Point-type plastic filling device of injection mold

An injection mold, point-type technology, which is applied in the design and manufacture of the injection mold inlet, and the injection mold point-type injection system field, can solve the problem that the sprue sleeve and the ejector plate are prone to flash and sprue sleeves. The extrusion strength with the ejector plate is high, and the difficulty and cost of mold maintenance are increased, so as to improve the heat loss too fast, save the raw materials of plastic particles, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further illustrate the technical means and beneficial effects adopted by the present invention to achieve its purpose, and to enable those skilled in the art to implement the present invention according to the detailed introduction of this specification, the following is combined with the accompanying drawings and preferred embodiments of the present invention , the specific embodiments of the present invention will be described in detail below.

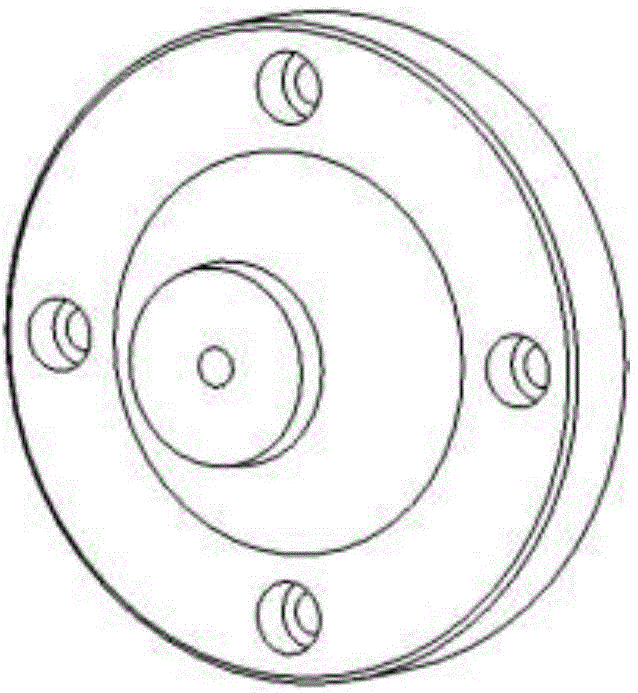

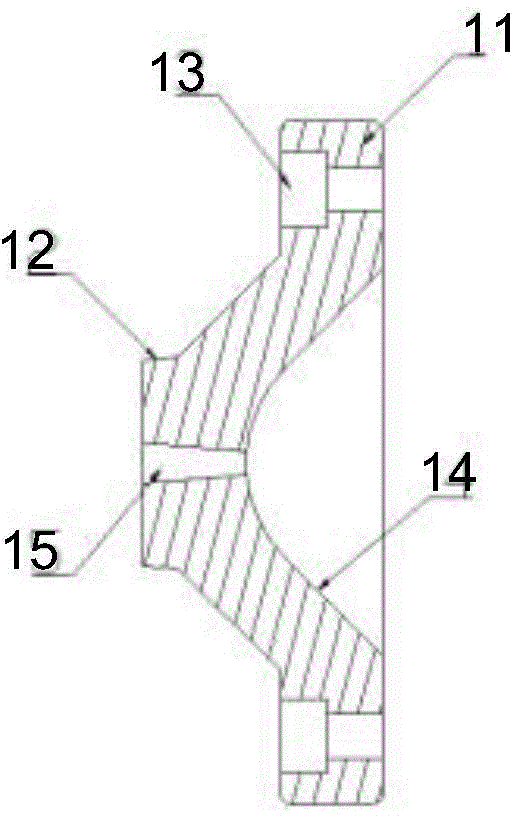

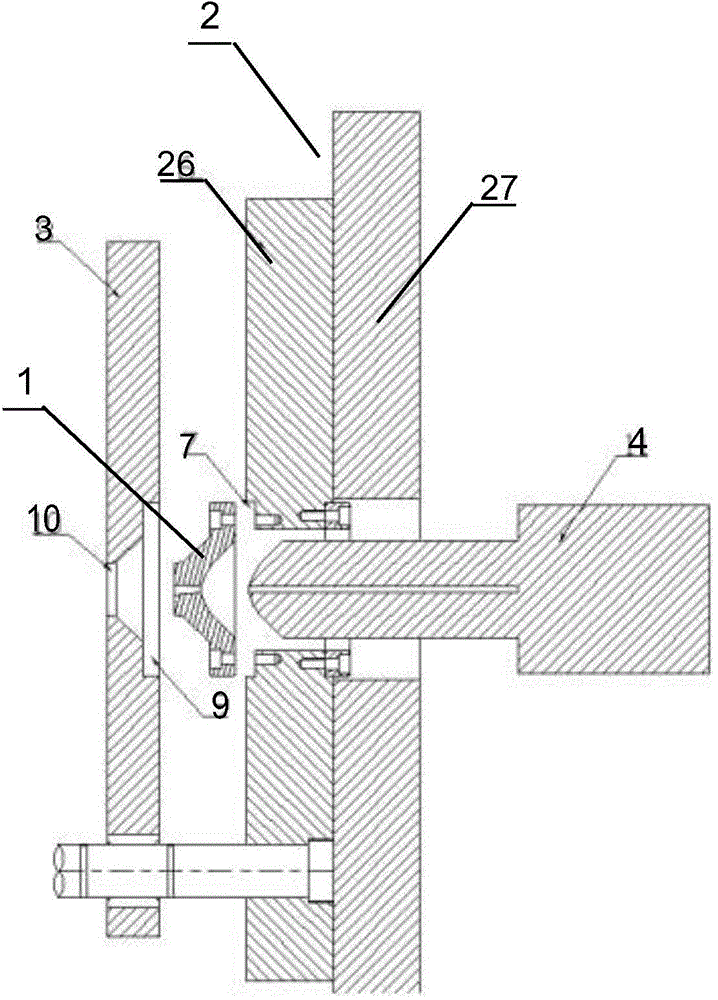

[0020] figure 1 and figure 2 Respectively, a schematic structural view and a cross-sectional view of a sprue sleeve of a point-type glue feeding device for an injection mold according to the present invention, image 3 It is a cross-sectional view of a point-type glue feeding device for an injection mold according to the present invention. see Figure 1 to Figure 3 , A point-type glue feeding device for an injection mold of the present invention includes: a sprue sleeve 1, a mechanical plate part 2, a pusher pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com