Scaling hob and cutter holder for TBM test bed

A test bench and tool holder technology, which is applied to educational appliances, instruments, teaching models, etc., can solve the problems of long experiment time, large quality and volume, inconvenient disassembly and assembly, and achieve convenient disassembly and installation, improve experimental efficiency, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

[0029] Combine below Figure 1-Figure 7 The present invention will be described in detail.

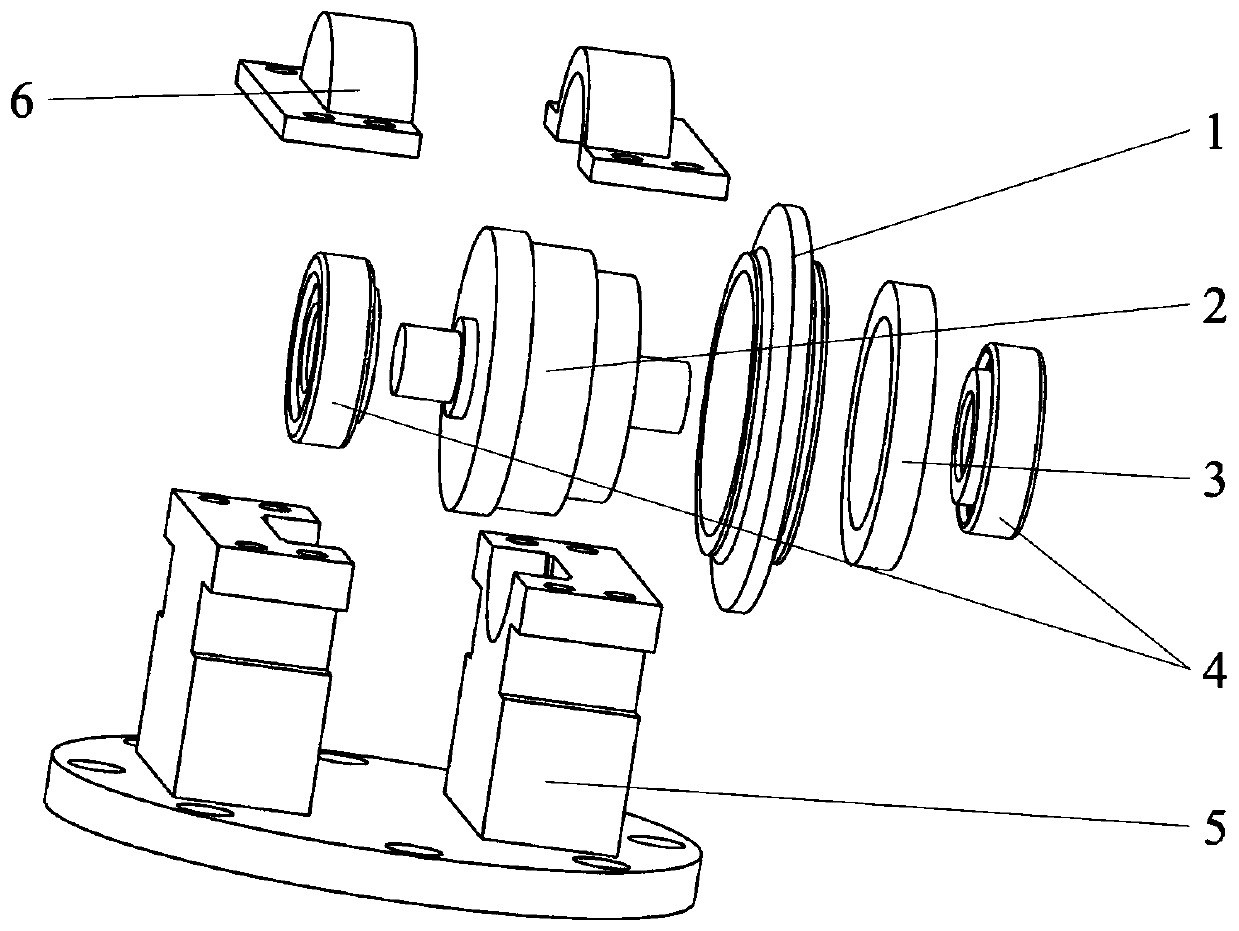

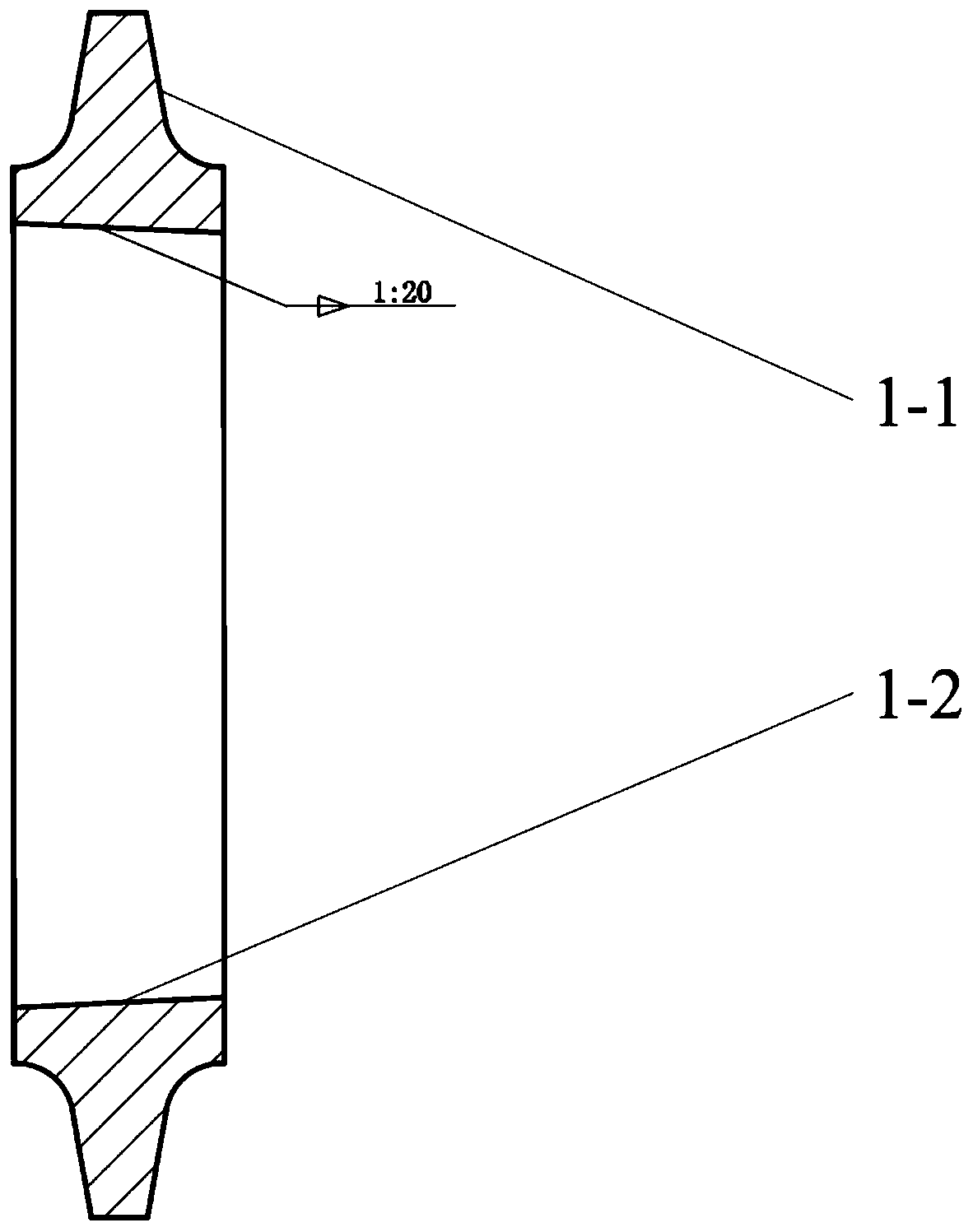

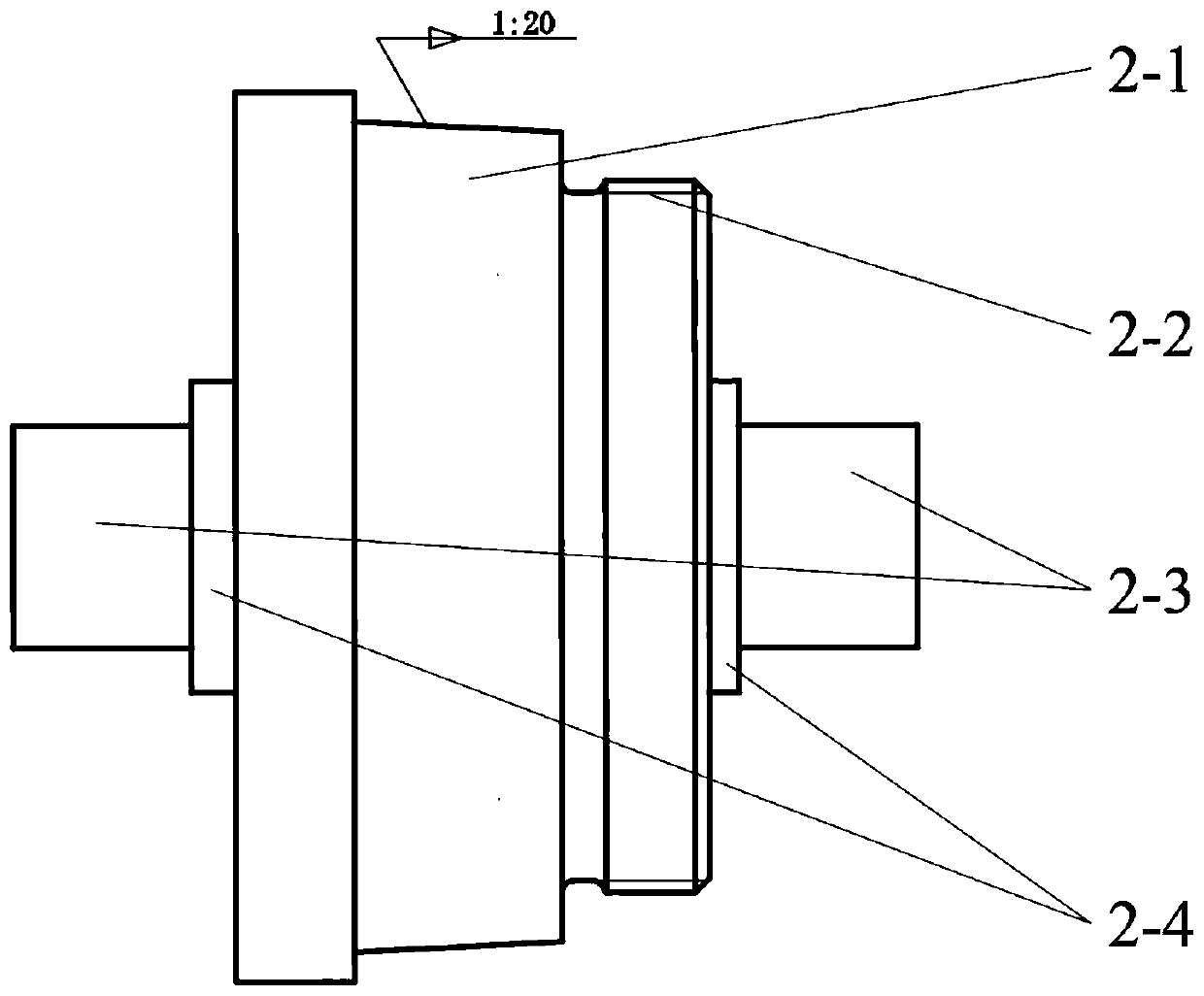

[0030] A scale hob and tool holder for a TBM test bench, comprising a tool holder 5, two supports 5-1 are arranged on the tool holder 5, and the two supports 5-1 are arranged adjacently, The support 5-1 is provided with a groove I5-1-2, the grooves I5-1-2 on the two supports 5-1 are arranged oppositely, and the groove I5-1-2 is set There is a bearing 4, and a bearing cover 6 is arranged around the groove I5-1-2, and the two bearings 4 are connected with a cutter shaft 2, and a cutter ring 1 is set on the cutter shaft 2, and the cutter shaft 2 The upper sleeve is provided with a cover 3, the knife ring 1 is arranged between the cutter shaft 2 and the cover 3, the inner diameter of the knife ring 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com