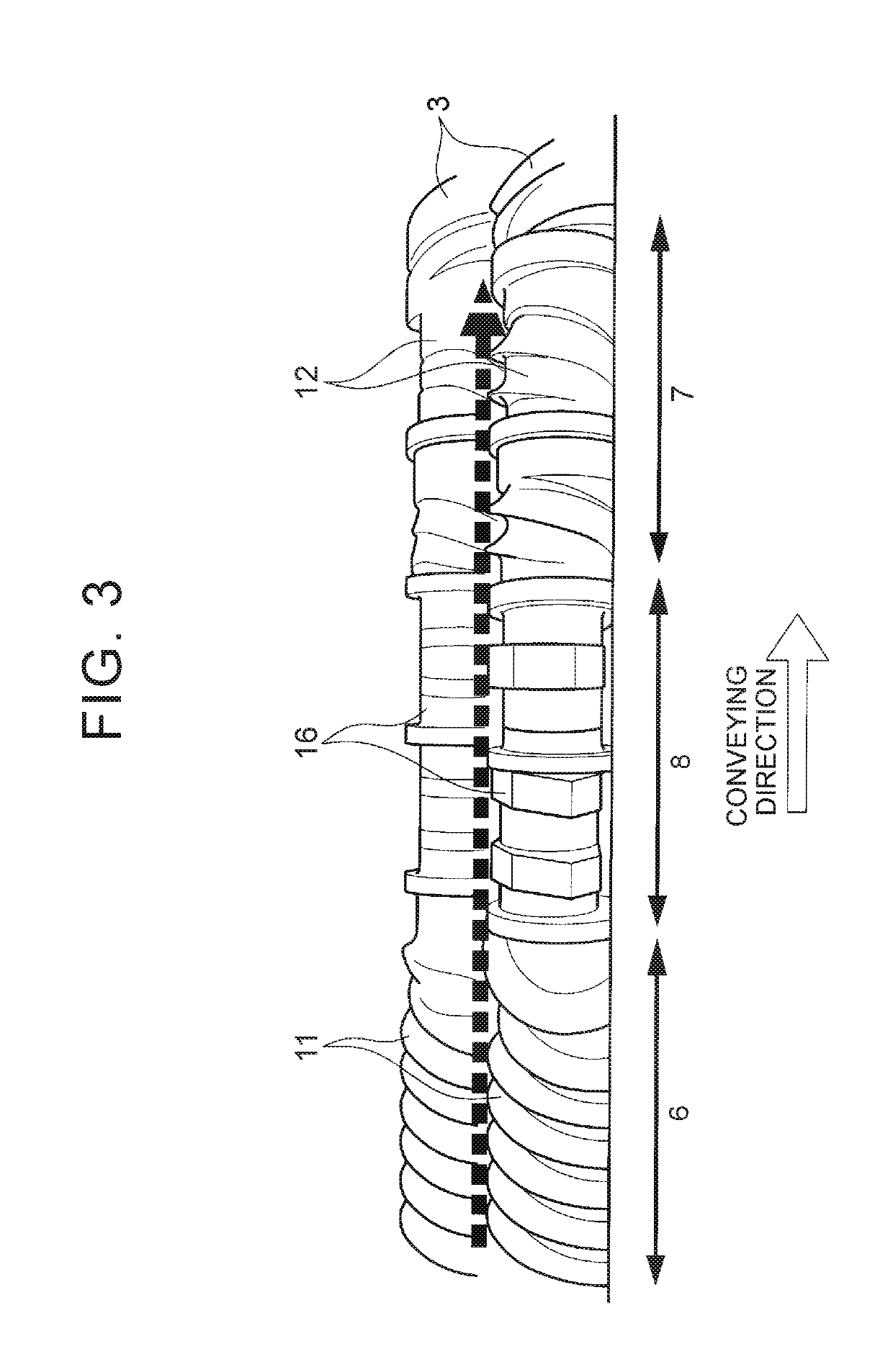

Kneader and manufacturing method of electrode body including electrode active material using the same

