A kind of method for improving the continuous reaction activity of pyrite catalysis class fenton

A reactive, pyrite technology, applied in the direction of oxidized water/sewage treatment, etc., can solve problems such as the decline of catalytic efficiency, and achieve the effect of enhancing valence change, improving catalytic oxidation activity, and overcoming low oxidation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The pyrite that will be reused many times and the catalytic efficiency declines is taken out from the reaction solution, and after drying, 10g of the pyrite material is weighed, and 100ml, 1.5 μmol / L copper sulfate solution is added, placed on a magnetic stirrer, and Stir at a speed of 200 rpm. During the stirring process, air is introduced into the solution by sand core aeration. The air flux is 2L / min under normal temperature and pressure conditions. After 40 minutes of reaction, add N to the reaction system ,N-bis(carboxymethyl)-L-glutamate tetrasodium solution, the mass ratio of pyrite or slag to N,N-bis(carboxymethyl)-L-glutamate tetrasodium is 110:1 Keep aeration and stirring, stop the aeration after 5 hours of reaction, add 5mL of sodium sulfide solution with a mass fraction of 3 / 10,000 to it, stir and react for one hour, let the minerals precipitate naturally, discharge the reaction solution after the precipitation is complete, and put the processed Minerals are...

Embodiment 2

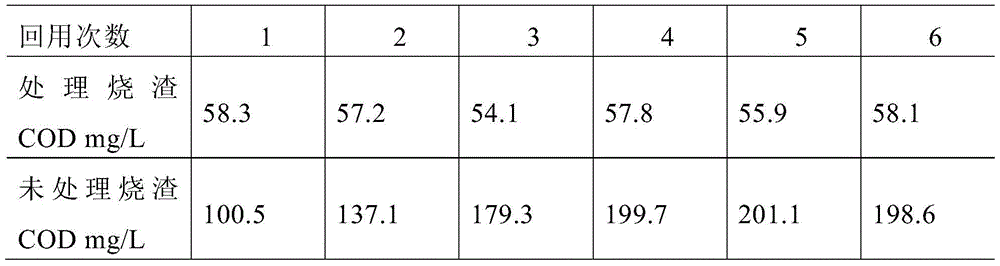

[0033] The pyrite slag that has been reused many times and the catalytic efficiency has decreased is taken out from the reaction solution, weighed 10g of the pyrite slag after drying, added 200ml, 1.5μmol / L copper sulfate solution, and placed in a magnetic stirrer Stir at a speed of 200 revolutions per minute. During the stirring process, air is introduced into the solution by sand core aeration. The air flux is 2L / min under normal temperature and pressure conditions. After 40 minutes of reaction, the reaction system is Add N,N-bis(carboxymethyl)-L-glutamate tetrasodium solution, the mass ratio of pyrite or slag to N,N-bis(carboxymethyl)-L-glutamate tetrasodium is 500:1 Keep aeration and stirring, stop the aeration after 5 hours of reaction, add 10mL of ammonium sulfide solution with a mass fraction of 3 / 10,000 to it, stir and react for three hours, let the minerals precipitate naturally, and discharge the reaction solution after the precipitation is complete. Naturally dry the ...

Embodiment 3

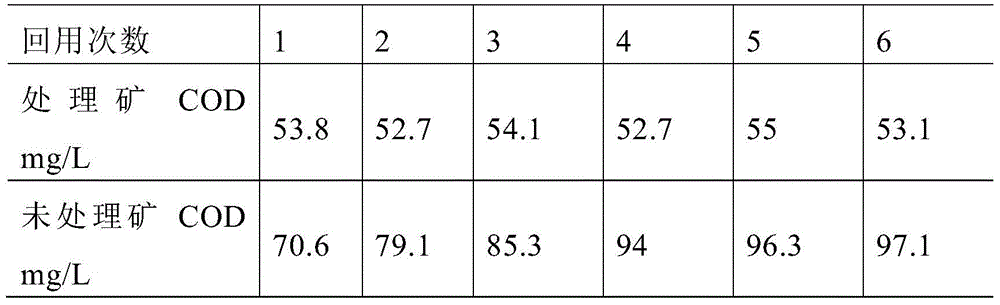

[0035] The biochemical effluent from the secondary sedimentation tank of the actual printing and dyeing wastewater has a pH of 7.48 and a COD of 104mg / L. Add 0.4g (i.e. 2g / L) of mineral prepared as described in Example 1, then add 0.02ml / L hydrogen peroxide therein, place on a magnetic stirrer, stir with 250 revolutions per minute for 30s, then with 100 revolutions per minute The reaction was stirred at a rotating speed of 2 hours for 2 hours. After the used mineral precipitate is taken out, it can be reused directly in the above way, and the water effluent effect is shown in Table 1.

[0036] Table 1 Reuse effect of pyrite treatment

[0037]

[0038] After treatment, the effect of pyrite is significantly improved, and it still has good catalytic activity after being reused for 6 times. The catalytic effect of untreated pyrite is not obvious in the process of recycling. The pyrite catalyzed by the technical conditions The effect is obviously better than that of untreated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com