Wires and harnesses with terminals

A technology of terminals and wires, which is applied in the field of wires with terminals and wire harnesses, can solve problems such as corrosion, and achieve the effect of ensuring anti-corrosion performance and high anti-corrosion performance

Active Publication Date: 2021-06-18

AUTONETWORKS TECH LTD +2

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0114] Examples of the present invention are shown below. In addition, the present invention is not limited by the following examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

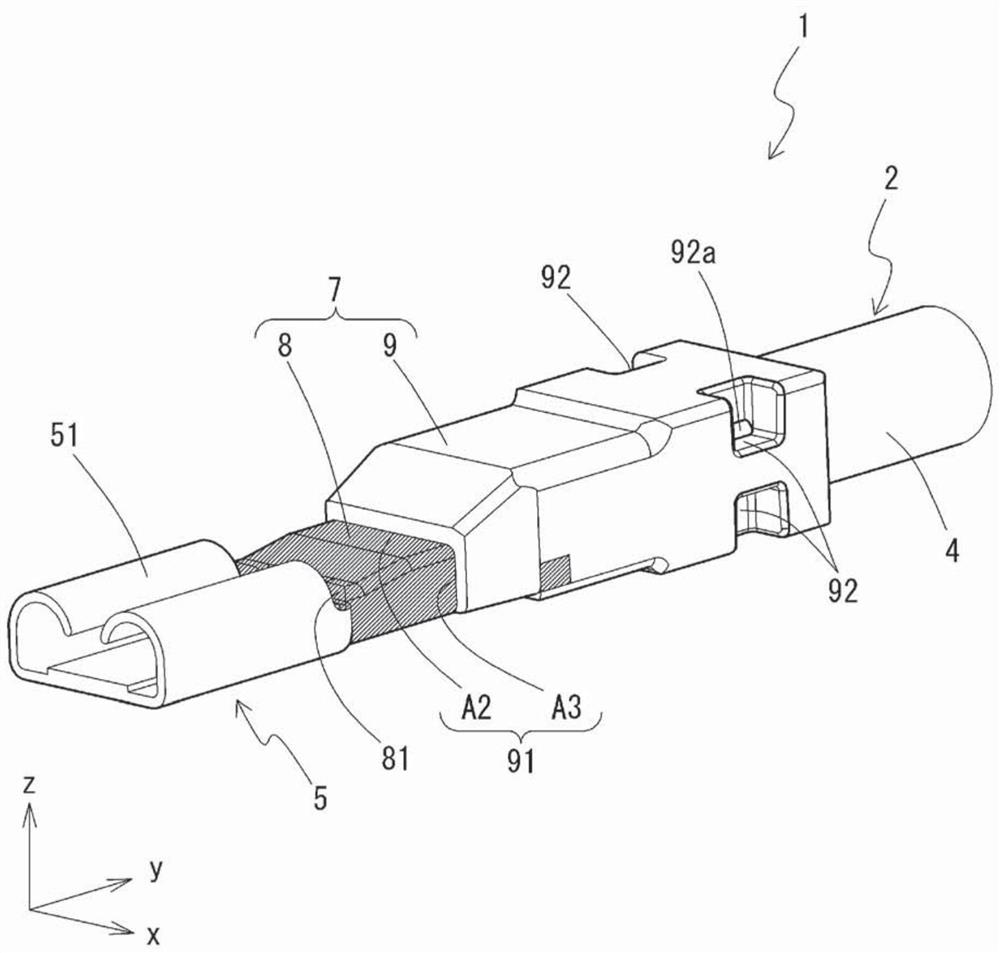

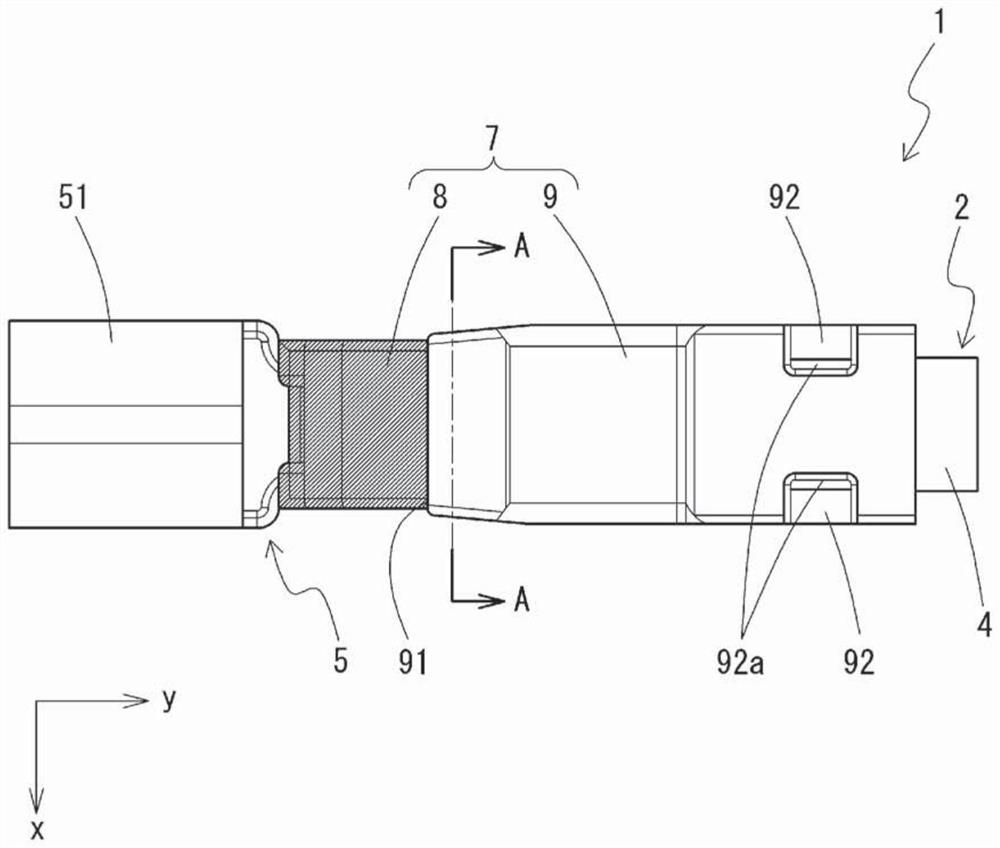

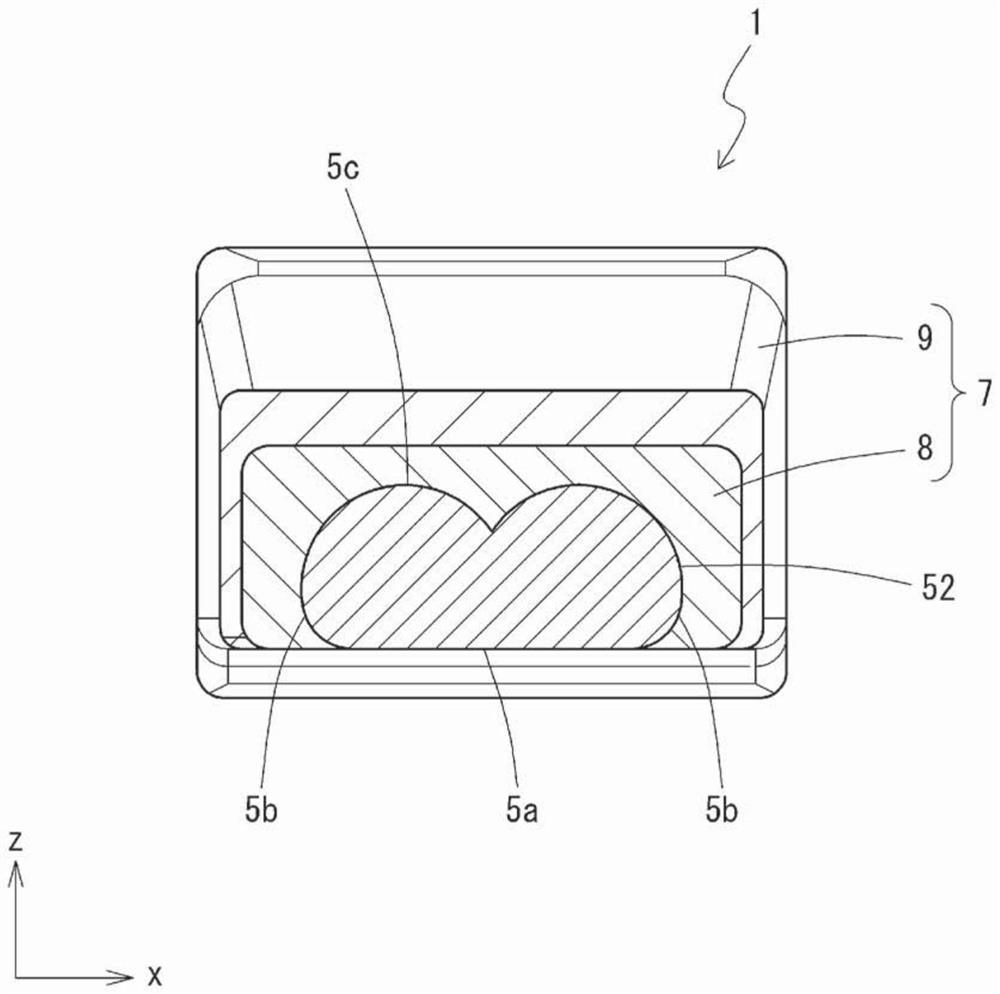

To provide an electric wire with a terminal and a wire harness which can easily ensure high anticorrosion performance even if the thickness of the resin material constituting the resin covering part which covers the electrical connection part between the terminal part and the electric wire conductor is reduced. cover. It is assumed that the terminal part (1) is as follows: the terminal part (5) and the electric wire (2) covered with the outer periphery of the conductor with the insulating coating layer (4) are electrically connected at the electrical connection part, and the terminal part (5) is made of a resin material and has an electrical connection. The resin covering part (7) covered by the connection part, wherein the resin covering part (7) has a first covering layer (8) and a second covering layer (9), and the first covering layer (8) and The