ActiveUS20170062797A1Uneven viscosityHigh content ratioRotary stirring mixersFinal product manufactureEngineeringElectrode material

Owner:TOYOTA JIDOSHA KK

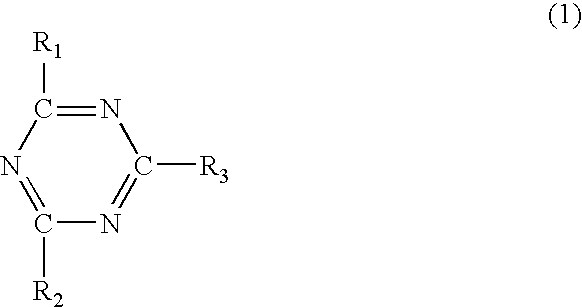

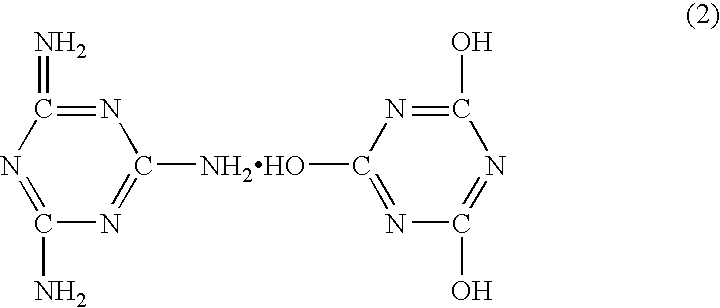

Lubricating oil composition for diesel oil vehicle

ActiveUS20090305921A1Excellent viscosity temperature characteristicsLess viscosity increaseOrganic chemistryAdditivesParticulatesChemical composition

A lubricating oil composition for diesel oil vehicle comprises lubricating base oil, in which the composition further comprises triazine compound. The wheel rim power of the diesel oil vehicle is increased by 8-10%, the carbon smoke particulate discharge in tail gas is reduced by 30-50%, oil saving rate is high up to more than 10% and the oil change-over period of machine oil is 2-3 times of that of a conventional one; the discharge fully meets the standard, at the same time eliminates the bad smell and taste of the raw oil, the tail gas discharge of currently used vehicle or new vehicle meet the national standards by using the lubricating oil composition provided by the present invention.

Owner:LI ZHENGZHAO

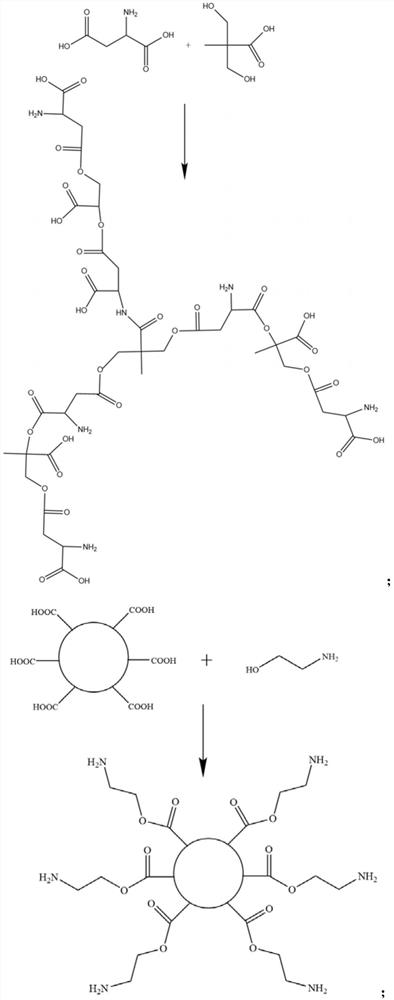

A kind of hb(a-m) modified boron nitride nanotube reinforced PVA fiber and preparation method thereof

