High water pressure waterproof micro speaker

A micro-speaker, high water pressure technology, applied in speaker screens, speaker housing brackets, transducers used underwater, etc., can solve problems such as affecting the waterproof failure rate, and achieve the effect of reducing waterproof failure and uniform combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

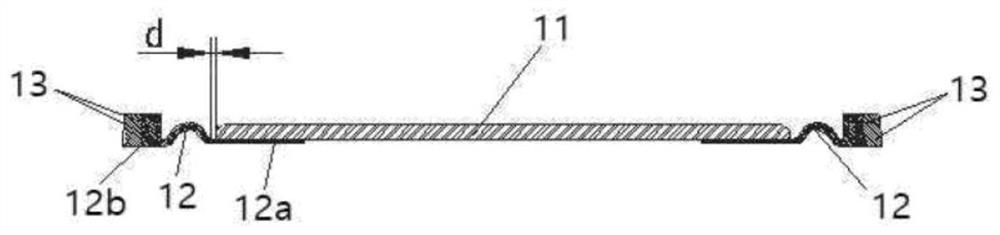

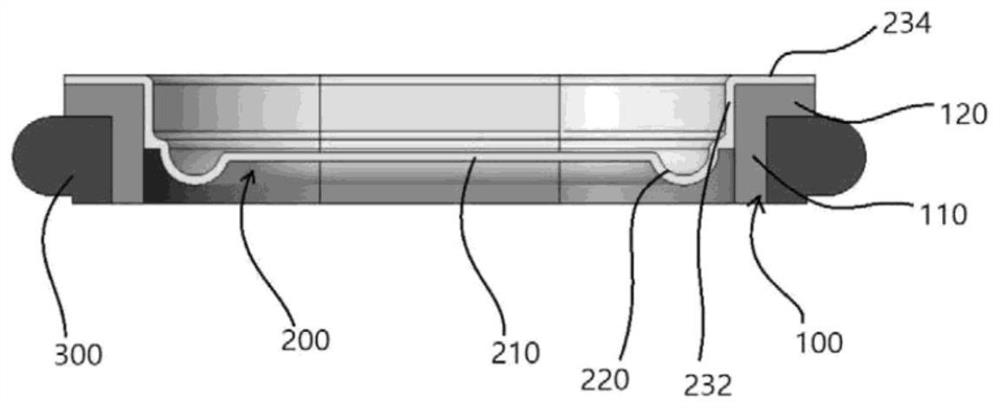

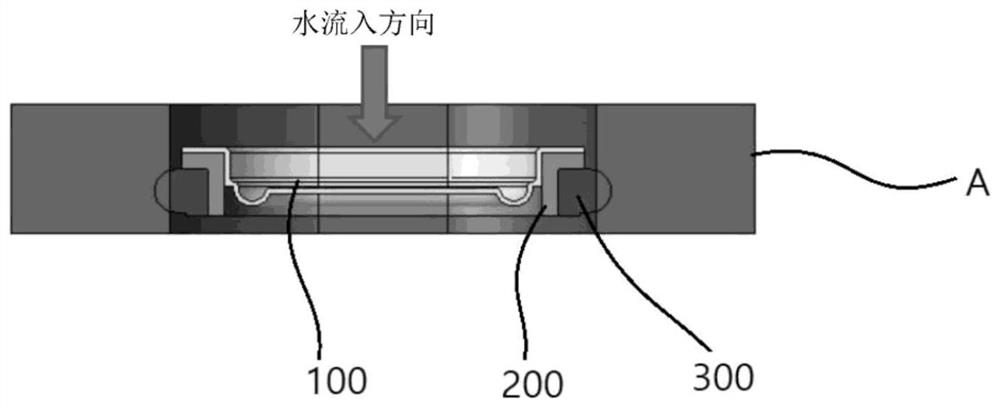

[0017] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings.

[0018] figure 2 is a view showing a high water pressure waterproof microspeaker according to an exemplary embodiment of the present invention.

[0019] The high water pressure waterproof micro speaker according to the exemplary embodiment of the present invention includes a frame 100 and a vibrating part inside the frame 100, and the vibrating part includes a diaphragm 200 and a vibrating member vibrating the diaphragm 200. The vibration member may be a generally used voice coil (not shown) and magnetic circuit (not shown), or may be a piezoelectric element attached to the diaphragm 200 .

[0020] The frame 100 includes a side wall 110 and a flange portion 120 extending outward from an upper edge of the side wall 110 . The aforementioned vibrating part is placed in a space defined by the side wall 110 . The frame 100 may be made of steel or injection mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com