Modified vegetable oil and preparation method thereof

A technology of modifying vegetable oil and vegetable oil, which is applied in the field of vegetable oil, can solve the problems of easy formation of sludge and sediment, unsatisfactory low-temperature performance, poor oxidation stability, etc., achieve good biodegradability, improve chemical stability, and good viscosity-temperature performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

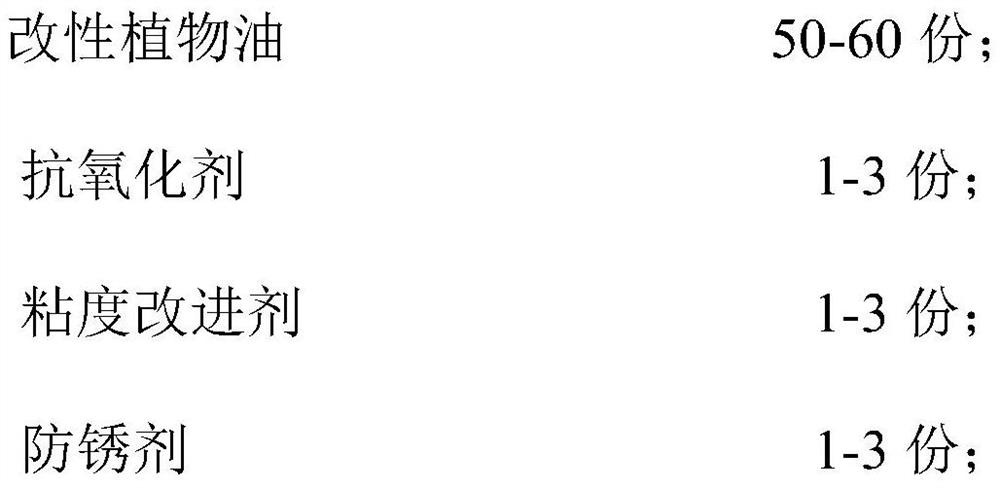

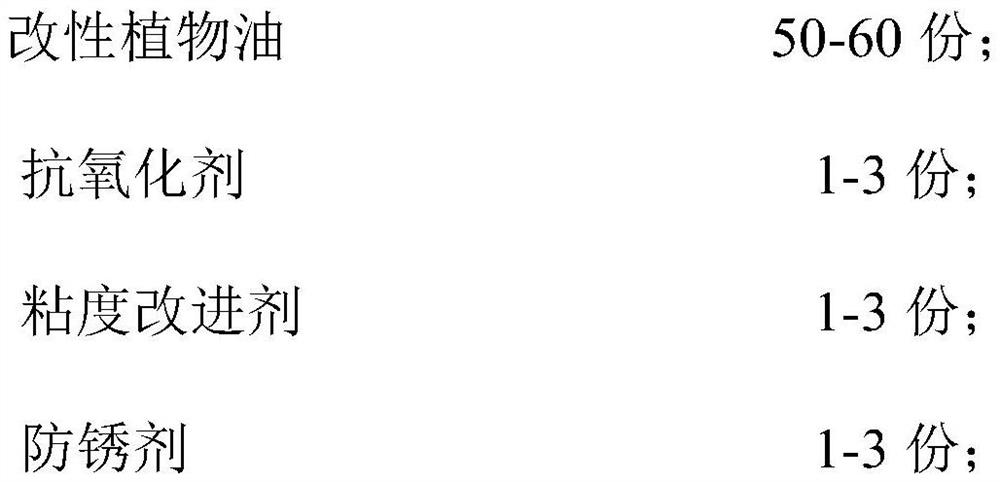

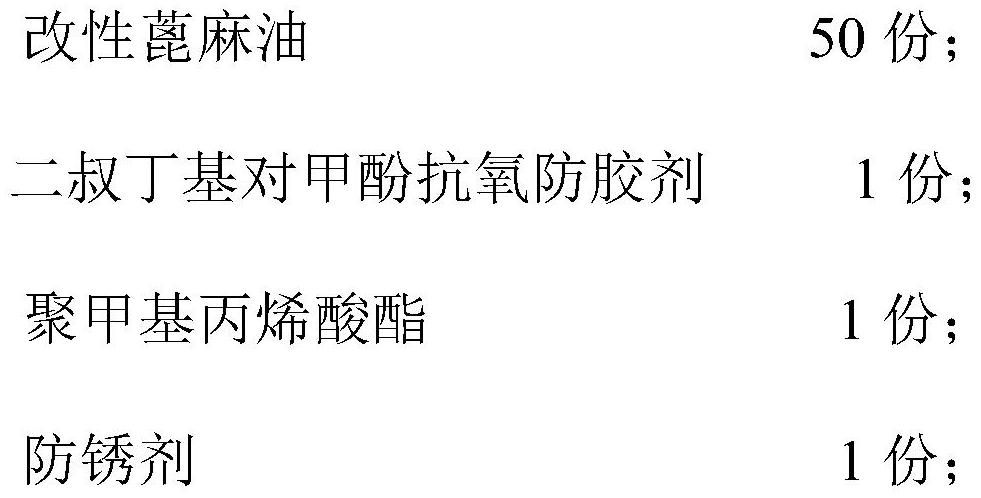

[0031] A kind of biodegradable environment-friendly lubricating oil, comprises the raw material of following weight part:

[0032]

[0033] Wherein, the preparation method of described modified castor oil, comprises the steps:

[0034] 1) Methyl hydrogen-containing silicone oil modified castor oil: Add 10 g of methyl hydrogen-containing silicone oil into a flask equipped with a constant temperature feeding funnel and a condenser tube, replace the air in the bottle with nitrogen, open the condensed water, and then add 0.3 g of catalyst, castor 13g of sesame oil and 50g of isopropanol were stirred and heated to 80°C, kept for 6 hours, and then the low-volatile substances were removed by distillation under reduced pressure to obtain castor oil modified by hydrogen-containing silicone oil; the catalyst was 2% chlorine Platinic acid in isopropanol;

[0035] 2) Transesterification: 20 g of castor oil modified with methyl hydrogen-containing silicone oil prepared in step 1), (2R,...

Embodiment 2

[0038] A kind of biodegradable environment-friendly lubricating oil, comprises the raw material of following weight part:

[0039]

[0040] Wherein, the preparation method of described modified palm oil comprises the steps:

