A method for preparing furan compounds and liquid naphthenes by full utilization of primary biomass

A biomass and compound technology, applied in furfural and liquid naphthene, preparation of furan compounds and liquid naphthene, and preparation of 5-hydroxymethyl furfural, can solve the problems of environmental pollution, lack of cost, serious corrosion of reaction equipment, etc. , to achieve the effect of causing equipment corrosion, environmental friendly, and not easy equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

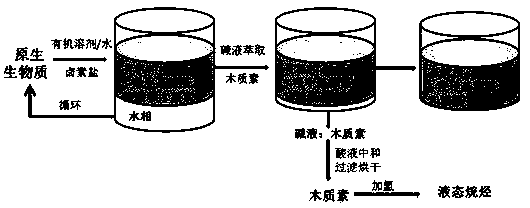

Method used

Image

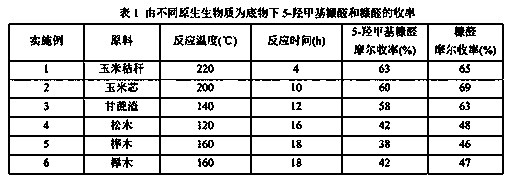

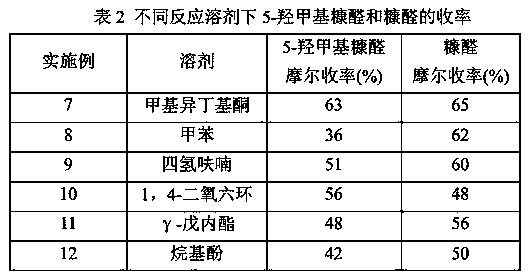

Examples

Embodiment 19-29

[0032] Example 19-29 Lignin obtained by treating the organic phase under different lye and acid conditions

[0033] The organic phase in Example 1 was adjusted to pH 13 with different lyes (0.2mol / L), lignin was separated in the form of salt, and the separated aqueous phase was treated with different acid solutions (0.2mol / L) Adjust to pH=2, lignin precipitates out, filter, wash and dry, weigh the obtained lignin and calculate the yield (calculated based on the mass of the original biomass).

[0034] Examples 30-38 Preparation of liquid alkanes by hydrogenation of lignin with different hydrogenation catalysts

[0035] Add 0.2g of the lignin obtained in Example 19 to nine reactors of the same type, then add 0.2g of hydrogenation catalyst, tighten the screws of the reactors, fill in a certain pressure of hydrogen, and place them in nine different In the heating mantle, raise the heating mantle to the predetermined temperature respectively, keep the temperature constant, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com