surface of the terminal part (5) is arranged in contact with the area covering at least a part of the terminal part (5), the second covering layer (9) covers at least part of the first covering layer (8), and the first The cladding layer (8) has a recess covered by the second cladding layer (9).

Description

technical field [0001] The present invention relates to an electric wire with a terminal and a wire harness. More specifically, it relates to an electric wire with a terminal having an anticorrosion resin coating portion on an electrical connection portion between a conductor and a terminal component, and a wire harness using the electric wire with a terminal. Background technique [0002] Terminal parts are connected to conductors at the ends of electric wires laid in vehicles such as automobiles. Corrosion prevention is required at an electrical connection portion where terminal parts and conductors of electric wires are electrically connected. In particular, when different metal materials are in contact with each other at the electrical connection part, there is a possibility that dissimilar metal-to-metal corrosion may occur. In electric wires used in vehicles, for the purpose of reducing the weight of vehicles, etc., aluminum or aluminum alloys are sometimes used as co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01R4/70H01B7/00H01R4/18H01R4/62

CPCH01B7/2806H01R4/184H01R4/62H01R4/70H02G15/04H01B7/0045H01R4/185H01R13/5216

Inventor 山下卓也中村哲也山野能章伊藤贵章小野纯一

Owner AUTONETWORKS TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com