Underwater integrated type system for vertical pipe production and conveying and mounting method thereof

An integrated, riser technology, applied in transportation and packaging, special-purpose ships, ship construction, etc., can solve the problems of asymmetric cross-section of production delivery pipes, fatigue damage VIV, complex galloping damage, etc., to reduce the deck Area and body size, meet thermal expansion requirements, avoid asymmetric effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings. The illustration of the present invention is described by taking four production delivery risers and one control riser as an example.

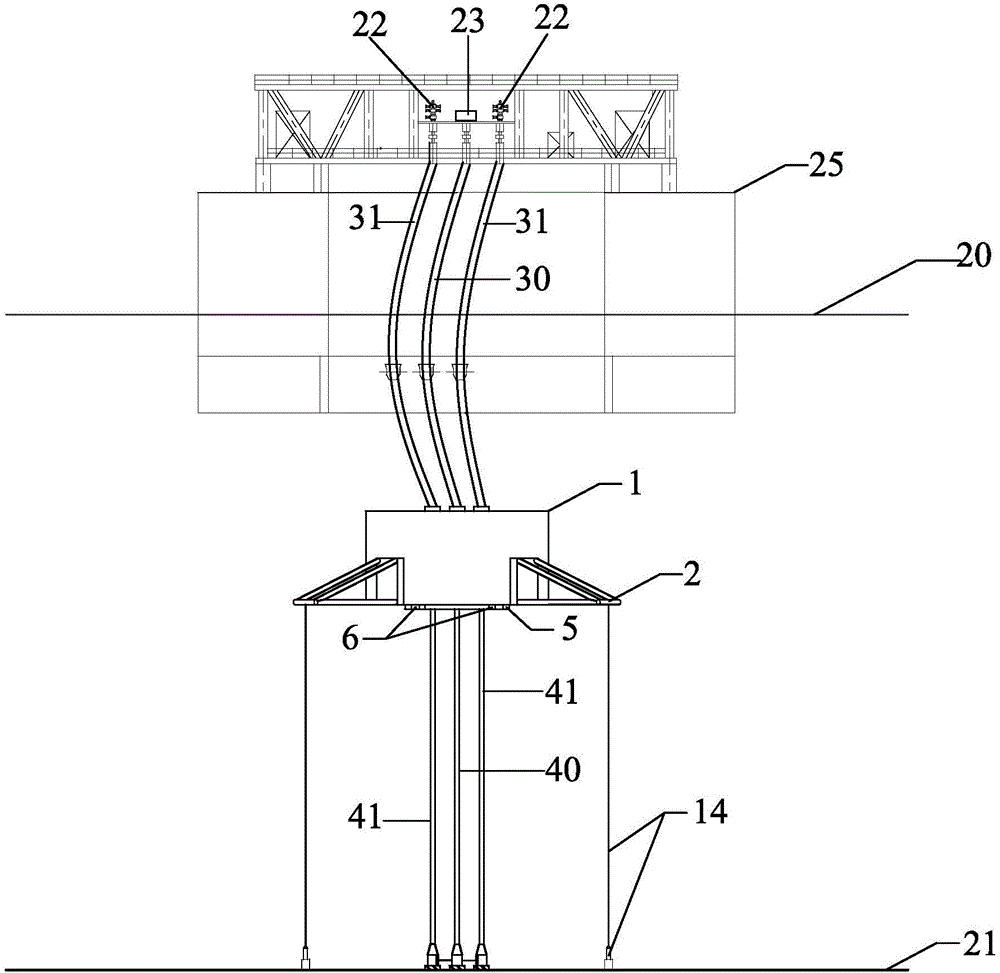

[0067] Such as Figure 1-9 As shown, an underwater integrated production delivery riser system includes a production riser assembly, a control riser assembly, a combined buoy 15 and a mooring device 14;