ActiveCN113215675BGood dispersionAvoid excessive viscosityMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to a HB(A-M) modified boron nitride nanotube reinforced PVA fiber and a preparation method thereof. The preparation method is as follows: PVA spinning solution containing HB(A-M) modified boron nitride nanotubes HB(A-M) modified boron nitride nanotubes reinforced PVA fibers were prepared by dry and wet spinning; HB(A-M) modified boron nitride nanotubes were obtained by dissolving HB(A-M) in In ionized water, add hydroxylated BNNT to it and carry out ultrasonic treatment to obtain; HB (A-M) is a hyperbranched polymer synthesized with AB as a monomer and dihydroxyethylamine as a core molecule, wherein AB is composed of mol The ratio is 1.0~1.2:1.7~2.4 aspartic acid reacts with dimethylolpropionic acid; the content of PVA in PVA spinning solution is 35~40wt%, and the viscosity of PVA spinning solution is 1500~2200Pa· s; the obtained HB(A-M) modified boron nitride nanotube reinforced PVA fiber has a fineness of 24.1-35.3 dtex, a breaking strength of 15.9-19.6 cN / dtex, and an elastic modulus of 376-389 cN / dtex. The invention effectively solves the problem of poor dispersibility of BNNT, and prepares the HB(A-M) modified boron nitride nanotube reinforced PVA fiber with excellent performance.

Owner:DONGHUA UNIV

Kneader and manufacturing method of electrode body including electrode active material using the same

ActiveUS10497926B2Avoid excessive viscosityStable productionFinal product manufactureRotary stirring mixersEngineeringElectrode

Owner:TOYOTA JIDOSHA KK

Oily protective pigment dispersion for protection against uv radiation, a process for preparing it, and a cosmetic composition

InactiveUS20050201954A1Convenience to mergeLow SPFCosmetic preparationsPigmenting treatmentUltravioletSun protection factor

The present invention relates to an oily dispersion of pigments for protection against UV radiation comprising, in a single base, zinc oxide and titanium dioxide added in the form of a powder, wherein the two pigments are dispersed in a single oily dispersing vehicle and the dispersion further comprises a single emollient vehicle. The invention also relates to a process for preparing said oily pigment dispersion. The dispersion of the present invention is useful to be added to cosmetic compositions, bringing about a faster way of producing compositions having a high sunshine protection factor, with a lower cost and more safety for the end products.

Owner:NATURA COSMETICOS SA

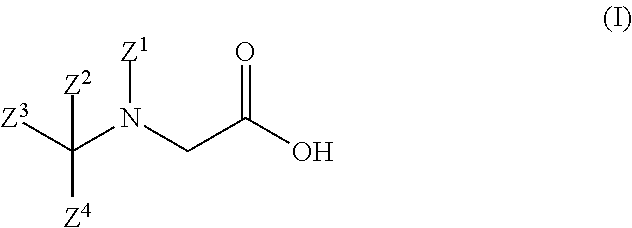

Aqueous pigment dispersions and inkjet inks

The present disclosure pertains to an aqueous pigment dispersion containing a pigment as colorant, a polymeric dispersant and a hydroxyl-substituted amino acid. The present disclosure further pertains to an ink containing an aqueous vehicle and the aqueous pigment dispersion, and ink sets with at least one of the inks containing the pigment dispersion.

Owner:DUPONT ELECTRONICS INC

Lubricating oil composition for diesel oil vehicle

ActiveUS8138131B2Easy dischargeExcellent viscosity temperature characteristicsOrganic chemistryAdditivesParticulatesChemical composition

