A kind of preparation method of tributyl citrate

A technology of tributyl citrate and citric acid, which is applied in the field of preparation of tributyl citrate, can solve problems such as unfavorable environmental protection, restriction of economic benefits, equipment corrosion, etc., and achieve not easy equipment corrosion, good application prospects, easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of catalyzed tributyl citrate, comprising the following steps:

[0027] Catalyst preparation: Take 1.5g of attapulgite clay, add 20mL (7.5g) of prepared 6.25M acetic acid, stir at room temperature for 52 hours, let it stand for aging for 12 hours, centrifuge to separate the lower layer of sediment, and then wash with water until the pH becomes neutral. Dry at 60°C, grind, then dry in a vacuum oven at 110°C for 2 hours, then slowly heat up to 300°C in a muffle furnace to activate for 3 hours to obtain the desired catalyst, which is attapulgite clay catalyst treated with phosphoric acid.

[0028] Esterification: Take 0.500g of the above catalyst, put it into a 500ml three-necked flask with a water separator, add 115.2g of citric acid, 284ml of n-butanol, and react for 5.5h after the system temperature is stabilized at 138°C, stop heating, and the esterification is completed .

[0029] Alcohol distillation: dealcoholize the above system at -0.10Mpa, 8...

Embodiment 2

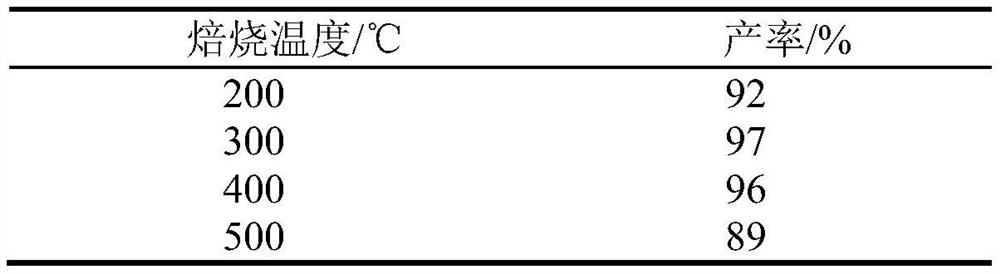

[0035] Change the catalyst calcination temperature, prepare the catalyst with reference to the method in Example 1, then prepare the tributyl citrate product according to the esterification method of Example 1, and the resulting tributyl citrate product yield results are shown in Table 1.

[0036] Catalyst catalyzed preparation tributyl citrate result prepared with the calcination temperature of table 1

[0037]

Embodiment 3

[0039] A preparation method of catalyzed tributyl citrate, comprising the following steps:

[0040] Catalyst preparation: take 1.5g of attapulgite clay, add 20ml of prepared 4M phosphoric acid, stir at room temperature for 52 hours, let stand for 12 hours of aging, centrifuge to separate the lower sediment, then wash with water until the pH becomes neutral, dry at 60°C, and grind , and then dried in a vacuum oven at 110°C for 2h, and then slowly heated to 300°C in a muffle furnace for activation for 3h to obtain the desired catalyst, which is an attapulgite clay catalyst treated with acetic acid.

[0041] Esterification: Take 0.500g of the above catalyst, put it into a 500ml three-necked flask with a water separator, add 115.2g of citric acid, 284ml of n-butanol, and react for 6h after the temperature is stabilized at 138°C, stop heating, and the esterification is completed.

[0042] Alcohol distillation: dealcoholize the above system at -0.10Mpa, 75°C for 10min.

[0043] Fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com