Multi-layer chemical glass tank

A glass tank and glass technology, applied in packaging, large containers, transportation and packaging, etc., can solve the problems of corrosive raw materials, rust, economic loss, etc., and achieve the effect of not easy to corrode, easy to use, and prevent leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

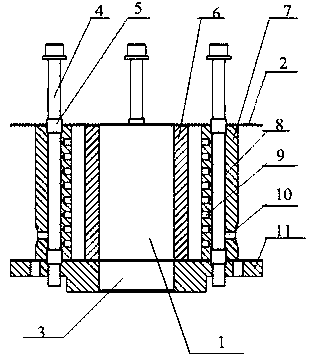

[0013] Such as figure 1 As shown, the embedded groove 1, the top cover 2, the base 3, the fixing rod 4, the bolt 5, the first glass baffle 6, the third glass baffle 7, the hollow groove 8, the second glass baffle 9, and the fixing bolt 10 , Support block 11.

[0014] A multi-layer chemical glass tank, which includes an embedded tank 1, a top cover 2 and a base 3, the embedded tank 1 is installed on the base 3, and the top cover 2 is installed on the embedded tank 1,

[0015] The inlaid groove 1 includes a first glass baffle 6, a third glass baffle 7, a hollow groove 8, a second glass baffle 9 and fixing bolts 10, the first glass baffle 6 is installed on one side of the inlaid groove 1, The second glass baffle 9 is installed on the right side of the first glass baffle 6, the hollow groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com