Device and method for monitoring rotating motor

A technology for rotating electrical machines and monitoring devices, applied in electromechanical devices, measuring devices, electronic commutation motor control, etc., can solve problems such as difficult real-time monitoring, great influence, and inability to detect temperature rises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] An embodiment of a rotating electric machine monitoring device and a monitoring method thereof according to the present invention will be described below with reference to the drawings.

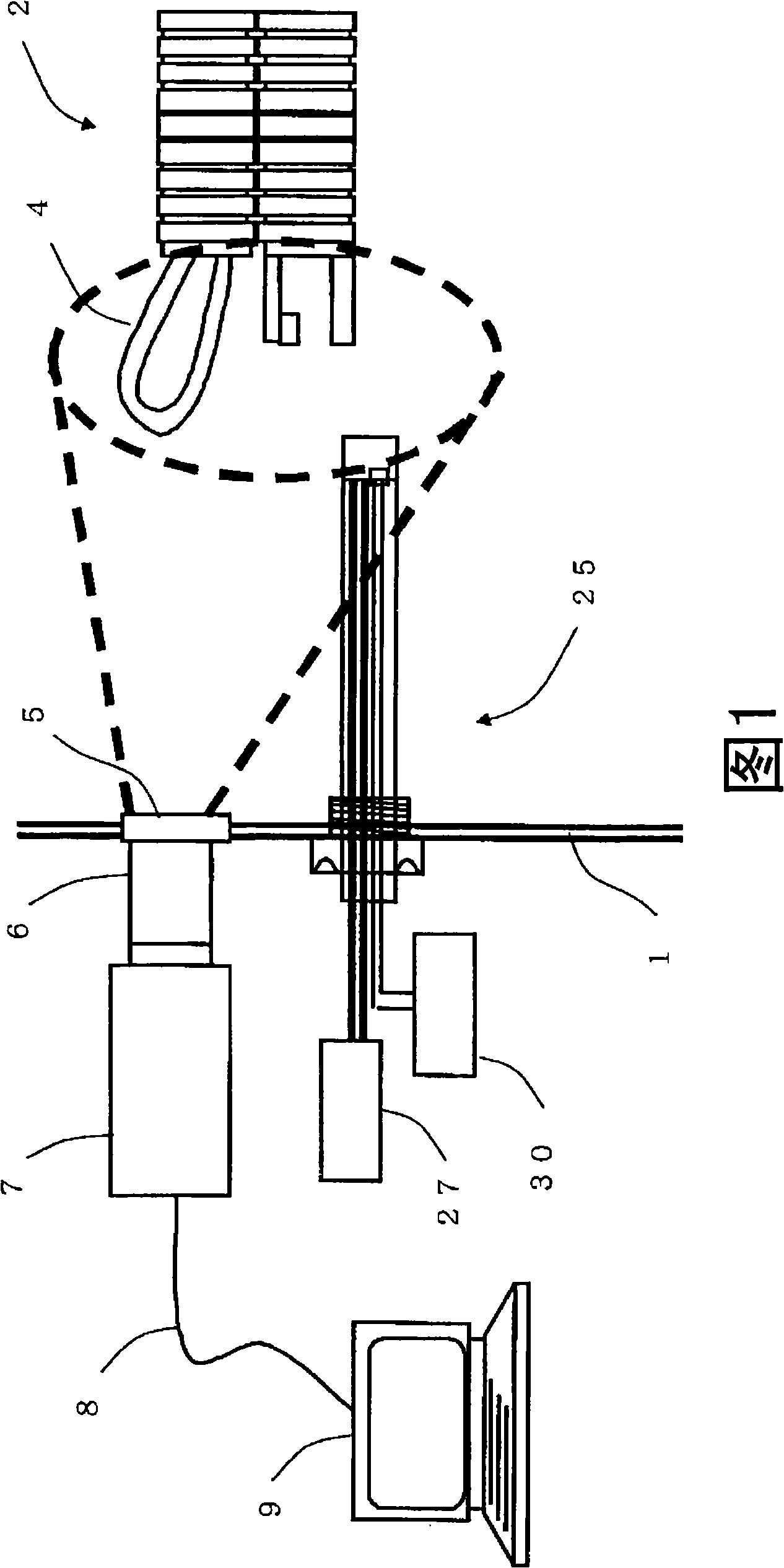

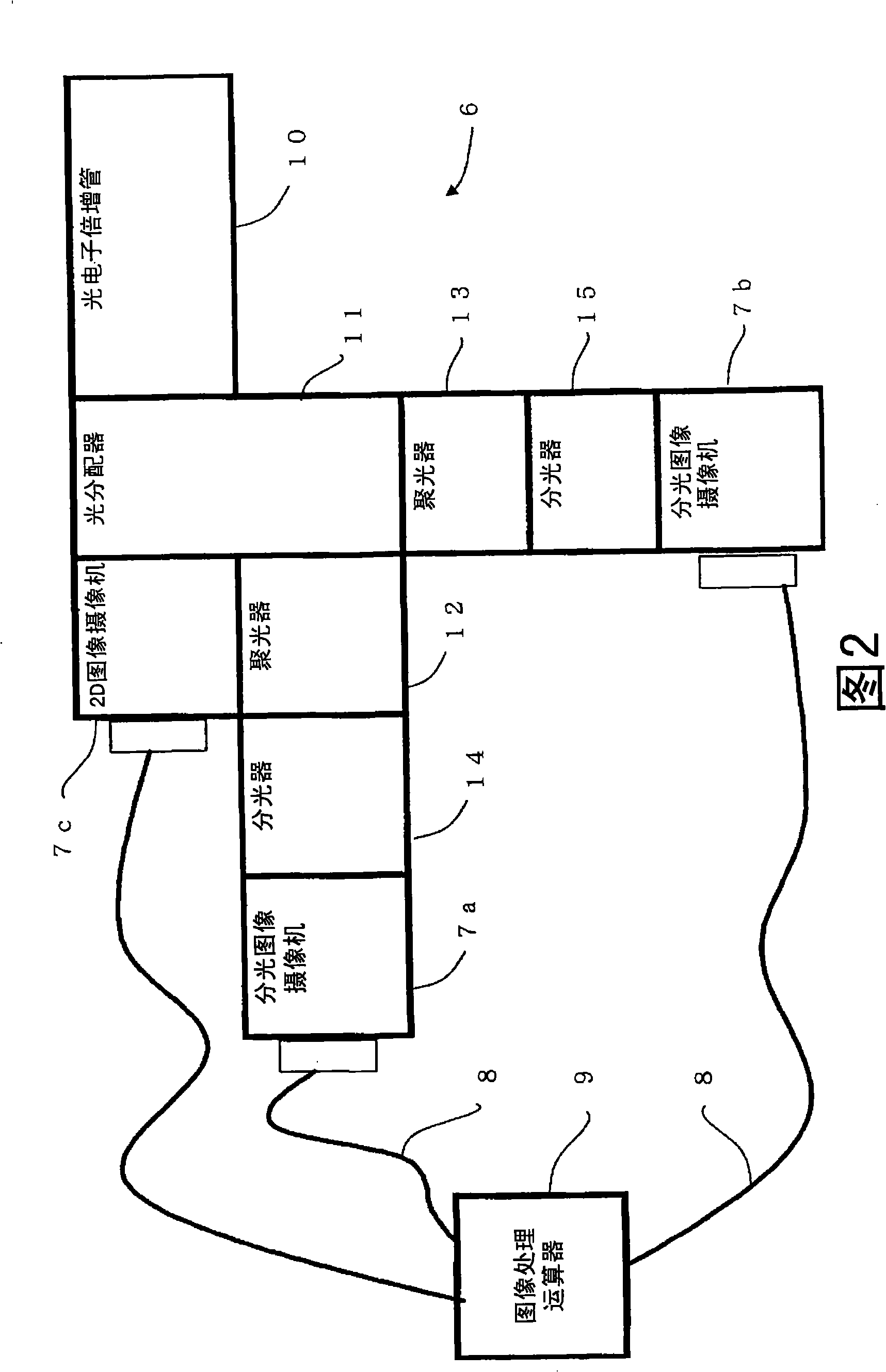

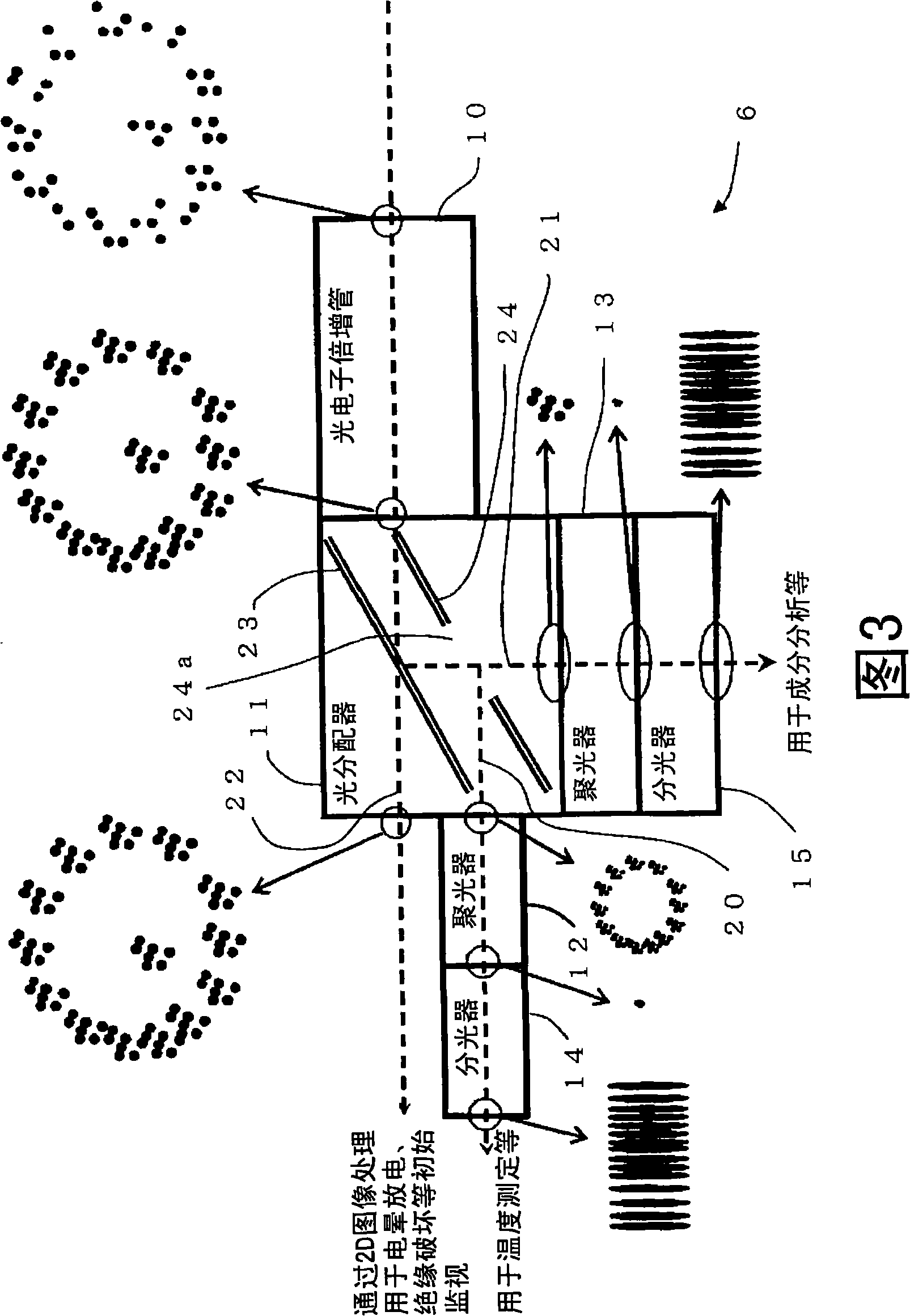

[0072] First, refer to Figure 1 to Figure 4 , and the configuration of the rotating electrical machine monitoring device according to this embodiment will be described. here, figure 1 It is a schematic vertical cross-sectional view showing the state in which the rotating electric machine monitoring device is installed on the rotating electric machine. in addition figure 2 It is a block diagram showing the configuration of the optical processing unit and its surroundings of the rotating electrical machine monitoring device. image 3 It is an explanatory diagram showing image data and the like on the optical processing unit and its surroundings. Figure 4 It is an enlarged longitudinal sectional view showing an auxiliary member heating device (attachment heater) in the rotating ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com