Method for measuring sliding length of high-pressure lubricant interface

A technology of length measurement and lubricating oil, which is applied in the field of interface slip experiment measurement, can solve the problems of high technical requirements for instrument debugging and testing, expensive testing instruments, etc., and achieves convenient calculation of quantitative parameters, simple structure, and high measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

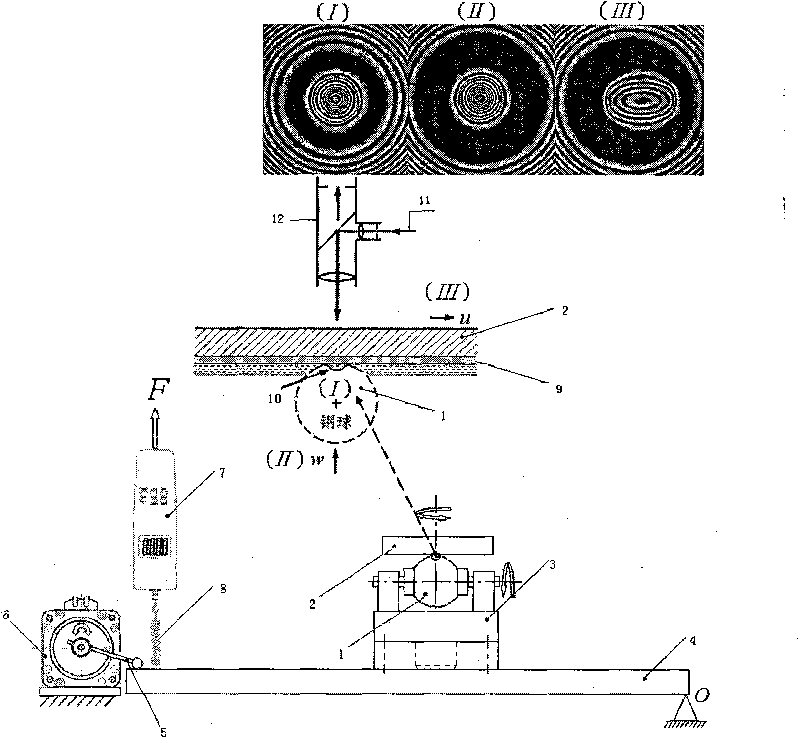

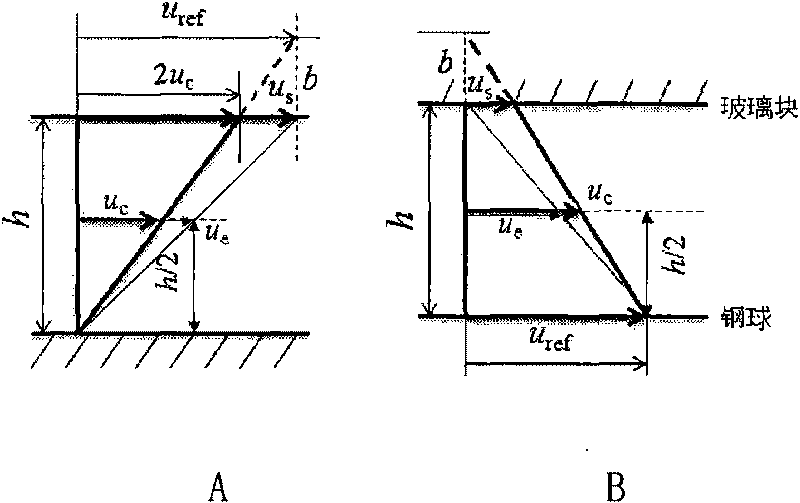

[0013] The structural principle of the system device in this embodiment is schematically shown as figure 1 As shown, the system device used in the measurement consists of steel ball 1, glass block 2, steel ball fixture, loading pallet 4, platen pin 5, motor 6, digital display tensioner 7, spring 8, chrome film 9, closed lubrication Devices such as oil 10, monochromatic light 11 and microscope 12 are assembled into an integrated device system for measurement according to the measurement principle. First, the initial depth of lubricating oil and sealing oil and the load to be applied are selected and determined according to the experimental objectives; The measurement of the sliding length of the high-pressure lubricating oil interface with visual technology applies a predetermined load to the steel ball 1 through the digital display tensioner 7; according to the precise control requirements of different initial oil sealing depths, the correlation of the motor 6 is set according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com