Polymer calcium zinc complex soap heat stabilizer, preparation method thereof and application thereof

A calcium-zinc composite and thermal stabilizer technology, which is applied in the field of polymer material processing and application, can solve problems such as the gap in thermal stability function, and achieve the effects of improving safety performance, increasing thermal deformation temperature, and long-term functionality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

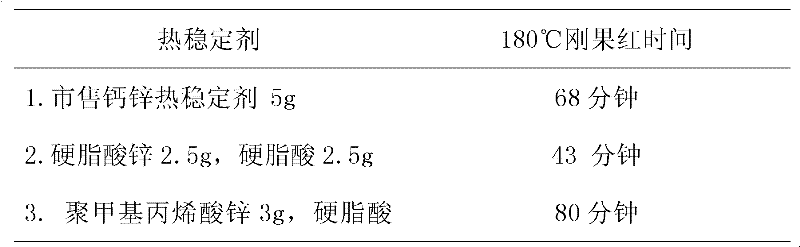

Examples

Embodiment 1

[0030] First prepare polymer calcium-zinc composite soap, and its preparation method is:

[0031] A. Add 2.5g potassium persulfate to 500mL distilled water and raise the temperature to 50°C;

[0032] B. Mix 50g of α-methacrylic acid and 0.01%-0.05% of the mass of α-methacrylic acid in tertiary mercaptan or dodecanethiol, and slowly add it dropwise to the aqueous solution obtained in step A while stirring, while controlling the temperature of the system At 40°C-90°C; after the end of the polymerization reaction, slowly add the mixture of zinc hydroxide and calcium hydroxide according to stoichiometry under stirring, wherein the mass ratio of calcium hydroxide to zinc hydroxide is 2:3, and the amount added makes the hydroxide The root completely neutralizes the carboxylic acid group shall prevail;

[0033] C. After the reaction is complete, the precipitate is filtered, dried, and pulverized to obtain the polymer calcium-zinc composite soap;

[0034]Then, in the PVC of 100 part...

Embodiment 2

[0036] Prepare polymer calcium-zinc composite soap according to the method of embodiment 1, difference is: in step A, add the hydrogen peroxide 5g of 30% mass fraction to replace potassium persulfate, dropwise add acrylic acid, maleic acid and β-methyl in step B Acrylic composition, and the mass ratio of calcium hydroxide to zinc hydroxide is 1:1.

[0037] Add 10 parts of dibutyl phthalate (DBP), 5 parts of the polymer calcium-zinc composite soap prepared above (wherein the mass ratio of calcium to zinc is 1:1), 3 parts of pentaerythritol, 0.5 parts in 100 parts by mass of PVC. Part of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, 0.2 part of stearic acid, uniformly mixed; sample preparation and measurement according to Example 1, its Congo red time was 92 minutes.

Embodiment 3

[0039] Polymer calcium-zinc composite soap was synthesized according to the method of Example 1, wherein the calcium-zinc mass ratio was 3:2.

[0040] Add 10 parts of dibutyl phthalate (DBP), 5 parts of polymer calcium-zinc composite soap (wherein the mass ratio of calcium to zinc is 3:2), 3 parts of methacrylic acid to 100 parts by mass of PVC Pentaerythritol monoester, 0.5 part of antioxidant 2, 2'-methylene bis(4-methyl-6-tert-butylphenol), 0.2 part of stearic acid, uniformly mixed; sample preparation and measurement according to Example 1, Its Congo red time is 82 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com