Hydrophobic anti-ultraviolet fabric and preparation method thereof

An anti-ultraviolet, fabric technology, applied in the direction of plant fibers, animal fibers, textiles and papermaking, can solve the problem of lack of affinity, and achieve the effect of improving the application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

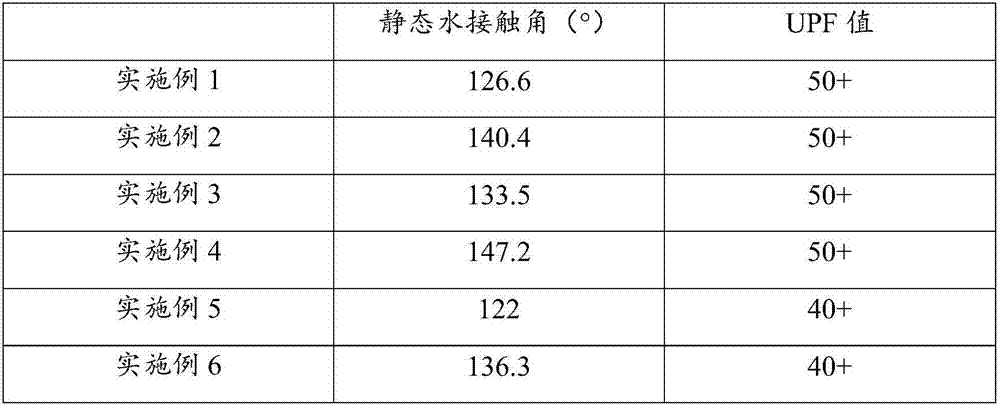

Examples

Embodiment 1

[0024] A hydrophobic anti-ultraviolet fabric, the base material of the fabric has a hydrophilic surface, graphene oxide and aminopropyl isobutyl silsesquioxane are supported on the fabric.

[0025] The base material is cotton.

[0026] Described hydrophobic anti-ultraviolet fabric is made by following method:

[0027] (1) Using natural flake graphite as raw material, graphene oxide is prepared by the improved Hummers method, wherein, the improved Hummers method refers to the literature: Marcano D.C., et al., Improved synthesis of graphene oxide, ACS Nano, 4(2010), 8, The method in pp.4806-4814 is carried out.

[0028] (2) 0.2 g of graphene oxide powder was ultrasonically dispersed in 200 mL of aqueous solution to obtain a graphene oxide dispersion with a concentration of 1 mg / mL. The cotton fabric was immersed in the above graphene oxide dispersion, the finishing time was 3 hours, and the finishing temperature was 70°C. After washing with water and drying, the graphene oxid...

Embodiment 2

[0031] The difference from Example 1 is that the concentration of the graphene oxide dispersion is 3 mg / mL, and a hydrophobic and UV-resistant fabric is prepared.

Embodiment 3

[0033] The difference from Example 1 is that the concentration of the aminopropyl isobutyl silsesquioxane dispersion is 2.5 mg / mL, and a hydrophobic and UV-resistant fabric is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com