Telescopic inner die and T-shaped pile die provided with same

A technology of inner mold and formwork, which is applied in the direction of mold fixing devices, mold auxiliary parts, manufacturing tools, etc., can solve the problems of easy puncture of airbags, poor versatility of airbags, and difficult removal of wooden molds, so as to achieve convenient insertion or removal, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

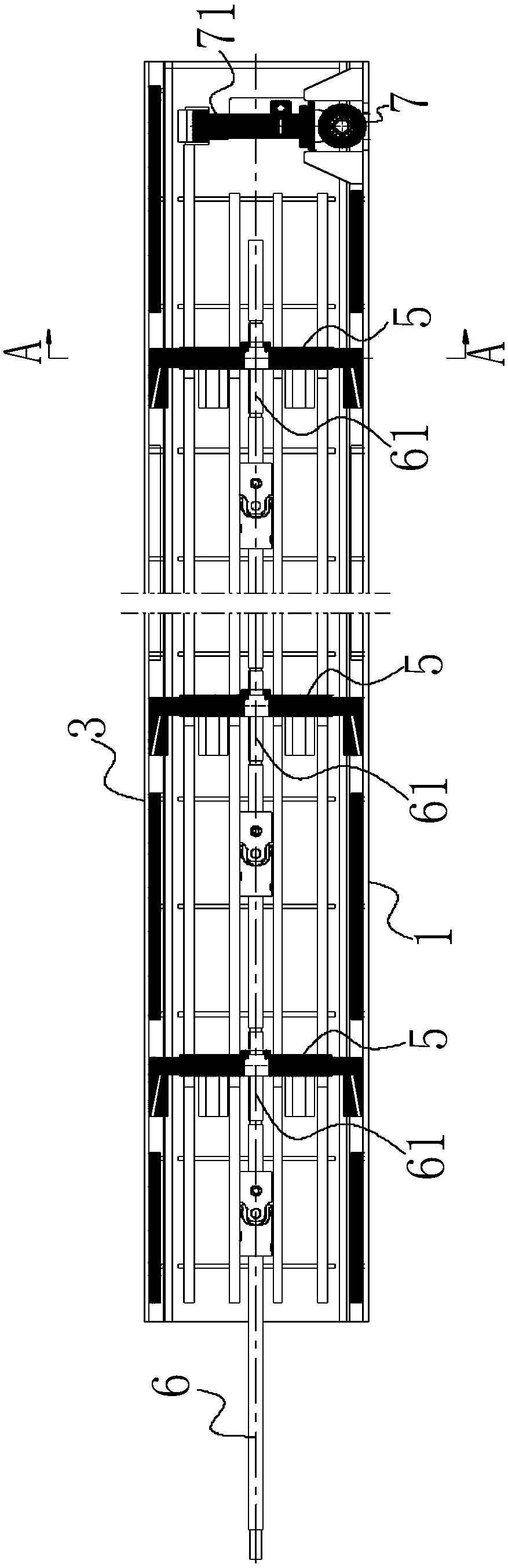

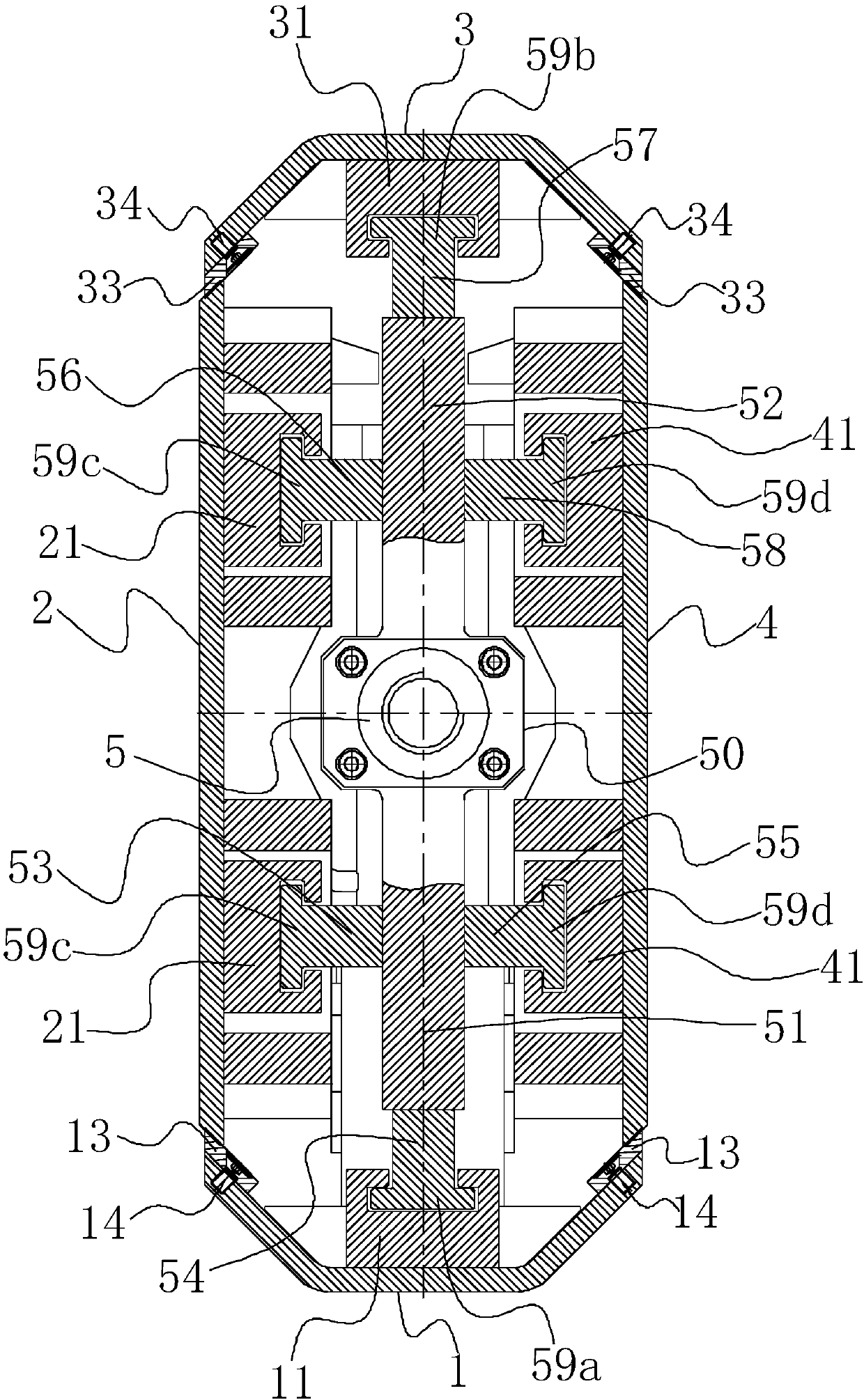

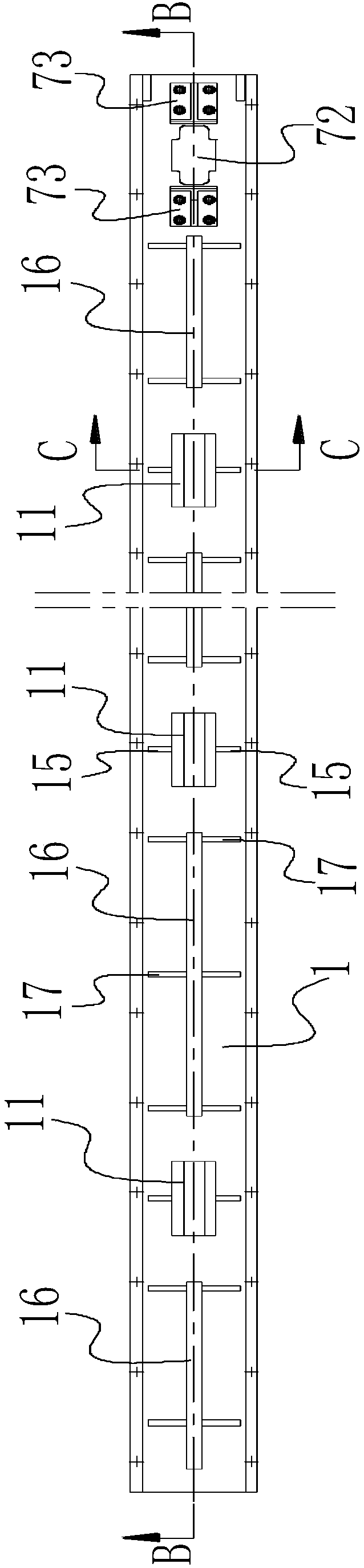

[0042] Such as figure 1 , figure 2 with Figure 15 As shown, the retractable inner mold provided in this embodiment includes a circumferentially closeable substantially rectangular frame formed by enclosing the lower template 1, the left template 2, the upper template 3, and the right template 4 in turn. The lower template 1, The lengths of the left formwork 2, the upper formwork 3, and the right formwork 4 are all the same, and a rotatable transmission rod 6 is arranged in the frame along the length direction, and the transmission rod 6 is provided with a plurality of intermediate mold assemblies at intervals along the axial direction 5. The middle mold assembly 5 includes a middle moving block, a guide rod protruding from the middle moving block towards each of the templates, a slide block fixed at one end of the guide rod and away from the middle moving block, and the template is provided with a slider seat, The slider seat is provided with a slideway for the slider to sl...

Embodiment 2

[0057] Such as Figure 16 to Figure 19 As shown, a T-shaped pile mold provided in this embodiment includes a bottom formwork 8, a left formwork 81 and a right formwork 82 hinged with the bottom formwork 8, and a bottom formwork 83 is provided in the middle of the bottom formwork 8 , the height of the bottom formwork 83 is higher than the bottom formwork 8, and the left formwork 81 and the right formwork 82 are respectively located on both sides of the bottom formwork 83, and the outer sides of the left formwork 81 and the right formwork 82 are respectively provided with a pair of Carry out the driver of opening and closing, the two ends of the driver outside the left mold base are respectively hinged with the bottom mold base 8 and the left mold base 81, and the two ends of the driver outside the right mold base are respectively hinged with the bottom mold base 8 and the right mold base 82. When the left mold base 81 and the right mold base 82 are closed, the left mold base 81...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com