Owner:LI ZHENGZHAO

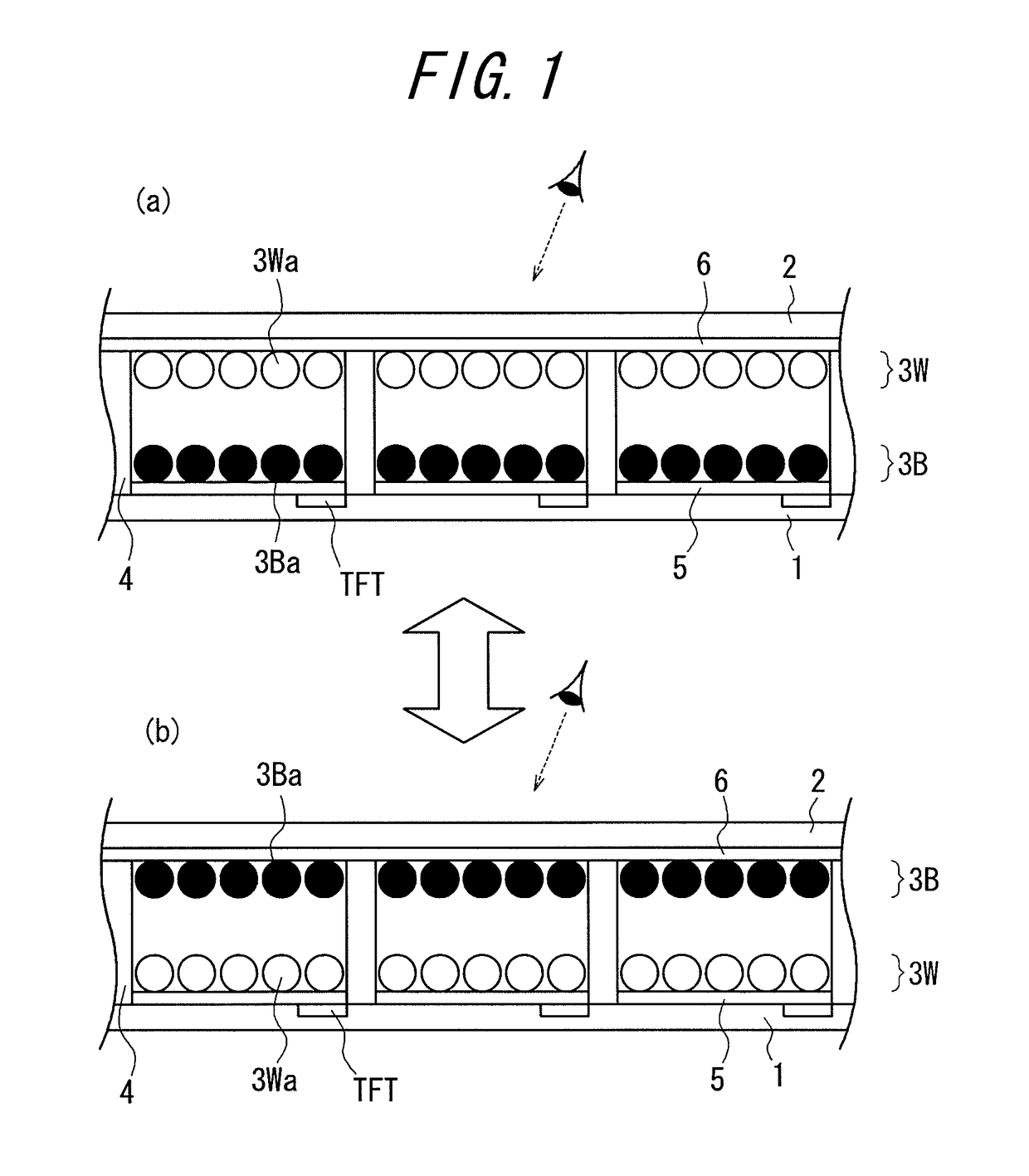

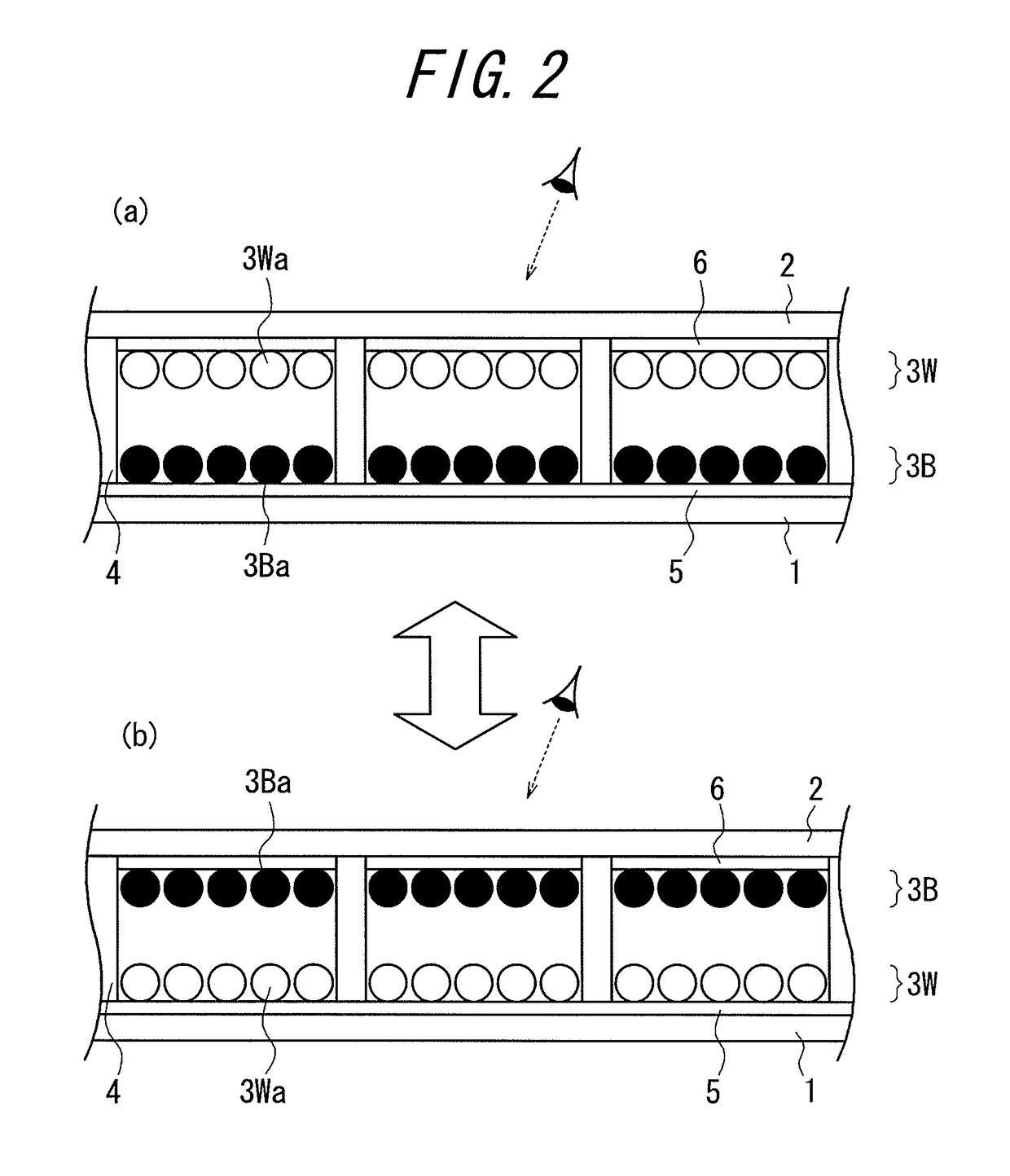

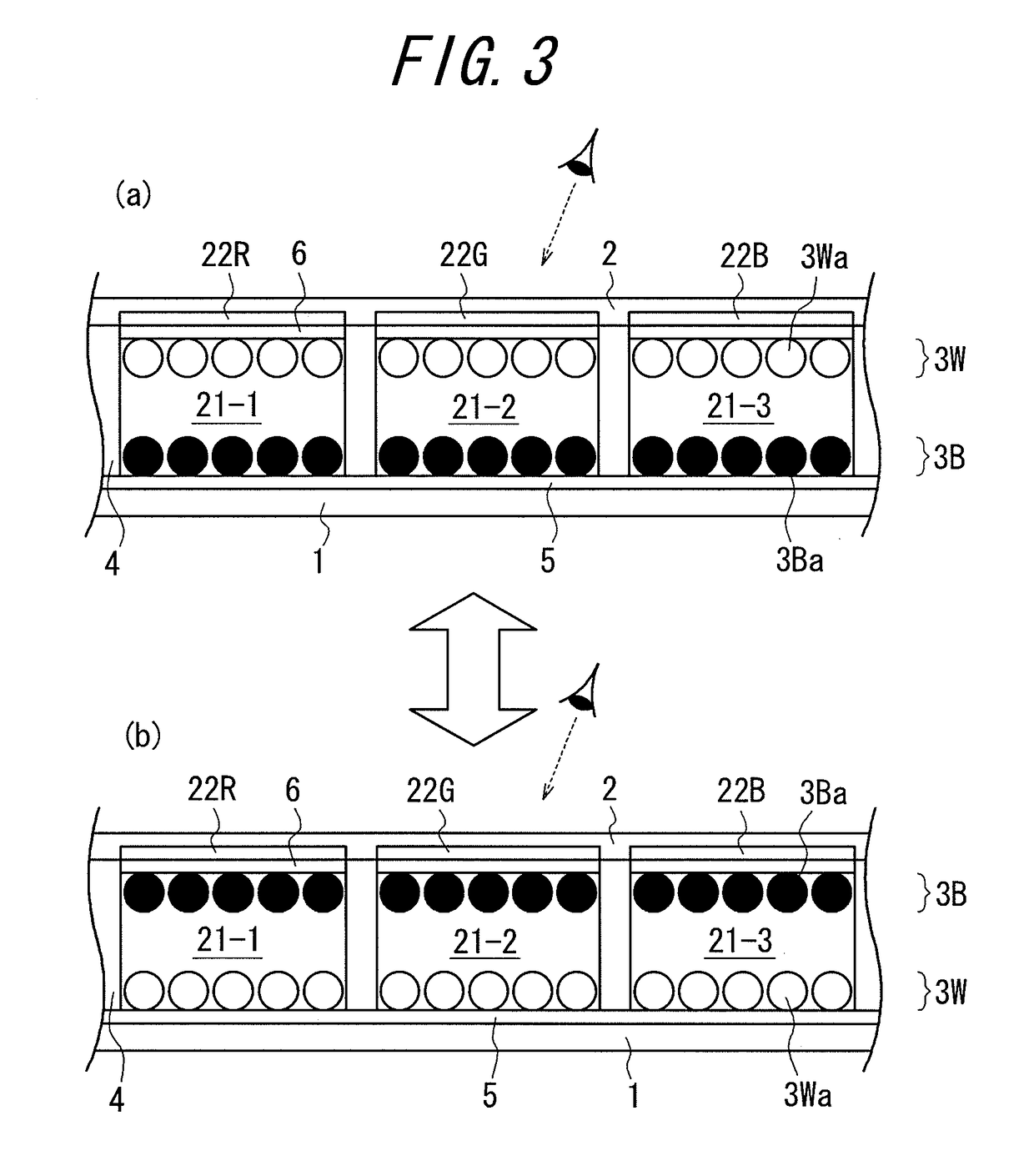

Display media particles and information display panel using the same

InactiveUS8120837B2Excellent in stabilization of electrical characteristic and durabilityPromote circulationNon-linear opticsOptical elementsShear rateComputer science

Owner:BRIDGESTONE CORP

Dark brown caramel color

PendingUS20220151269A1Improve stabilityGood colorConfectionerySweetmeatsFood gradeProcess engineering

A process for preparing a caramel color using a sugar source, further incorporating into the color-making process a food-grade spacing agent, and a caramel color.

Owner:THE WILLIAMSON GRP LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com