Oilless compressor and auxiliary compressor set

A compressor unit and compressor technology, which is applied to machines/engines, mechanical equipment, liquid variable capacity machinery, etc. Air volume, avoid excessive working temperature, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

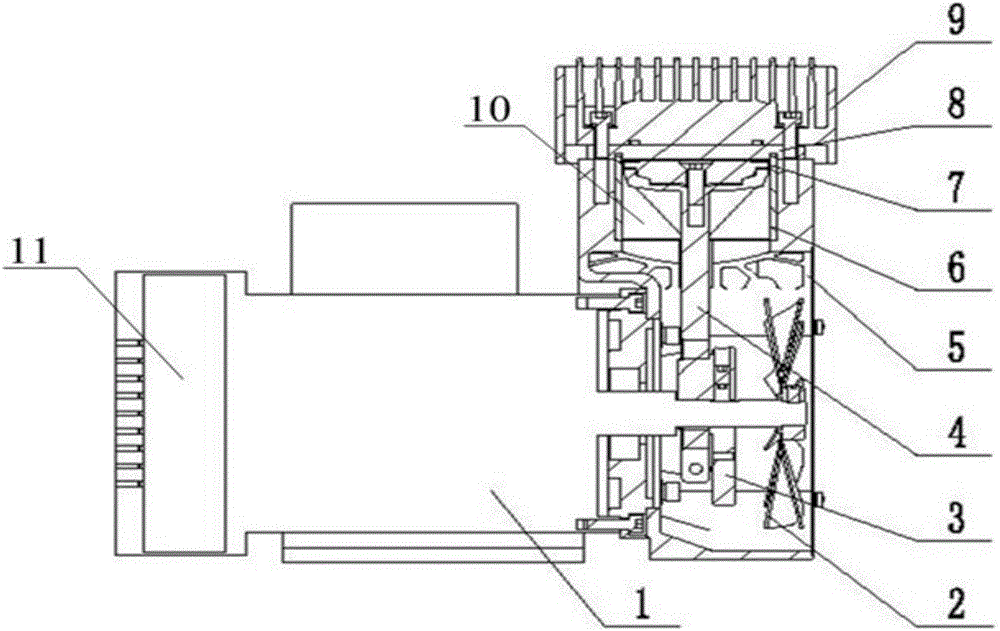

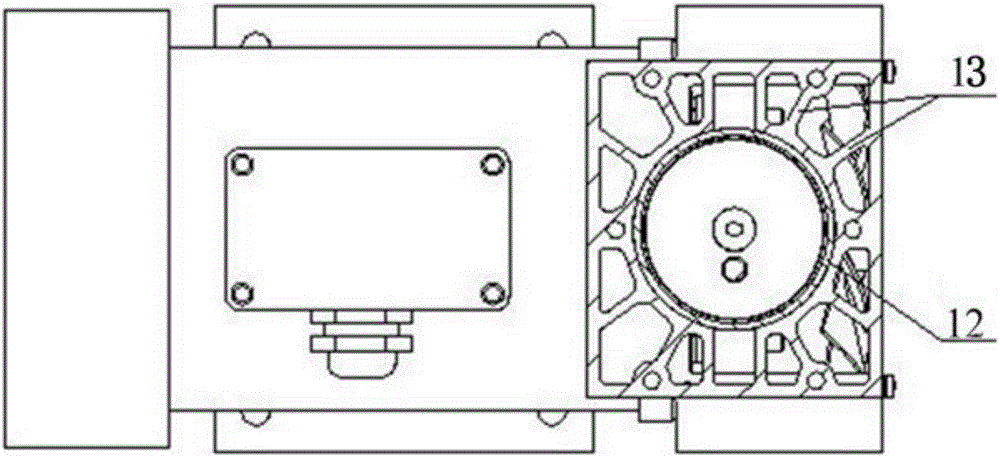

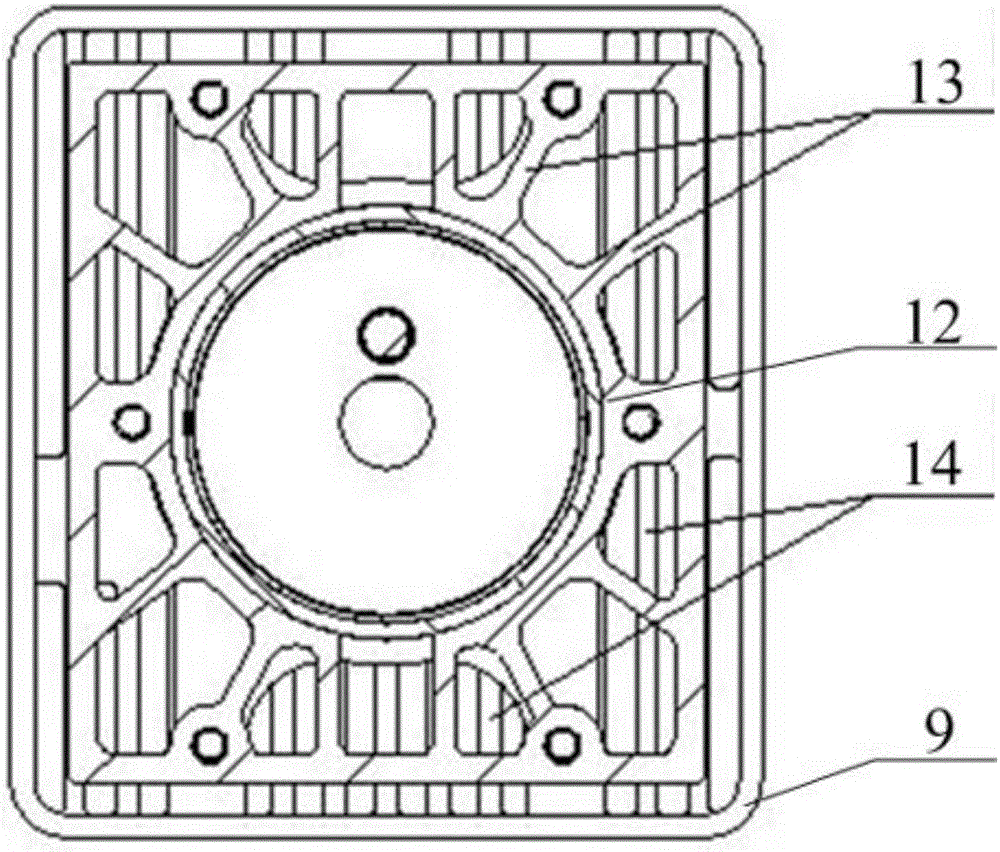

[0024] like figure 1 and 2 As shown, the oil-free compressor of the present invention adopts a single-cylinder structure, including a rare earth permanent magnet DC motor 1, fan blade 2, crankshaft 3, connecting rod 4, box body 5, cylinder 6, piston ring 7, valve plate 8, Cylinder head 9 and piston 10. The rare earth permanent magnet DC motor 1 is fixedly connected with the box body 5 , and the output shaft of the rare earth permanent magnet DC motor 1 extends into the box body 5 and is located at the bottom of the box body 5 . Fan blades 2 are installed on the outer end of the output shaft of the rare-earth permanent magnet DC motor 1 to provide a cooling air source. The shell of the rare earth permanent magnet direct motor 1 is processed by alloy aluminum material to reduce the overall weight of the compressor. A flywheel 11 is installed at the origin o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com