Frequency response adjustable miniature sound pressure amplification structure

A miniature, frequency-response technology, applied in the direction of frequency response correction, diaphragm structure, sensor type, etc., to achieve a wide range of options, a wide range of structural applications, and a wide range of value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the following will be combined with the accompanying drawings and preferred embodiments to describe a party and government official document auxiliary generation system and party and government official document auxiliary system proposed according to the present invention. The generated method, its specific implementation, method, steps and effects thereof are described in detail below.

[0034] Through the description of the specific implementation mode, when the technical means and effects adopted by the present invention to achieve the predetermined purpose can be obtained a more in-depth and specific understanding, but the accompanying drawings are only for reference and description, and are not used to explain the present invention be restricted.

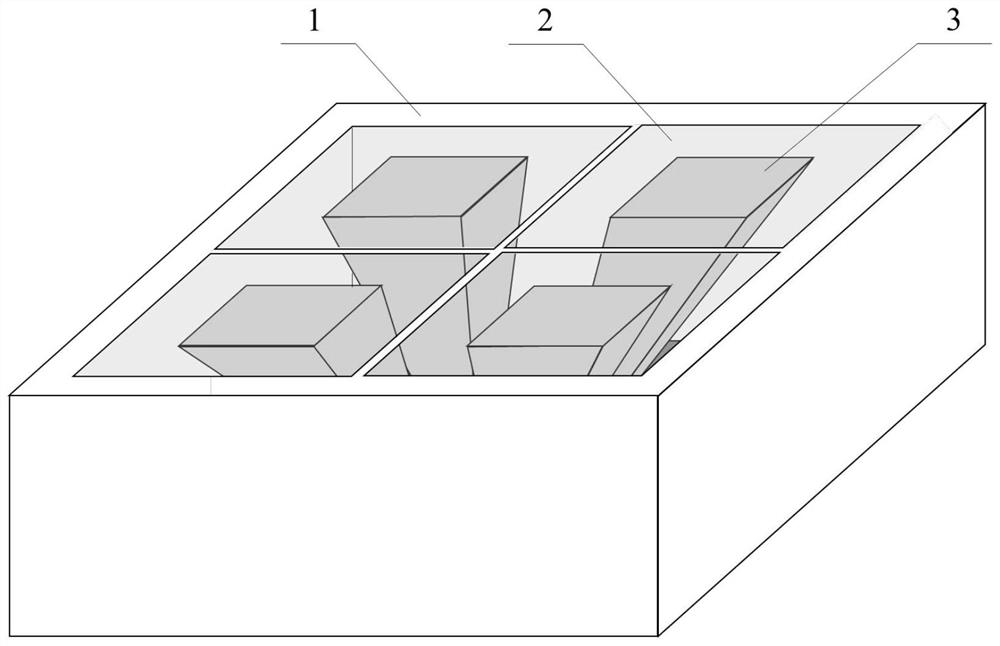

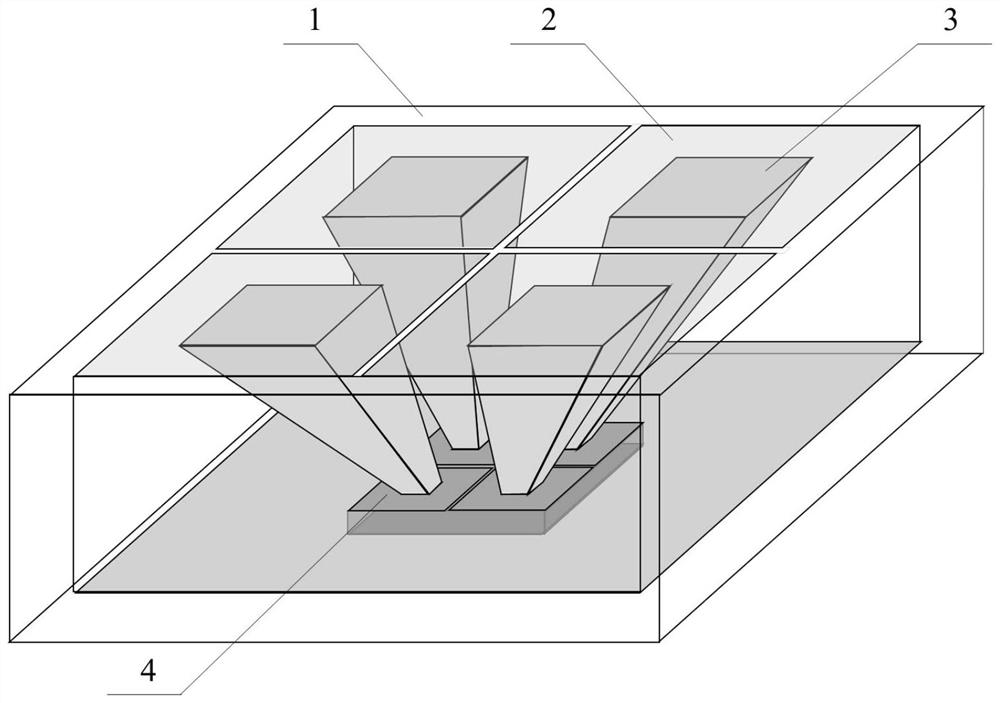

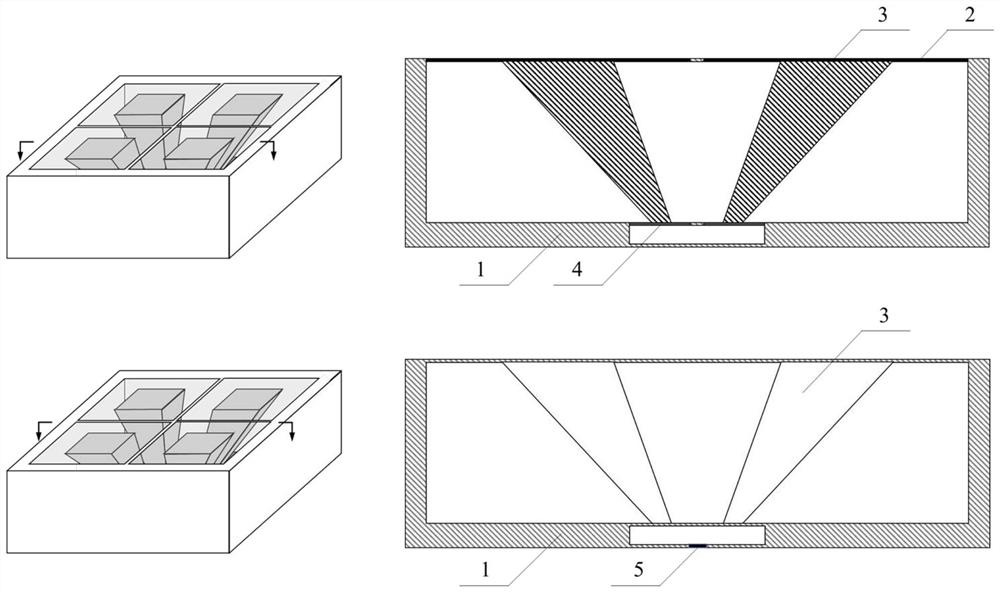

[0035] Such as figure 1 , figure 2 , image 3 As shown, a sound pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com