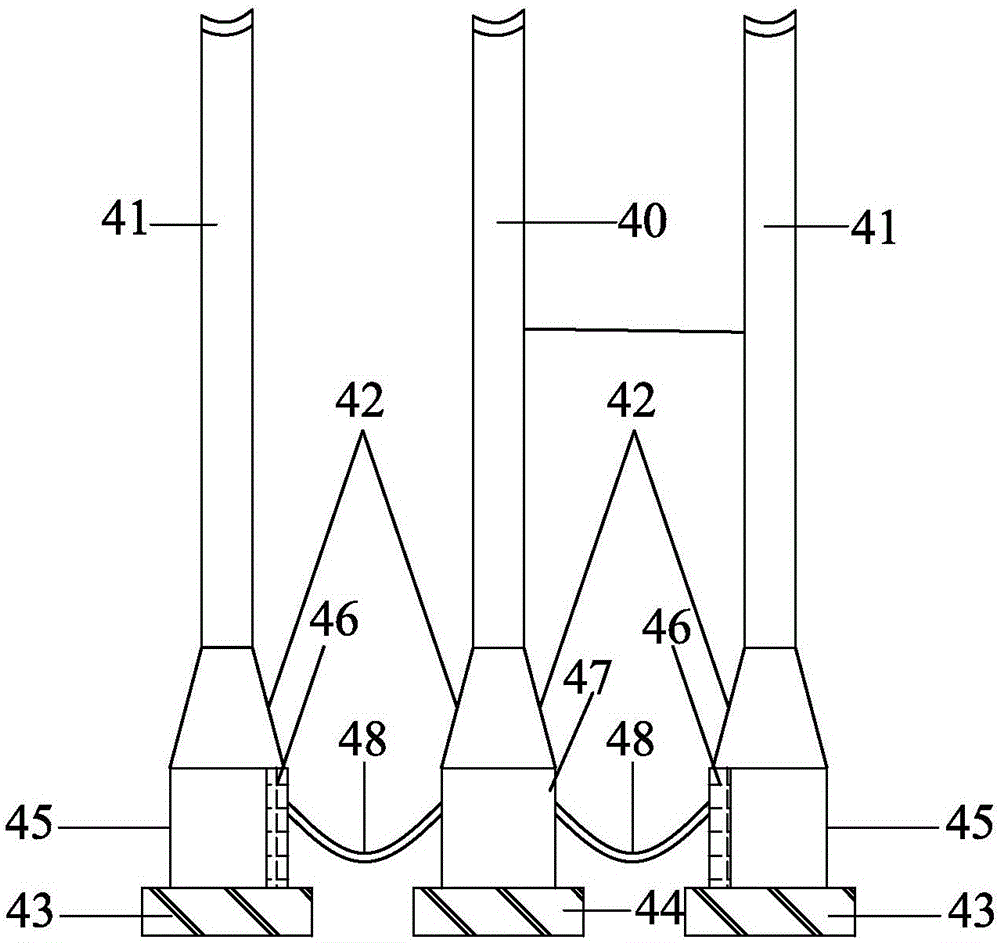

[0068] The production riser assembly includes a flexible production riser 31 and a rigid production riser 41, the control riser assembly includes a rigid protection pipe 40 and a flexible control umbilical 30, and the combined buoy 15 includes an outer buoy 1 and the inner buoy 5; the inner buoy 5 is nested in the outer buoy 1;

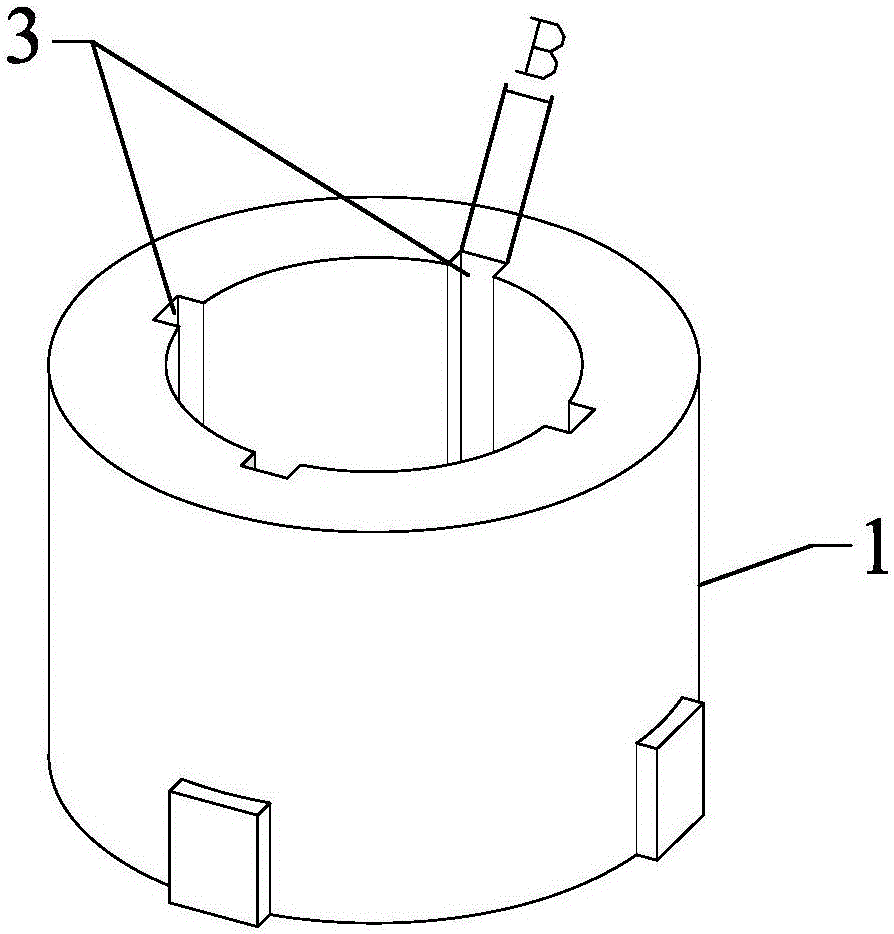

[0069] The main body of the outer buoy 1 is a ring cylinder structure, the bottom edge of the outer wall of the outer buoy 1 is connected to four cantilever buoys 2, and the four cantilever buoys 2 are unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com