[0041] 1) Modified palm oil with methyl hydrogen-containing silicone oil: Add 13g of methyl hydrogen-containing silicone oil into a flask equipped with a constant temperature feeding funnel and a condenser tube, replace the air in the bottle with argon, open the condensed water, and then add 0.5g of catalyst, 14g of palm oil and 65g of isopropanol were stirred and heated to 82°C, kept for 6.3 hours, then vacuum distillation to remove low-volatile substances to obtain hydrogen-containing silicone oil-modified palm oil; the catalyst was 2.4% by mass fraction Chloroplatinic acid solution in isopropanol;

[0042] 2) Transesterification: 20 g of palm oil modified by methyl hydrogen-containing silicone oil prepared in step 1), (2R,3S)-2,3,4-trihydroxy-3-met...

Embodiment 3

[0045] A kind of biodegradable environment-friendly lubricating oil, comprises the raw material of following weight part:

[0046]

[0047] Wherein, the preparation method of described modified coconut oil comprises the steps:

[0048] 1) Methyl hydrogen-containing silicone oil modified coconut oil: Add 17g of methyl hydrogen-containing silicone oil into a flask equipped with a constant temperature feeding funnel and a condenser tube, replace the air in the bottle with neon gas, open the condensed water, and then add 0.7g of catalyst, Coconut oil 18g and isopropanol 90g, stir and heat up to 84 ℃, keep warm for 6.8 hours, then vacuum distillation sloughs off low-volatile matter, obtains coconut oil modified by hydrogen-containing silicone oil; the catalyst is 2.8% Chloroplatinic acid solution in isopropanol;

[0049]2) Transesterification: 20 g of coconut oil modified with methyl hydrogen-containing silicone oil prepared in step 1), (2R,3S)-2,3,4-trihydroxy-3-methylbutyl di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com