Co-rotating differential multi-screw extruding machine with gradually changing type thread number and machining method thereof

A multi-screw extruder and gradient technology, applied in the field of twin-screw extruders, can solve the problems of weak stretching field, large and complex structure, high equipment cost, and achieve the effect of promoting interface renewal and expanding exhaust area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

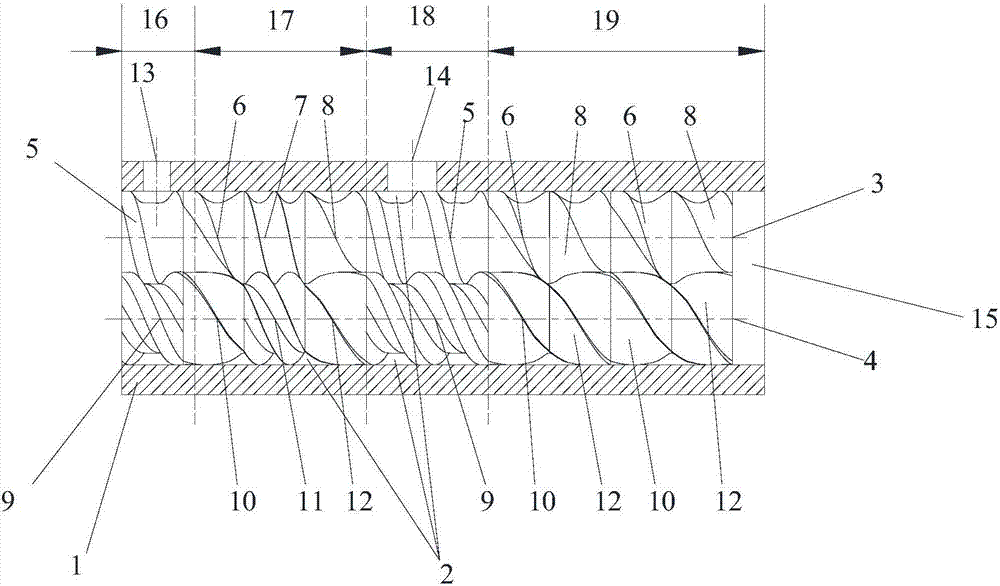

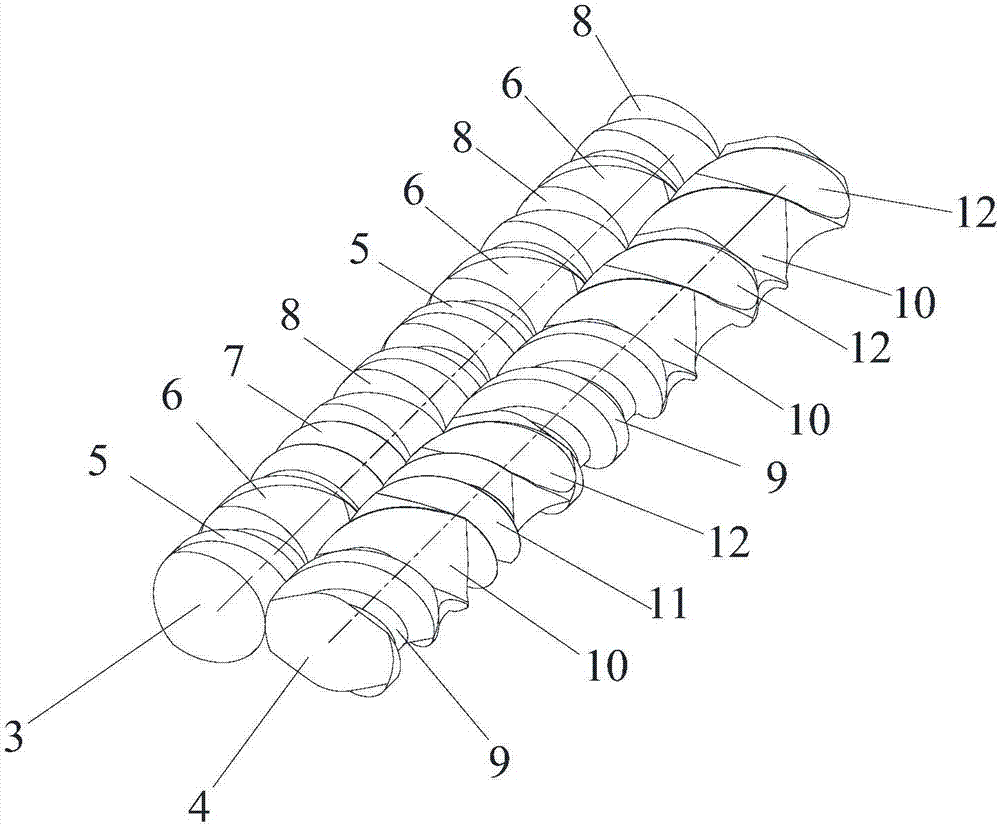

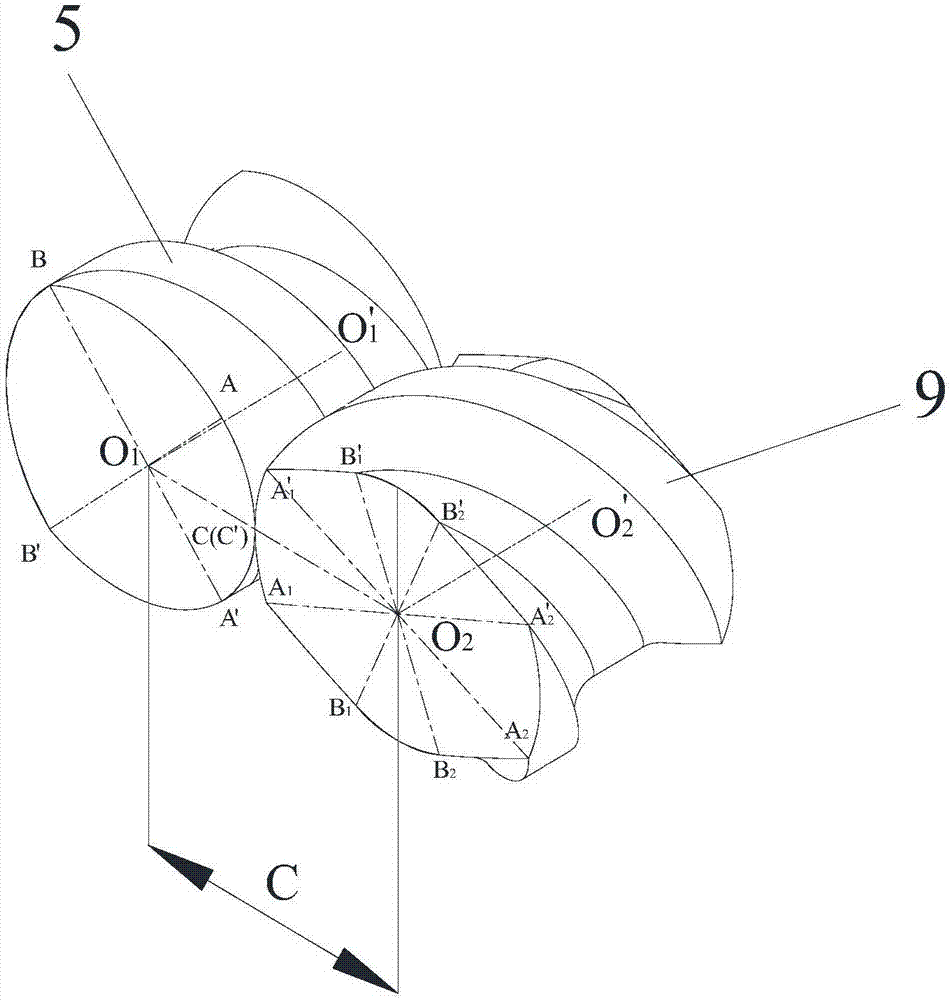

[0049] This embodiment is a kind of co-rotating differential speed twin-screw extruder with gradually changing number of threads, its structure is as follows Figure 1-6 As shown, it includes a barrel 1 and a screw mechanism. The barrel 1 is provided with an inner cavity 2, and the screw mechanism is installed in the inner cavity. The screw mechanism includes a first screw 3 and a second screw 4, and the first screw and the second screw are connected to each other. Engage, and the outermost edges of the first screw and the second screw are tangent to the inner wall of the inner cavity; the first screw, the second screw and the inner cavity of the barrel form a flow channel; when the first screw and the second screw are in the same direction When rotating, the rotation speed of the first screw is twice the rotation speed of the second screw, and the two screws are always in meshing contact with each other to realize the self-cleaning function. Such as Figure 1-6 As shown, the...

Embodiment 2

[0087] This embodiment is a kind of co-rotating differential multi-screw extruder with gradually changing number of threads. Compared with Embodiment 1, the difference is that the screw mechanism also includes a third screw, and the structure of the third screw is the same as that of the first screw. The screws are the same, and the first screw, the second screw and the third screw are connected in sequence to form an in-line three-screw arrangement.

Embodiment 3

[0089] This embodiment is a kind of co-directional differential multi-screw extruder with gradual change in the number of threads. Compared with Embodiment 1, the difference is that the screw mechanism also includes a third screw, and the structure of the third screw is different from that of the second screw. The screws are the same, and the second screw, the first screw and the third screw are connected in sequence to form an in-line three-screw arrangement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com